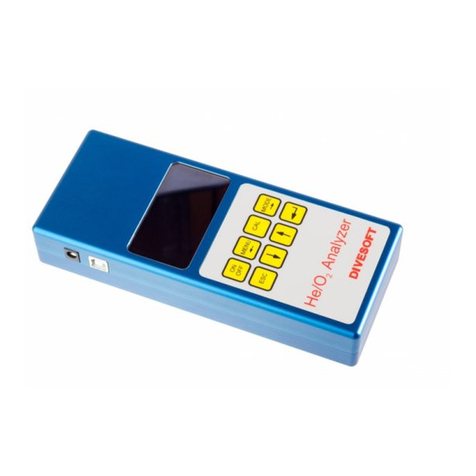

Divesoft He/O2 Analyzer User manual

He/O2Analyzer

User’s Manual

July 2012, EN

ON

OFF MENU

ESC

CAL MODE

He/O Analyzer

2

He/O2Analyzer | 3|

Content

Safety warning ....................................................... 5

1. About firmware and hardware versions .................................. 6

2. Measuring principle ............................................... 7

3. Description of the analyzer .......................................... 8

4. Operating the analyzer ............................................. 9

5. Measuring O2and He concentration .................................. 10

6. Display modes .................................................. 11

6.1 Calibration of the oxygen sensor ..................................... 13

7. Other functions ................................................. 14

7.1 Continuous analysis ................................................ 14

7.2 Gas mixing solver ................................................. 14

7.3 Gas mixing simulation ............................................. 16

7.4 Ambient pressure .................................................. 16

8. Special accessories ............................................... 17

8.1 Flow regulator .................................................... 17

8.2 Pressure measuring ................................................ 18

8.3 Measuring of pressure and tank temperature ........................... 18

8.4 Voltage measuring ................................................. 20

8.5 Resistance measuring .............................................. 21

8.6 Emergency disconnection of filling station ............................. 21

9. Set-up ........................................................ 23

9.1 Preferences ....................................................... 23

9.2 Measurement units ................................................ 23

9.3 Mixing of gases ................................................... 24

9.4 Continual analysis ................................................. 24

10. Charging and battery status ........................................ 25

11. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11.1 Battery replacement ................................................ 26

11.2 Oxygen sensor replacement ......................................... 26

| 4| He/O2Analyzer

11.3 Flow adjusting .................................................... 27

11.4 Disassembly of the instrument ....................................... 28

12. Connecting to a computer .......................................... 29

13. Defects and removal thereof ........................................ 30

13.1 Error messages .................................................... 30

13.2 Instrument malfunctions ........................................... 31

14. Technical data .................................................. 32

Appendix .......................................................... 33

He/O2Analyzer | 5|

Safety warning

Safety warning

This analyzer is designed for measuring the content of oxygen and helium in an air-oxygen-helium

gas mixture. It cannot be used to analyze mixes containing other gases, including, for instance,

mixes prepared using anything but pure gases or mixes in which air has been replaced with pure

nitrogen (without atmospheric argon).

The physical and chemical principles of the sensors used do not guarantee that the sensors

will be selectively sensitive to a specific gas (oxygen, helium); there are a number of gases to

which the sensors respond. Therefore, the gas composition shown by the analyzer does not mean

by itself that the real composition of the mix is equal to the displayed values. The displayed mix

composition is invalid unless the mixing technology ensures that there are no other gases present

in the mix except air, pure oxygen and pure helium.

The analyzer is not a certified measuring instrument. The results of measuring are only

informative and it is not possible to use such results where a certified measuring instrument is

required.

When analyzing mixes in situations where the incorrect composition of the mixes could cause

material damage, injury to health or threaten human health or life, for example in the case of

breathing mixes for diving, the results of the analysis may not be used as confirmation of the

correct mix composition. In these cases, the analyzer can only be used as an aid for increasing the

probability that such incorrect mix composition will be detected before its use. The correctness

of the mix composition must be established by the technology used to prepare it.

The correct preparation of breathing mixes for diving (nitrox – oxygen-enriched air, trimix –

a mixture of air, oxygen and helium, heliox – a mixture of oxygen and helium) requires special

knowledge and experience which is possible to gain, for example, through an appropriate course.

