DIS Sensors QG65N2 Series User manual

rin

USER MANUAL

QG65N2 CANopen Inclinometer (Type I)

V2.0, Jul-21

DIS SENSORS BV 1

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

Contents

1. Safety information ..........................................................................................................................................3

1.1. Intended use...........................................................................................................................................3

1.2. Incorrect use...........................................................................................................................................3

1.3. Sensor defective .....................................................................................................................................3

2. About this manual...........................................................................................................................................4

2.1. Intended use...........................................................................................................................................4

2.2. Symbols used in the text ........................................................................................................................4

2.3. Copyright ................................................................................................................................................4

2.4. Document revision control.....................................................................................................................5

3. Quick reference...............................................................................................................................................6

4. Installation guide.............................................................................................................................................7

4.1. Mechanical drawing ...............................................................................................................................7

4.2. Mounting................................................................................................................................................ 7

4.3. Connection .............................................................................................................................................8

4.4. CAN termination.....................................................................................................................................9

5. Technical data .................................................................................................................................................9

6. Functional description...................................................................................................................................10

6.1. Inclination measurement principle ......................................................................................................10

6.2. Measuring axis and direction ...............................................................................................................10

6.2.1. Measuring axis and direction for Inclination ...............................................................................10

6.2.2.Measuring axis and direction for acceleration ............................................................................11

6.3. Signal processing ..................................................................................................................................12

6.3.1. Sampling rate...............................................................................................................................12

6.3.2. Filter algorithm ............................................................................................................................12

6.3.3. Digital filters.................................................................................................................................12

6.4. Function mode .....................................................................................................................................14

6.5. Output format ......................................................................................................................................15

6.6. Boot-up procedure ...............................................................................................................................15

6.7. Emergency message .............................................................................................................................16

6.8. LSS (Layer Setting Service, according to CiA305-DSP) ..........................................................................17

6.9. Firmware management ........................................................................................................................17

6.10. Load factory default settings................................................................................................................19

6.11. Zero adjustment ...................................................................................................................................20

6.12. EDS & DCF.............................................................................................................................................20

6.13. Mappable objects.................................................................................................................................21

7. CANopen specification ..................................................................................................................................22

7.1. CANopen Communication Objects (COB).............................................................................................22

7.2. Predefined CAN-IDs..............................................................................................................................22

7.3. PDO (Reading sensor output)...............................................................................................................23

7.4. SDO (configuring Object Dictionary) ....................................................................................................23

7.5. NMT state.............................................................................................................................................24

7.6. Object Dictionary (device parameters) ................................................................................................24

8. CAN Object dictionary overview ...................................................................................................................25

8.1. 25

8.2. Communication profile (Index 1000h - 1FFFh).....................................................................................25

8.2.1. Object 1001hError register..........................................................................................................27

8.2.2. Object 1002hManufacturer status register.................................................................................27

8.2.3. Object 1003hPredefined error field ............................................................................................28

8.2.4. Object 1005h COB-ID SYNC message...........................................................................................28

8.2.5. Object 1006h Communication cycle period ................................................................................29

DIS SENSORS BV 2

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

8.2.6. Object 1010h Store parameters ...................................................................................................30

8.2.7. Object 1011hRestore factory default parameters ......................................................................30

8.2.8. Object 1014hCOB-ID EMCY .........................................................................................................31

8.2.9. Object 1020hverify configuration................................................................................................31

8.2.10. Object 1029herror behaviour......................................................................................................31

8.2.11. Object 1800h, 1801hTPDO communication parameter...............................................................32

8.2.12. Object 1A00h, 1A01hTPDO Mapping parameter .........................................................................32

8.2.13. Object 1F80hNMT start-up behaviour.........................................................................................33

8.3. Manufacturer-specific profile (2000h - 5FFFh).....................................................................................34

8.3.1. Object 3007hFunction mode.......................................................................................................35

8.3.2. Object 300Fh Zero adjustment Inclination ..................................................................................35

8.3.3. Object 301Eh Manufacturer status register error mask...............................................................35

8.3.4. Object 301Fh Manufacturer status register mapping ..................................................................36

