2.2 Electrical & Optical Cables

2.2.1 Electrical Cables

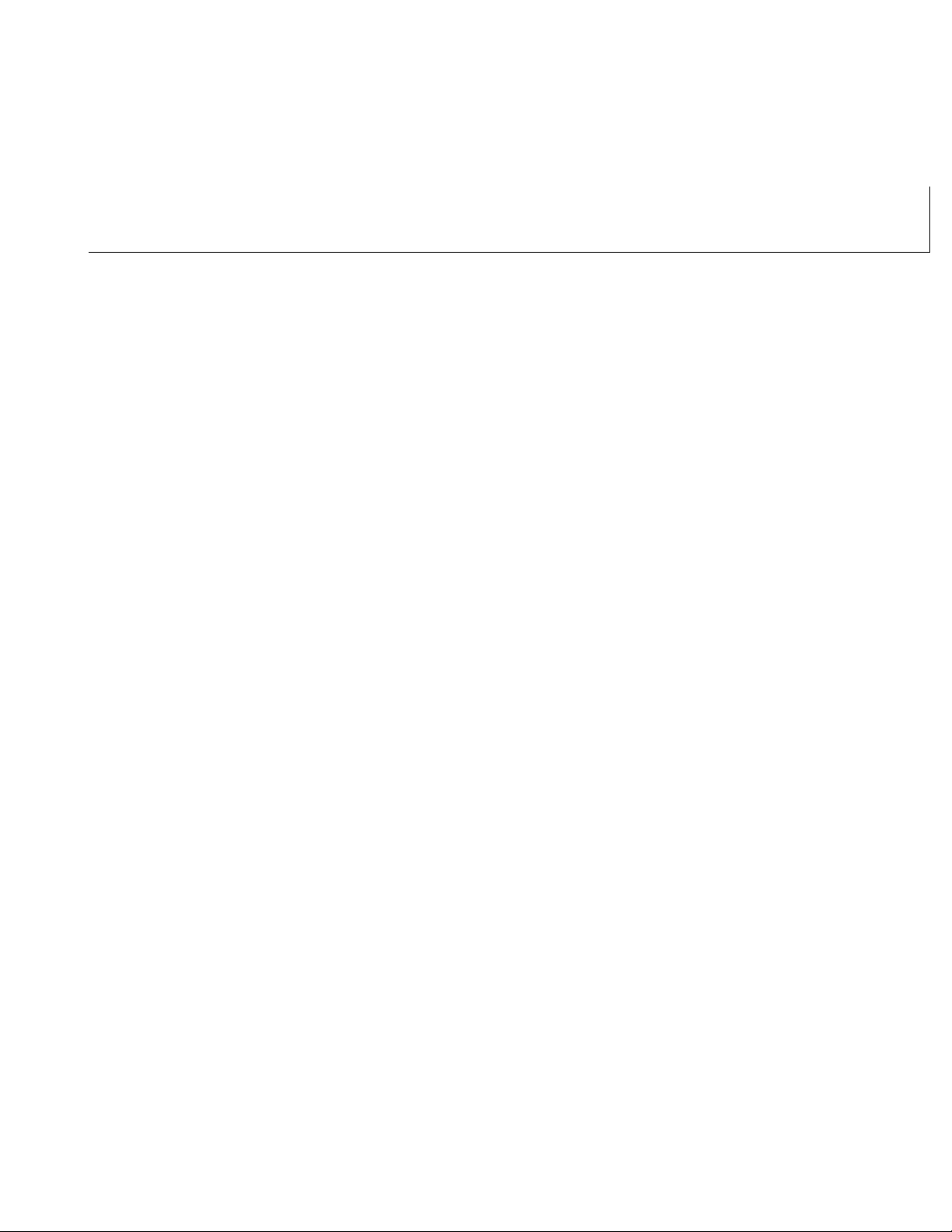

The rotary joint is assembled using either HDMI or Harwin (6 or 12 contacts) electrical connectors. The number of

electrical contacts does not necessarily equal the number of recording channels. The system requires a signal cable

(connecting to a console, computer or other signaling device) and a subject cable (connecting to the experimental sub-

ject).