A failure to apply such knowledge can lead to an incorrect mix, even though the results of the

analysis are seemingly correct. Such a situation can also be the result of a failure to take into

account the influence of temperature and compressibility, an insufficient blending of the mix

and other factors.

Please remember that the analyzer can be broken or damaged and that the oxygen sensor is

by its nature subject to ageing and thus its properties deteriorate.

Therefore always verify the measured data in another way, such as by precise preparation

of the mix, another analytical method, etc. In addition, the measured value must be subject to

critical assessment using a common-sense approach and if it differs from the allowable variation

of mixing accuracy, it must be considered invalid.

| 6| He/O2Analyzer

About firmware and hardware versions

1. About firmware and hardware versions

The He/O

2

analyzer is equipped with a microprocessor whose program (firmware) is conti-

nuously updated. This manual is for firmware release 2.18., but the manual can be applied to

any hardware version. Manual is primarily written for hardware version 2.4. Older versions

of hardware analyzers are not equipped with certain elements and are therefore not able to

perform some functions described in the manual.

He/O2Analyzer | 7|

Measuring principle

2. Measuring principle

The described measuring principle is valid only for mixes of air, oxygen and helium.

An electrochemical sensor is used to determine the oxygen content. The voltage at the

sensor’s output is proportional to the oxygen content in the analyzed mix. The sensor has a li-

mited service life and the proportionality of the dependence of voltage on the oxygen content

changes over time; therefore, it has to be regularly calibrated. It is possible to choose between

single-point, two-point and three-point calibration. Single-point calibration is fast, especially

if air is chosen as the calibrating mix. For greater accuracy of the measurement, two-point

calibration is used with two different mixes, typically air and pure oxygen. For strongly hypoxic

mixes, i.e. mixes containing less than approximately 15% oxygen, three-point calibration is

recommended. In this case, the third calibration gas should be a gas with zero oxygen content,

i.e. pure helium or argon.

Helium content is determined on the basis of measuring the speed of sound in the analyzed

mix. The speed of sound depends on the content of helium and oxygen, and the temperature

of the mix. The dependence of the speed of sound on pressure is small and can be disregarded

under normal atmospheric pressure.

At 0º C the speed of sound is approximately 970 m/s in pure helium, 330 m/s in air and

315 m/s in pure oxygen. Raising the temperature by one degree increases the speed of sound

by 0.175 %. The speed of sound in the mix is described by a non-linear function of temperature,

oxygen content and helium content.

The content of helium is determined by measuring the speed of sound, temperature of the

mix and the content of oxygen. When measuring the concentration of helium, it is therefore

necessary to have the oxygen sensor correctly calibrated or to know the oxygen content and

enter it into the instrument.

The speed of sound is measured directly as the time it takes for an acoustic impulse to travel

between two microphones. This measurement is performed alternately in both directions to

make it possible to eliminate the influence of the gas flow-rate in the probe on the calculation.

The acoustic impulses are heard as weak “clicks” from the probe in the helium-measuring mode.

Gas is delivered to the analyzer from a sampler connected to the compressed-gas tank

and the gas flow is controlled using a nozzle to provide the volume needed for the analysis.

| 8| He/O2Analyzer

Description of the analyzer

3. Description of the analyzer

The analyzer is manufactured from high-strength aluminum alloy, which guarantees stable

dimensions and resistance against mechanical damage. The surface is hard-anodized to protect

it against scratching.

On the front side, the analyzer features a membrane keypad and an OLED display on

which the measured values are shown.

Measured gas is fed into the analyzed-mix inlet on the back of the analyzer and passes

through the helium-concentration sensor. From there, it enters the oxygen-sensor block and

is expelled into the air by the mix exhaust. The rated flow of the analyzed mix is 0.2 L/min

The analyzer is powered by a standard nine-volt battery (type 6F22) or by an external power

supply connected to the left side. The battery is accessible from the bottom by removing the

two screws of the retaining cover.

On the back of the analyzer, there is a connector for attaching auxiliary devices (for mea-

suring pressure, tank temperature, electrical voltage, etc.). A USB connector is located on the

side for transferring data to a computer and for updating firmware.

