DITABIS HLC AA 02 User manual

Vacuum Aspiration Systems

AA –AC –AZ –AE –AK

Operating Manual

Bedienungsanleitung

DOMINIQUE DUTSCHER SAS

2

Content

1. Basic Data.................................................................................... 4

Safety .............................................................................................................4

Warranty ........................................................................................................5

Disclaimer of warranty…………………………..…………………………………………………..5

Components ...................................................................................................5

2. First Steps.................................................................................... 6

Assembly of systems AA and AC ....................................................................6

Assembly of system AZ...................................................................................7

Setup ..............................................................................................................8

Recommended operating times.....................................................................8

Disposal of liquids ..........................................................................................9

3. Automatic systems AA ................................................................. 9

Pump operation .............................................................................................9

Handle ..........................................................................................................10

Connection of additional units .....................................................................11

4. Basic systems AC........................................................................ 13

Pump operation ...........................................................................................13

5. Compact systems AZ .................................................................. 14

Pump operation ...........................................................................................14

6. Aspiration systems AE & AK ....................................................... 15

Pump operation ...........................................................................................15

7. Maintenance ............................................................................. 15

Cleaning........................................................................................................15

Service ..........................................................................................................16

8. Article description accessories.................................................... 18

9. Explanations…………………………………………………..……………..…..………19

DOMINIQUE DUTSCHER SAS

3

Inhaltsverzeichnis

1. Basisdaten................................................................................. 20

Sicherheit .....................................................................................................20

Gewährleistung und Garantie ......................................................................21

Haftungsausschluss…..…………………………..……….………………………………………..21

Bestandteile .................................................................................................22

2. Erste Schritte ............................................................................. 22

Zusammenbau der Systeme AA und AC.......................................................22

Zusammenbau des Systems AZ....................................................................23

Inbetriebnahme ...........................................................................................24

Empfohlene Laufzeiten ................................................................................25

Entsorgen der Flüssigkeit .............................................................................25

3. Die automatischen Systeme AA.................................................. 26

Betrieb der Pumpe .......................................................................................26

Handgriff ......................................................................................................26

Anschluss weiterer Entnahmestellen ...........................................................27

4. Die manuellen Systeme AC......................................................... 30

Betrieb der Pumpe .......................................................................................30

5. Die kompakten Systeme AZ........................................................ 31

Betrieb der Pumpe .......................................................................................31

6. Absaugsysteme AE & AK ............................................................ 32

Betrieb der Pumpe .......................................................................................32

7. Instandhaltung .......................................................................... 32

Reinigung......................................................................................................32

Service ..........................................................................................................33

8. Artikelbeschreibung Zubehör ..................................................... 35

9. Erläuterungen……………………………………..……………………………..………36

DOMINIQUE DUTSCHER SAS

4

Basic Data

The HLC by DITABIS Aspiration Systems are made for the controlled aspiration

of liquids from typical lab containers like cuvetts, tubes, microplates, petri

dishes or roller bottles. They are also suited for the disposal of liquid biological

or chemical waste and filtration of liquids by means of filter systems. If there

are any uncertainties regarding the liquids, which should be aspirated, please

contact DITABIS. The HLC by DITABIS devices are meant for indoor usage only.

Please use only HLC by DITABIS accessories or accessories recommended by

HLC by DITABIS.

Safety

The HLC by DITABIS devices possess an EC declaration, which the DITABIS AG

will provide on request. The devices comply with the standards and directives

mentioned in the EN DIN 61010-1 norm. IQ, OQ and PQ documents are

available on request.

Please take note of the following safety measures:

Do only connect the system to a Schuko socket of 230 V, 50

Hz.

Attach the safety filter before the vacuum pump. No liquid

may get into the pump.

Empty the collection bottle in time (max. filling level 75%).

The ventilation of the device must not be blocked. To ensure

the proper ventilation at all times please consider a

minimum distance of 10 centimetres on each side of the

device.

Damaged mains cable should only be replaced with equal

ones.

Operational conditions of the system

The device does not own an admission to be placed within

an explosiv atmosphere and to extract contents within

explosiv atmospheres.

