84 • Engine Air Filtration

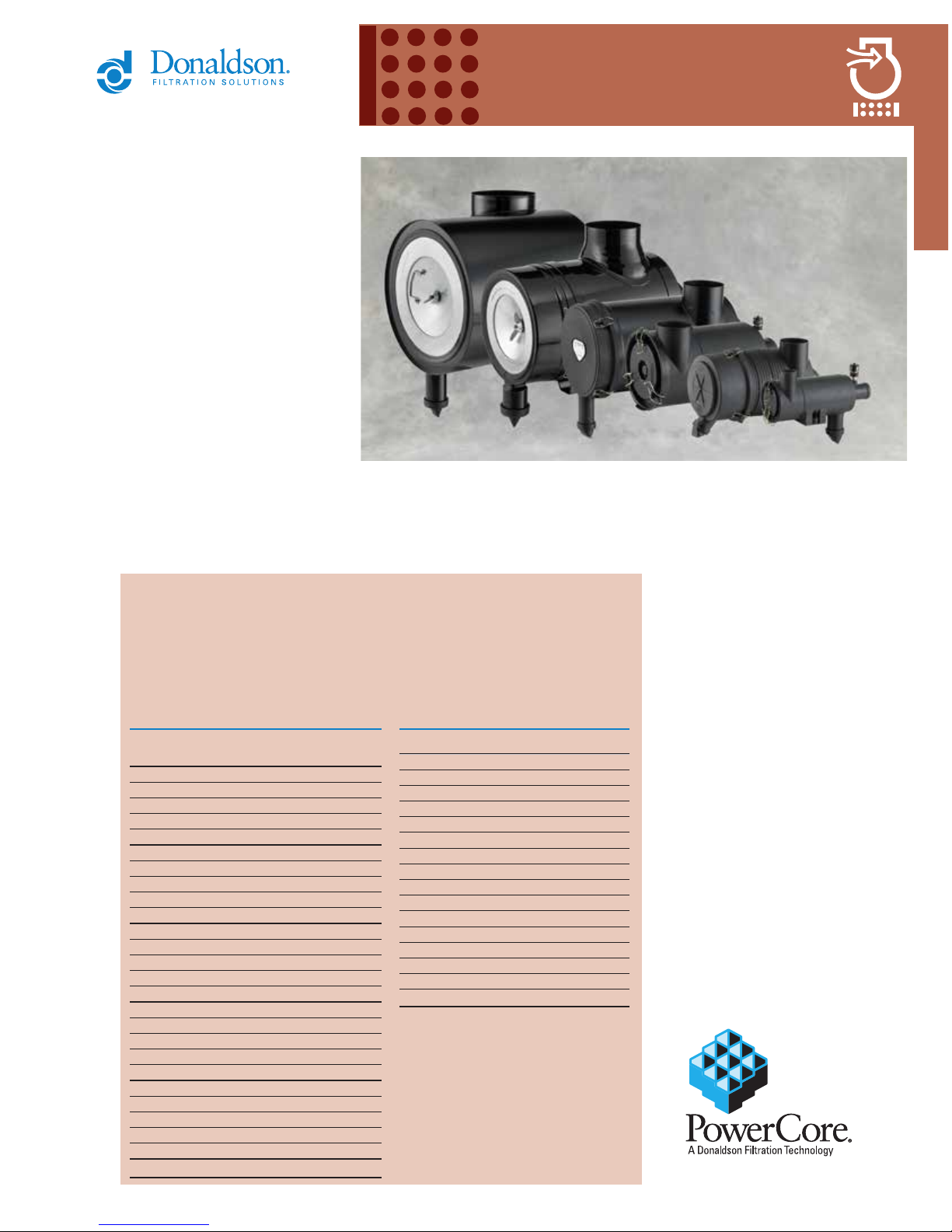

FKB Air Cleaners

MEDIUM DUST AIR CLEANERS

www.buydonaldson.com

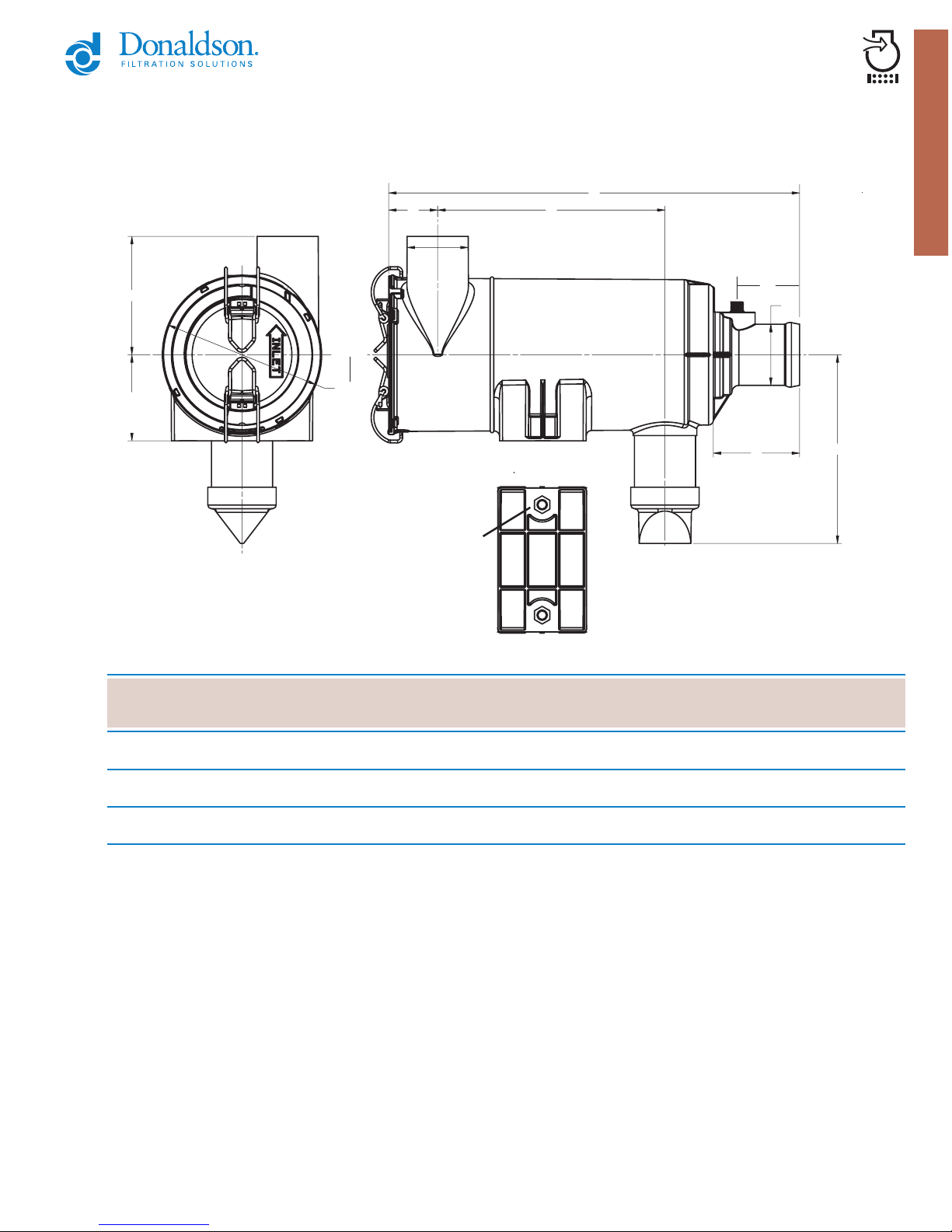

Installation Recommendations

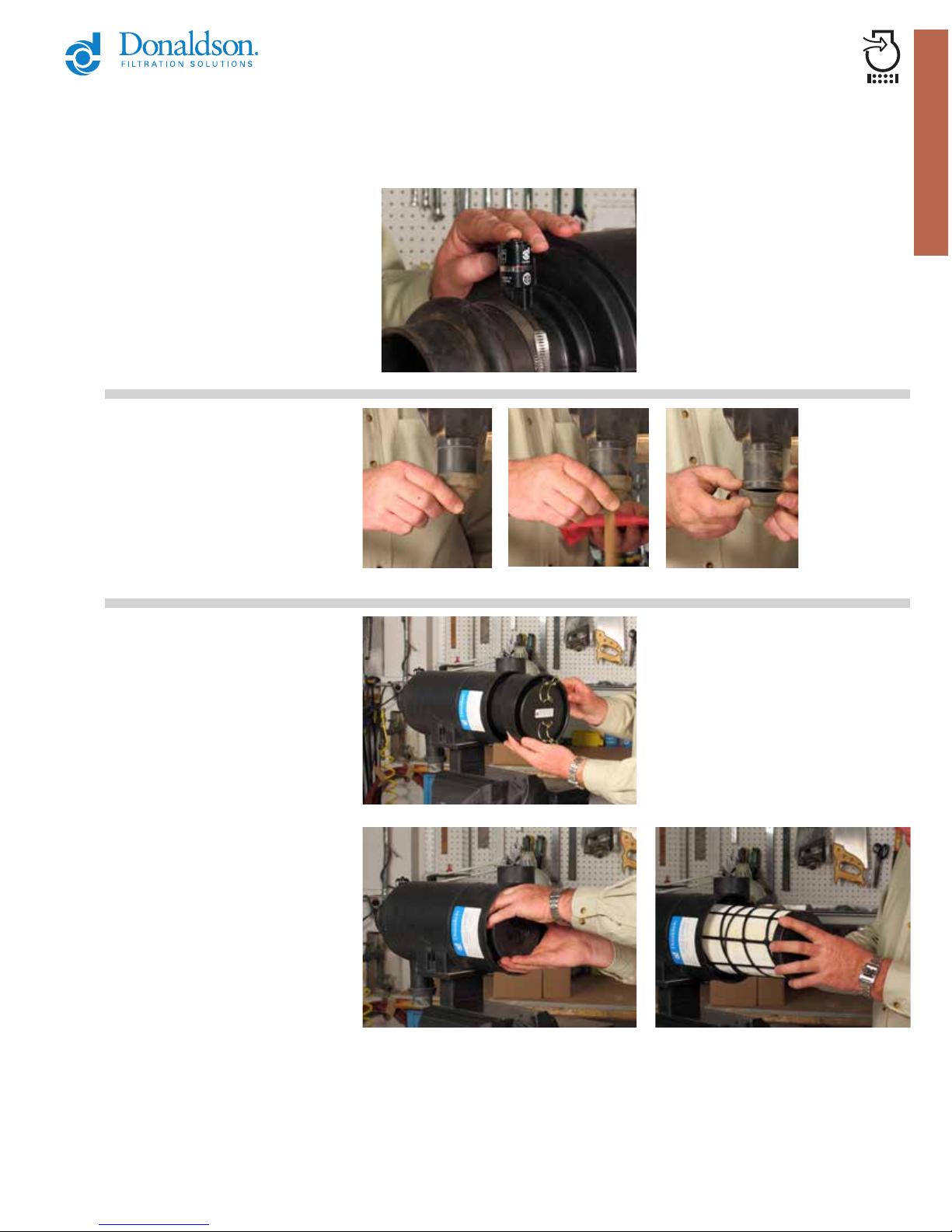

• Shut off your engine.

• Air cleaner orientation is horizontal, with the drop tube pointing down — within +/- 15º.

For service clearance, allow the entire length of the filter for removal and 35mm for

service cover latches.

• Mounting is M8 x 1.25, with a maximum torque of 15 ft•lb.

• Connections: Inlet/Outlet maximum torque 40 in•lb. Indicator port maximum torque

1.5 ft•lb.

• Inlet accessory note: The air cleaner housing can accommodate a lightweight inlet hood,

but not a pre-cleaner or any other accessory. Use of an unapproved intake accessory will

void your Donaldson warranty.