USB connector

Power-supply connector

Connector for attaching

auxiliary devices

Analyzed-gas inlet

Exhaust

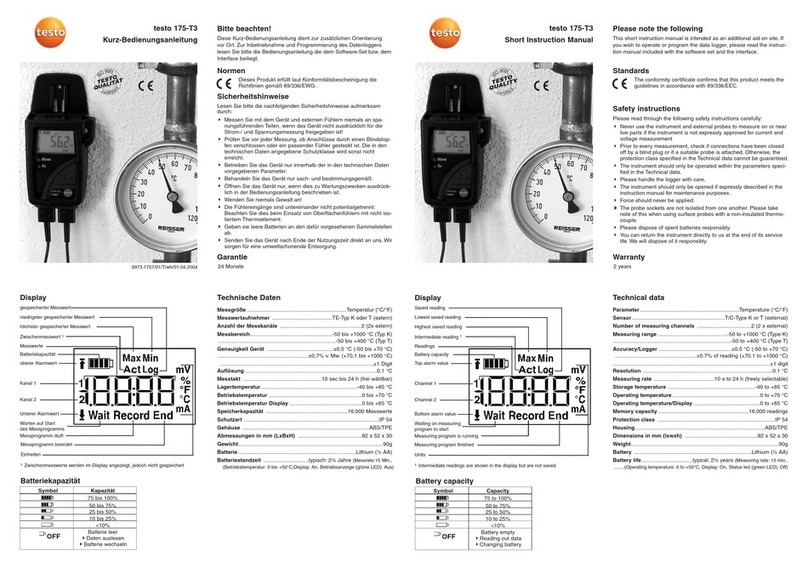

Display5x21

characters

Keypad

He/O2Analyzer | 9|

Operating the analyzer

4. Operating the analyzer

The analyzer is operated using the

keys on its front panel.

It is activated by pressing the

ON/OFF key for approximately

one second. Upon activation, an

automatic check of the instrument

is performed and the analyzer auto-

matically switches to the measuring

mode.

When this key is pressed, the

firmware version code and serial

number of the analyzer are displayed. If you need to read this information, just hold the key

down longer when activating the unit.

The analyzer is deactivated by pressing the ON/OFF key for about one second again.

The MENU key displays the available options. The menu changes in individual measuring

modes, depending on the functions relevant to the applicable mode.

The key is used to enter the selected menu item, confirm a changed value or perform

the prepared action. The selected menu item can also be called up by repeatedly pressing the

MENU key.

The ESC key is used to exit the menu or return from the value editing mode without

saving the changed value.

The and keys are used to browse the menu or change the value of a number above

the cursor.

The MODE key is used to change the display mode or to change the cursor position in

the number editing mode.

Other functions of the keys are described in the relevant chapters.

