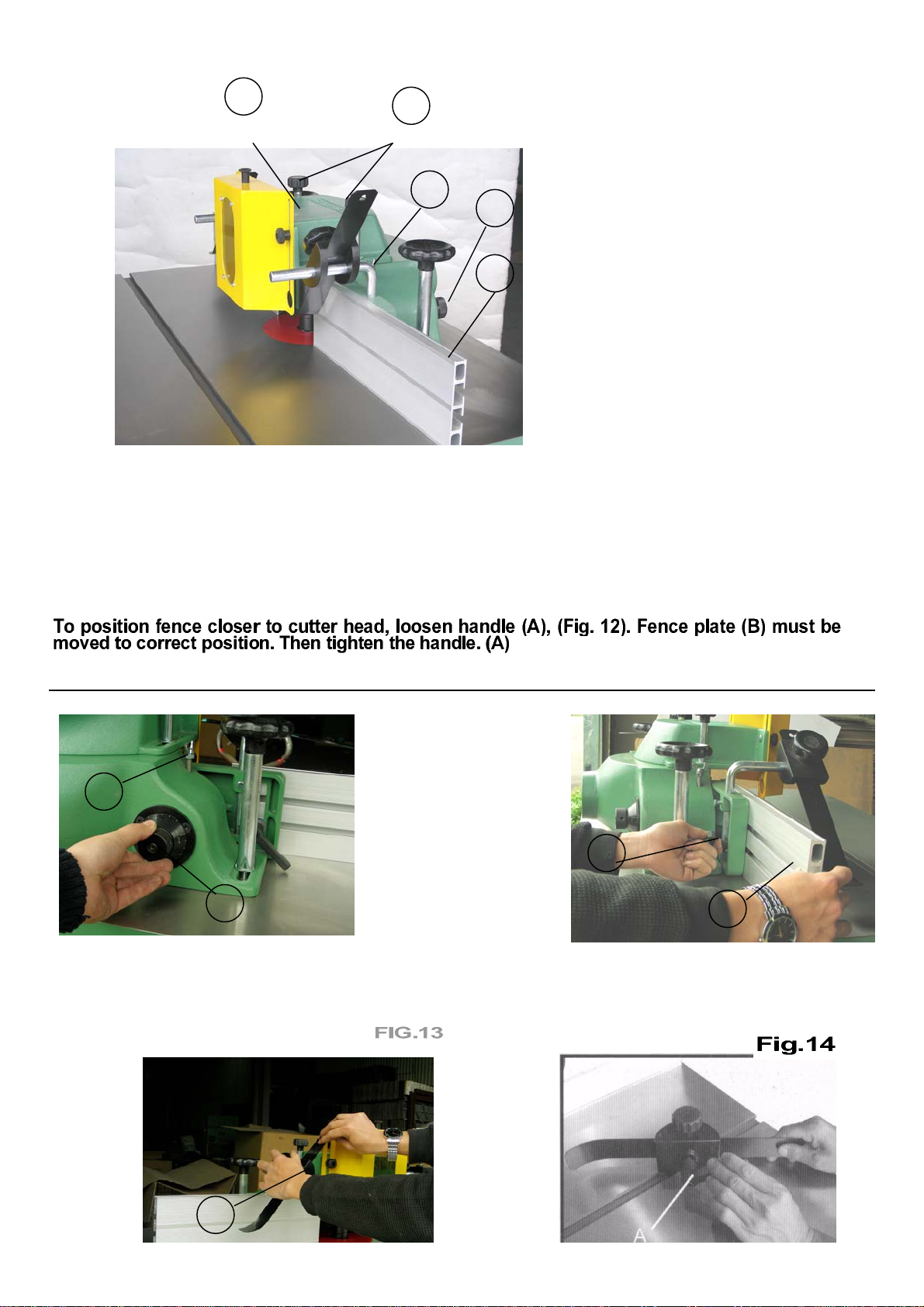

GRAIN DIRECTION

The work piece should always be shaped in the same direction as the grain (if possible). When

cut against the wood grain, woods as redwood, fir and oak will leave a rough, or slightly

splintered edge.

CAUTION: When deep cuts are required, they will need strong power and a pushing force in

order to control the cut. Deep cuts can also cause the wood to split or splinter, this may lead to

loss of control or injures to the work operator. When a finished edge is not to your satisfaction,

cut a few more times with no more than 1/16" deep. Pre-cut stock on band saw 1/16" whenever

possible.