8.3.5. Object 300EhOutput filter ...........................................................................................................36

8.3.6. Object 300DhMoving average filter TPDO1 and TPDO2 .............................................................36

8.3.7. Object 3014hLowpass filter ........................................................................................................37

8.4. Standardized device profile (6000h – 9FFFh) (CiA410) ........................................................................38

8.4.1. Object 6000h Resolution ..............................................................................................................39

8.4.2. Object 6011h, 6021hOperating parameter ..................................................................................39

8.4.3. Object 6012h, 6022hPre-set inclination value..............................................................................39

8.4.4. Object 6013h, 6023hOffset inclination value...............................................................................39

8.4.5.Object 6401hSensor outputs.......................................................................................................40

8.5. Data type ..............................................................................................................................................40

9. Configuration tool .........................................................................................................................................41

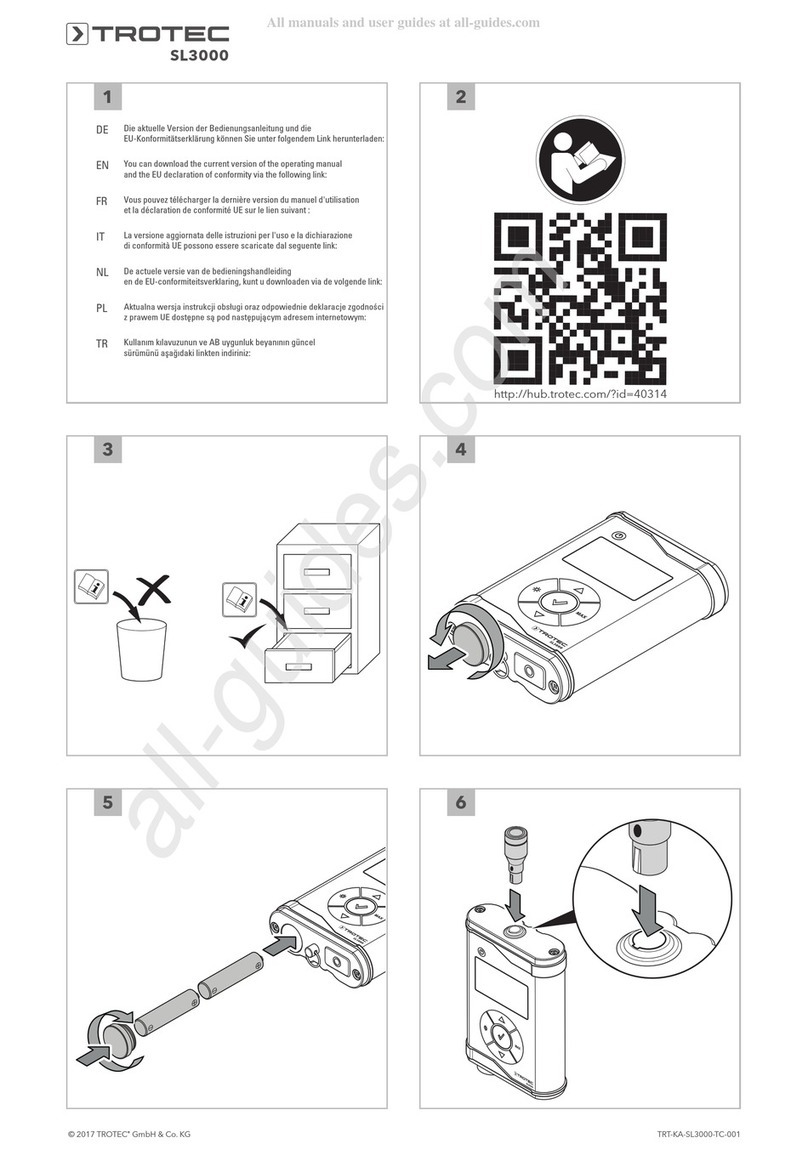

9.1. Configuration kit...................................................................................................................................41

9.2. PC software ..........................................................................................................................................43

10. Abbreviations and definitions .......................................................................................................................48

11. Normative references ...................................................................................................................................48

DIS SENSORS BV 3

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

1. Safety information

1.1. Intended use

The QG65N2 CANopen Inclinometer is a MEMS-based inclination sensor with CANopen interface.