The device is not designed for the aspiration of

ounstable materials

omaterials, which might react explosive under impact

(mechanical duress) and / or under elevated

temperature without air supply

DOMINIQUE DUTSCHER SAS

5

oself-igniting materials

omaterials, which might explode without air supply

oexplosive material

The devices are not authorized for usage in underground

mining.

The devices are not designed for the aspiration of dusts.

Warranty

All functions of the systems have been tested thoroughly. After that, the

system and the accessories were packed carefully in perfect condition. If,

however, any damages or defects are detected during installation or setup,

please contact your local dealer or the DITABIS service department. The

DITABIS contact information can be found at www.ditabis.com (see also our

Terms and Conditions at www.ditabis.com). If used under normal laboratory

conditions according to the Operating Manual, DITABIS grants a warranty of 1

year, starting with the day of shipment.

Disclaimer of warranty

In case of unspecified use of the device, the manufacturer assumes no

responsibility.

Components

The following components are part of every HLC by DITABIS aspirations

system:

1 x Autoclavable collection bottle (2 or 4 litres) incl. screw cap

2 x Self-locking fast lock clutches

1 x Ventilation insert

2 x Hose clips

1 x Safety filter

3 m Silicone hose (Øinside 6mm, Ø outside 9mm)

Y-manifold for connecting several outlets (standard only for AA 24)

