5

• Do not short circuit a battery or allow metallic conductive objects to

contact battery terminals.

• Replace the battery only with another battery that has been qualified

for the system.The use of an unqualified battery may present a risk of

fire, explosion, leakage, or other hazards.

• Avoid dropping the device or battery. If the device or battery is

dropped, especially on a hard surface, and the user suspects damage,

take it to a service center for inspection.

1.4 Personal Protective Equipment

• Use Personal Protective Equipment, including clothing, glasses,

insulated gloves, and boots.

• Do not wear rings, watches, bracelets, or necklaces when handling or

working near the battery.

2. SPECIFICATIONS

Specifications are published at 25oC / 77oF

2.1 Electrical Specifications

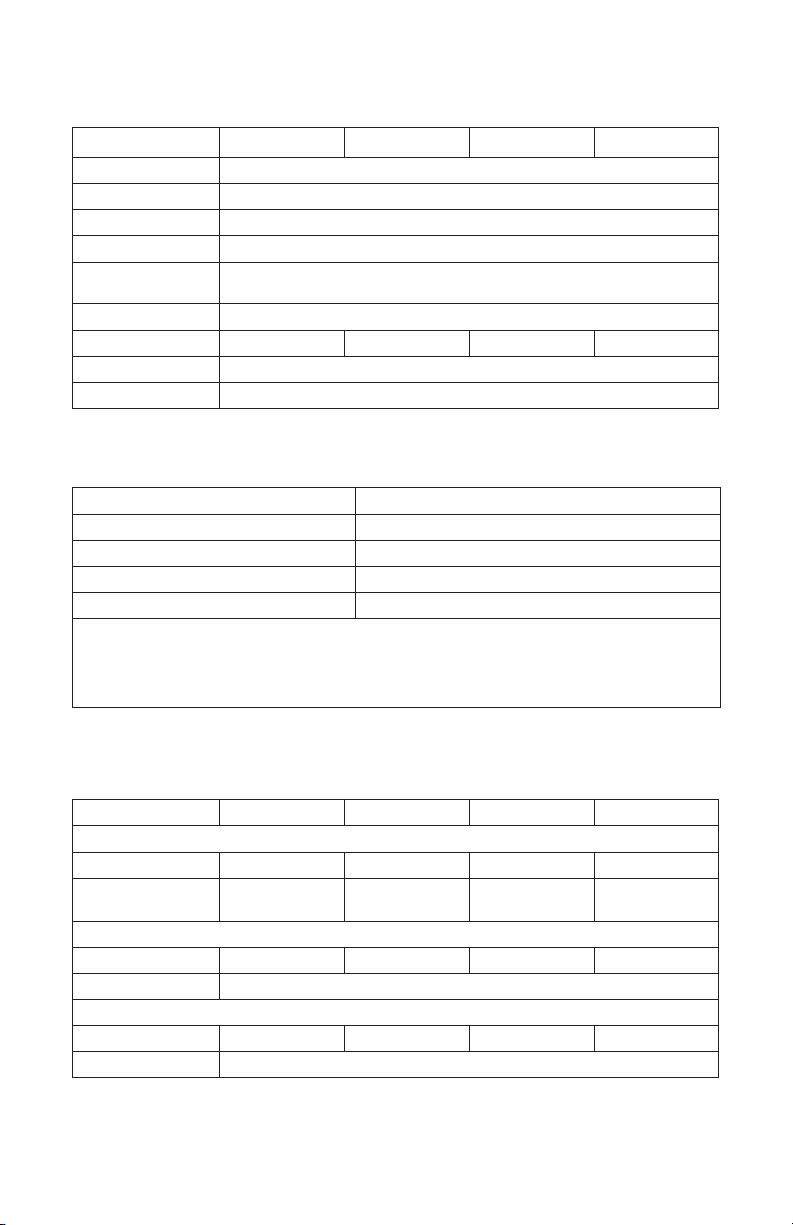

Table 2-1. DLP-GC2 Electrical Specifications

Electrical Spec DLP-GC2-12V DLP-GC2-24V DLP-GC2-36V DLP-GC2-48V

Nominal Voltage 12.8 V 25.6 V 38.4 V 51.2 V

Energy 1536 Wh 1536 Wh 1152 Wh 1536 Wh

Capacity 1Hr 120 Ah 60 Ah 30 Ah 30 Ah

Reserve Capacity 25A

288 minutes 144 minutes 72 minutes 72 minutes

Charge Bulk Voltage - Bulk VDC 13.8 - 14.2 V 27.6 - 28.4 V 41.4 - 42.6 V 55.2 - 56.8 V

Charge Absorption Voltage - U1 MAX 13.8 V 27.6 V 41.4 V 55.2 V

Charge Float Voltage - U2 13.6 V 27.2 V 40.8 V 53.6 V

ChargeTermination Current

a

3.00 A 1.50 A 0.75 A 0.75 A

Low Voltage Disconnect Recommended 12.0 V 24.0 V 36.0 V 48.0 V

Low Voltage Disconnect 10.0 V 20.0 V 30.0 V 40.0 V

Max. Continuous Discharge Current 200 A 120 A 60 A 60 A

Nominal Charge Current 120 A 60 A 30 A 30 A

Max. Continuous Charge Current 120 A 60 A 30 A 30 A

Peak Discharge Current (3 seconds) 360 A RMS 180 A RMS 90 A RMS 90 A RMS

Fuse 200 A 125 A 60 A 60 A

Maximum Load Input Capacitance 49 mF 106 mF 51 mF 23 mF

a

Charge current termination is permitted to be less than specified. Note: when the charger termination current is

lowered, the internal balancing function will have more time to operate.