This device provides precise and reliable inclination measurement in (semi)static conditions. The use

of this device in a machine or system is permitted only under the following conditions:

•The user is trained and competent in the integration and use of inclination sensors in machinery.

•The user is familiar with the contents of both the datasheet and user manual.

•The user has a full understanding of CAN and CANopen.

•The device is used within the specified environmental conditions.

•The device is properly configured for its intended use.

•The device is mounted correctly as described in the datasheet and user manual.

•The device data is expressly not interpreted as safety data, except when used redundantly in a control

system that is designed and tested for cross-check functionality between the primary and redundant

devices.

1.2. Incorrect use

•Use of non-standard CAN cables.

•Device mounted incorrectly.

•Zero adjustment outside the specified range.

•Incorrect or absent CAN bus termination.

•Device used outside the specifications.

1.3. Sensor defective

The sensor is considered “defective” when

•No CAN output can be detected.

•An emergency message with sensor error information is detected. (→ 6.7 Emergency message)

In the event of uncertainty, contact the distributor or manufacturer. Any unauthorised modification

or unapproved use will void both the warranty and any liability on the part of the manufacturer.

DIS SENSORS BV 4

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

2. About this manual

2.1. Intended use

This manual applies solely to the QG65N2 CANopen inclinometer (Type I) with the following model

designations:

•QG65N2-KIXv-360-CAN-C(F)M-UL —— 1 axis, ± 180°, vertical mounting, std. acccuracy.

•QG65N2-KDXYh-090-CAN-C(F)M-UL —— 2 axes, ± 90°, horizontal mounting, std. acccuracy.

•QG65N2-KDXYh-030-CAN-C(F)M-UL —— 2 axes, ± 30°, horizontal mounting, std. acccuracy.

•QG65N2-KIXv-360H-CAN-C(F)M-UL —— 1 axis, ± 180°, vertical mounting, high acccuracy.

•QG65N2-KDXYh-090H-CAN-C(F)M-UL —— 2 axes, ± 90°, horizontal mounting, high acccuracy.

•QG65N2-KDXYh-030H-CAN-C(F)M-UL —— 2 axes, ± 30°, horizontal mounting, high acccuracy.

DIS product code can be identified here.

2.2. Symbols used in the text

h Subscript for hexadecimal values.

d Subscript for decimal values.

Caution that indicates either potential damage to the sensor or explains how to

avoid a problem.

Important information.

→Cross-reference

2.3. Copyright

© Copyright 2021 DIS Sensors bv.

This manual is subject to change without notice.

All rights according to the copyright remain explicitly reserved for DIS Sensors bv.

DIS SENSORS BV 5

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

2.4. Document revision control

Version

Date(y-m-d)

Revision

V1.0

2021-03-19

1st release.

V2.0

2021-7-2

Correct errors in function mode 2, 6 and 7.

Updated screenshots of configurator.

Added message structure of object 1003h.

Document revision control is put to the end of chapter2 due to

the page length.

Correct format 1003h in table communication profile.

Improved description of data processing.

Correct command SYNC.

Added high accuracy model name.

Table 1 - Document revision

DIS SENSORS BV 6

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

3. Quick reference

General

•1-axis ± 180° and 2-axes ± 30°/± 90° inclinometer

•Output type: CANopen

•Inclination, acceleration outputs defined by Function modes (→ object 3007h)

•Sensor outputs can be customised using TPDO mapping parameters (→ object 1A00h)

•Internal sample rate MEMS: 1000Hz; output rate: 100 Hz

•2nd order Low pass Bessel filter: 10Hz (→object 3014h)

•Output filter: adjustable 1st order LPF (→ object 300Eh)

•Moving average filter: averaging time interval adjustable from 10 ms to 100 ms (→ object

300Dh)

•An optional configurator is available on request

•Approved for automotive use, approval number: E4-10R-05-4662

CAN, CANopen

•CAN interface: CAN2.0 A/B (compliant with ISO11898-1&2)

