PROGRAMMABLE

DIN RAIL

TEMPERATURE

TRANSMITTER

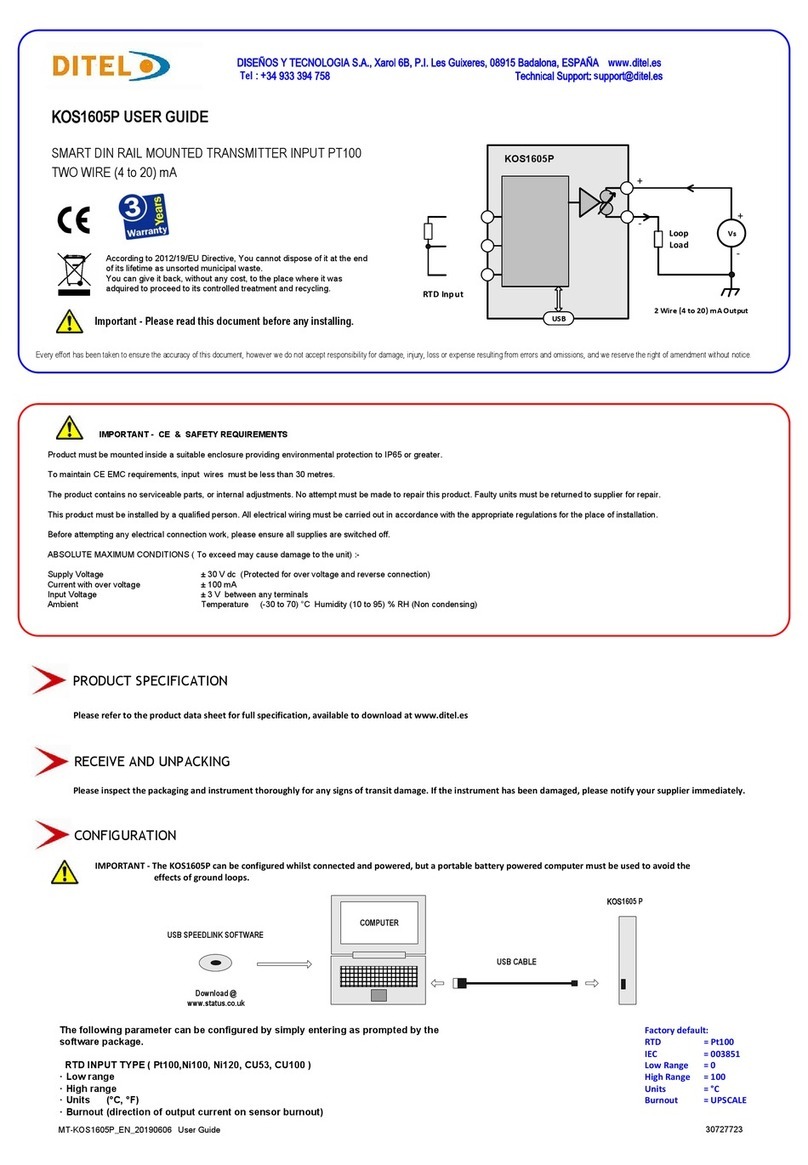

The KOS215 is a universal DIN Rail mounted temperature transmitter that accepts

most commonly used temperature sensors, slide wire transducers or mV signals and

transmits them as a 4-20mA signal to a host system. The unit can be programmed by

the user from a selection of preset ranges selected by DIL switches or by computer if

required.

2.0 SPECIFICATION @ 24ºC

2.11 RTD Input (Pt100)

Sensor Range -200 to +850ºC (18 a 390Ω)

Minimum Span125ºC

Linearisation BS EN 60751 (IEC 751)

BS1904 (DIN 43670)

JISC 1604

Basic Measurement Accuracy 2±0.01% FRI 5±0.05% Rdg

Thermal Drift Zero 0.008 ºC/ºC, Span 100 ppm / ºC

Excitation current 300µA a 550µA

Maximum lead resistance 50Ω/ leg

Lead resistance effect 0.002ºC /Ω

Preset ranges Refer to section 3.3

2.12 Thermocouple Input

Sensor Ranges Termocouple type Measuring RangeºC4Minimum Span1

TC Tipo K -200 a 1370 50

TC Tipo J -200 a 1200 50

TCTipo T -210 a 400 25

TC Tipo R -10 a 1760 100

TC Tipo S -10 a 1760 100

TC Tipo E -200 a 1000 50

TC Tipo F(L) -100 a 600 25

TC Tipo N -180 a 1300 50

Linearisation BS EN 60584-2, IEC 584-2 (BS 4937)