The trailing board edge will splinter when shaping across the grain. The best solution would be

to cut the board 1 /4" oversize in width shape the board and simply trim off the excess.

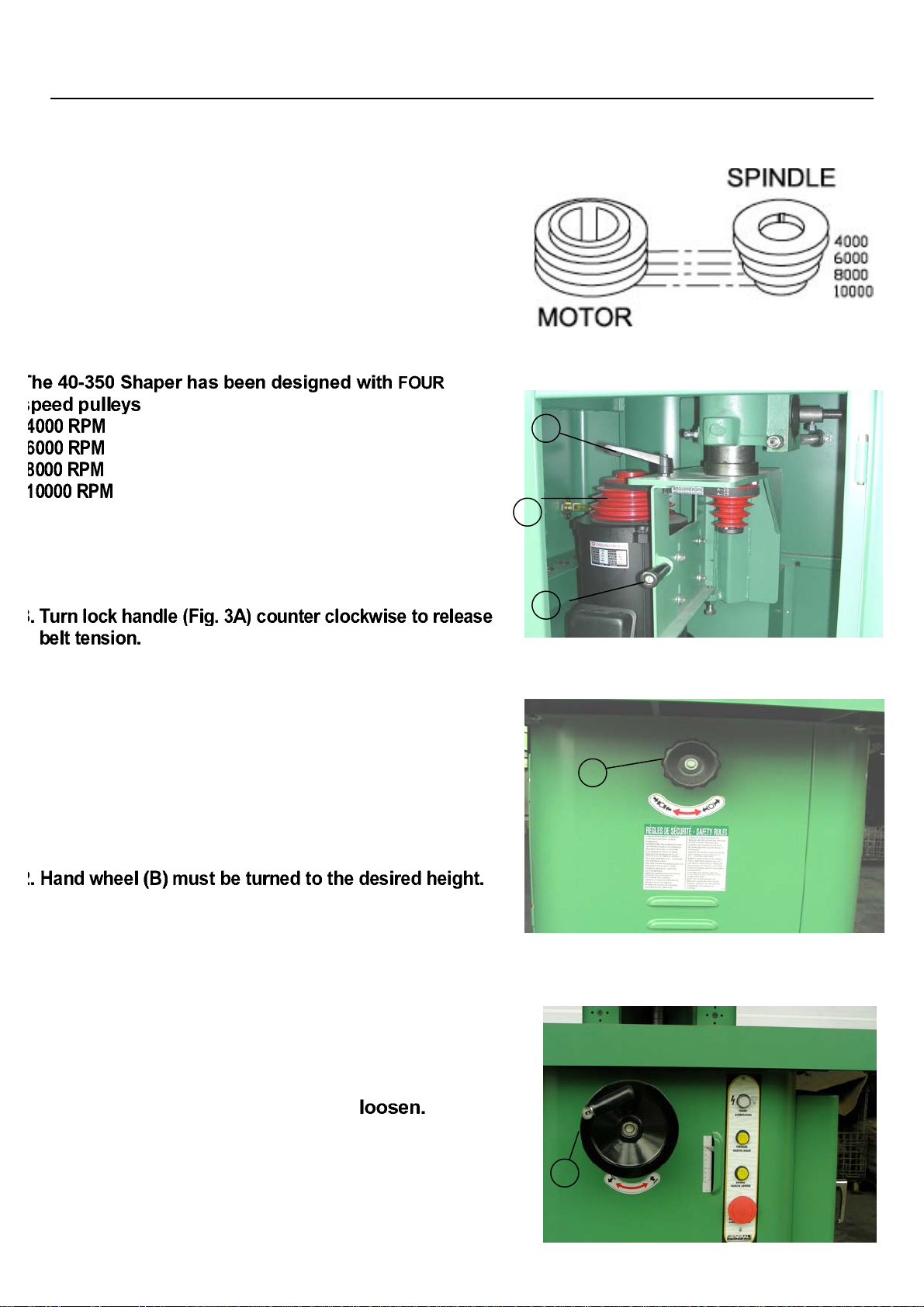

STRAIGHT EDGE SHAPING •

The work piece must always be against the fence to

perform straight edge shaping, follow these procedures to

set up:

1. Disconnect machine from the power source.

2. Fence faces must be parallel, properly in line or offset If

necessary,

3. Cutter must be rotated and inspected for clearance.

4. Position the leading face of a cutter head blade at 90

degrees to the infeed fence and adjust the spindle to

the desired height of the cut. At the same time check

the desired depth of cut with the blade in the 90

degrees position.(Fig. 20)

