- 9 -

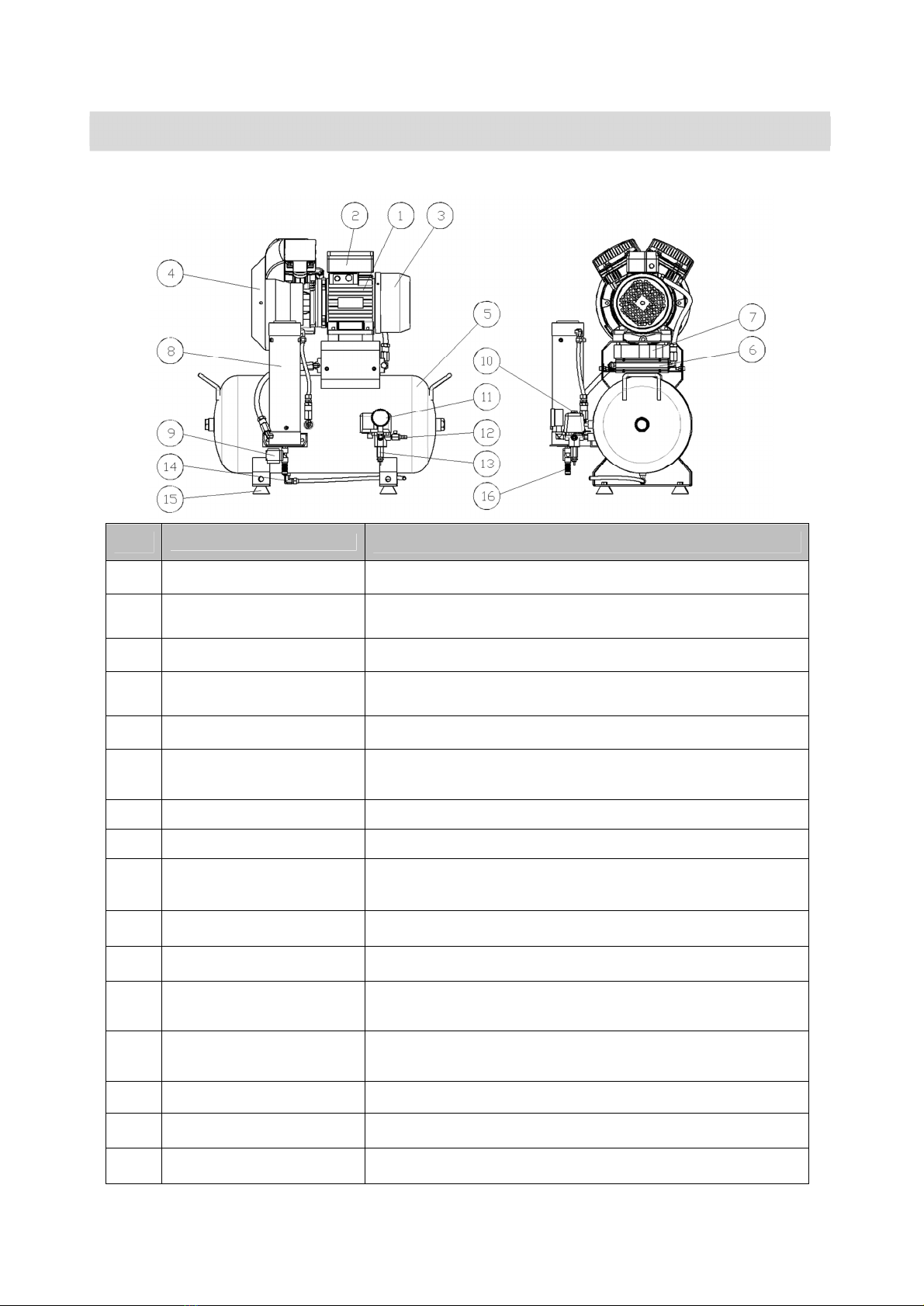

3.1 Preparation for operation

(1) Check user voltage and hertz before operating equipment.

(2) Check if there is any foreign material in the cooling fan part of the motor.

(3) Connect the air supply hose to the air supply valve.

(Make sure that the pressure gauge is in position "0" because power is not applied.)

(4) Connect the hose to the drain valve and place it in the sewer.

(5) Plug the power cord into a wall outlet that meets your requirements.

(6) Plug the power cord into a suitable outlet and turn the red pressure switch to the

right to activate the equipment.

3.2 Test run of machine

(1) Turn the operation handle of pressure controlled switch to “AUTO” and the machine

will start immediately.

(2) The reading of barometer will slowly rise with increasing pressure inside the air tank.

When the reading of barometer reaches 8 bar, pressure controlled switch activates,

the power supper is cut off, machine stops running.

(3) At the same time the load-releasing valve of pressure controlled switch activates to

lower high pressure in the cylinder of compression machine so that the machine

can be started again; during the period when the machine stops running observe if

the reading of barometer is decreasing. If there is no leakage of air in the machine,

open air supply valve to begin supply of compressed air. When the pressure in the

air tank decreases to 5bar, pressure controlled switch resets and power supply

resumes, the machine starts running again.

(4) The pressure in air tank increases again. If the machine can automatically stop and

start the machine works normally.

(5) Check for abnormal noise or vibration in the compressor system. In this case, see

the troubleshooting guide in this manual. After removing the cause of the noise and

vibration, restart the system.

3.3 Operation

(1) To operate the machine correctly and safely read carefully this instruction.

(2) Insert the plug of the machine in power socket of single phase 10A.

Open air supply valve, turn the operation handle for pressure controlled switch to

“AUTO” position, the machine will run in a normal condition.