•CANopen application layer and communication profile: EN50325-4 (CiA301 v4.0 and 4.2.0)

•CANopen device profile for inclinometer: CiA410

•LSS (Layer Setting Service) implemented

•TPDO1 (CAN-ID: 180h+ Node ID) and TPDO2 (CAN-ID: 280h+ Node ID)

•Outputs: inclination X-axis (longitudinal) in object 6010h; inclination Y-axis (lateral) in object

6020h

•Internal switchable CAN termination resistor: default off (→object 3003h)

•CAN bus bit rate: default 250 kbit/s (→object 3001h)

•Node ID: default 01h(→ object 3000hrange: 01h– 7Fh, max. 127 nodes)

•Heartbeat: default on, 2 s (→ object 1017h)

•Two modes of PDO transmission (→ object 1800h / 1801h)

- Event mode: default on, event timer default 100 ms (range 10 ms – 500 ms)

- Sync mode: default off

•Vendor ID DIS: 000001BDh(→object 1018h)

•Firmware version available via CAN Object Dictionary (→ object 1018h)

•Serial number format: xxxxxx-xxx (→ object 1018h)

•Zero adjustment of inclination available via CAN Object Dictionary (→ object 300Fh).

•Pre-set inclination setting available via CAN Object Dictionary (→ objects 6012h and 6022h).

•Bootup in NMT Operational state (→object 1F80h)

•Negative values: two’s complement

•Byte-sequence on CAN bus: little-endian (least significant byte first)

DIS SENSORS BV 7

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

4. Installation guide

4.1. Mechanical drawing

Figure 1 - Mechanical drawing of QG65N2 with a male M12.

4.2. Mounting

•Use the 4 screws provided (M5x25 mm zinc plated steel Pozidrive pan head screws with

self-tapping PZ DIN7500CZ) to mount the device.

•If a software zero adjustment is impossible or undesirable, DIS provides an optional

reference solution of replacing 2 of the provided screws with 2 optional 4mm Ø

positioning pins, which can serve as mechanical reference.

•Tightening torque max. 2.5 Nm. A higher torque can cause damage to the housing or the

internal electronics.

•Fix the sensor to a perfectly flat surface.

•A 1-axis inclinometer must be mounted vertically. The factory default zero position is with

the male connector pointing down as shown in Figure 2 . Sensor can be zero adjusted at

any position within the full range.

•A 2-axis inclinometer must be mounted horizontally. The factory default zero position is

shown in Figure 2. After installation, sensor can be zero adjusted to eliminate the

mechanical offsets within a ±5° offset range.

Figure 3 - Vertical mounting 1-axis inclination

Figure 2 - Horizontal mounting 2-axes inclination

DIS SENSORS BV 8

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

4.3. Connection

The sensor is equipped with either a single 5-pole M12 (A-coded) male connector according to IEC

61076-2-101, or with an additional 5-pole M12 (A-coded) female connector. This is specified in the

suffix of the device model designation: suffix CM indicates single male connector; suffix CFM

indicates both a female and a male connector.

The advantage of two connectors is that devices can be daisy-chained in the CAN network. The

voltage supply is forwarded from the male to the female connector, providing both power and bus-

connection to the next sensor with a single cable harness. The connection between male and female

connector acts as an internal T-junction.

The pin assignment is according to CiA 303-1 V1.8.0.

Pin

Assignment

Pin 1

Shield

Pin 2

Vcc

Pin 3

Gnd & CAN_GND

Pin 4

CAN_H

Pin 5

CAN_L

Figure 4 - Pin definition

•The maximum current for the internal T-junction is 2.5 A. This must be taken into account when

using daisy-chained connections.

•The voltage supply must be dimensioned to prevent exceeding the specified voltage limits.

•The power consumption is about 50mA typical.

•This device must be connected to a class 2 power supply.

•Connect the sensor only to an approved CAN controller which must have a grounded shield.

Alternative: connect the sensor housing to a grounded shield. All mentioned EMC standards that are

met (see Declaration of Conformity) have been done with the housing connected to a grounded

shield.

