5. Operation

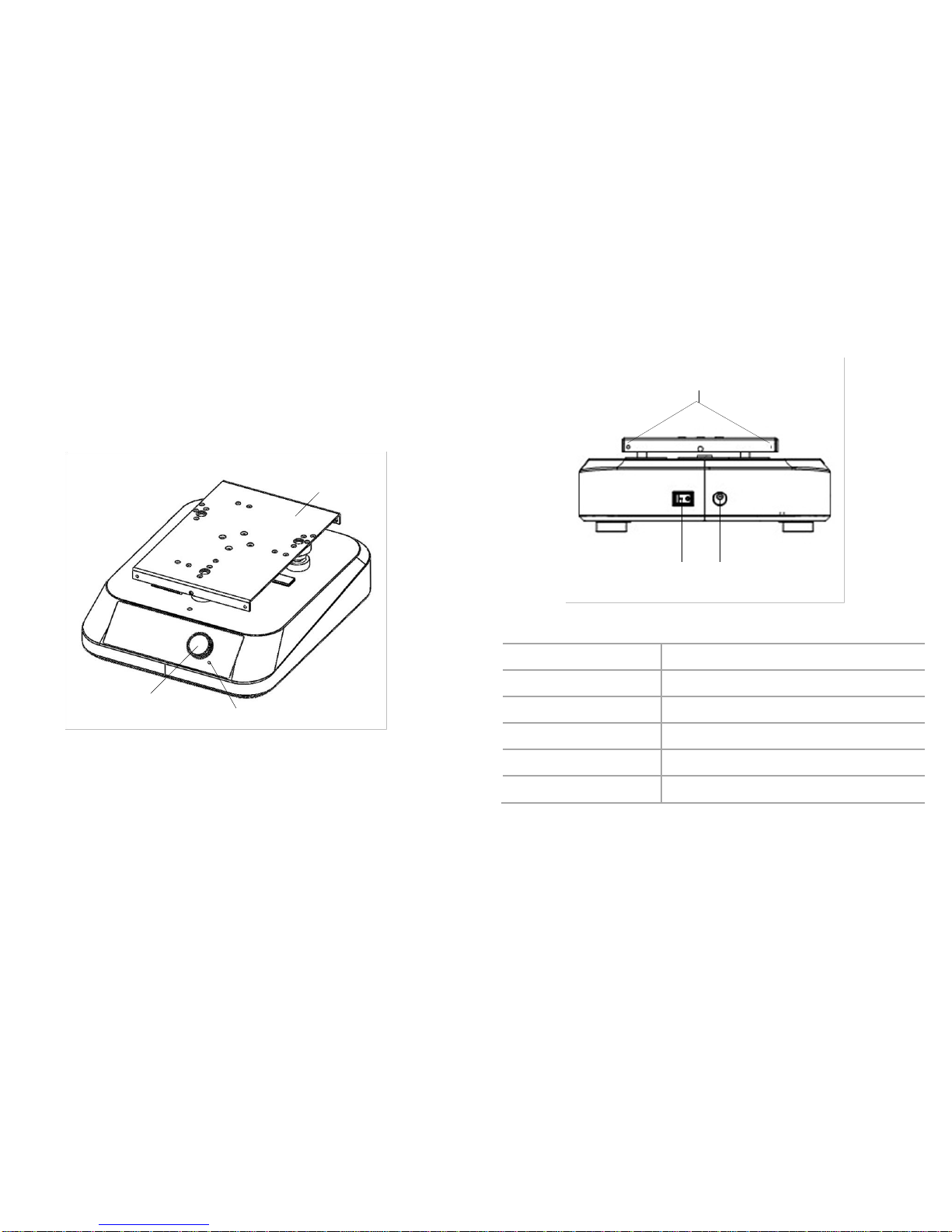

5.1 Analog Model

•Place the instrument in safe and stable surface, ensure

the required operating voltage and power supply

voltage matched.

•Connect the power cable.

•Install the platform.

•Switch ON the instrument.

•Rotate the speed control knob clockwise to set target

speed, and the shaking function will be switched on.

•Rotate the speed control knob to the left-most position

to switch off the shaking function.

•Switch OFF the instrument.

