3 BL400, BL600 LED Operation & Maintenance Manual

ACKNOWLEDGEMENTS

You have just acquired a balloon. Thank you for choosing

DOOSAN. We hope this product gives you total

satisfaction.

Please feel free to send your remarks to our Customer

Service department.

LET THERE BE LIGHT

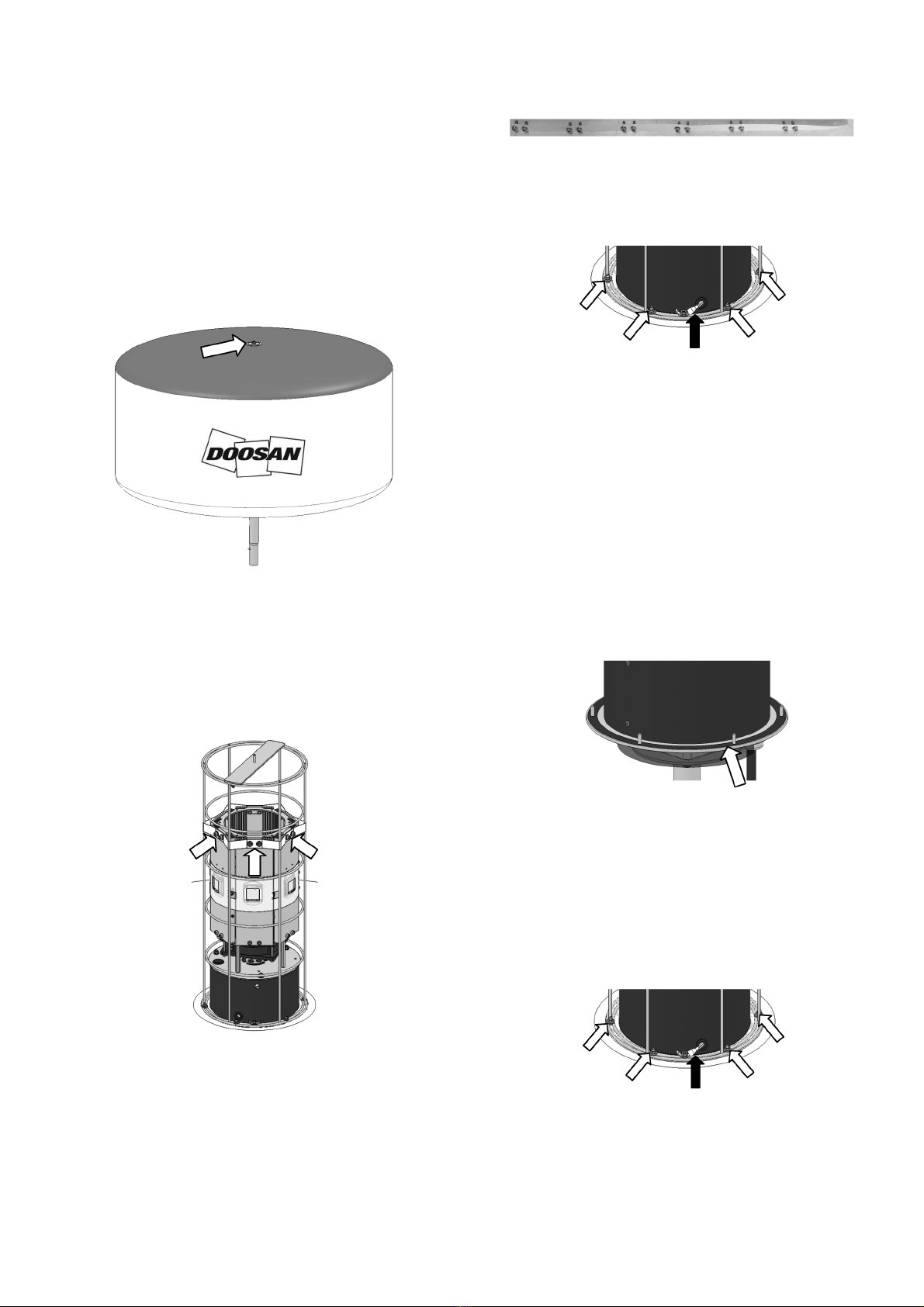

The BALLOON LIGHT is specifically designed for night

work: rescue, safety, work-site operations, etc.

EXTREMELY IMPORTANT SAFETY

INSTRUCTIONS

Ensure that the operator reads and understands the

decals and consults the manuals before maintenance or

operation.

REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

EXPOSURE TO EXCESSIVE UV RADIATION, OR

INJURY:

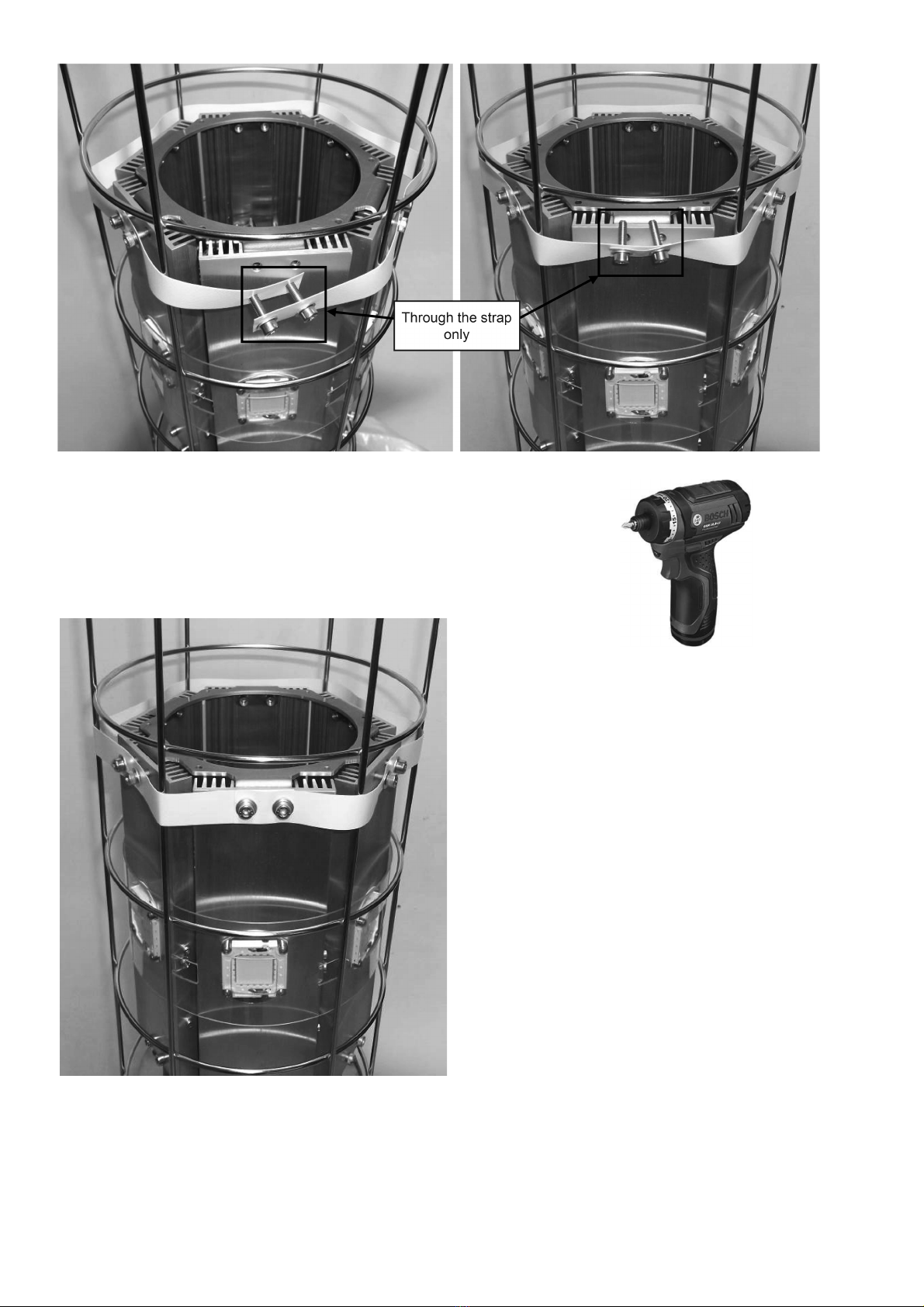

1. LIGHTED LEDs ARE EXTREMELY HOT. Turn off,

unplug, and allow the unit to cool before touching

LEDs.

2. ALWAYS disconnect your equipment before

servicing.

3. Do not touch the lamp cage until it has completely

cooled.

4. Do not look directly at lighted lamps.

5. Do not operate the Balloon Light unit near flammable

materials.

6. Use only with LED light engine

46769985

(BL400 -

6000°K) or 46700835 (BL600 - 6000°K).

7. Use a soft cloth or glove when handling lamps. Oil

from skin may damage the lamp during operation.

8. Do not operate the Balloon Light with damaged

electronics or if parts are missing.

9. Do not operate the Balloon Light with a damaged

envelope or without an envelope.

10. All service must be performed by DOOSAN qualified

personnel only. See Warranty Info for details.

11. Always use this lighting equipment at heights of at

least 5ft (1,5m).

12. Do not operate your stand-mounted Balloon Light on

an uneven surface or a gradient of more than 8

degrees.

13. Do not use the Envelope if the wind speed exceeds

50mph (80km/h).

14. Use only recommended stands with an ability to

support a 20lb (9kg) Balloon Light unit, and endure

wind speeds of 50mph (80km/h) at a height of 16,5ft

(5m).

When using outdoors, basic safety precautions

should always be followed to reduce the risk of fire,

electric shock, and personal injury, including the

following:

1. Use only NEMA 5-15 “Edison” plug extension cords

connected to the correct electrical source outlets.

2. Always use Ground Fault Circuit Interrupter (GFCI)

protection when operating your Balloon Light in areas

near water, and during inclement weather.

KEEP THESE INSTRUCTIONS WITH YOUR PRODUCT