ON

OFF MENU

ESC

CAL MODE

| 10 | He/O2Analyzer

Measuring O2 and He concentration

5. Measuring O2and He concentration

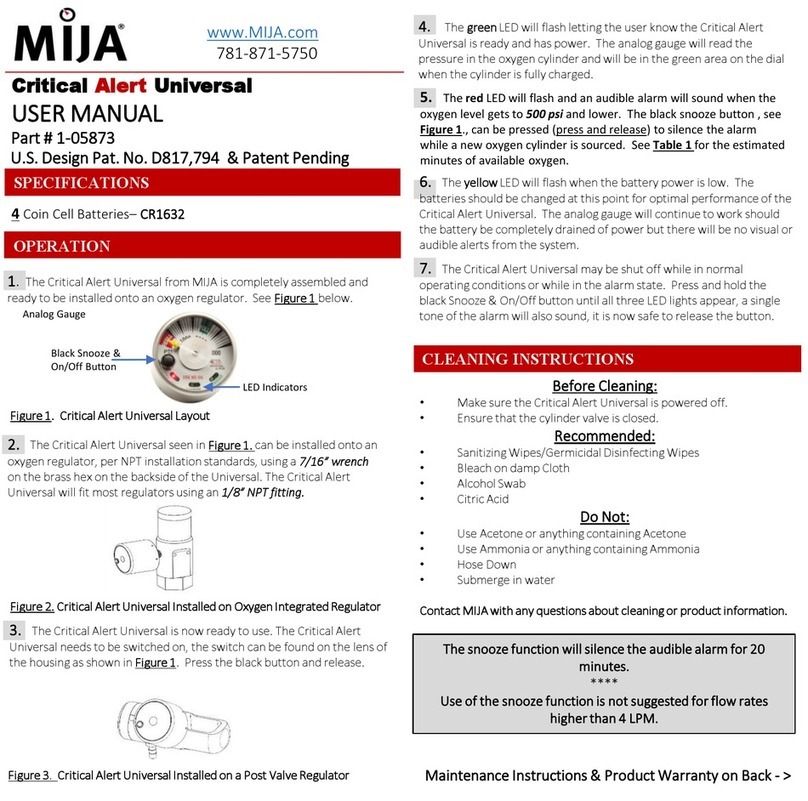

The flow limiter with nozzle is used in the basic configuration (see illustration).

Attach the sampler to the compressed gas bottle and use the hose to connect it to the

analyzer. The hose is slightly inserted into both components.

The analyzer switches into the helium and oxygen measuring mode upon activation, so

there is no need for you to set up anything. Open the valve on the bottle to let the gas flow in.

The gas composition is displayed after approximately 5–10 seconds. If the pressure inside the

bottle is distinctly lower than 200 bars, the gas flow through the sampler will be slower and

the measuring result will take somewhat longer to determine.

With the key, you can suspend and, by pressing it again, resume measuring. When

measuring is suspended, the last measured values remain displayed. During measuring, the

key can be used for temporarily increasing the brightness of the display to maximum (e.g.

if the display is exposed to sunlight).

When the measuring is completed, close the valve on the tank and by loosening the dis-

charge valve (generally ½ turn suffices) discharge the excess pressure of the gas so that the

flow limiter can be unscrewed from the tank valve.

Warning:

Do not unscrew the discharge-valve spindle completely; a steal ball is contained

inside which upon opening could be expelled and cause injury or be lost.

To the analyzer Plug

Connector to tank

valve DIN G 5/8

Limiting

nozzle

Discharge

valve

He/O2Analyzer | 11 |

Display modes

6. Display modes

Upon activation, the analyzer is normally in the O2/He measuring mode, in one of the two

display formats.

The basic format shows the oxygen and helium content in the mixture in percent in separate

lines and, for information, also the temperature at which the gas was measured.

After the measuring begins, the helium concentration may appear in square brackets for

several seconds in the basic format. This means that the result is interim, with lower accuracy.

When the brackets disappear, the accuracy of the result is final.

In case of a measuring error, for instance at a pneumatic shock in the inlet hose, the value

of the measured helium concentration disappears for the time of duration of the error state.

The well-arranged format shows the composition in a way used by divers to call the mixtures:

— Air: air with the oxygen content between 20.5 % and 21.5 %.

— EAN, for instance EAN 36, is air enriched with oxygen, in this case up to 36 % oxygen.

— TMX, for instance TMX 18/45, is trimix or the mixture of air, oxygen and helium, in this

particular case containing 18 % oxygen and 45 % helium.

— Heliox, for instance Heliox 16 % O2, is a mixture of oxygen and helium.

— Foul Air, for instance Foul Air (10 % O2), is foul or vitiated air with a reduced oxygen content.

It cannot be mixed with gases designed for preparation of breathing mixes commonly avail-

able to the diver (air, oxygen, helium); therefore, its presence indicates a problem. This may

include ongoing corrosion inside the bottle or contamination of the mix with argon, carbon

dioxide or another gas. Such air cannot be used for breathing under any circumstances.

In addition to the mix composition, this well-arranged format shows approximate values of the

maximum operating depth (MOD) and an equivalent narcotic depth (END).

MOD indicates the depth to which the diver can dive for a short time under otherwise ideal

conditions. The limit of partial oxygen pressure equal to 1.6 kPa is used in the calculation,

and seawater and the static pressure at sea level are taken into account. This reading is for

orientation only, and for an actual dive it must be calculated using the data of the specific dive.

