5

Start up procedure

Ensure the dryer inlet and outlet isolation valves are fully closed and that all covers on the dryer are secure.

Ensure that a suitable supply of compressed air to within the dryers technical specifications is available.

Turn ON external electrical isolator, the yellow power on LED should illuminate and the dryer should commence

cycling.

NB - all valves must be opened and closed gradually

Proceed as follows

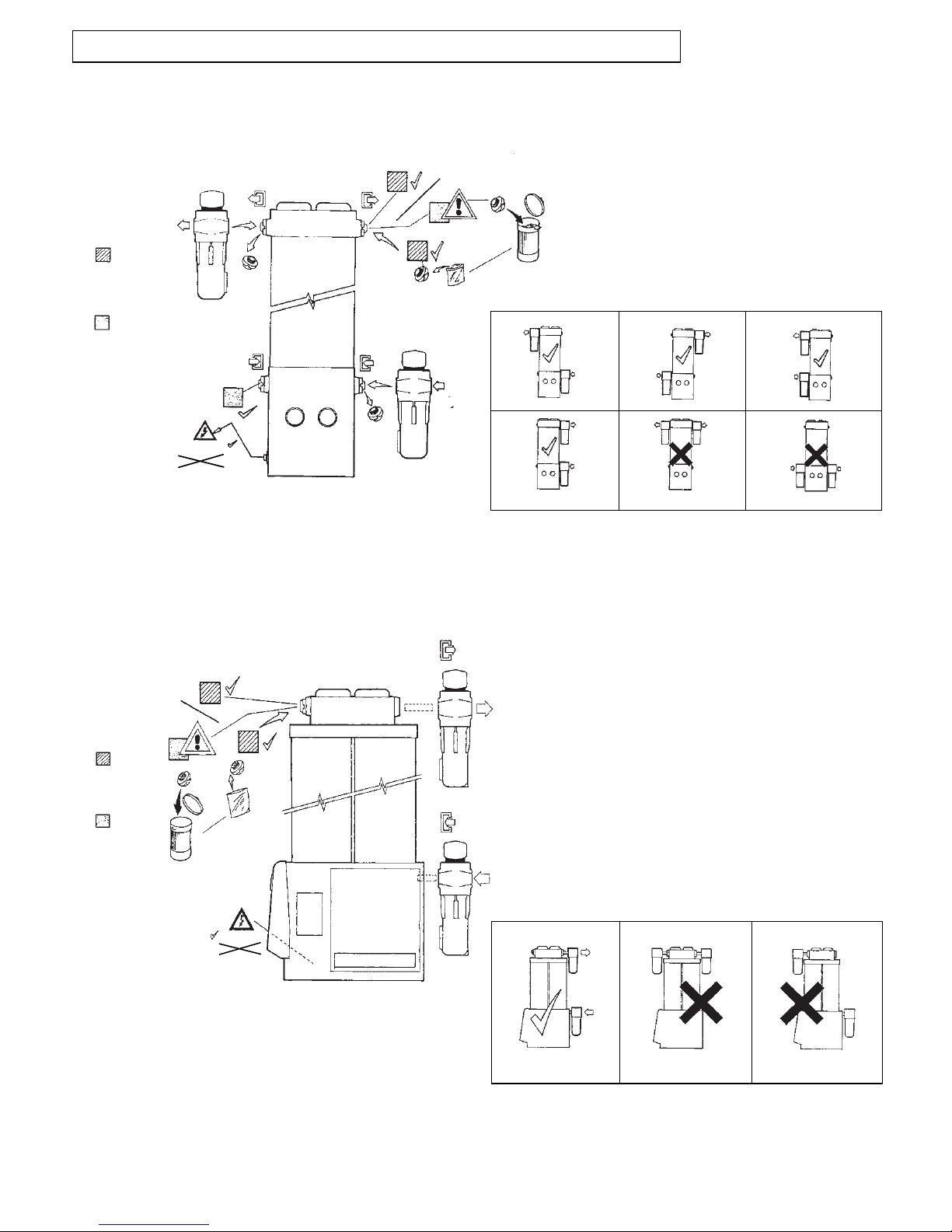

Using by-pass line

With the by-pass valve fully open, introduce air into the dryer by opening the inlet valve until fully open.

Allow the dryer to fully pressurise to full system pressure, then open the outlet valve while simultaneously

closing the by-pass valve.

The dryer is now on stream.

Without by-pass line

Introduce air into the dryer by opening the inlet valve until fully open.

Allow dryer to fully pressurise to full system pressure, then open the outlet valve.

The dryer is now on stream.

During operation

During normal operating conditions the dryer is fully automatic and requires no further attention until shut-down.

The yellow power on LED should be “ON” continuously.