DOMINIQUE DUTSCHER SAS

6

First Steps

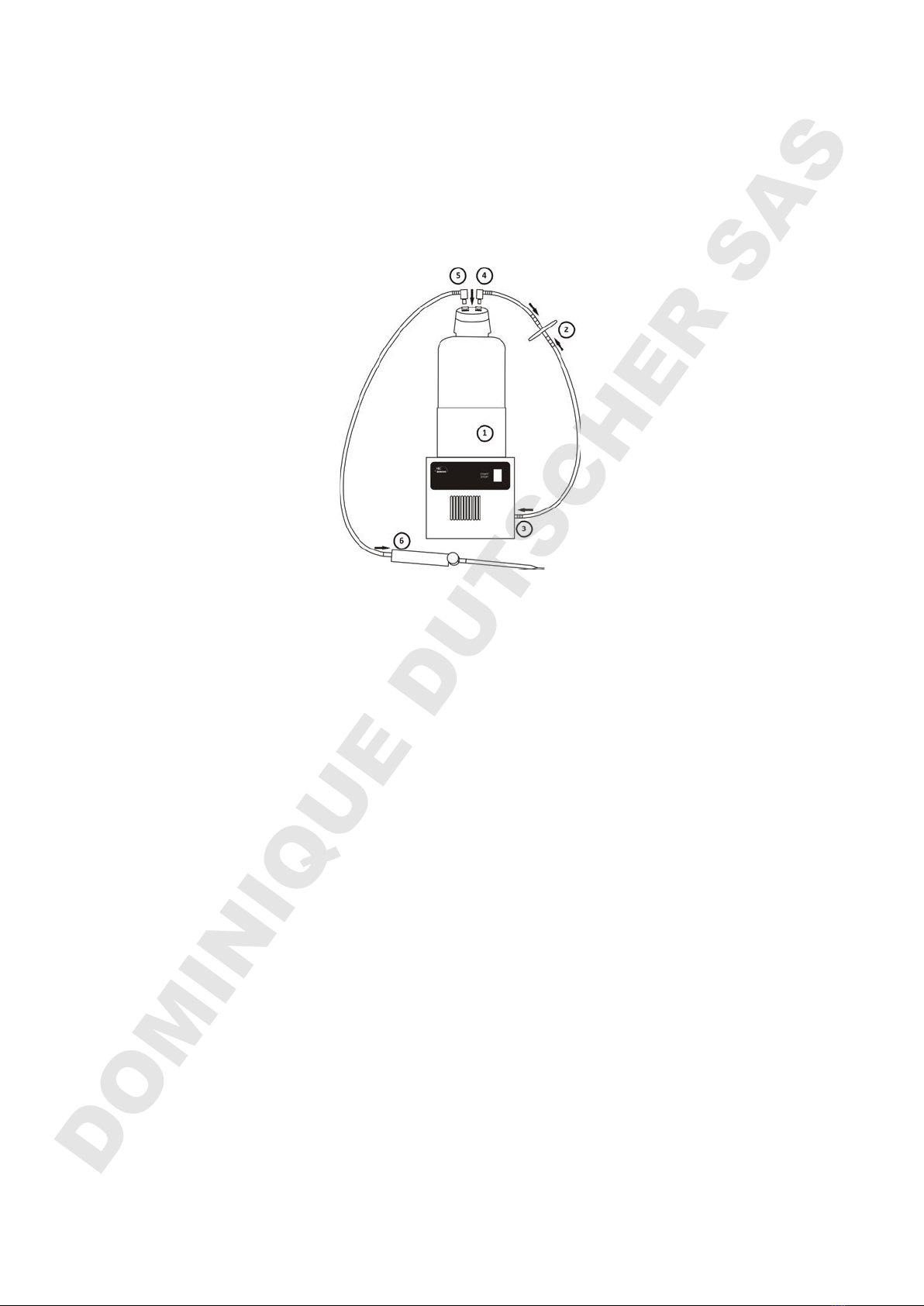

Assembly of systems AA and AC

Place the bottle in the safety bottle holder (1). Cut off a piece of the silicone

hose as required for connecting bottle and pump. Cut this hose in two and

place the safety filter between bottle and pump, relatively close to the bottle

(2).

Insert a free hose end into the hose olive at the back of the pump (3). Put a

hose clip on the other end of the hose which is inserted into the self-locking

clutch on the cap (4).

Cut off another piece of the silicone hose, the length depending on the

desired distance between bottle and workplace. Put the second hose clip on a

free hose end which is inserted into the second self-locking clutch on the cap

(5).

Put the other hose end in the olive of the handle (6).

collection bottle

silicone hose

filter

hose clip

ventilation insert

Y

-

manifold

(for AA 24)