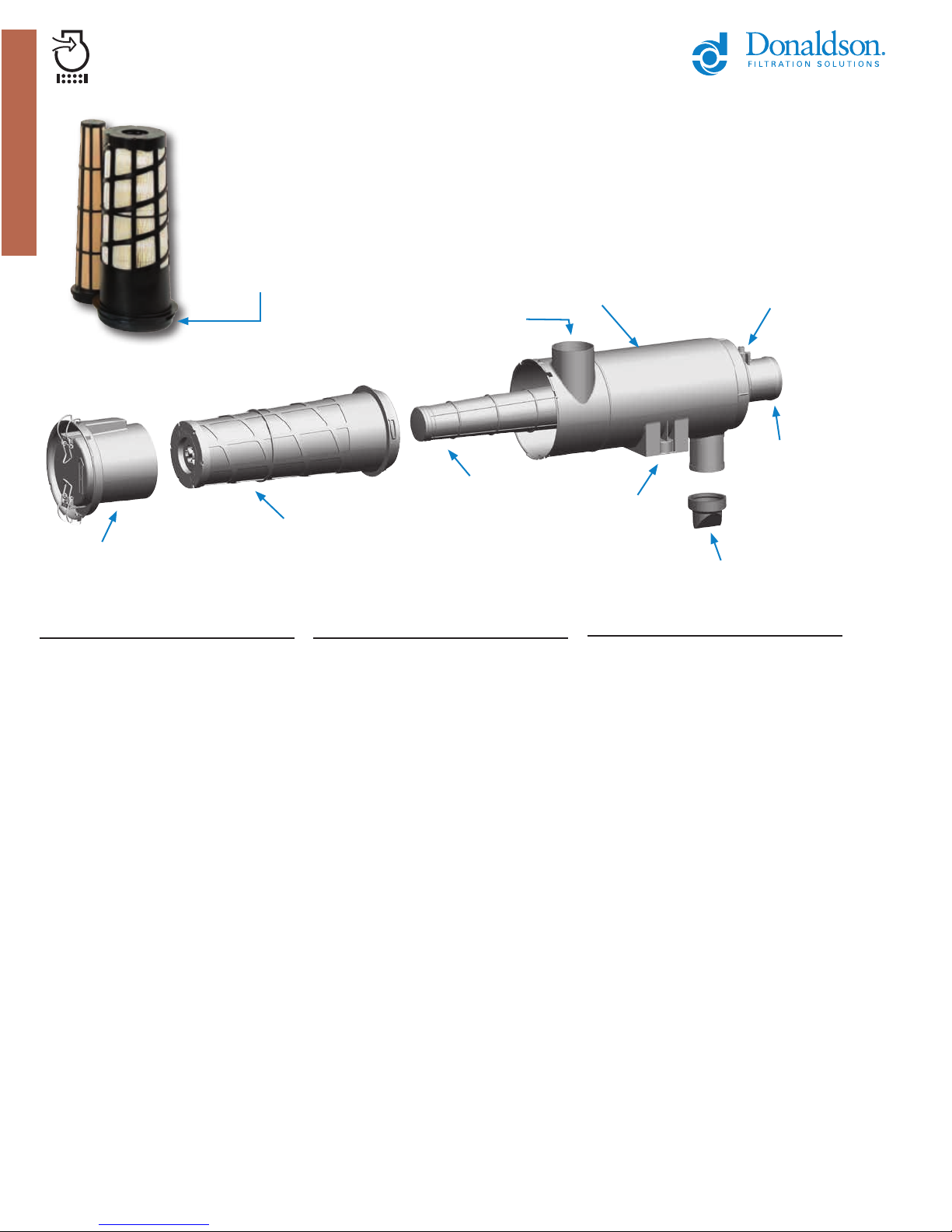

Vacuator™Valve

Built-in

Mounting

Bracket

Primary Filter

Filter Service

Indicator Port

Plastic Housing

Air Inlet

Outlet to

Engine

Safety Filter

Service Cover

Unique twist and lock filters ensure proper

positioning during filter service. FKB air cleaners

assemblies include primary and safety filters.

FKB Service Parts & Accessories

B045008 FKB

Cover................................................. P606497

Filter, primary ................................... P604457 .....3

Filter, safety...................................... P603729 .....3

Vacuator™Valve .............................. P158914

Elbow, 45º ......................................... P105541

Elbow, 90º ......................................... P105529

Informer™indicator 25" H2O........... X002277

Inlet hood, plastic............................ H001377

Outlet band clamp........................... P148337

B065045 FKB

Cover................................................. P608592

Elbow, 45º ......................................... P105544

Elbow, 90º ......................................... P105532

Elbow, 90º reducing ........................ P123462

Filter, primary ................................... P609221 .....3

Filter, safety...................................... P608599 .....3

Hump hose ....................................... P105608

Informer™indicator 25" H2O........... X002277

Inlet hood, plastic............................ H001379

Outlet band clamp........................... P148341

Vacuator™Valve .............................. P158914

NOTES:

3 = Shipped with air cleaner initially

B055006 FKB

Cover................................................. P609219

Filter, primary ................................... P609218 .....3

Filter, safety...................................... P602427 .....3

Vacuator™Valve .............................. P158914

Elbow, 45º ......................................... P105543

Elbow, 90º ......................................... P105531

Informer™indicator 25" H2O........... X002277

Inlet hood, plastic............................ H001378

Outlet band clamp........................... P148339