Discount Equipment MGT MPC 80 User manual

MENEGOTTI TECHNICAL MANUAL

Before operang the Menego equipment, read

this technical manual, it will inform and instruct

the operator about the operaon of the product.

This way, you avoid possible work accidents and

premature equipment maintenance.

Attention:

Illustrave Image.

VIBRATORY COMPACTOR

MPC 80

To order go to Discount-Equipment.com

02

Congratulaons on purchasing a Menego product!

With the highest quality, designed and built especially to serve you

with technology to suit your needs.

This manual was wrien to provide you with the informaon and

instrucons necessary for the use and maintenance of our equipment,

as well as to present you with data relang to its technical characteris-

cs.

Before you put your equipment into operaon for the first me,

carefully read the informaon contained herein.

The durability of your equipment depends only on the way it is treated

during service (operaon) and its sasfactory performance is the

result of your careful work, carried out regularly.

Menego is prepared to offer you all the necessary technical

assistance, as well as to meet yourneeds for spare parts.

Welcome, you are now a part of the great Menego "client family".

MENEGOTTI Aer Sales and

Technical Assistance departments.

Index

Cauon: For best convenience, keep this manual in a appropriate place

where it can be consulted when necessary.

The Company

The Product

Safety Informaons

Technical Specificaons

Working Operaon

Equipment Maintenance

Product Warranty

Warranty Term

03

03

03

04

05

05

07

07

To order go to Discount-Equipment.com

03

The Company

The Product

Safety Informaons

This manual must be completely read before any operaon. On it there is useful informaon about the product, manufacturer, safety, replacement

parts,maintenance and conservaon. Keep this manual, on a proper place, so it may be consulted when necessary.

Reference of quality in the construcon machinery segment. Leading brand on sales of Concrete Mixers. Present in

over 40 countries in the world. Recognized for having a complete range of products, providing greater producvity and

profitability to the business. We are Menego North America, a Company from Menego Group, and we want to

bring you the best we’ve got!

Vibratory compactor is a compacon machine, able to work quickly by applying consecuve impacts to the ground surface to level the uneven ground

surface, uniformizing it so that the space between the parcles shrinks, and to increase the dry density of the soil that has its moisture removed by the

compacon process. The vibratory compactor is intended exclusively for the compacon of: Sand, Clay, Gravel, Asphalt, Wet concrete, Interlocking floors,

to avoid sedimentaon and provide a firm and solid foundaon.

• NEVER allow any person to operate the machine without adequate instrucon. The operator must be trained or qualified to operate this

equipment.

• ENSURE all operators read, understand and follow the operang instrucons.

• SERIOUS INJURY could result from improper or careless use of this machine.

• DO NOT operate the machine unless all protecve guards are in place.

• KEEP handles and feet clear of rotang and moving parts as they will cause injury if contacted.

• ENSURE that the motor operaon switch is in the OFF posion and the spark plug ignion lead is disconnected before

removing the guards or making adjustments.

• DO NOT leave the machine in operaon while it is unaended.

• It is expressly prohibited to remove or alter any safety device or feature, if it occurs Menego will not be held responsible.

• Use the equipment according to the instrucons on this manual.

• In case of damage or missing parts, contact MGT North America on our telephone number 770 9107450 for replacement.

• With the machine turned off, conduct a daily inspecon of the machine's parts. In case of problems, immediately stop the operaon and

contact Mengo's authorized service.

To order go to Discount-Equipment.com

04

• Maintain a limited area exclusive for working with the equipment, always

keeping this place clean, without obstrucons and with proper

illuminaon.

• Do not use clothing that is too loose and which might get caught in the

machine.

• Always wear gloves, safety gloves and ear protecon.

• Perform the maintenance recommended on this manual with qualified

people and within the correct periods.

• Avoid contact with hot surfaces.

• Avoid contact with rotang parts.

• ENSURE that the area to be compacted does not contain any “live”

electrical cables, gas, water or communicaon services which may be

damaged by the acon of vibraon.

• DO NOT refuel the motor while it is in operaon or hot.

• DO NOT refuel the motor in the vicinity of sparks, a naked flame or a

person smoking.

• DO NOT operate or refuel a gasoline motor in a confined area without

adequate venlaon.

• WEAR an approved hearing protecon device to limit noise exposure.

• Do not break the seal and change the engine rotaon, which may cause

excessive wear on the engine, base and eccentric of this machine.

• Do not lt machine to eccentric pulley side, because oil will leak from the

eccentric vent.

• Do not use on compacted terrain.

“OPERATOR SHOULD BE OVER 18 YEARS OLD, BE TRAINED TO OPERATE

THIS EQUIPMENT AND ALWAYS USE COMPULSORY PERSONAL PROTEC-

TIVE EQUIPMENT (PPE)!!!”