Installation of wiring and the opening and closing of electrical connections must only be carried out in

de-energized state! Short-circuits, voltage spikes, etc. can cause malfunctions and/or cause the installation

to become uncontrolled, creating a serious risk of injury or damage to property.

DIS SENSORS BV 9

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

4.4. CAN termination

A CAN bus should be terminated properly to prevent signal reflections. The QG65N2 CANopen

Inclinometer has an internal 120 Ohm termination resistor. By default, this is disabled, but it can be

enabled with object 3003h.

A separate M12 termination resistor and T-connector are also available as accessories for CANopen

devices.

Figure 5 - M12 CAN terminator male 5p.

Order code: 10217

Figure 6 - M12 CAN terminator female 5p.

Order code: 10194

Figure 7 - M12 T-connector male 5p.

Order code: 11822

The advantage of using a separate termination plug instead of the internal termination resistor is

that an external termination plug is clearly visible. This helps to prevent an inadvertent double

termination that could cause the entire CAN bus to malfunction.

5. Technical data

Please refer to the datasheet of your product.

DIS SENSORS BV 10

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

6. Functional description

6.1. Inclination measurement principle

QG65N2 Inclinometers measure inclination by measuring static acceleration of gravity using an

accelerometer MEMS. In static conditions, inclination measurement by this principle is accurate and

reliable.

However, the vibrations or movements present on almost all industrial machines generate

undesirable g-forces. These dynamic g-forces accumulate and overlay the static g-forces, causing a

‘dirty’ inclination output that includes spurious or noise components.

A low-pass filter can stabilize the output, that can be enough for some applications. The downside of

this filtering is that it increases the reaction time (latency) of the inclinometer. In a control system

this results in a limit on the speed of movements, and reduced machine efficiency.

If the dynamic effects are dominant and acceptable delay time is limited, please consider our

Dynamic inclinometer, where with the help of a gyroscope a sort of filtering is achieved without

having the downside of delay time.

6.2. Measuring axis and direction

6.2.1. Measuring axis and direction for Inclination

A single-axis inclinometer (vertical mount) measures the inclination in the vertical plane over

the full range 0-360° (X-output). The default 0° position and the measuring direction are shown in

Figure 8.

Figure 8 - Measuring axis and direction of 1-axis inclination.

DIS SENSORS BV 11

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

A dual-axis inclinometer (horizontal mount) measures the inclination on both X and Y axis.

Measuring range is up to 90°. Due to the measurement principle, only one axis may tilt more than

45°.

Figure 9 – Measuring axis and direction of 2-axis inclination.

Cross-tilt error: when the cross axis (axis perpendicular to the measuring axis) tilts more than 45° during the

measurement, the measuring axis will be disabled. The sensor will send a fixed CAN output to indicate that the

sensor is now at a cross-tilt error position (→Knowledgebase): 20000d(200°) for the measuring range ±180°,

±30°/ ±90°, and 40000d(400°) for the measuring range 0°-360°. In addition, an EMCY message will also be sent,

in which the last 5 bytes (00 00 00 00 01/02h) specifies the cross-tilt error on the X or Y axis (→Object 1002h

Manufacturer status register).

6.2.2. Measuring axis and direction for acceleration

In acceleration mode (→6.4 Function mode), the device measures the acceleration values on all 3

axes. The measuring direction of three axes in the factory default setting is shown in Figure 11.

Figure 10 – Measuring axis and direction of acceleration.

DIS SENSORS BV 12

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

6.3. Signal processing

Figure 11 - Signal processing

6.3.1. Sampling rate

Each axis of the acceleration MEMS is sampled by the internal microcontroller at a rate of 1000 Hz.

Those samples are fed into the filter algorithm and will be processed further.

6.3.2. Filter algorithm

Filter algorithm is implemented to improve the quality of the sampled raw data. The calculation rate

is 100Hz.

6.3.3. Digital filters

The inclination values can be further processed with digital filters, which can significantly eliminate

noises or reduce the bandwidth, making the sensor much less sensitive to accelerations or vibrations.

Different filters can be enabled/disabled or configured with the DIS configurator set CAN, or with the

CAN object dictionary.

