4

INSTALLATION

GENERAL INSTRUCTION

This appliance is designed for storage of foods and

storage of frozen foods and making ice.

This appliance is certified under the latest edition of

ANSI Z21.19•CSA 1.4 Refrigerators using gas fuel.

The installation must conform with local codes, or in

absence of local codes, the following standards as ap-

plicable.

In the U.S. the installation must conform with:

1. National Fuel Gas Code,ANSI Z223.1/NFPA54

(latest edition).

2. Recreational Vehicles Code,ANSIA119.2 (latest

edition)

3. Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280.

If an external electrical source is utilized, the refrigera-

tor, when installed, must be electrically grounded in ac-

cordance with local codes or, in the absence of local

codes,theNational ElectricalCode,ANSI/NFPA70- (lat-

est edition).

In CANADA, the installation must conform with:

1. Natural Gas and Propane Installation Code,

CSAB149.1

2. CSAZ240 RV Series, Recreational Vehicles.

3. Current CSA Z240.4, Gas-equipped Recreational

Vehicles and Mobile Housing.

If an external electrical source is utilized, the refrigera-

tor, when installed, must be electrically grounded in ac-

cordance with local codes or, in the absence of local

codes, the Canadian Electrical Code, CSAC22.1, Parts

Iand II - (latest edition).

VENTILATION

The installation shall be made in such a manner as to

separate the combustion system from the living space

of the mobile home or recreational vehicle. Openings

forairsupplyorforventingofcombustionproductsshall

have a minimum dimension of not less than 1/4 inch.

Proper installation requires one lower fresh air intake

and one upper exhaust vent. The ventilation kits shown

inthisinstruction manual have beencertifiedforuse with

the refrigerator models listed in the table. For “Certified

Vent System Kits” see page 15.

The ventilation kits must be installed and used without

modification.An openingtowardtheoutsideatfloor level

in the refrigerator compartment must be provided for

ventilationofheavier-than-airfuel gases.Thelowervent

of the recommended kits is provided with proper size

openings.Theflow ofcombustionandventilatingair must

not be obstructed.

Thelowersideventisfittedwithapanel,which provides

an adequate access opening for ready serviceability of

the burner and control manifold of the refrigerator. This

should be centered on the back of the refrigerator.

GAS CONNECTION

Hook up to the gas supply line is accomplished at the

manual gas valve, which is furnished with a 3/8" SAE

(UNF5/8"-18) male flareconnection.Allcompletedcon-

nections should be checked for leaks with soapy water.

DO NOT use a flame to check for gas leaks.

Thegassupplysystemmustincorporate apressure regu-

lator to maintain a supply pressure of not more than 11

inches water column.

Whentestingthegassupplysystem at test pressures in

excessof 1/2psi,therefrigeratorand itsindividualshutoff

valve must be disconnected from the gas supply piping

system.

When testing the gas supply system at pressures less

than or equal to 1/2 psi, the appliance must be isolated

from the gas supply piping system by closing its indi-

vidual manual shutoff valve.

In case detailed instructions on the installation and con-

nection to the gas supply are required, contact your

dealer or distributor.

ELECTRICAL CONNECTION

120 Volts AC Connection

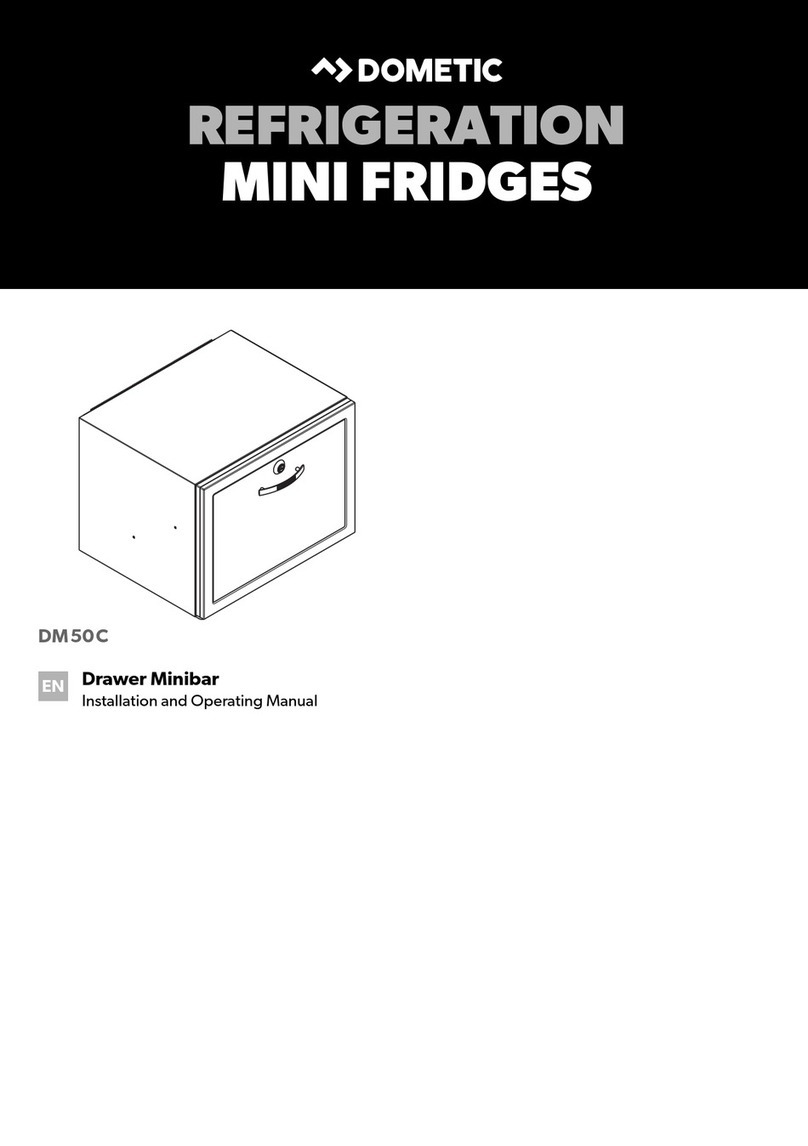

Therefrigeratorisequippedwithathree-prong(ground-

ing) plug for your protection against shock hazards and

shouldbepluggeddirectlyintoa properlygrounded three-

prongreceptacle.DONOTcut or remove the grounding

prongfrom this plug.Thefreelengthof the cord is 2 feet

and therefore recommended that the receptacle be lo-

cated to the right side of the refrigerator (viewed from

therear)and approximately 10inchesfrom the floor(see

FIG. 3). This allows easy access through the vent door.

The cord should be routed to avoid direct contact with

the burner cover, flue cover or any other components

that could damage the cord insulation.

! WARNING

FIG. 3

10’’

120 Volt AC

receptacle