5

Standard Features

The Doran GuardianXL is a full-featured digital weight Indicator with a number of

advanced features including dual displays, keypad data entry, set points, accumulators,

ID, date & time and serial data communications capability. NTEP approved to 10,000

divisions, the GuardianXL calibration and pushbutton features can be accessed via the

front panel using a pass code. NTEP integrity is maintained by an audit trail feature that

records all metrological activity. Powered by external rechargeable battery or AC line

power, the GuardianXL carries approvals from NTEP and Factory Mutual.

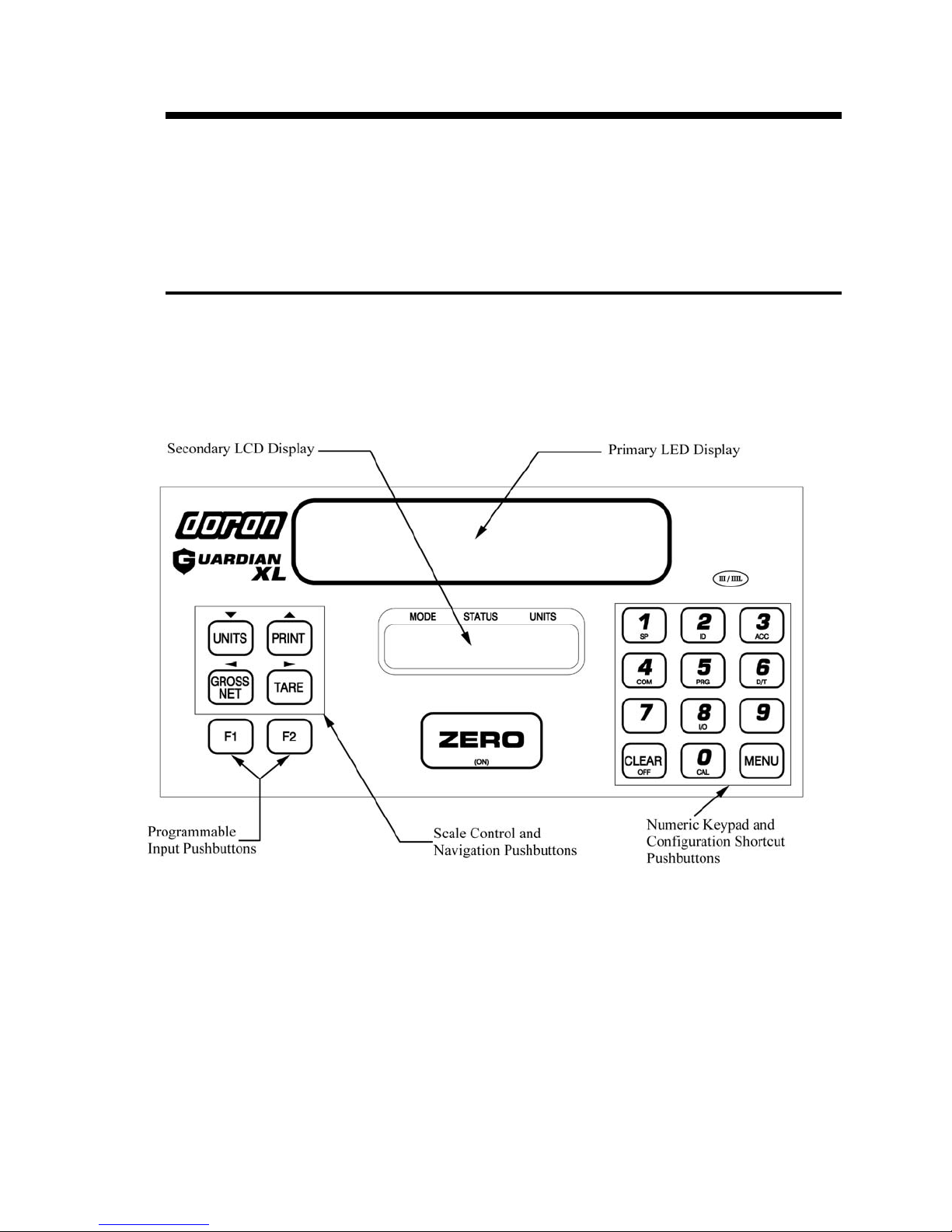

¾Dual Displays – Bright, highly visible, 1” high, 6 digit, red LED display is the

primary digital weight display. A two line, 32 character, alphanumeric, backlit

Liquid Crystal Display (LCD) provides custom messaging for excellent user

feedback, including Mode, Status and Units.

¾Zero – Pushbutton ZERO up to 100% of scale capacity.

¾Tare – A tare value can be entered in two ways – pushbutton tare or digital tare entry.

¾Keypad Data Entry – Numeric keypad for digital entry of tare and set point values.

Numeric pushbuttons have dual function to access pushbutton indicator functions.

¾Gross/Net – Display gross or net weight at the push of a button

¾Units – Selects up to 6 weight display units – lb, kg, g, oz, lb&oz or user units.

¾Print – Activates a serial data transmission to external devices

¾Accumulator and Counter – automatically accumulates gross and net weight.

Standard print string available for accumulator and counter output.

¾Time & Date

¾Digital Calibration – Set via front panel with operator pass code, and recorded in

two audit trail memory. Select any capacity value and the corresponding resolution

will be automatically selected. Zero and Span are independently set, allowing for

easy calibration in large scale filling or hopper applications.

¾Resolution – Display resolution from 200 to 50,000 divisions.

¾Update Rate – Select from 5.5 to 11 updates/second

¾Digital Filters - Wide selection of digital filter settings for maximum stability in the

presence of vibration or air movement.

¾Auto Zero Tracking feature compensates for small changes in zero and is selectable

from 0.5 to 5.0 divisions.

¾Full Duplex RS-232 Communications standard

¾Digital I/O Standard – Access to four TTL inputs and four TTL outputs on board.

¾Microprocessor Watchdog System monitors operation to prevent scale failure or

lock-up under severe fault conditions.

¾Approvals – NTEP Class III certification to 10,000 divisions.