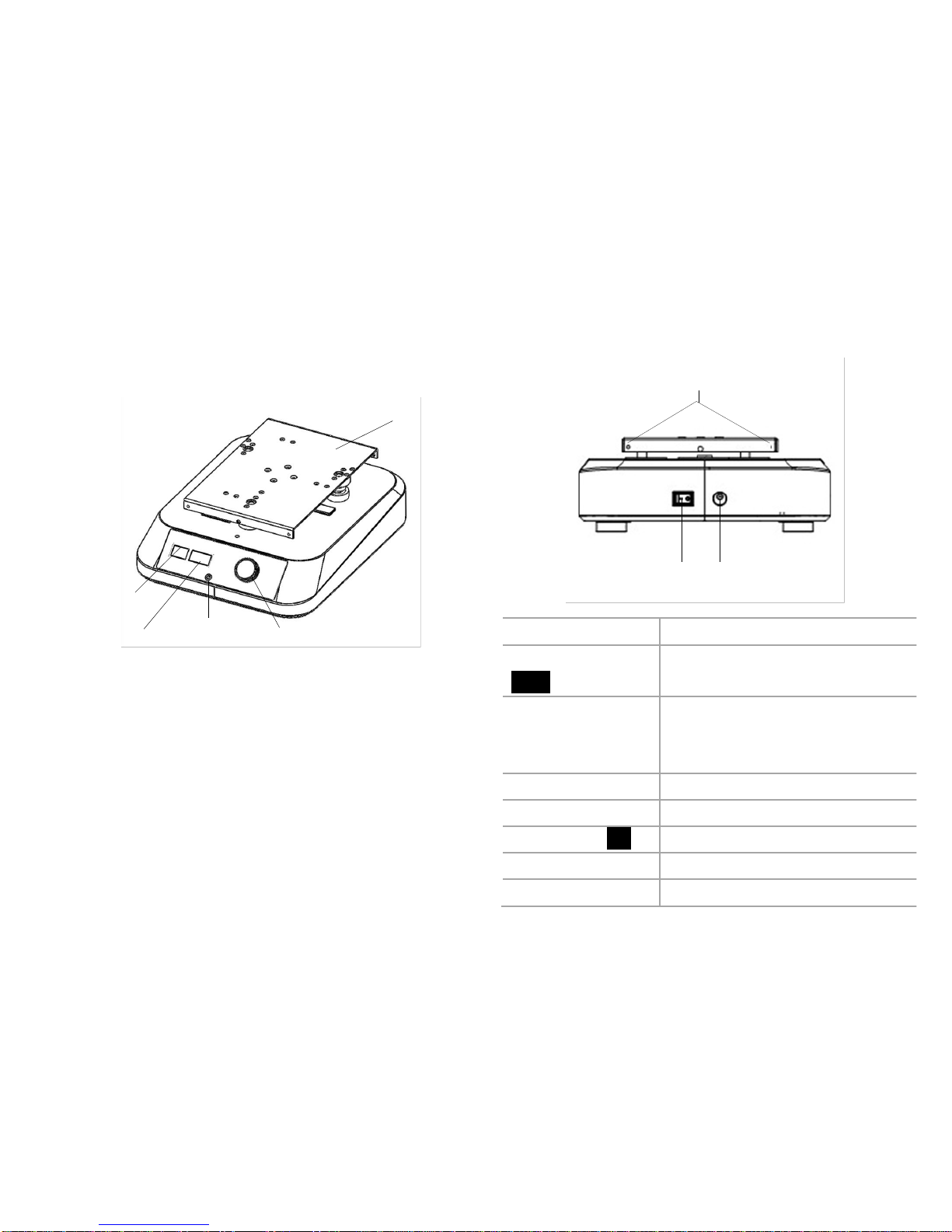

5.2 LED Digital Model

•Place the instrument in safe and stable surface, ensure

the required operating voltage and power supply

voltage matched.

•Connect the power cable.

•Install the platform.

•Switch ON the instrument.

•The instrument begins self-checking.

•When initialization is over, LED displays the last

running values of speed and timer.

•Rotate the speed/timer control knob to set target speed.

a. Press the mode switch button to choose the speed

or timer setup interface. When the character of LED

display is flashing, rotate the parameter adjusting knob

to set the target parameter. Press the knob to start the

motion.

b. During operation, motion can be stopped at any

time by pressing the parameter adjusting knob. If the

knob is pressed again, motion will start again and the

timer will continue to countdown. When the timer

reaches zero, the unit will be automatically halted.

c. When the timer is set to be 00:00, start the

continuous motion.

•Switch OFF the instrument.

If these operations above are normal, the instrument is

ready to operate. If not, the instrument may be damaged

during transportation, please contact technical support of

manufacturer/supplier.