Track Excavator Maintenance Safety

1-1-7

DX380LC-5

Proper Work Tools and Attachments

Only use work tools and attachments that are recommended by

DOOSAN for use on DOOSAN machines. When installing and

using optional attachments, read instruction manual for

attachment, and general information related to attachments in this

manual. Because DOOSAN cannot anticipate, identify or test all

attachments that owners may want to install on their machines,

contact DOOSAN for written authorization and approval of

attachments, and their compatibility with optional kits.

Attachments and attachment control systems that are

compatible with the machine are required for safe and reliable

machine operation. Do not exceed maximum operating weight

(machine weight plus attachment) that is listed on ROPS

certification plate.

Make sure that all guards and shields are in place on machine

and on work tool. Depending on type or combination of work

equipment, there is a potential that work equipment could

interfere with the cabin or other parts of machine. Before using

unfamiliar work equipment, check if there is any potential of

interference, and operate with caution.

While you are performing any maintenance, testing, or

adjustments to attachments, stay clear of the following areas:

cutting edges, pinch points, and crushing surfaces.

Never use attachment as a work platform or manlift.

Contact your DOOSAN distributor about auxiliary hydraulic kits

for attachments installation. If you are in doubt about

compatibility of a particular attachment with a machine, consult

your DOOSAN distributor.

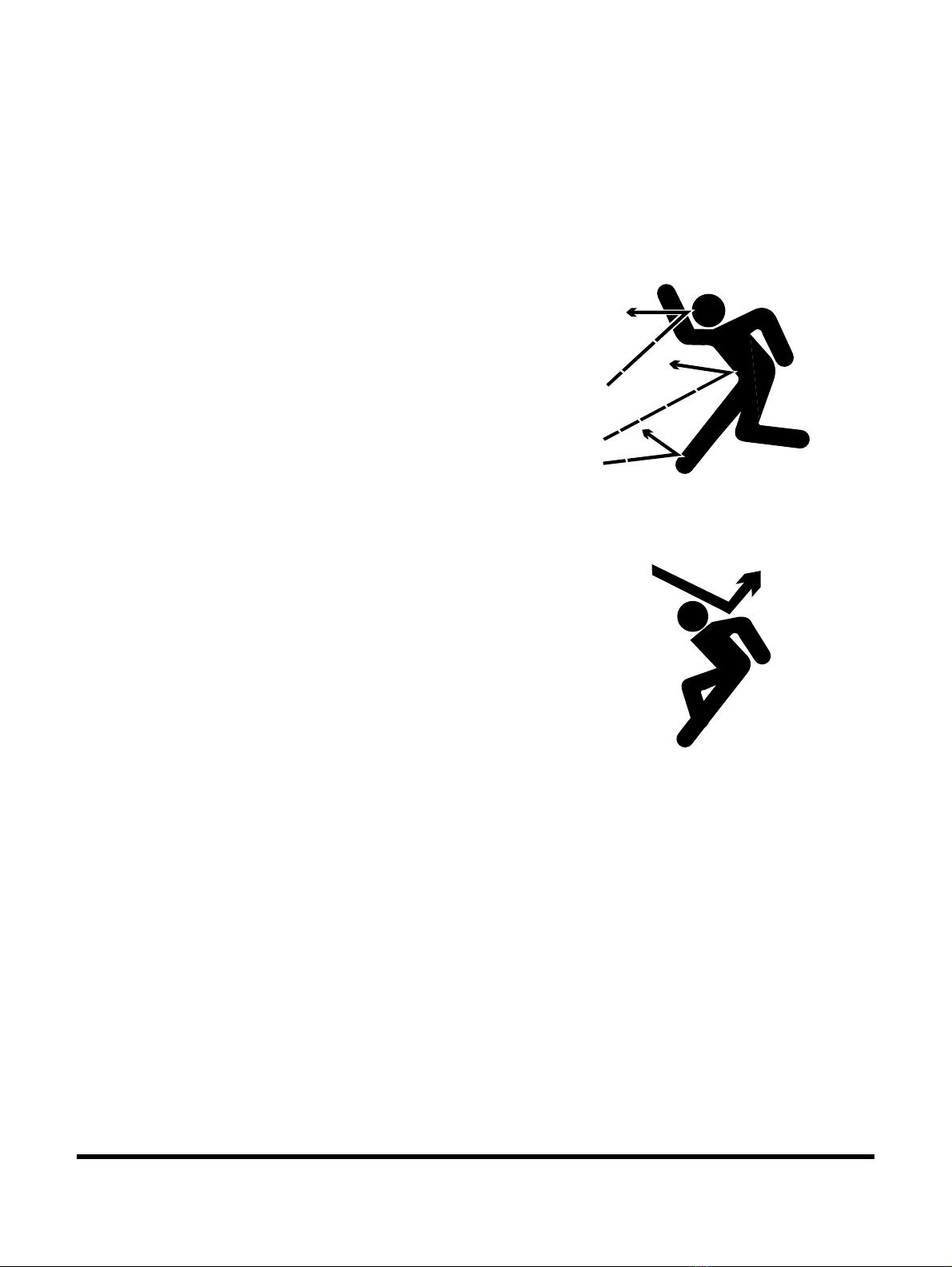

Pressurized Fluids

Pressurized air or fluids can cause debris and/or fluids to be

blown out. This could result in death or serious injury.

Immediately after operations are stopped, coolant, engine oil,

and hydraulic oil are at their highest temperatures and the

radiator and hydraulic tank are still under pressure. Always wait

for temperature to cool down. Follow specified procedures when

attempting to remove caps, drain oil or coolant, or replacing

filters. Always wait for temperature to cool down, and follow

specified procedures when performing these operations. Failure

to do so can result in death or serious injury.

When pressurized air and/or pressurized water is used for

cleaning, wear protective clothing, protective shoes, and eye

protection. Eye protection includes goggles or a protective face

shield.

Pressure can be trapped in a hydraulic system and must be

relieved before maintenance is started.

Releasing trapped pressure can cause sudden machine

movement or attachment movement. Use caution if you

disconnect hydraulic lines or fittings.

FG018457

Figure 1