Bessel Low pass filter

Normally, an inclinometer with a bandwidth of 10Hz is fast enough for most applications. Therefore a

2nd order low-pass Bessel filter with a fixed cut-off frequency of 10Hz is implemented. You can only

turn this filter ON/OFF with object 3014h. This filter is ON as default and effective on all sensing axes.

For standard inclination measurements it is highly recommended to leave this filter on.

Output filter

An additional 1st order low-pass filter called ‘output filter’ is implemented for further additional

reduction of bandwidth and extra noise filtering. This filter is useful for slow-moving applications

with a lower bandwidth than 10Hz. By setting a time-constant τ1in object 300Eh, the cut-off

1τ time in which the output changes to 70% of the step after a step response

MEMS Sampling

•3 DOF raw outputs

•Sampling rate 1000Hz

Filter Algorithm

•Calculation rate 100Hz

Digital Filters

•2nd order Bessel LPF

(10Hz)

•Output filter

•Moving average filter

DIS SENSORS BV 13

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

frequency can be calculated by the formula f = 1 / (2π*τ). A longer filter time results in a narrower

bandwidth and therefore less noise, but also causes a longer phase delay.

Normally this filter is used in addition to the 2nd order Bessel LPF. Therefore, it does not make sense

to set the output filter to a higher frequency than 10Hz (i.e. τshould be >16ms). Common filter time

are 50ms (3Hz), 100ms (1.6Hz) or 200ms (0.8Hz).

This -3 dB frequency is independent of TPDO event time. However, when the output filter time-

constant is set to a value lower than the TPDO event time, the output filter is automatically disabled.

For example, if TPDO event time is set to 100 ms, and output filter time is set to 50 ms, this filter will

not work.

Moving average filter

The final inclination output is an average of the last N samples. This filter can be used to reduce the

noise level further, although it has only limited effect.

The sampling rate of this filter is 10 ms. This filter can be controlled via CAN object 300Dh.

N must be a number from 0d -10d. Setting the N to 0dand 1d will disable this filter.

The TPDO event timer decides the cycle time of the TPDO message. By default, the sensor sends a

new TPDO every 100 ms. This TPDO message contains an inclination measurement which is an

average of the preceding N x 10ms samples and is totally independent of the TPDO event time.

Example:

TPDO event timer = 50 ms, N = 7: every 50 ms, a new average inclination value from the previous

70 ms samples will be supplied in the TPDO message.

DIS SENSORS BV 14

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

6.4. Function mode

The QG65N2 can measure inclination and acceleration. By selecting the function mode via object

3007h, the sensor is configured to function as an inclinometer or accelerometer. Once a function

mode is selected, the TPDO mapping parameters (→8.1.12, page 32) are automatically configured

with the predefined objects and object entries. The user can also define the TPDO mapping objects

manually; the function mode is then changed to Mode FFh (user defined mode).

Function

mode

Output

TPDO mapping objects (1A00

h,

1A01

h

)

Mode 0

(default)

Inclination (CiA410)

TPDO1: 6010

h

- 00

h

(1-axis model)

TPDO1: 6010h- 00h, 6020h- 00h(2-axis model)

TPDO2: disabled

Mode 1

Inclination (CiA410) alternative

orientation

TPDO1: 6010

h

- 00

h

(1-axis model inverted)

TPDO1: 6020h- 00h, 6010h- 00h

(2-axis model with X and Y swapped, X and Y inverted)

TPDO2: disabled

Mode 2

Inclination (CiA410) +

Temperature

TPDO1: 6511

h

–

00

h,

6010

h

- 00

h,

(1-axis model)

TPDO1: 6511h–00h, 6010h- 00h, 6020h- 00h, (2-axis model)

TPDO2: disabled

Mode 3

Acceleration (3 axes)

TPDO1: 6401

h

-

01

h,

6401

h

-

02

h,

6401

h

-

03

h

TPDO2: disabled

Mode 4-5

Reserved

Mode 6

Inclination (compatible with

QG65 CAN firmware v4B)

TPDO1: 6401

h

– 0E

h

, (1-axis model)

6401h- 04h, 6401h- 05h(2-axis model)

TPDO2: disabled, 6401h- 01h, 6401h – 02h, 6401h– 03h

Mode 7

Inclination (compatible with

QG65N CAN firmware v6)

TPDO1: 6401

h

- 04

h

(1-axis model)

6401h- 04h, 6401h- 05h (2-axis model)

TPDO2: disabled, 6401h- 01h, 6401h – 02h, 6401h– 03h

Mode FF

User defined mode

(Output defined by user)

TPDO1: user defined

TPDO2: user defined

Table 2 – Sensor output configuration in different function modes.