Basic measurement Accuracy² ±0.04% FE5±0.04% L o 0.5ºC

(Which ever is greater)

Thermal Drift Zero 0.1µV/ ºC, Span 100 ppm/ºC

Cold junction error ±0.5ºC

Cold junction Tracking 0.05ºC/ºC

Cold junction Range -40 to +85ºC

Preset Ranges Refer to section 3.3

2.13 Millivolt input

Input voltage source

Range -10 to +75 mV

Minimum Span¹ 5 mV

Basic Measurement Accuracy2±10µV ±0.07% Rdg

Input Impedance 10 MΩ

Thermal Drift Zero 0.1µV/ºC, Span 100 ppm / ºC

2.14 Slidewire input

Input 3 Wire potentiometer

Resistence Range 10Ωto390Ω(entre extremos) Para entrada a R > 390 los

terminales 9 y 10 deben estar unidos

Characterisation Linear.

Minimum Span15% of full range

Basic Measurement Accuracy20.1% FRI5

Thermal Drift 100 ppm / ºC

Notes.

1Any Span may be selected, full accuracy is only guaranteed for spans

greater than the minimum recomended.

2. Basic Measurement Accuracy includes the effects of calibration,

linearisation and repeatability.

4. Consult thermocouple reference standards for thermocouple material

limitation.

5. FRI = Full Range Input.

Output range 4-20mA (<3.8 to >20.2 mA)

Maximum Output 23mA

Accuracy ±5µA

VoltageEffect 0.2µA /V

Thermal Drift 1µA / ºC

Supply voltage 10 to 35V

Maximum Output Load [(V Supply -10)/20] KΩ(i.e. 700Ω@ 24V)

Restricted to 300ΩMaximum for inloop

programming

Protection Reverse connection overvoltage 35V

2.3 General

Input/Output Isolation 500VAC rms (galvanically isolated)

Update time 250 mS Maximum

Time constant (Filter Off) < 1 Second (Time to reach 63% of final value)