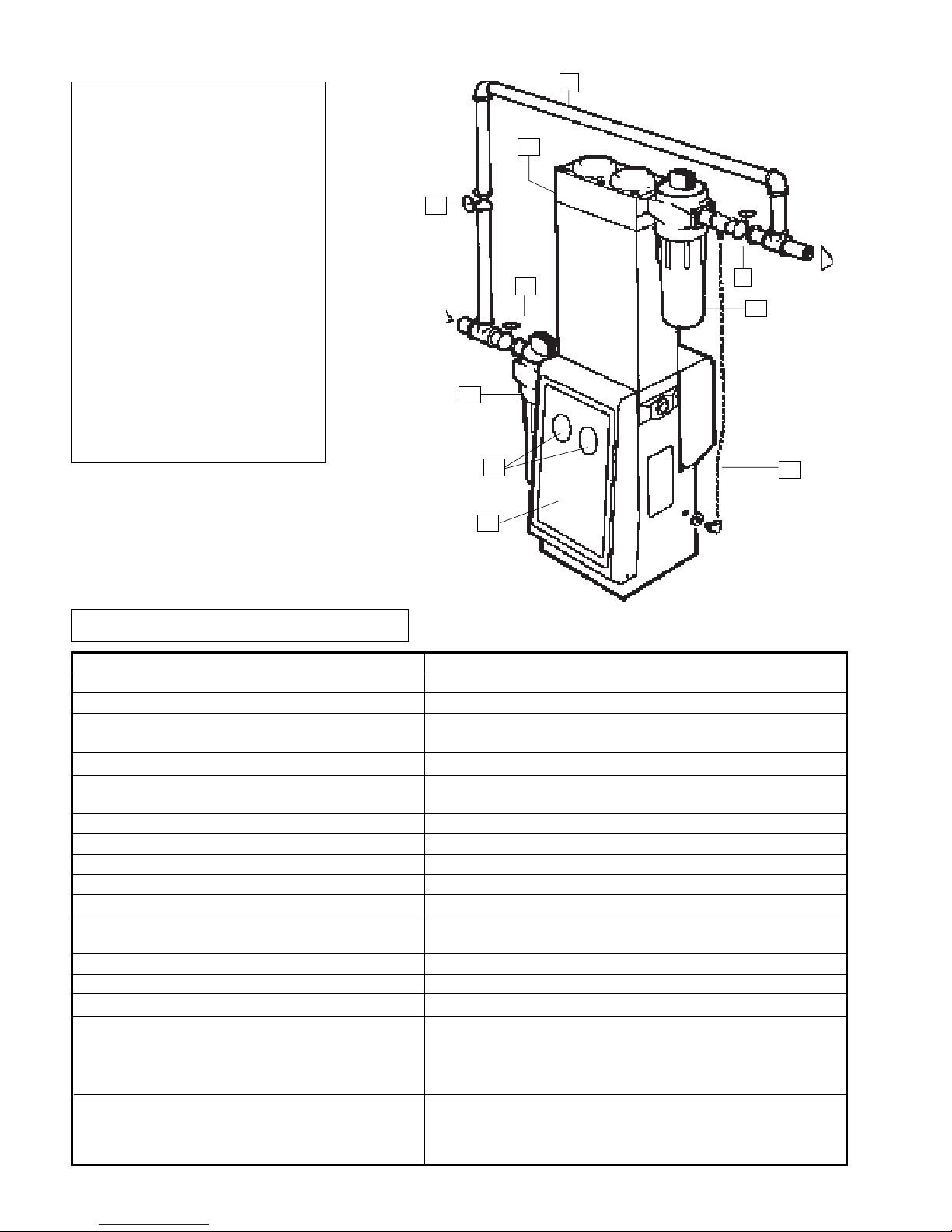

The dryer column contains two chambers of desiccant material. Whilst one chamber is drying the compressed

air (adsorption) the other chamber is simultaneously undergoing regeneration (desorption). Every three

minutes the chambers are reversed in function, this is the changeover point.

Changeover is characterised by a immediate venting of compressed air from the chamber entering

regeneration.

The adsorption chamber is indicated by the relevant pressure gauge on the dryer reading full system air

pressure.

The desorption chamber is indicated by the relevant pressure gauge on the dryer reading virtually zero.

After 2 1/2 minutes the desorption chamber repressurises to equal the adsorption chamber pressure, ready for

changeover of the chambers.

The pressure gauges and sight glass moisture indicator are for indication purposes only.

Dewpoint Dependent Switching (DDS) - optional

The DDS system operates as described above, with the following modifications.

If the dryer is producing air at a better dewpoint than specified the DDS system will hold the dryer at a point

just before the changeover occurs. The green “ECO” LED will illuminate. Both pressure gauges will read full

system pressure.

The dryer will resume normal operation the instant the DDS system monitors a fall in dewpoint to the specified

level.

The crystals in the outlet sight glass moisture indicator should be orange for correct operation, however, if these

change colour to clear the dryer is producing a wetter dewpoint than required, and the cause of this must be

investigated (refer to fault diagnosis table).

Shut-down procedure

The dryer can be shut down at any point in its cycle.

Using by-pass line

6. OPERATING THE DME DESICCANT AIR DRYER