DIS SENSORS BV 15

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

6.5. Output format

Inclination output format: CAN output = 100*α. (α = angle in degrees, factory resolution is 0.01°).

CAN outputs are sent with PDOs (→7.3 PDO (Reading sensor output).

For example:

Figure 12 - Output 1-axis ±180° sensor

Figure 13 - Output 2-axis ±90° sensor

In Figure 12, the sensor sends 1 axis inclination output with 2 Bytes Integer (Table 3).

Byte1

Byte0

23

h

82

h

Inclination output: 2382

h

= 9090

d

= 90.9°

Table 3 - Output 1-axis ±180° sensor

In Figure 13, the sensor sends 2 axis inclination outputs with 4 bytes integer. The 1st two bytes are

the X inclination and the 2nd two bytes are the Y inclination (Table 4).

Byte3

Byte2

Byte1

Byte0

Y inclination

X inclination

00

h

82

h

0B

h

C8

h

0080

h

= 130

d

= 1.3°

0BC8

h

= 3016

d

= 30.16°

Table 4 - TPDO1 of QG65N2-KDXYh-090H-CAN-C(F)M

Besides inclination values, the device also provides acceleration, angular rate and device

temperature. The user can customise the device outputs by changing the TPDO mapping parameters.

(→Object 1A00h, 1A01hTPDO Mapping parameter). For example, 1st two bytes are the device

temperature, the 2nd two bytes are the inclination output (Table 5).

Byte3 Byte2 Byte1 Byte0

23h 82h 00h 1Ah

Inclination output: 2382h= 9090d = 90.9° Device temperature: 001Ah = 26d °C

Table 5 - Customised TPDO message

6.6. Boot-up procedure

When the device is powered on, it automatically enters NMT Initialisation state. In this state, the

device will be initialised with the default parameters of the manufacturer-specific profile area and of

the standardized device profile area. When initialisation is complete, a bootup message 00hwill be

DIS SENSORS BV 16

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

sent with the heartbeat (700h+ Node ID). If an error is detected during the boot up, an emergency

message with the error information will be sent.

6.7. Emergency message

When the device detects an internal error, an emergency object (80h+Node ID) with 8-bytes message

is transmitted. The error code is inserted at the location of object 1003h (pre-defined error field), and

the device enters the error state which is defined in Object 1029hError Behaviour (default: NMT pre-

operational state).

The first 3 bytes indicates the error code specified in CiA301 and error register specified in Object

1001h. The remaining 5 bytes indicate the manufacturer-specific error specified in Object 1002h.

Byte7 Byte6 Byte5 Byte4 Byte3 Byte2 Byte1 Byte0

Manufacturer-specific error (1002h) Error register (1001h) EMCY error code (CiA301)

00 00 00 00 00h =no error

00 00 00 00 01h =X-axis Cross-Tilt Error

00 00 00 00 02h =Y axis Cross-Tilt Error

00 00 00 00 08h= EEPROM error

More:

→ 8.1.2 Object 1002h Manufacturer status register

00h =no error

01h= Generic error

05h = Voltage error

81h= Manufacturer specific error

More:

→ 8.1.1 Object 1001h Error register

00 00h =No error. Always sent at start-up

10 xxh = Generic error

50 00h= Voltage error

50 10h = Self-test error

50 30h= Error during sensor initialization

60 00h = Watchdog error

60 00h = Error handler activated

62 00h = Device software error

80 00h = Sent at every change of the

manufacturer status register

81 xxh = CANopen stack message

82 xxh = CANopen stack message

FF 20h = EEPROM error

Table 6 – format EMCY message

When all errors are corrected, the device enters the error-free state and transmits an emergency

object with the error code ‘reset error / no error’ containing all 0 s.

