5

discretion of DNTLworks. The responsibility of DNTLworks does not include repair and replacement cost

resulting from misuse, abuse, improper maintenance, or normal wear and tear.

DNTLworks will pay for labor costs for warranty service for a period of 90 days from the date of

purchase. DNTLworks sole obligation under said warranty is to repair, or, at its option, replace the

defective part. The buyer will have no options.

Warranties for products not manufactured by DNTLworks, but sold in combination with DNTLworks

products, will be honored by DNTLworks for the entire duration of the original manufacturer’s warranty

period.

The warranty will be voided by alterations, tampering with, improper installation or maintenance,

accident or modification of the equipment, with the exception of work performed by DNTLworks or one

of its authorized service agents. This warranty expressly excludes all damage to the products resulting

from careless or neglectful transportation. DNTLworks will in no event be responsible for any work done

without first obtaining DNTLworks’ written consent.

This warranty is made expressly in lieu of all other warranties, expressed or implied, including any

implied warranties of merchantability or fitness for a particular purpose. No employee, agent, franchise,

dealer or other person is authorized to give any warranties of any nature on behalf of DNTLworks.

Except as provided herein, DNTLworks will have no liability or responsibility to the customer or any

other person or entity with respect to any liability, loss or damage caused or alleged to be caused

directly or indirectly by equipment sold, leased, or furnished by DNTLworks, including, but not limited

to, any interruption of services, loss of business or anticipatory profits or consequential damage arising

out of or connected with the sale, lease, use, or anticipated use of equipment. Notwithstanding the

above limitations and warranties, DNTLworks liability hereunder for damages incurred by customer or

other will not exceed the amount paid by customer for the particular equipment involved.

Returns

Purchased goods may not be returned without the express written consent of DNTLworks and a Return

Goods Authorization Number (RGA#). All items must be returned within 14 days of initial delivery and

are subject to a 15% restocking charge. Special order items cannot be returned for credit consideration.

Freight charges on approved return items shall be borne by the customer.

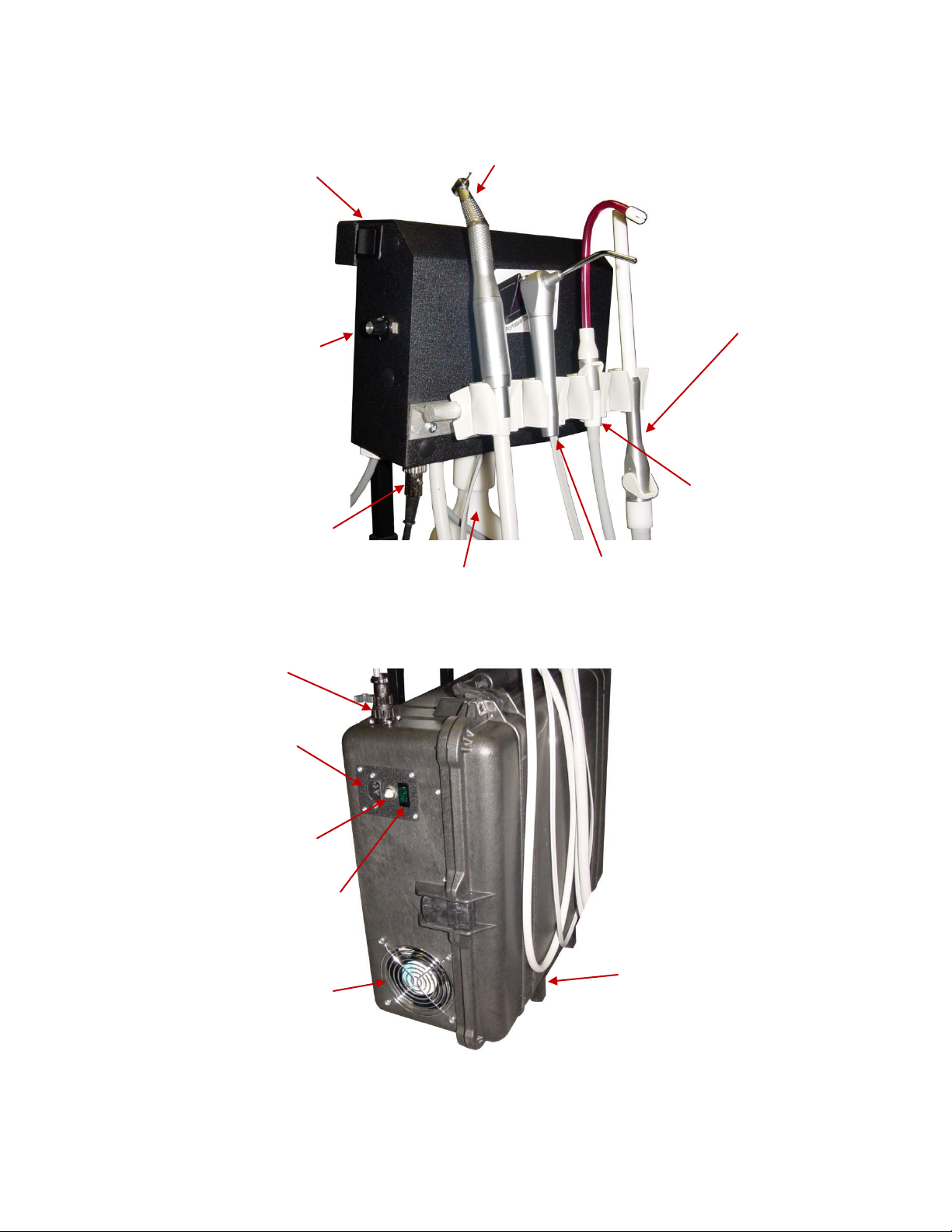

Description of Unit

The ProSeal IITM is a lightweight, powerful sealant, prophy, and vacuum unit which allows the operator

to irrigate and dry prepared surfaces, perform prophy treatments, and quickly aspirate liquid dental

waste. This unit includes a non-water-capable lowspeed handpiece.

While visually similar to the ProSeal IITM, the ProQuest I or IITM is equipped with a highspeed electric

handpiece with water adjustment, enabling the operator to perform most dental procedures. The

ProQuest IITM features fiber-optic capability. ProSeal IITM or ProQuest I or IITM units may be upgraded

with a piezo-electric scaler.