Technical Specificaons

551

921

440

1009

552

652

TECHNICAL DATA MPC 80

Weight (Lb) 176,3

Base Dimensions - WxL (inch) 17,7x21,6

FuelGasoline

Fuel Consumpon (l/h) 1,5

Tank Capacity (gal) 0,95

Water Tank Capacity (gal)3,17

Forward Speed (m/min) 25m/80 / min

Impact Force (lbs) 3,375

Frequency (Hz) 98

Compacon Depth (inch) up to 11,8

Compacon Area (m²/h) 660m²/7,000sq / h

To order go to Discount-Equipment.com

05

Working Operaon

1) START

• Turn the power switch – ON posion (1).

• Move fuel lever to the right (2).

• Move choke lever le (3).

• Move throle to minimum speed posion (4).

• Slowly pull the rope start (5), unl you feel resistance. Allow the handle

to pull back to the starng posion and pull hard.

• Allow the engine to warm up for a few minutes and move the choke to

the right and the throle to full speed to begin compacng.

2) TURN OFF THE ENGINE

• Move throle lever to minimum speed.

• Move fuel tap right to close.

• Turning the power switch to OFF posion.

3) HOW TO OPERATE PROPERLY

• Start the drive motor.

• Move throle to full speed posion.

• Guide the vibratory compactor by its handle. Let the machine move, do

not try to force the machine.

• Stop the operaon: reduce to minimum acceleraon, for the engine

operate to idling speed, close the fuel valve, let the engine shut down and

move the power switch to the OFF posion.

12

345

1) ENGINE OIL LEVEL:

• Remove oil level indicator and measure.

• Oil level should be between minimum and maximum marks.

2) REPLACE ENGINE OIL:

• Place a drainer recipient at the end of the machine's oil drain.

• Remove oil fill cap, oil indicator.

• Remove the engine drain plug.

• Drain oil while engine is warm to ensure quick and complete drainage.

• When the engine is completely empty disconnect the oil flow pipe and

replace oil.

3) AIR FILTER

• Loosen the air filter cover.

• Remove air filter and clean to engine manufacturer's specificaons.

• In case of damage or excess impuries, replace the filter element.

Equipment Maintenance

To order go to Discount-Equipment.com

06

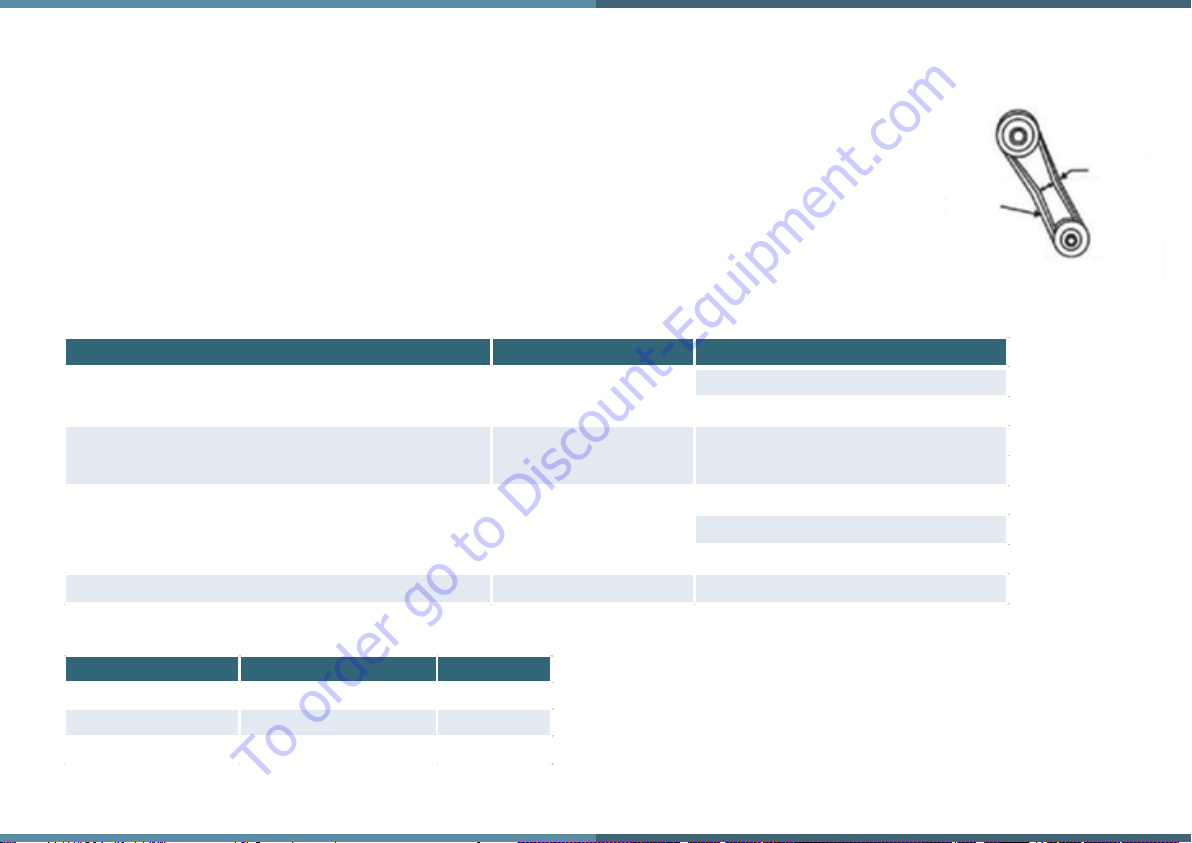

Prevenve Maintenance Plan:

MAINTENANCE PERIOD ITEM ACTION

- Oil replace

- Tighten all accessible bolts and nuts.