Examples:

00 00 00 00 01 05 50 00h— Voltage error detected during initialization

00 00 00 00 01 81 80 00h— Cross-tilt error on X axis

DIS SENSORS BV 17

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

6.8. LSS (Layer Setting Service, according to CiA305-DSP)

Layer setting services (LSS) and protocols are used to request or change the settings of three

parameters of the physical layer, data link layer and application layer on a CANopen device via the

CAN network. It is supported only in NMT stop mode or pre-operational mode.

The QG65D device is serviced as a CAN device, and a CAN master such as a PLC can detect and

configure those three parameters with LSS:

•Node ID (→object 3000h)

•CAN bus bit rate (→object 3001h)

•LSS address: 128-bit number to identify each node uniquely, consisting of the vendor ID, product

code, revision number and serial number with 32 bits each (→object 1018h)

After changing parameters using LSS, a save action must be performed. Normally your LSS tool can

be configured to perform an automatic save (store), as shown below:

Figure 14 - LSS save action

6.9. Firmware management

The factory-installed firmware version is stated on the device label.

Figure 15 - Firmware version

DIS SENSORS BV 18

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

It can also be requested with object 100AhManufacturer software version. The message format is

“Vx.x.x” in ASCII, for example: V1.0.0.

The currently-installed firmware version might vary from the version on the sticker due to a firmware

update. Always check the actual version in the object dictionary.

It will soon be possible to update the firmware via the DIS configuration tool. This tool can check the

current firmware version in your device and upload the new firmware to the device. The user can

upload the new firmware to the device by simply clicking a button (Figure 16).

Figure 16 - Firmware update via configurator

The firmware release notes are available at www.dis-sensors.com under “downloads/user manuals”.

DIS SENSORS BV 19

User Manual - QG65N2 CANopen Inclinometer (Type I) V2.0

6.10. Load factory default settings

Factory reset or load factory default settings allows users to restore the device to its original

manufacturer settings. The customer settings which were saved to the EEPROM will be overwritten

by the factory default settings.

With object 1011h, the factory default settings below can be restored. Customised products may

have different factory default values, which may deviate from this manual. See the datasheet of your

customized products for these customized factory default values.

DIS factory default - communication parameters

Parameters Object DIS standard default value

COB-ID SYNC 1005h 00000080h

Communication Cycle Period

1006h00h

COB-ID EMCY

1014h00000081h

Producer heartbeat time

1017h2000d – 2000 ms

Error behaviour

1029h00h- Switch to pre-operational

NMT Start-up behaviour 1F80h00000000h – Start in operational

Node ID

3000h01h

Baud Rate

3001h03h - 250 kBit/s

Termination resistor

3003h00h - Disabled

Error masks 301Eh80001D40h

Table 7 – DIS standard factory default communication parameters

DIS standard factory default - application parameters

Parameters Object DIS standard default value

Function mode 3007h00h– Inclination (CiA 410)

Moving Average filtering

3022h sub 07h and 300Dh00h– Moving Average filtering OFF

Output Filter time

3022h sub 06h and 300Eh

00h – Output filter OFF

Operating parameters 6011h, 6021h02h – DIS default measuring direction

Pre-set enabled

Pre-set inclination value

(Zero value)

Offset inclination value

(Zero offset)

6012h, 6022h

6013h, 6023h

00h

Zero offset by calibration at factory.

Various per sensor

Table 8 – DIS standard factory default application parameters.

Other manuals for QG65N2 Series

1

This manual suits for next models

6

Table of contents

Other DIS Sensors Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Emerson

Emerson Rosemount 751 quick start guide

Kobold

Kobold ADI-1F Series Operating instruction

ABB

ABB AWT210 Operating instruction

GCC Technologies

GCC Technologies StellarMark C Series user manual

Status Instruments

Status Instruments SEM1600B User instructions

Reed Instruments

Reed Instruments R5065 instruction manual