Dolmar MS-220 User manual

Other Dolmar Trimmer manuals

Dolmar

Dolmar EH6000S User manual

Dolmar

Dolmar HT-2249 D User manual

Dolmar

Dolmar AT-1832 C User manual

Dolmar

Dolmar HT-550 Instruction Manual

Dolmar

Dolmar AT-1831 U User manual

Dolmar

Dolmar AT-3623 AT-3630 User manual

Dolmar

Dolmar HT-5510 Instruction Manual

Dolmar

Dolmar MS-27 U User guide

Dolmar

Dolmar HT-6510 Instruction Manual

Dolmar

Dolmar AE-3649 User manual

Dolmar

Dolmar AH3766XE3 User manual

Dolmar

Dolmar ET-70 C User manual

Dolmar

Dolmar MS-22C User manual

Dolmar

Dolmar HEDGE HT-345 Instruction Manual

Dolmar

Dolmar AT-1831 C User manual

Dolmar

Dolmar AH-1853H User manual

Dolmar

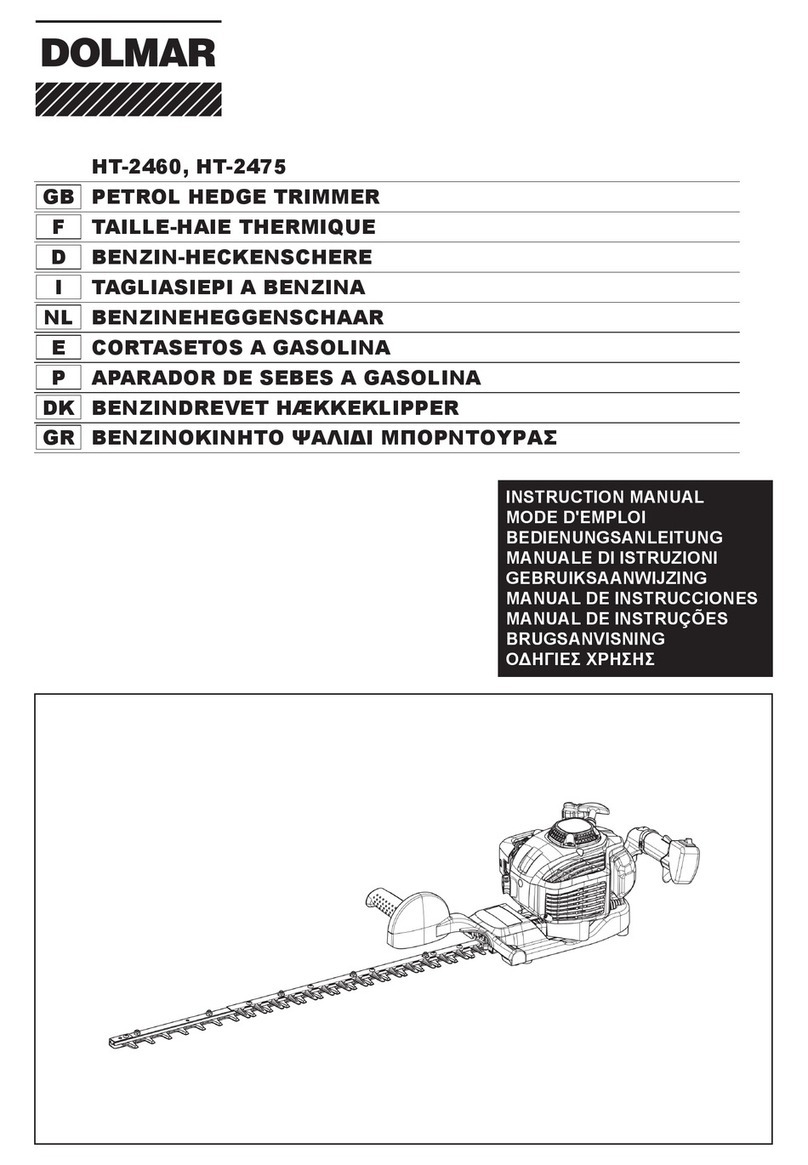

Dolmar HT-2460 User manual

Dolmar

Dolmar HT-5510 User manual

Dolmar

Dolmar MS-3202 User guide

Dolmar

Dolmar MS-4520 B User manual