(a) Electrical Connectors (b) Cable Placement

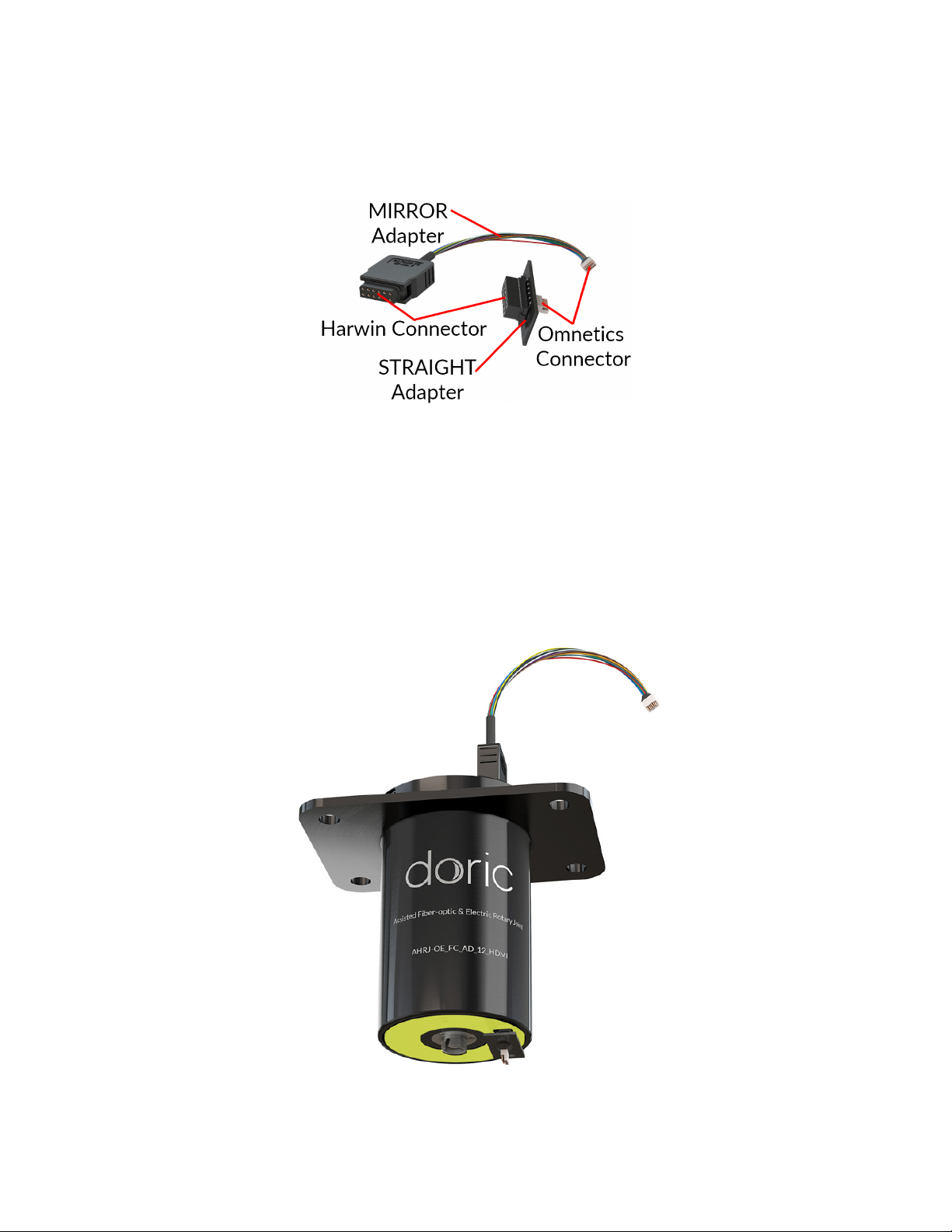

(c) Electrical Rotary Joint Underside

Figure 2.5: Electrical Connector Placement

1. Ensure that the electrical connectors are free of dust using an air duster before installing the cables. When not in

use, install plastic caps on connectors for protection and cleanliness.

2. Connect the signal electrical cable to the fixed electrical connector (Fig. 2.5a and 2.5b).

3. Connect the subject electrical cable to the rotary connector (Fig. 2.5a and 2.5b).

4. If using the Horizontal Cable Holder, the subject electrical cable can be looped into the Cable Holder Standoff

(Fig. 2.5b) to provide extra torque. The cable is secured into the clamp (Fig. 2.5c) using a #4-40 nylon socket-head

cap screw. See section 2.2.2 for the installation of the Horizontal Cable Holder.

