DIVERSIFIED METAL FABRICATORS, INC. RW-1016

1-2 © 2017 DMF, Inc. All Rights Reserved.

1.1 GENERAL DESCRIPTION, WEIGHTS & CAPACITIES

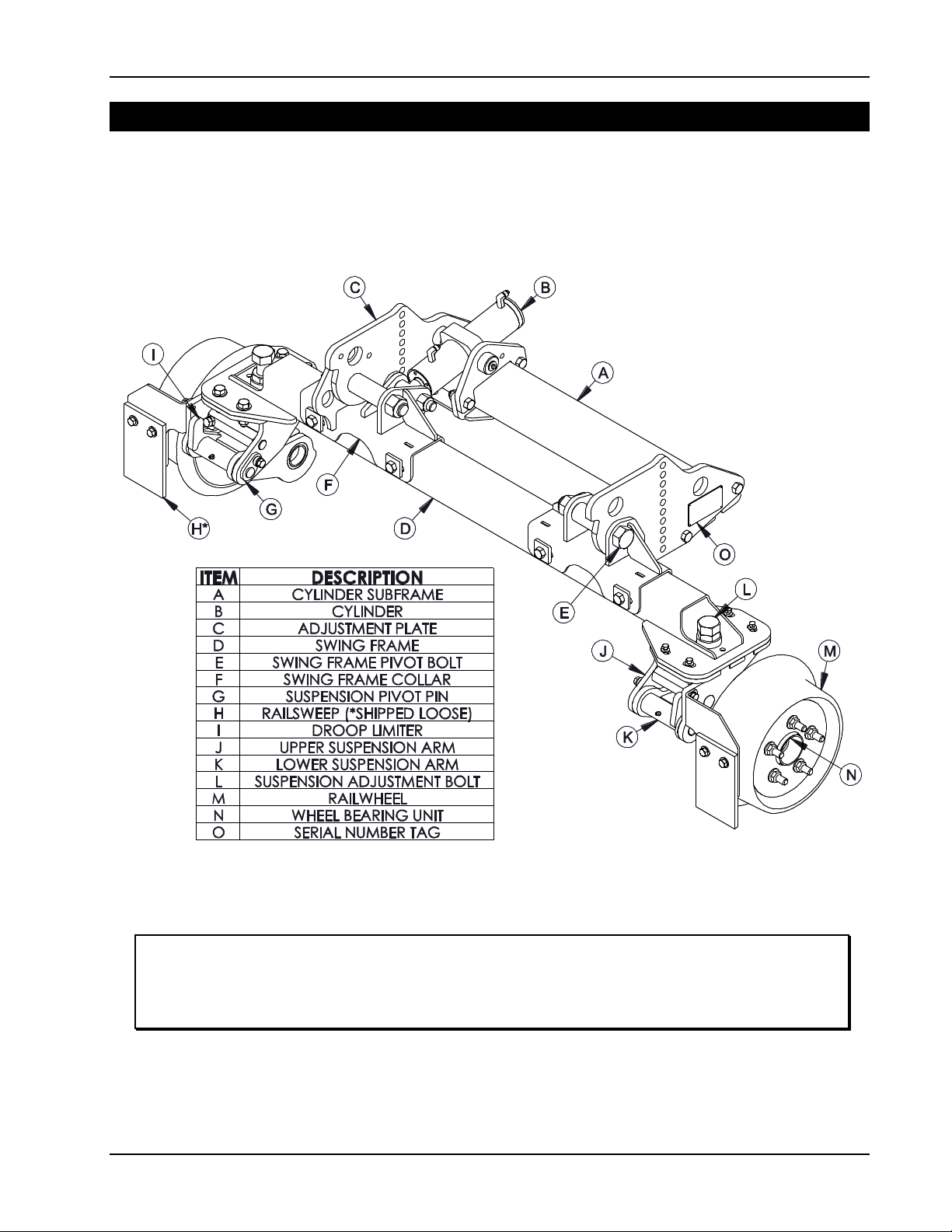

1.1.1 Features and Description

DMF’s RW-1016 Railgear is designed for Class 2 & 3 single rear wheel heavy duty pickup trucks.

The front and rear Railgear assemblies are visually similar and share many common

components. Railgear assemblies attach to the truck frame with bracketry specific to the

vehicle make and model. All structural members and brackets are constructed of carbon steel.

Select components are hot dip galvanized or zinc plated for additional corrosion resistance.

Each Railgear assembly is actuated is by a single hydraulic cylinder. In the rail position, the

Railgear is “over-center”, which prevents a hydraulic failure from allowing the gear to collapse.

In the highway position, hydraulic locking valves prevent the Railgear from falling due to a

system leak. An emergency hand pump allows the gear to be lifted into the highway position in

the event of hydraulic system failure while on rail.

RW-1016 Railgear features an independent suspension system at each railwheel. Rubber

springs provide a smooth and quiet ride over uneven rail surfaces. The load on each railwheel

can be adjusted individually. The 10” guide wheels are machined from cast steel, and mounted

to automotive-style unitized hub bearings that maximize service life and minimize maintenance

Unlike most of our larger models, RW-1016 does not lift the steer axle off the rail. All vehicle

tires remain in contact with the rail. RW-1016 does not provide braking or drive power, and

relies on the vehicle tires for those functions.

Most vehicles require installation of alternate wheels and tires to properly align the vehicle’s

track width to the rails. DMF offers Wheel Modification Kits for many popular chassis models for

use on standard gage rail. These kits include the necessary rims, wheel adapters, TPMS

sensors, steering stops, and steering wheel locks.

RW-1016 was engineered to meet a wide range of customer requirements in its standard

configuration. DMF also offers many options for RW-1016 to meet your specialized needs.

Contact DMF for additional information on standard and optional features.

RW-1016 Standard Features

56.5” rail gauge

Steel tread railwheels

Wireless Railgear controls

4-corner rail wheel insulation

Hydraulic locking valves, highway & rail position (front & rear)

Low-profile 12VDC hydraulic power unit and emergency hand pump

Front and rear rail sweeps and de-rail skids

RW-1016 Optional Features

Truck wheel and tire modification kits

In-cab switchable rail shunting

Heavy duty cable pinoff system (front & rear)

Rubber tread railwheels

Additional wireless handheld transmitter for backup/emergency use

Hardwired Railgear controls @ bumpers and/or in cab

Railgear position sensing for GPS/Telematics integration

Custom rail gauges & wheel profiles