The following formula is used for the calculation:

2

max

O 0

P

R P

MOD g

ρ

−

=

kde Pmax is the maximum allowable partial oxygen pressure, chosen as 160,000 Pa

P0is the static pressure at sea level, 101,325 Pa

RO2 relative molar concentration of oxygen in the interval 0 to 1

ρis the seawater density, 1028 kg m−3

gis the standard acceleration of gravity, 9.80665 m s−2

| 12 | He/O2Analyzer

Display modes

Warning:

The maximum operating depth (MOD) calculated for an actual dive is usually lower

than the depth indicated by the analyzer.

END is the depth at which the narcotic effect of the mix on the diver is identical to that of

air. It is specified in the percentage of a dive depth with air, i.e. for instance the END of 45 %

means that at a depth of 100 m with an analyzed mix, the diver will perceive the same narcotic

effects as if diving to 45 m with air. There are a number of various formulas for the calculation

of END, each giving different results. The value displayed by the analyzer uses only one of

them and is used for orientation purposes only. For an actual dive, it is necessary to calculate

the END using the data of the specific dive and the tested formulas of your preference.

The following formula is used for calculation:

END = 100 − 77 RHe

kde RHe is the relative molar concentration of helium in the ration 0 to 1

The formula is based on the following conditions:

— relative narcotic potential of nitrogen = 1

— relative narcotic potential of oxygen = 1

— relative narcotic potential of helium = 0.23

Warning:

The equivalent narcotic depth (END) indicated by the calculation is for orientation

purposes only and is different from the END values calculated using different

methodologies.

Warning:

To determine the END and MOD values, always use the procedures and formulas

that you learned in specialized courses of diving with mixes. The values indicated

by the analyzer are for orientation purposes only and are not sufficient for correct

dive planning.

He/O2Analyzer | 13 |

Display modes

6.1 Calibration of the oxygen sensor

The oxygen sensor’s properties change over time and it is therefore necessary to recalibrate it.

We recommend that such calibration be performed at least once a month. Analyzer with the

older version than 2.4, the calibration is always necessary when changing altitude. Version 2.4

has a built-in barometer sensor, which corrects itself. If you require the most precise results,

calibrate the sensor before each measuring.

Calibration of the sensor is performed as either single-point or two-point or three-point.

During single-point calibration, the content of oxygen in air, which is known and constant

(20.95 %), is measured by the sensor. The calibration constant of the sensor is set so that the

instrument displays 21.0 % (after rounding).

Two-point calibration proceeds in the same manner as single-point calibration, but uses two

calibration gases – pure oxygen and air. Two-point calibration is more arduous as it requires

the use of oxygen. However, it provides more precise results during measuring.

Thee-point calibration is recommended for measuring hypoxic mixes, containing less than

approximately 15 % oxygen. In this case, the third calibration gas should be a gas with zero

oxygen content, i.e. pure helium or argon.

Calibration of the oxygen sensor is started by pressing the CAL key at any time during

the measuring.

As the first step of calibration, we must choose between single-point, two-point or three-

-point calibration using the and keys and confirm the selection using the key.

It is then necessary to choose the oxygen content in the calibration mixture.

The oxygen content is adjusted by tenths of a percent by pressing the key (to increase

the content) or the key (to decrease the content). Use the MODE key to choose whether to

make adjustments by tenths, whole units, or units of ten percentage points. Upon setting the

desired values, confirm the data using the key.

For quickly setting typical values when setting the oxygen content it is possible to use the

CAL key, which sets the oxygen content at 21 % in the case of the first calibration point or

100 % at the second point and 0 % at the third point.

Upon setting and confirming the calibration of gases, calibration of the sensor begins. The

current calibration point, sensor voltage in millivolts and the temperature of the gas appear

on the display.

After the temperature and voltage have stabilized (however, at least after ten seconds), the

STABLE prompt appears, which means that it is possible to confirm the performed calibration

using the key. If the measured values change before the key is pressed, the STABLE

sign disappears and calibration proceeds until further steady values are attained. If multi-point

calibration is set up, then calibration according to the other gases proceeds similarly.

| 14 | He/O2Analyzer

Other functions

7. Other functions

7.1 Continuous analysis

The Menu/Continual Analysis option activates the function of continuous-filling monitoring.