- Oil replace

- Replace fuel filter

- Replace oil filter

Aer every 300 hours of operaon / annually Eccentric - Oil replace

EngineAer the first 25 hours of operaon

EngineAer every 50 hours of operaon / semi-annually

Air filterAer every 8 hours of operaon / daily- Clean the air filter and control it

for damage. Replace if necessary.

References and Quanes:

ITEM OIL / FUEL QTY.

GX160 Engine SAE 20W50 or 10W30 0,15 gal

GX160 Tank Gasoline 0,95 gal

Eccentric SAE 20W50 50ml

BELT

4) ECCENTRIC OIL:

• Loosen the oil outlet screw and let the oil drain.

• To replace oil, lt the machine slightly and insert new oil through the same opening.

5) CHECKING AND REPLACING BELTS:

• Aer stopping the engine, remove the upper belt guard to check tension or replace the belt. The appropriate tension when

pressed hard with your fingers between the axes: 7mm.

• Loose or worn belts reduce the efficiency of power transmission, causing poor compacon and reducing belt life.

• Always use the original belt to avoid changing the adjustment paerns.

To order go to Discount-Equipment.com

07

The warranty is not transferable under the condions and within the

prescribed period and will be valid from the date of purchase of the

equipment, through presentaon of the sales invoice to the first end

consumer. At the me of delivery of the equipment, the customer must

receive the informaon and technical guidelines for the equipment as per

the content of this manual.

Therefore, defects caused by mistreatment, carelessness, negligence,

recklessness or malpracce, are not covered by this warranty, nor are any

repairs or alteraons of any part and/or piece of equipment. Also not

covered is any assembly of the parts by any party other than the factory

itself or Technical Assistant, applicaon outside the specificaon, mechani-

cal or electrical overloads or phase failure, use in an environment for which

it was not designed, incorrect voltages of frequencies, incorrect lubricaon,

damage caused by accidents of any kind, such as floods, strong winds, fires,

landslides or resulng from transportaon.

The removal or alteraon of the serial numbers originally placed on the

product void the warranty, which must be presented on the sales invoice

and the Warranty Cerficate for the equipment in queson.

The warranty assumed is limited to the repair, spare parts or parts

assembly of the set of parts, in which the review is conducted by an

Authorized Menego Technical Assistant and authorized in advance by the

Factory, to double check the existence of the manufacturing defect. This

repair or exchange will be made by an Authorized Technical Assistant, with

the buyer bearing the risks or costs of transportaon to and from the

Technical Assistant, with the labor and replaced parts being free, under the

terms of this warranty.

This supersedes any other warranty, express or implied as well as any and

all liability or responsibility of our company concerning the above product.

MENEGOTTI Aer Sales and Technical Assistance departments.

Product Warranty

By the present CERTIFICATE provided from original purchaser, Menego

guarantees this product against manufacturing defects, for a period of 6

(six) months, being: the first 3 (three) months of legal guarantee, and the

last 3 (three) months a special warranty guaranteed by Menego, counted

from the invoice issue date of the first final consumer.The components of

daily use such as: bearings, clutch disc, gears, res, brake shoes, etc. are not

included in the warranty.

This warranty includes spare parts and repair against manufacturing defects

duly verified by the factory or Authorized Technical Assistance. The warran-

ty for this product will be void if it suffers damage caused by accidents,

natural events, applicaon outside the specificaon, or in the case of

alteraons or repairs by a person or workshop not authorized by Menegot-

. The product freight charges, including the technical assistant or factory,

are borne by the consumer. Menego has a wide network of Technical

Assistants throughout the country.

If the equipament is purchased with the eletric engine warranty covers

defects arising from the internal engine manufacture. Not covered by

warranty defects of: broken or crushed shell due to carelessness in

transporng/or storage, energizaon of the motor coupling or out specifca-

on defects, general misuse and /or incorrect installaon, overcharging due

to lack or excess of phase and use of voltage out of the specificaon.

Aware of this term,

Warranty Term

Customer:

Model: Serial Number:

City: Date:

Customer Menego Authorized Service

To order go to Discount-Equipment.com

Rev. 01 | APRIL/2020

To order go to Discount-Equipment.com

Table of contents

Popular Power Tools manuals by other brands

Napa

Napa Carlyle Tools 6-1037A instruction manual

Hilti

Hilti TE 1000-AVR Original operating instructions

Adkins

Adkins Studio Clam Operator's handbook

Meister

Meister MPS800-1 Translation of the original instructions

Chicago Pneumatic

Chicago Pneumatic B20L manual

SBI Connectors

SBI Connectors Y35 user manual