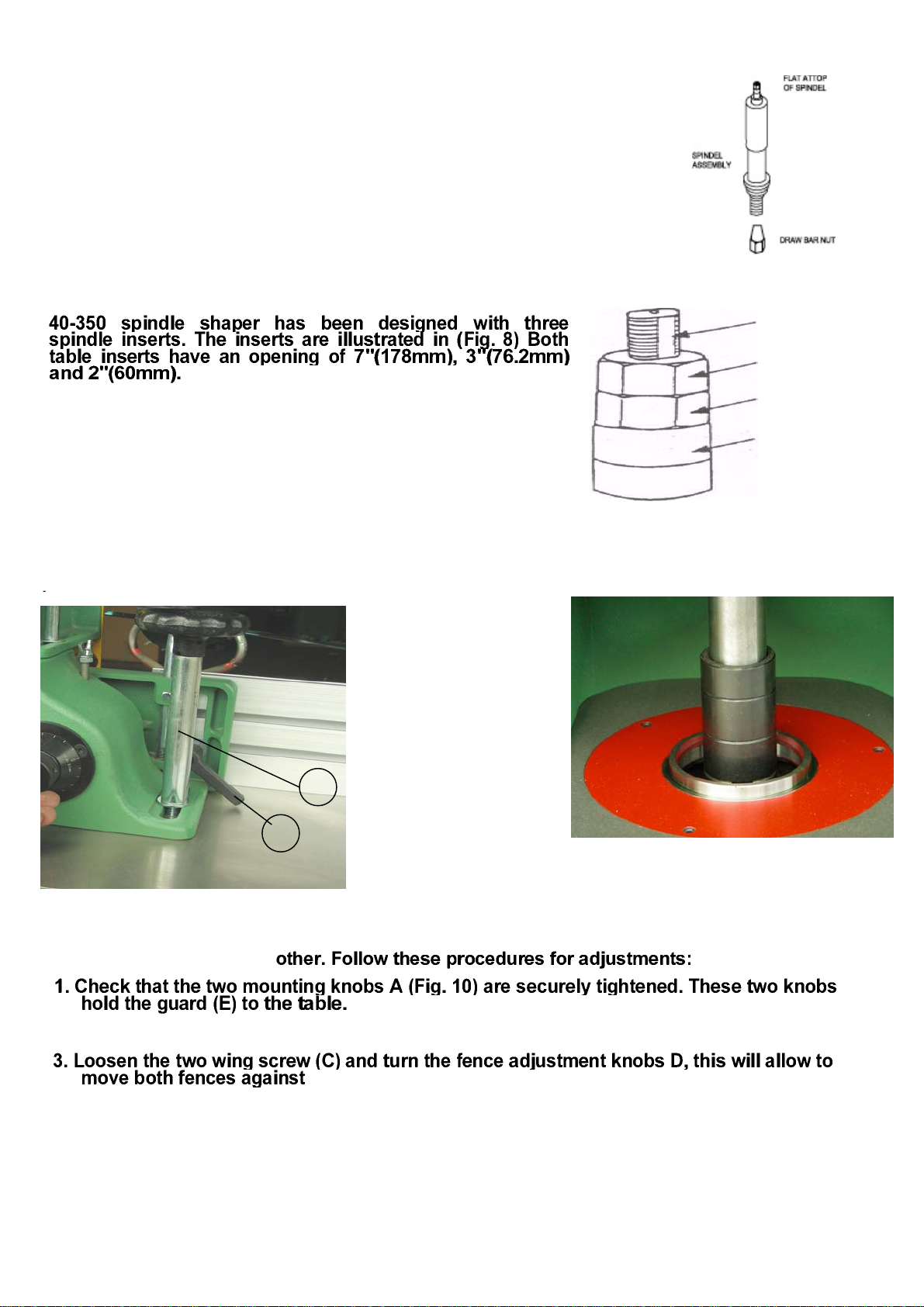

DEPTH OF CUT

The depth of cut is the distance from the outside circumference edge of the collar which the

work rides against to the outside edge of the cutter. The depth of the cut is determined by the

position of the fence relative to the cutter head or by the use of shaper collars.

1. Spindle must be locked.

2. Right guard should be installed wherever possible.

3. Connect to the power source.

Note: To determine if the cut, profile and depth are correct you will only need a short cut.

