AZ motor Edition 4

Instructions for bearings replacement 9

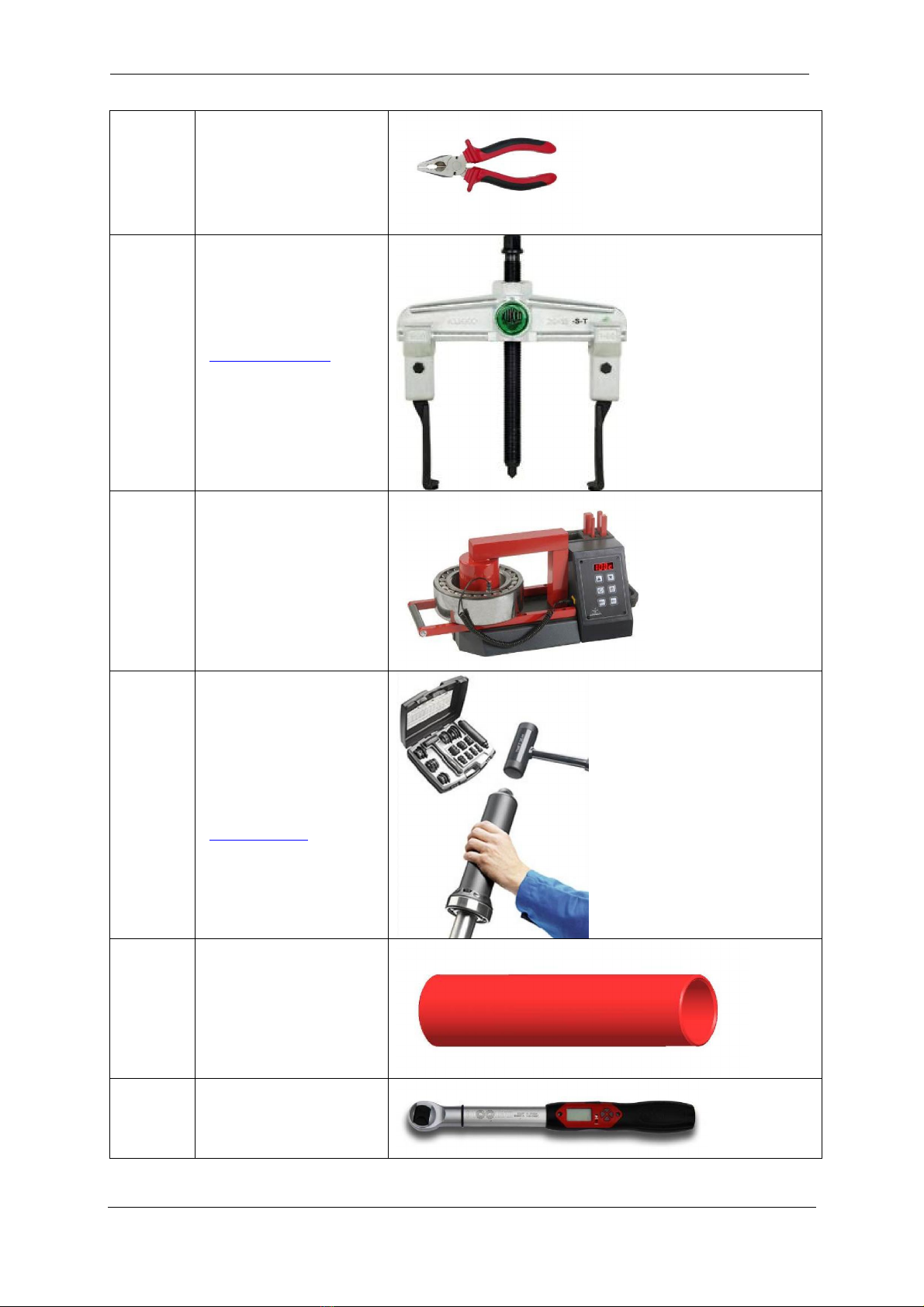

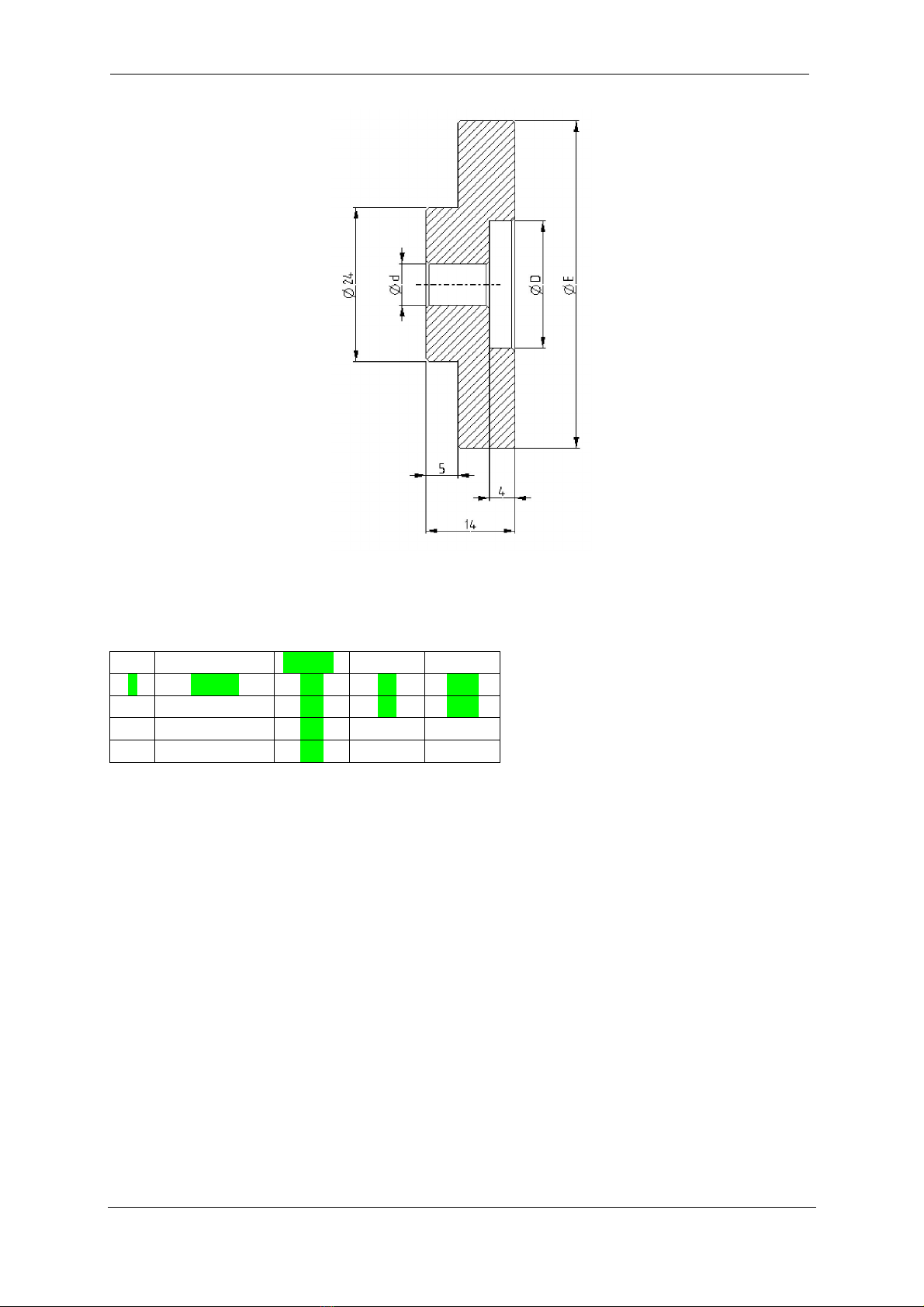

747.3.392 AZ 108-55 6204 DDU 6203 DDU 33x39,1x0,5x2,9

747.3.397 AZ 108-55 6204 DDU 6203 DDU 33x39,1x0,5x2,9

748.3.292 AZ 150-45 6205 ZZ 6205 ZZ 42x51x0,5x3,4

748.3.492 AZ 150-70 6205 ZZ 6205 ZZ 42x51x0,5x3,4

748.3.496 AZ 150-70 6205 ZZ 6205 ZZ 42x51x0,5x3,4

749.3.392 AZ 220-55 6206 ZZ 6206 ZZ 51x61x0,5x3,7

749.3.393 AZ 220-55 6206 ZZ 6206 ZZ 51x61x0,5x3,7

749.3.692 AZ 220-100 6206 ZZ 6206 ZZ 51x61x0,5x3,7

749.3.694 AZ 220-100 6206 ZZ 6206 ZZ 51x61x0,5x3,7

749.3.695 AZ 220-100 6206 ZZ 6206 ZZ 51x61x0,5x3,7

749.3.901 AZ 220-55-

100 6206 ZZ 6206 ZZ 51x61x0,5x3,7

Sufficient bearings life time is guaranteed

just with bearings specified in table 5.

These bearings are filled with special

grease that ensures appropriate life time.

Using other bearing types can lead to

shorter motor life time and Domel cannot

guarantee for these bearings.

Explanation of bearing designation:

Bearing producer

Grease quantity

S - standard (35% of free bearing space)

Type of special grease

Production location

Noise level mark

E – quiet bearing

Radial internal clearance

C3 - 6202, 6203 (11-25 m)

6204, 6205, 6206 (13-28 m)

Bearing sealing

ZZ – shields on both sides

DDU – contact rubber seals on both sides

Bearing geometry number

Other data important for new bearing selection:

Consider ambient temperatures expected for motor operation (Motors are designed for

long term operation at temperatures from -40°C to +52°C).

Max. long term bearing operating temperature can reach 80°C

Grease viscosity must prevent grease leakage from bearing