This mode makes it possible to set up the upper and lower limit of oxygen and helium content.

The analyzer continuously measures the concentration of these components and if the preset

limits are exceeded, it makes a beeping sound. This mode is applied when the analyzer is used

as a safety component during continuous nitrox filling, where a defect of the mixing apparatus

could cause increased oxygen concentration potentially resulting in a fire or an explosion of

the compressor.

In the continual analysis mode can press the MENU button to set the limits of all mea-

sured values.

7.2 Gas mixing solver

When the Menu/Gas mix solver option is selected, the gas-mixing solver function is activated.

The solver computes the procedure for mixing the required gas mix of up to three gases. It

can even include the remaining mix in the bottle to be filled in the calculation. The gases are

displayed in the following order: the remaining gas in the bottle, added mix 1–3, the required

mix. For each mix, the composition, volume of the bottle (the actual, „water“ volume of the

bottle is specified) and gas pressure in the bottle are specified. If the volume of the gas is

unlimited (for instance, if supplied by a compressor at a constant pressure), enter the bottle

volume as zero. The mix composition may be entered either manually (after pressing the CAL,

or the analyzer can be switched to the measuring mode by pressing the key and the relevant

mix can be measured directly. After pressing the CAL is necessary to change the values press

. Then you can enter values . Press MENU to move the cursor in the order. Confirm

the selected value . After the data are entered, initiate the calculation by choice MENU/

SOLVE (because it is a first menu item, just double press MENU). The calculation may take

up to one minute. Upon completion, results are displayed in one of the three possible forms,

which can be switched between using the MODE key (see the example).

He/O2Analyzer | 15 |

Other functions

Example

There is remaining air with the pressure of 120 bars in the twin bottles with the volume of

2 x 12 liters (total volume of 24 liters). The required mix is trimix 18/40 with the required pres-

sure of 200 bars. You have fifty-liter distribution bottles containing oxygen and helium and

a compressor with the output of 330 bars. Enter:

A: Air 24L 120

1: He 50L 200

2: O2 50L 200

3: Air 300

D: 18.0/40.0 24L 200

and run the calculation. When the calculation is completed, the following data are displayed:

Disch. to 79.5 bar

He to 159.5 bar

O2 to 173.2 bar

Air to 200.0 bar

meaning that the twin should be discharged to the pressure of 79.5 bars, then He added until

the pressure of 159.5 bars is achieved, then oxygen added to 173.2 bars and, finally, air added

to reach 200 bars. When the MODE key is pressed, the same result is displayed; however, it

is expressed in pressure to add or to discharge:

Disch. -40.5 bar

Add 80.0 bar He

Add 13.7 bar O2

Add 26.8 bar Air

or decrease the pressure by 40.5 bars, increase the pressure by 80 bars by adding helium,

add 13.7 bars of oxygen and 26.8 bars of air. The last mode is similar, but as it is designed

for gravimetric filling (using a chemical balance), the amount of gas is specified in kilograms:

Disch. -1.2382 kg

Add 0.3392 kg He

Add 0.4669 kg O2

Add 0.8230 kg Air

Please note that the solver takes into account the pressure drop in the gas charging bottles;

therefore it does not try to recommend adding oxygen to reach 200 bars (which would be im-

possible anyway, given the limited oxygen supply); rather, it allows air to be partly discharged

and oxygen is only added to reach the realistic 173.2 bars, with the rest of the air to be added

by the compressor. At the same time, however, the solver saves the mix already contained in

| 16 | He/O2Analyzer

Other functions

the bottle to the maximum possible extent; therefore, it does not let it discharge completely.

Instead, only the necessary part of the mix is discharged.

7.3 Gas mixing simulation

Option Menu/Gas mix simulator is for Gas mix simulator function. Simulator will compute

mixture content mixed up to from four gases. At every mixture is displayed composition and

quantity of added gas in pressure units. You can enter mix composition manually (by pressing

CAL) or switch to measurement mode by pressing and directly measure concrete mixture.