5. Make adjustments if required, or proceed shaping using the work piece.

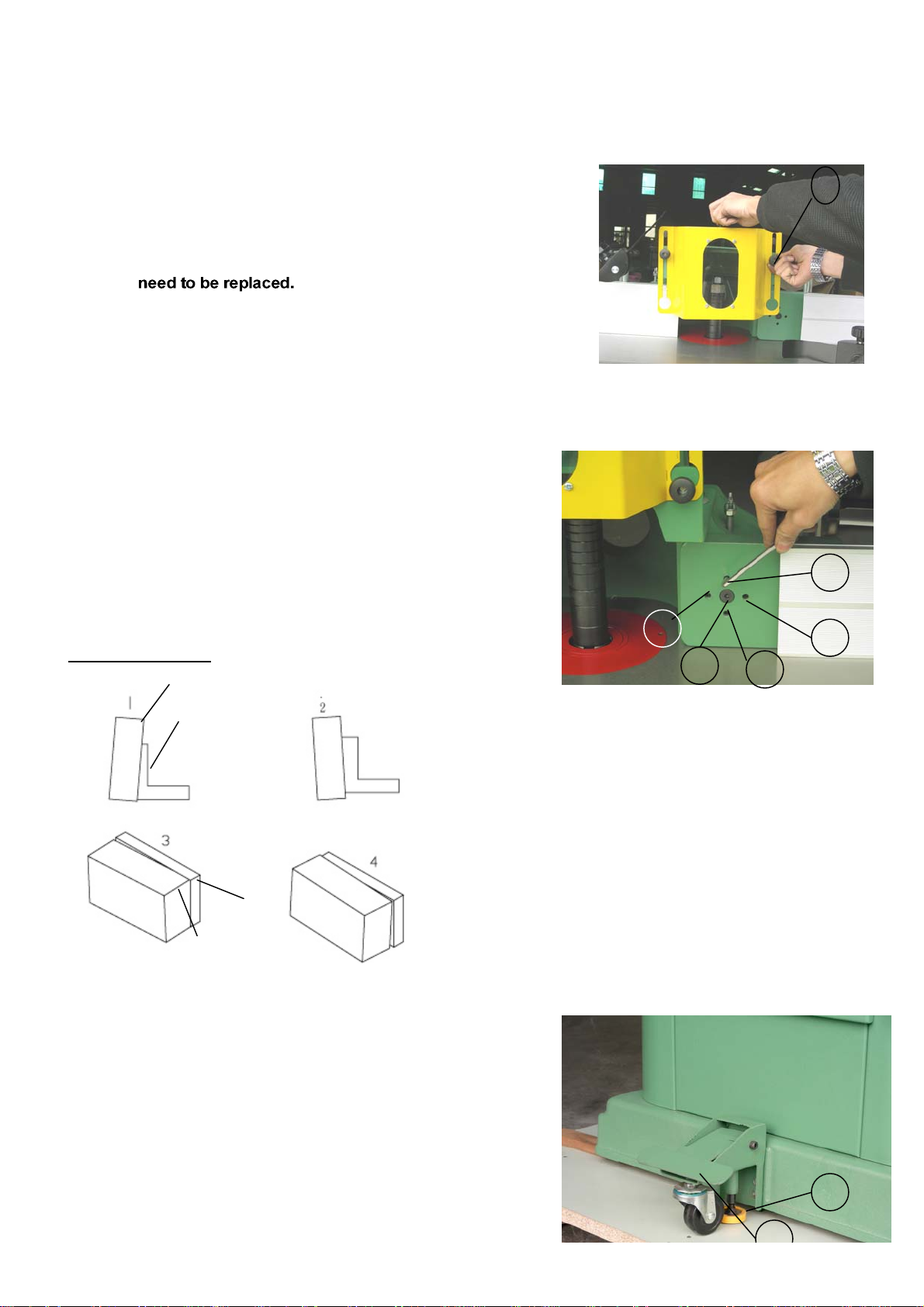

EDGE SHAPING: LONG BOARDS

The work piece must be at least 12 inches long when edge

shaping long boards.

1. To hold work piece down and against the fence use the

hold -downs and horizontal clamps. If the work piece is too

wide for the horizontal clamps(Fig. 21), clamp a scrap board to

the table to keep the work piece against the fence.

3. To make a smooth cut the work piece should be fed slowly

and steadily with firm, even pressure. Note: The rate feed depends

on depth of cut and experience of operator.