7

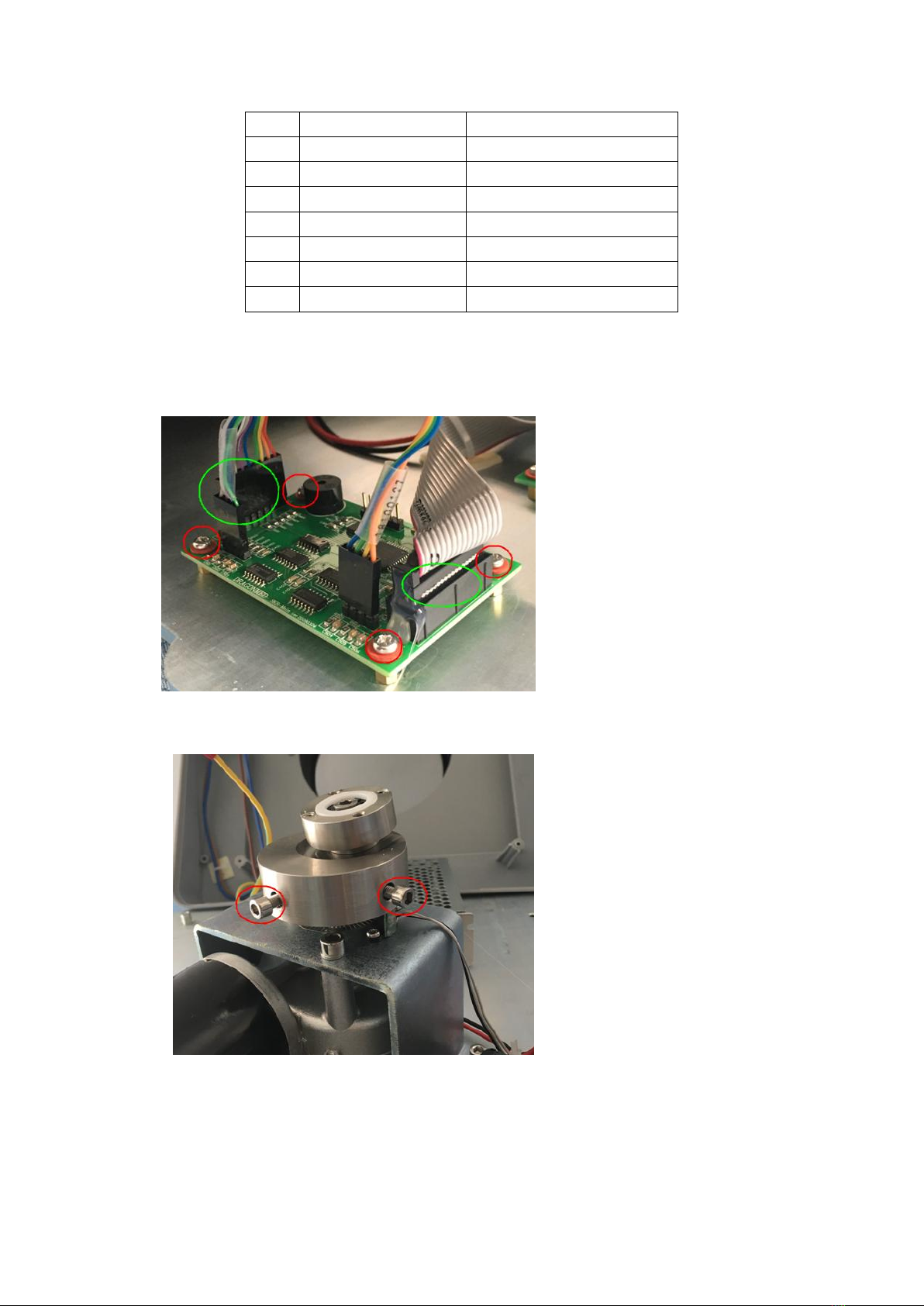

2.6 Replacement of motor drive board

As shown in the left figure, unplug

connectors marked by green circle,

loosen the 2 screws marked by blue

circle and unplug 2 cables, remove 4

screws marked by red circle, then

replace motor drive board, then

assemble it in sequence.