Calculation of final mixture proceed continuously and mixture constitution is displayed on

last row. Input values is the same as in the previous case.

7.4 Ambient pressure

Analyzer is equipped with a barometric pressure sensor. Thanks to this device can be calibra-

ted for the atmospheric conditions and altitude. The atmospheric pressure and altitude can be

displayed in the menu ambient pressure. Altitude is calculated from the ambient pressure and,

depending on atmospheric conditions may differ from reality.

He/O2Analyzer | 17 |

Special accessories

8. Special accessories

8.1 Flow regulator

For taking a gas sample for analysis, it is possible to use the flow regulator. It is used in a similar

manner as the limiter. However, thanks to the use of a reduction valve, there is no decrease

in flow and the measuring period is thus extended even with lower pressure in the tank. Its

use is therefore suitable in filling stations and dive centers in which the content of half-empty

tanks is checked.

The regulator is constructed from the Divesoft M12 modular system. The illustration

shows only one of the possible configurations. Because the leads of the distribution block are

equivalent, it is possible to freely reconfigure individual elements according to the user’s ne-

eds. Similarly, it is possible to replace the limiting nozzle with a reduction valve without the

necessity of buying a full regulator assembly.

The regulator is connected similarly as the limiter. Besides the tank valve, it is possible to

close off the gas output directly with the gas-output cut-off

Warning:

Over-tightening of the gas-output cut-off can damage or prematurely wear out the

reduction-valve seat.

To the analyzer

Plug

Connector to tank

valve DIN G 5/8

Regulator

Discharge

valve

Cut-off valve

| 18 | He/O2Analyzer

Special accessories

8.2 Pressure measuring

A pressure sensor can be connected to the analyzer. The pressure sensor is generally attached

to the connector with the regulator described in the preceding chapter (instead of the plug),

so that it is possible to cut off the gas output and measure only the pressure. Of course, it is

possible to simultaneously measure the pressure and the gas composition.

The attachment equipped with a pressure sensor (and other elements) is shown in the

illustration in the following chapter.

After plugged in pressure sensor in basic format display shows measured pressure in the

range 0―400 bars, například

Oxygen: 20.1 %

Helium: 30.5 %

Temperature: 25.5 °C

Pressure: 202.6 bar

As in the basic mode, Temperature data shows the temperature of the gas inside the analyzer.

With the MODE key it is possible to format the display in which are shown the absolute

and relative pressure, e.g.:

Pressure: 202.6 bar

Relative: 52.6 bar

In this format, the CAL key can be used to nullify the relative pressure and thus measure, for

example, the increase of pressure in the tank. In the stated example, the pressure was nullified

when reaching absolute pressure of 150.0 bars and from that time a pressure increase of 52.6 bars

occurred. This option is useful when blending mixes using the partial pressures method.

Connection of the pressure sensor is involved in some of the analyzer’s other functions.

In gas-mixing calculation, the display shows the immediate pressure, which makes it possible

to directly fill the tank according to the displayed procedure. In the continual analysis mode,

the measured pressure is used as an additional quantity for sounding of the alarm. When

measuring the gas composition in the calculation and simulation of gas mixing, the gas pressure

is automatically taken over. The pressure sensor can be connected to the analyzer

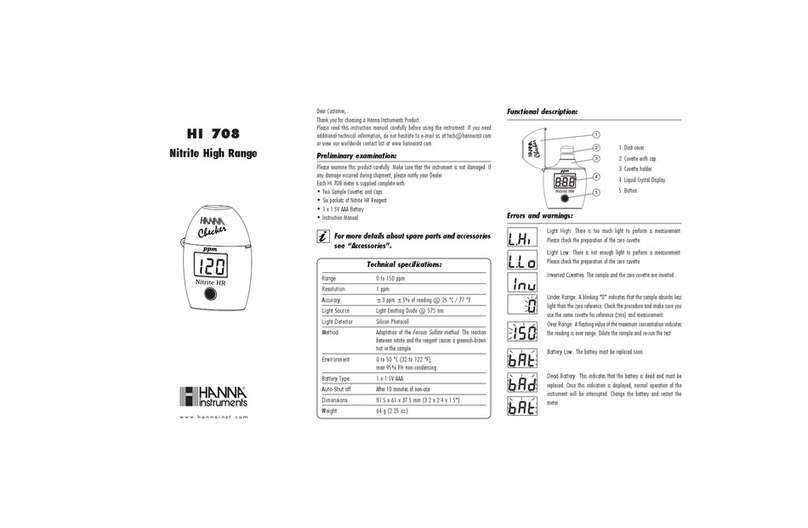

8.3 Measuring of pressure and tank temperature

When filling a pressure tank with gas, the temperature of the gas (and thus the tank) increases