DOMINIQUE DUTSCHER SAS

7

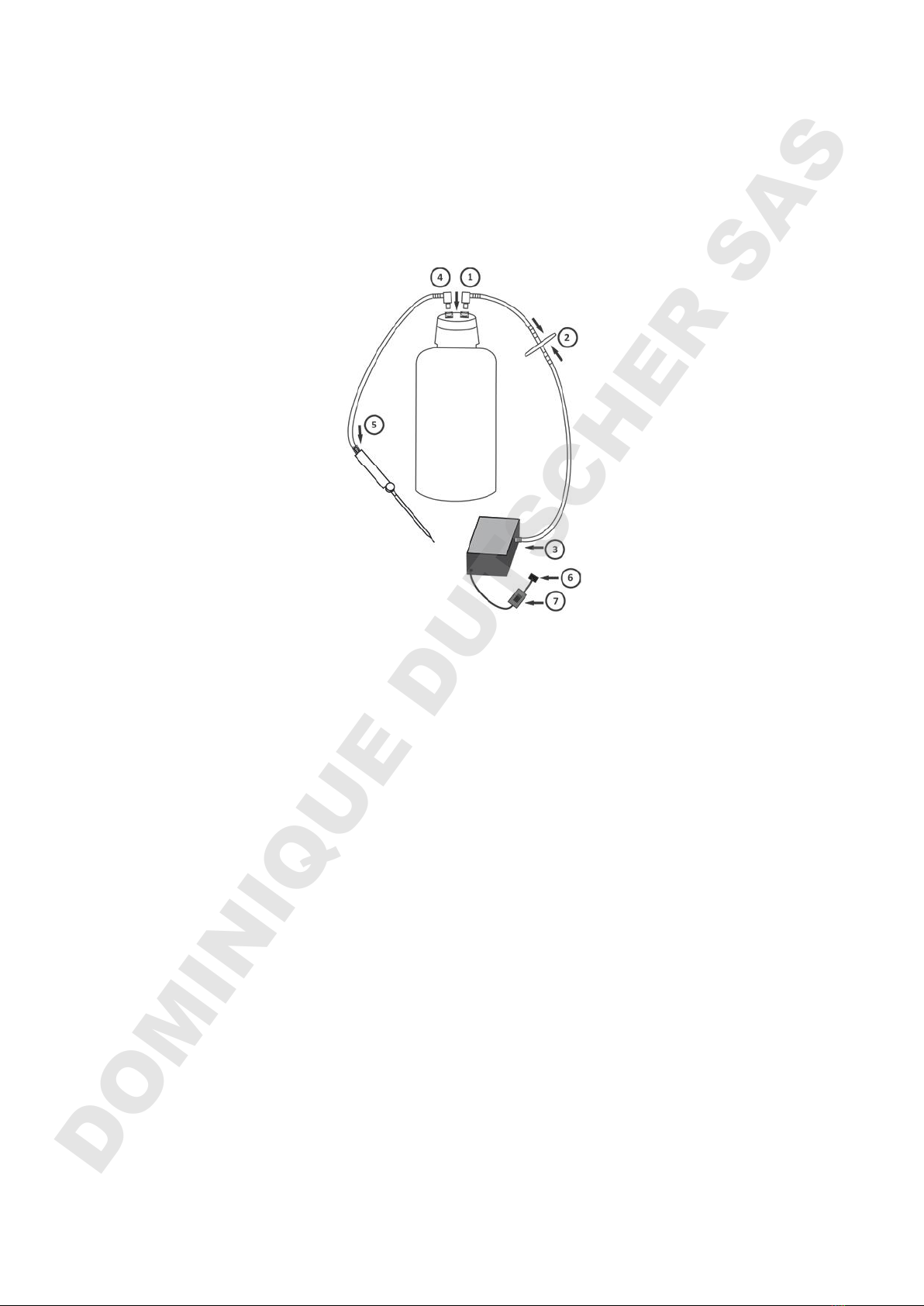

Assembly of system AZ

Cut off a piece of the silicone hose as required for connecting bottle and

safety filter. Put the hose clip on a free hose end which is inserted into one of

the self-locking clutches on the cap (1). Cut this hose in two and place the

safety filter between bottle and pump, relatively close to the bottle (2).

Insert the hose end, which leads away from the safety filter, into the lateral

nipple of the separate pump (3).

Cut off another piece of the silicone hose, the length depending on the

desired distance between bottle and workplace. Put a hose clip on the end of

the hose, which is inserted into the second self-locking clutch on the cap (4).

Insert another free hose end into the hose olive and then connect it to your

aspiration instrument (e.g. Pasteur pipette) (5).

Connect the mains cable with plug (6) and the cable switch (7) to a socket with

230 V, 50 Hz.

DOMINIQUE DUTSCHER SAS

8

Setup

For the systems AA and AC: Plug the mains cable in the IEC socket on the back

of the system and connect it with the mains power 230 V, 50 Hz via a Schuko

socket. For the system AZ: Connect the mains cable with the cable switch with

the mains power 230 V, 50 Hz via a Schuko socket.

Recommended operating times

AA 02 / 04 (Pump AP 30)

The pump turns off automatically after reaching its maximum vacuum,

therefore the system is suited for continuous operation.

AC 02 / 04 (Pump AP 15)

If the system gets turned off regularly or a foot switch is used, the system is

suited for continuous operation. The maximum approved uninterrupted

operating time is 60 minutes, after that, a break for cooling down is required.

DOMINIQUE DUTSCHER SAS

9

AZ 02 / 04 (Pump AP 04)

The system is suitable for continuous operation, there is no danger of failure

or overheating.

Disposal of liquids

For the quick and easy separation and removal of the collection bottle, it is

provided with fast-lock clutches. For unlocking the clutches, push on the

lateral metal plate and pull the hose clip out of the clutch on the cap. Now,

the bottle is hermetically sealed since the integrated clutches lock

automatically. The bottle can be transported safely.

If you want to autoclave the bottle in sealed state, insert

the provided ventilation insert into one of the fast-lock

clutches on the cap. This opens the bottle and the

pressure equalization required for autoclaving is

ensured.