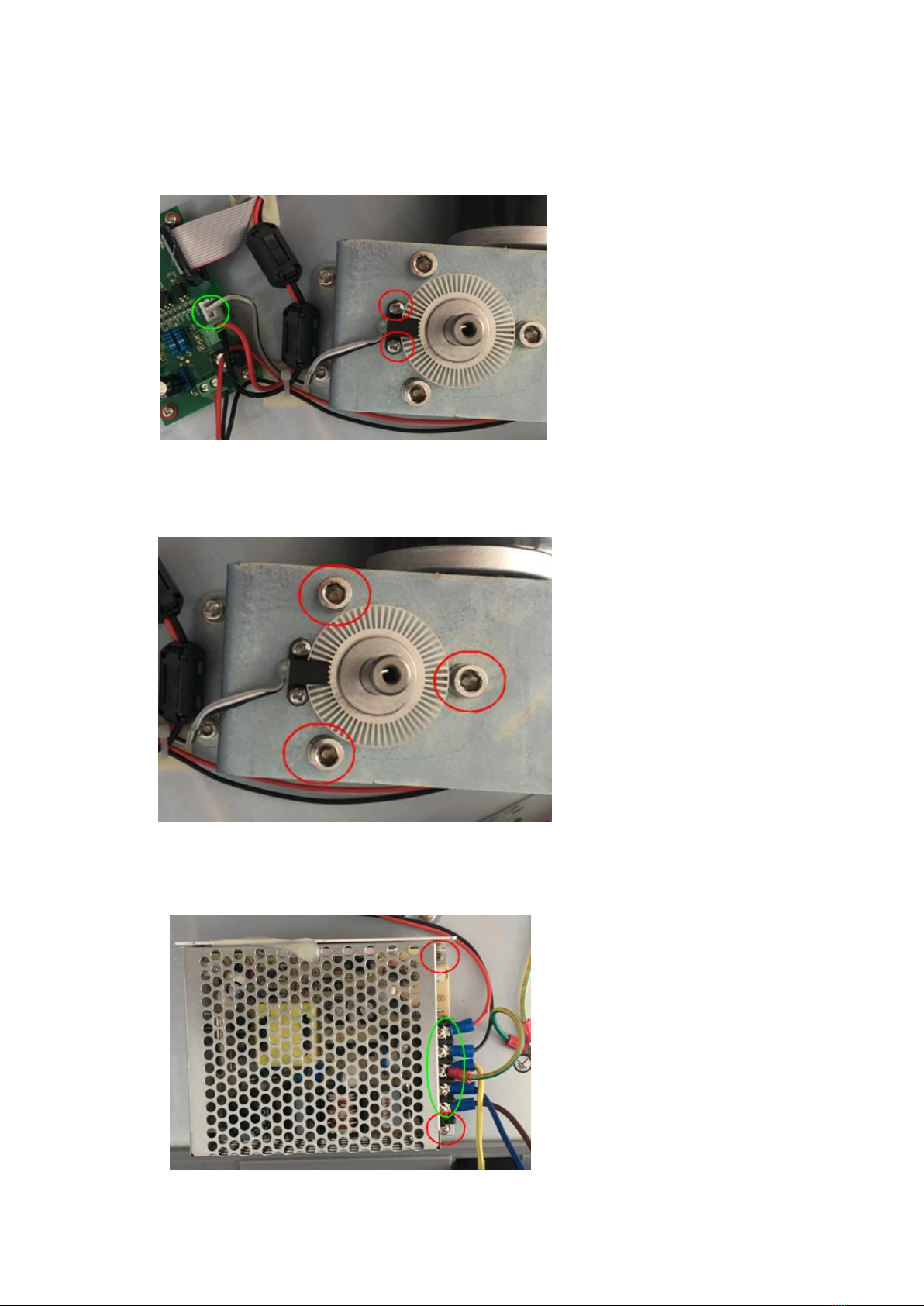

Chapter 3: Trouble shooting

FAULT

CODE

PROBLEM CAUSE SOLUTION

E01

Instruments can’t be power

on

The power line is

unplugged

Check whether the power line is

unplugged, an power on it again

The power switch put off Put on the power switch

The fuse is broken Replace the fuse

Power board is failure Replace power board

Main board is failure Replace mainbaord

The display screen is

broken

Replace display screen

E02 Instrument doesn’t

movement

No setting target speed Set a target speed, the speed

indicator is on.

The drive board is failure

Replace the drive board, please

reference chapter 2.5

power board is failure Replace power board

component

Motor is failure Replace motor

E03 LCD display garbled

characters

Display board is failure Replace display board

E04

Instrument speed is not

accurate

Photo electronic switch is

failure

Replace photo electronic switch

The position of photo

electronic switch goes

failure

Adjust the position of photo

electronic switch