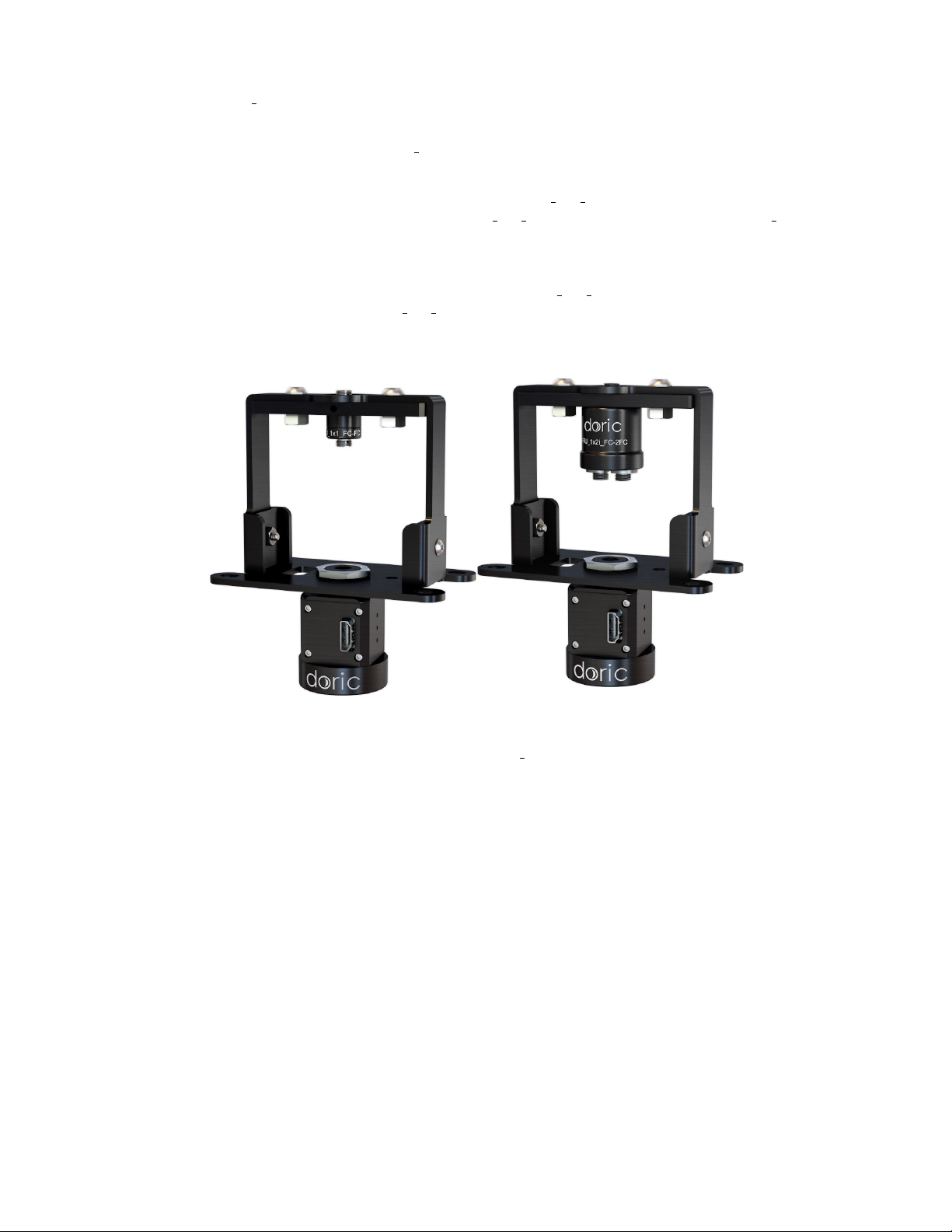

2.2.2 Horizontal Cable Holder

The horizontal cable holder keeping electrical cables off-center can be added to increase the effective torque applied on

the rotor. To install the Horizontal Cable Holder:

Chapter 2. Operations Guide 9