If liquid gets into the hose leading to the pump during

aspiration, a 5 cm hose can be put on the olive of a fast-

lock clutch inside the cap. This increases the distance

between ingress of liquid and vacuum.

Take care that the collection bottle does not exceed app. 75% of its filling

volume. If the vacuum gets noticeably weaker, check the permeability of the

filter and replace it if required.

Automatic systems AA

Pump operation

Switch on the pump with the mains switch "Start / Stop"; the green mains

control light turns on, the pump runs and generates a vacuum in the bottle.

The pump runs until a vacuum is generated in the bottle or as long as the

valve of the handle is opened. It is normal that the pump switches off shortly

DOMINIQUE DUTSCHER SAS

10

if you work with very thin aspiration instruments since the vacuum in the

bottle is sufficient for them. Even if the handle is closed, the pump runs

temporarily in irregular intervals since it continuously provides the optimal

vacuum. During long operation stops you should switch off the pump in order

to avoid unnecessary running noises and prevent unnecessary consumption of

electricity. Take note that the collection bottle does not exceed 75% of its

filling volume if possible. If the vacuum gets noticeably weaker, check the

permeability of the filter and replace it if required.

Handle

The handle AH 01 can be used by right-handed as well as left-handed persons

comfortable with one hand. The thumb is e.g. placed on the even surface, the

valve is rotated by the index finger self-retaining between 0° and 90°.

If the mark on the rotary knob points to the direction of the flow, the valve is

completely open. The valve can be rotated clockwise up to app. 90° until it is

completely closed.

If the valve is completely closed, the pump switches off automatically as soon

as the desired vacuum is generated in the bottle. In this way, required vacuum

is available continuously even without the pump running. For multi-user

systems, an unused handle must always be closed since otherwise there is a

continuous flow there and now vacuum can be generated. If you use a Pasteur

pipette or a suction rake, please cut off a short piece of the enclosed silicone

hose and connect your aspirator and the pump with it. High quality steel

aspirators can be screwed on the handle. Pipette tips can be connected to the

handle with the adapter AR 40, which can be bought separately.

DOMINIQUE DUTSCHER SAS

11

Cleaning

After the completion of the aspiration process, the handle should be rinsed to

avoid a blocking of the valve. During rinsing, slowly close and open the valve.

If the valve is blocked, please contact our service department or remove the

little lower knurled screw and try to loosen the valve by means of dissolving

liquid.

Technical Data AA 02 / 04, AA 24

Vacuum pump

Aspiration capacity 17 l / min

Final vacuum 100 mbar abs.

Material of pump head aluminium

Housing

Dimensions (W x L x H) 170 x 220 x 155 mm

Height with bottle 02 l 440 mm

Height with bottle 04 l 510 mm

Weight without accessories 5.5 kg

Material housing aluminium

Power input 100 W

Electr. supply 230 V / 50 Hz

Fuse 2 AT

Environmental conditions

ambient air temperature 4 –40°C

in service (non-condensing)

relative humidity max. 80%

Connection of additional units

This description refers to the connection of additional units to the systems

AA 02, AA 04 and AA 24

Up to 4 additional units can be connected to the aspiration systems. This can

be done with 4 bottles with one handle each.

DOMINIQUE DUTSCHER SAS

12

Or with 2 bottles with two handles each - or with a part of each option.

In both cases it is required that the Y-manifold AY 01 of HLC by DITABIS is used

for connecting the bottles since this ensures a straight-line connection to the

fast-lock caps of the b o ttles (see d escrip tio n “A ssem b ly A A 24 for 2

Workplaces”.

Assembly of the system AA 24 for 2 workplaces

Extend the three connection of the Y-manifold with one short piece of hose

each. Then insert the Y-manifold into a fast-lock clutch on the cap (1). Connect

each handle with the Y-manifold (2).

DOMINIQUE DUTSCHER SAS

13

If more than one handle is used –for the multi-user systems AA 02 and AA 04

as well as for the two-user system AA 24 –the unused handles must always be

closed since otherwise no vacuum can be generated in the bottle.

Basic systems AC

Pump operation

Switch on the pump with the mains switch "Start / Stop"; the green mains

control light turns on, the pump runs and generates a vacuum in the bottle.