Filter factor Programmable Off, 2sec, 10sec or Adaptative

Warm-upTime 2 minutes to full accuracy

Stability 0.1% FRI 5or 0.1ºC/year

Environmental

ambient operating range -40 to 60ºC

ambient storage temperature -25 to 70ºC

ambient humidity range 10 to 90% HR non condensing

EMC

Emissions EN50081-1

Inmunity EN50082-2

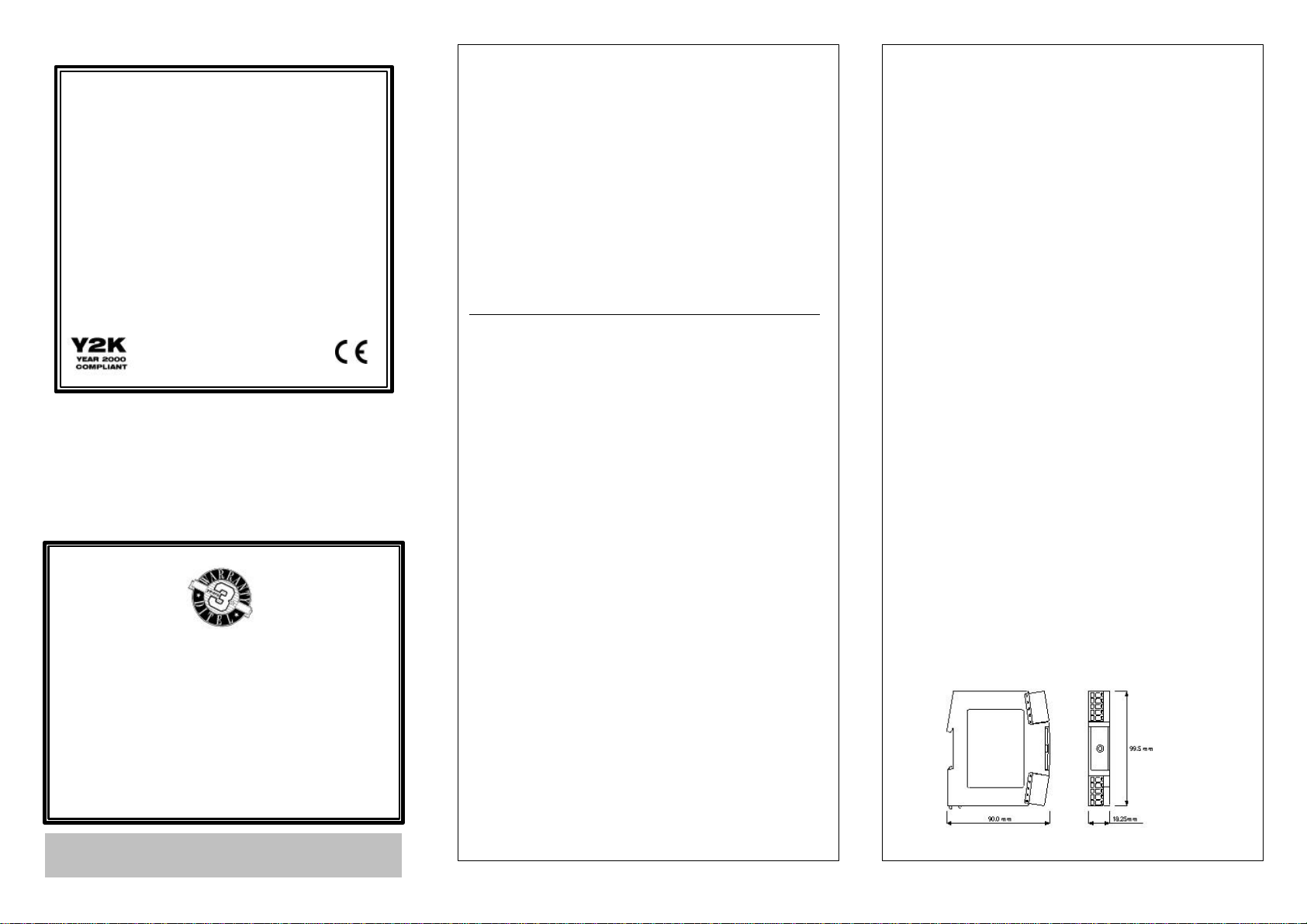

Mechanical

Enclosure Din rail EN 50022-35

Material ABS

Weight 70g

Flammability SEI UL 94-VI

Dimensions 90 x 99 x 18.5mm

Connections Tension clamp two part terminals and 3.5mm jack for comms

Communications

PC Interface RS232 via PC

Loop Load 100-300Ωin loop programming

(Available as quick selector or via PC)

Maximum cable length 1000m

Configurable Parameters Sensor type:Burnout: ºC/ºF: output:

Available as quick selector or via PC

: Hi/Lo: Filter: Tag: user Offset

(available via PC programming only)

Comms protocol ANSI X3.28 1976

Data Rate 1200 baud

3.0 INSTALLATION

3.1 Mechanical

The transmitter is designed to mount onto a standard Din Rail. The transmitter should

be installed with adequate protection from moisture and corrosive atmospheres. The

transmittermay be mountedin any orientation.

Care must be taken when locating the transmitter to ensure the ambient temperature

remains within the specified operating rang. The figure shows the mechanical layout of

thetransmitter.

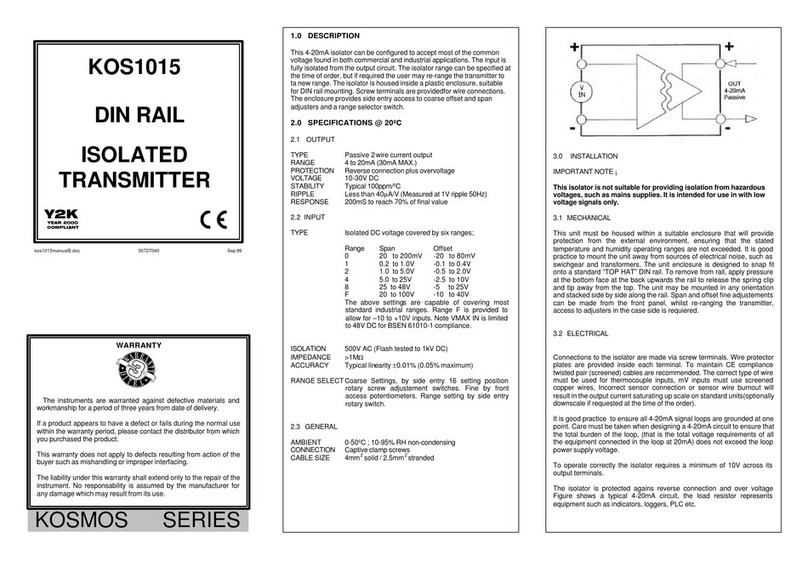

The instruments are warranted against defective materials and

workmanship for a period of three years from date of delivery.

If a product appears to have a defect or fails during the normal use

within the warranty period, please contact the distributor from which

you purchased the product.

This warranty does not apply to defects resulting from action of the

buyer such as mishandling or improper interfacing.

The liability under this warranty shall extend only to the repair of the

instrument. No responsability is assumed by the manufacturer for

any damage which may result from its use.