by up to ten degrees Celsius. According to Gay-Lussac’s law, less gas will thus go into a warm

tank than into a cold one at the same pressure.

A direct consequence of this phenomenon is the fact known from experience that the

pressure in a freshly filled tank gradually decreases. Depending on the ambient temperature,

this decrease persists for up to several hours, which complicates the preparation of a gas mix

He/O2Analyzer | 19 |

Special accessories

using the partial pressures method and its precision depends on the blender’s experience and

estimation.

If we know the current gas pressure, tank temperature, gas composition and ambient

temperature, we can predict the extent of this decrease on the base of a calculation according

to the state equation.

The analyzer can perform this calculation automatically if the temperature sensor is

attached to the pressure sensor. The complete assembly for simultaneous measuring of the

gas composition and pressure including the tank temperature is shown in the illustration. The

temperature sensor is attached to the tank with a flexible Velcro strap.

After connecting the temperature sensor, the measured pressure is shown in the basic

display format.

In the scale of 0–400 bars, similarly as in the case of separate pressure measuring but

supplemented with other data which show the anticipated pressure after the tank cools, for

example bars, similarly as in the case of separate pressure measuring but supplemented with

other data which show the anticipated pressure after the tank cools, for example

Oxygen: 20.1 %

Helium: 30.5 %

Temperature: 25.5 °C

0 202.6 bar @ 32.1 °C

\ 190.0 bar @ 25.5 °C

The fourth line shows the actual pressure and temperature of the tank; the fifth line shows

the pressure after cooling to the stated temperature. The state equation is used for calculating

the measured gas composition.

The temperature of the tank after cooling can be selected in Menu/Preferences/Ref.temp.

source. When selecting the Ambient variant, the current ambient temperature (or, more preci-

sely, the temperature of the analyzer’s aluminum body) is used; with the Defined variant, the

temperature set in the following menu item (Ref. temperature) is used.

With the MODE key, it is possible to select the third display format which shows the

absolute and relative pressure, both as current and anticipated after cooling, for exampled

bar Actual @ 25.5 °C

Abs: 202.6 190.0

Rel: 52.6 49.3

Tank temp.: 32.1 °C

The measured tank temperature is used also in some of the He/O2analyzer’s other modes (display

of the results of the gas-blending calculation, emergency disconnection of the filling station).

| 20 | He/O2Analyzer

Special accessories

8.4 Voltage measuring

Optional measuring cables can be attached to the analyzer to measure electric voltage. After

the “V” connector is plugged in, the analyzer automatically switches to the mode of a simple

low-voltage voltmeter. The voltmeter is designed to be used as a tool when repairing diving

equipment in the field (diving lamp, storage or plain battery check, etc.) The maximum allowed

DC voltage is 40V (any polarity) or 28V AC with sinusoidal wave. The effective value (RMS)

is measured for AC voltage.

Warning:

The voltmeter must not in any case be connected to the power distribution network

or to any equipment connected to mains!

Tank

temperature

sensor

Tank

pressure

sensor

Discharge valve

Connector

DIN G 5/8 Flow regulator

Cut-off valve

Table of contents

Other Divesoft Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Rice Lake

Rice Lake MSI9000 Operator's manual

Merkur

Merkur DTS353 user manual

Siemens

Siemens 7ME4613 Installatio and user's operating instructions

BAFANG

BAFANG DP C260.CAN user manual

WATANABE ELECTRIC INDUSTRY

WATANABE ELECTRIC INDUSTRY A7X18-X Operation manual

Extech Instruments

Extech Instruments EasyView EA33 user manual