During long operation stops you should switch off the pump in order to avoid

unnecessary running noises and prevent unnecessary consumption of

electricity. Take note that the collection bottle does not exceed 75% of its

filling volume if possible. If the vacuum gets noticeably weaker, check the

permeability of the filter and replace it if required.

Technical Data AC 02 / 04

Vacuum pump

Aspiration capacity 25 l / min

Final vacuum 250 mbar abs.

Material of the pump head aluminium

Housing

Dimensions (W x L x H) 170 x 220 x 155 mm

Height with bottle 02 l 440 mm

Height with bottle 04 l 510 mm

DOMINIQUE DUTSCHER SAS

14

Weight without accessories 4.5 kg

Material housing aluminium

Power input 100 W

Electr. supply 230 V / 50 Hz

(115 V / 60 Hz available)

Fuse 2 AT

Environmental conditions

ambient air temperature 4 –40°C

in service (non-condensing)

relative humidity max. 80%

Compact systems AZ

Pump operation

Connect the hose to the lateral nipple of the pump and turn it on by using the

cable switch. The pump runs and generates a vacuum in the bottle. It is

reasonable to use the bottle holder and the foot switch AF 01 in addition,

these two can be bought as an option. During long operation stops you should

switch off the pump in order to avoid unnecessary running noises and prevent

unnecessary consumption of electricity. Take note that the collection bottle

does not exceed 75% of its filling volume if possible. If the vacuum gets

noticeably weaker, check the permeability of the filter and replace it if

required.

Technical Data AZ 02 / 04

Vacuum pump

Aspiration capacity 8 l / min

Final vacuum 700 mbar abs.

Material of the pump head aluminium

Housing

Dimensions of the pump (W x L x H) 75 x 170 x 60 mm

Height bottle 02 l 290 mm

Height bottle 04 l 360 mm

Weight without accessories 0.8 kg

Power input 5 W

DOMINIQUE DUTSCHER SAS

15

Electr. supply 230 V / 50 Hz

(115 V / 60 Hz available)

Environmental conditions

ambient air temperature 4 –40°C

in service (non-condensing)

relative humidity max. 80%

Aspiration systems AE & AK

Pump operation

The AE and AK systems are suited for labs where a vacuum port is present.

Connect the hose of the bottle with the vacuum port in your lab. If the

vacuum gets noticeably weaker, check the permeability of the filter and

replace it if required.

Dimensions AE & AK 02 / 04

Height bottle 02 l 290 mm

Height bottle 04 l 360 mm

Maintenance

Cleaning

Regularly clean the housing of the vacuum safety aspiration systems.

Precautions for avoiding electric shock

Electronic devices can cause electric shocks in case of an

operating error. Never try to repair electric parts. Never open

the housing.

Switch off the system and disconnect it from the power

supply before starting with cleaning or disinfection

works.

Never let get liquids inside the housing (ventilations

slit).

DOMINIQUE DUTSCHER SAS

16

Do not perform spray disinfection.

Do only connect the system with the power supply if it is

completely dry.

The repair service may only be performed by staff authorized

and trained by the manufacturer. A modification of the system is

not permitted.

Caution when handling aggressive chemicals

Do not use aggressive chemicals like e.g. strong and weak bases,

strong acids, formaldehyde, acetone, halogenated hydrocarbons

or phenol for cleaning the system and its accessories.

In case of contamination with aggressive chemicals,

clean the system with a neutral detergent immediately.

Use neither corrosive detergents nor aggressive solvents

or abrasive polishing agents.

Cleaning

1. Disconnect the system from the power supply before you start

cleaning.

2. Clean all outer parts of the system with a mild detergent and a lint-

free cloth.

3. Wipe off the detergent with Aqua dest.

4. Dry all cleaned parts.

Desinfection

1. Disconnect the system from the power supply before you start

disinfecting.

2. Let the system cool down.

3. Clean the system as described above.

4. Select a disinfection method compliant to the applicable local legal

regulations and directives.

5. Wipe off all outer parts of the system with the disinfectant and a lint-

free cloth.

Service

If a technical problem arises, please contact your local dealer or the DITABIS

service department. The DITABIS contact information can be found at

DOMINIQUE DUTSCHER SAS

17

www.ditabis.com. If required, the system will be returned for repair –please

take note of our service guidelines, which can be found at www.ditabis.com as

well.

Decontamination before shipment

If you send the system to the authorised technical service for repair or to your

distributor for disposal, please decontaminate all parts you want to send.

Document the decontamination in a Decontamination Certificate inclusive

serial number.

DOMINIQUE DUTSCHER SAS

18

Article description accessories

Bottles / bottle accessories

Art. No. Description

800014600 Spare bottle 2 l with fast-lock clutches

800014700 Spare bottle 4 l with fast-lock clutches

800010100 Bottle holder for 2 l bottle

800010200 Bottle holder for 4 l bottle

100021028 Hose clip

800015900 Y-manifold, for connecting several collection units

800015800 Safety filter (shipping unit 3 pcs.)

800014400 Cap for 2 l bottle with fast-lock clutches

800014500 Cap for 4 l bottle with fast-lock clutches

Handle / adapter

Art. No. Description

800013200 Handle with flow regulation

800013300 Stainless steel aspiration adapter, length 60 mm

800013400 Stainless steel aspiration adapter, length 150 mm

800013500 Stainless steel aspiration adapter, length 200 mm

800013600 Aspiration adapter for yellow pipette tips

800013700 Adapter with aspiration rake, 8-channel, autoclavable

800015600 Aspiration rake, 8-channel, as spare part

Pumps & foot-operated switches

Art. No. Description

800015300 Membrane vacuum pump

800015000 Membrane vacuum pump

800015100 Membrane vacuum pump

800014000 Foot-operated switch for switching the pump on and off

DOMINIQUE DUTSCHER SAS

19

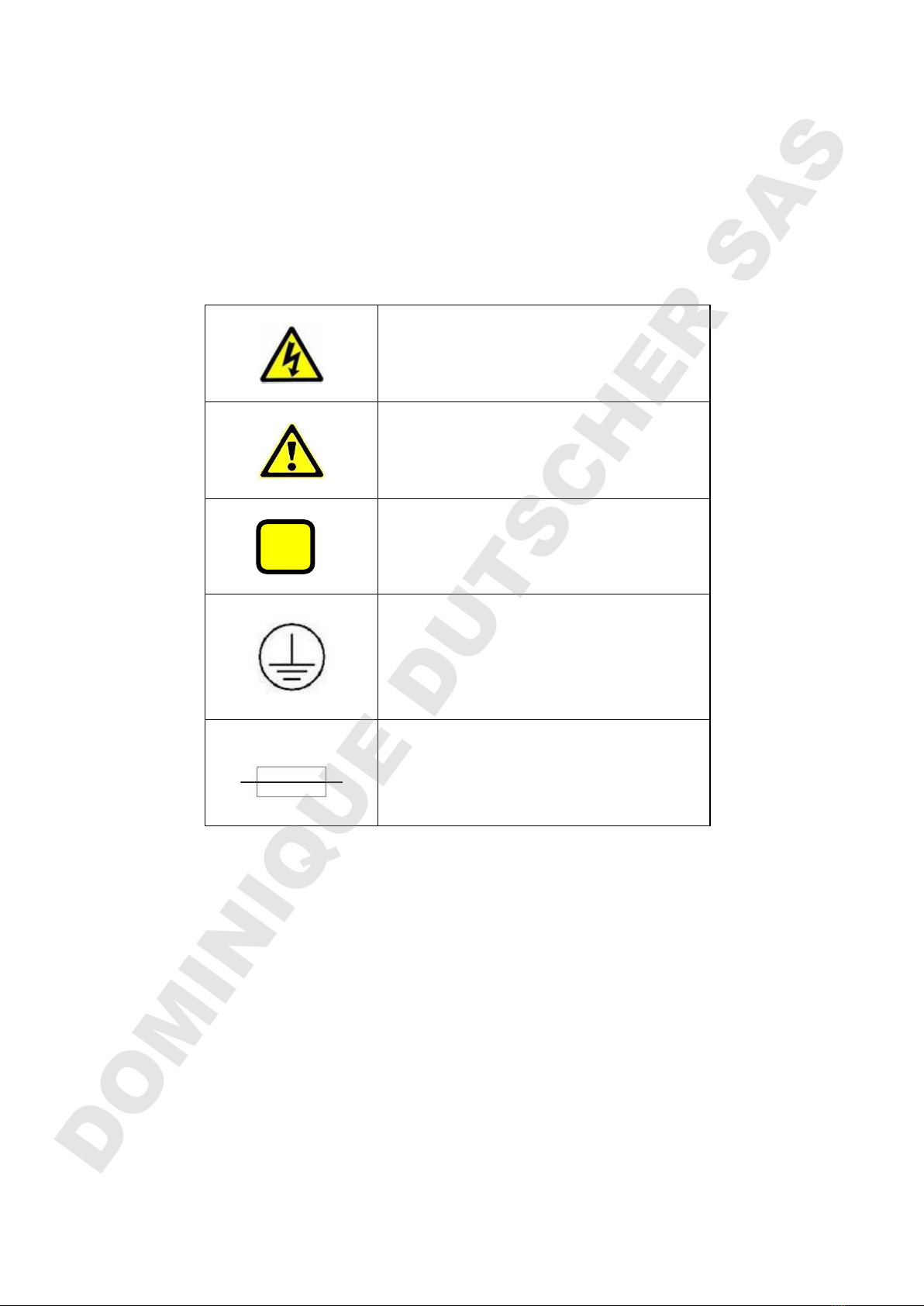

Explanations

Caution! Risk of electric shock!

Caution!

Important information

Earth conductor

Fuse

i

DOMINIQUE DUTSCHER SAS

20

Basisdaten

Die HLC by DITABIS Vakuum-Sicherheits-Absaugsysteme sind für das

kontrollierte Absaugen von Flüssigkeiten aus herkömmlichen Laborgefäßen

wie Kuvetten, Röhrchen, Mikrotiterplatten, Petrischalen, Rollerflaschen etc.

vorgesehen. Die Systeme sind ebenso für die Entsorgung von flüssigen

biologischen und chemischen Abfällen sowie Filterung von Flüssigkeiten,

durch Einsatz eines speziellen Filtersystems, geeignet. Im Falle von

Unklarheiten im Bezug auf die abzusaugenden Flüssigkeiten kontaktieren Sie

bitte DITABIS. Die HLC by DITABIS Geräte sind für die Verwendung in

Innenräumen bestimmt. Verwenden Sie bitte aus-schließlich HLC by DITABIS

Zubehör oder das von DITABIS empfohlene Zubehör.

Sicherheit

HLC by DITABIS Geräte besitzen eine CE Konformitätserklärung. Diese stellt

DITABIS auf Anfrage zur Verfügung. Die Instrumente entsprechen den

Sicherheitsnormen für Laborgeräte IEC 61010-1. IQ, OQ und PQ Dokumente

erhalten Sie gesondert auf Anfrage.

Bitte beachten Sie folgende Sicherheitsmaßnahmen:

Schließen Sie das Gerät nur an eine Schuko-Steckdose 230 V,

50 Hz an.

Bringen Sie den Sicherheitsfilter vor der Vakuumpumpe an,

In die Pumpe darf keine Flüssigkeit gelangen.

Leeren Sie die Auffangflasche rechtzeitig (max. 75%

Füllhöhe).

Die Lüftungsschlitze des Gerätes müssen jederzeit frei

zugänglich sein.

Defekte Netzkabel dürfen ausschließlich durch gleichwertige

Netzkabel ersetzt werden.

Einsatzbedingungen des Systems

Die Geräte besitzen keine Zulassung für die Aufstellung in

und die Förderung aus explosionsgefährdeten Bereichen.

Die Geräte sind nicht geeignet für Förderung von

oinstabilen Stoffen

DOMINIQUE DUTSCHER SAS

This manual suits for next models

10

Table of contents

Languages: