Stand 08.02.2012 Technische Änderungen vorbehalten

Software-Update_Ver1010_GB.doc DORMA KT-Systeme Seite 3 von 14

KTC-2 (MS9)

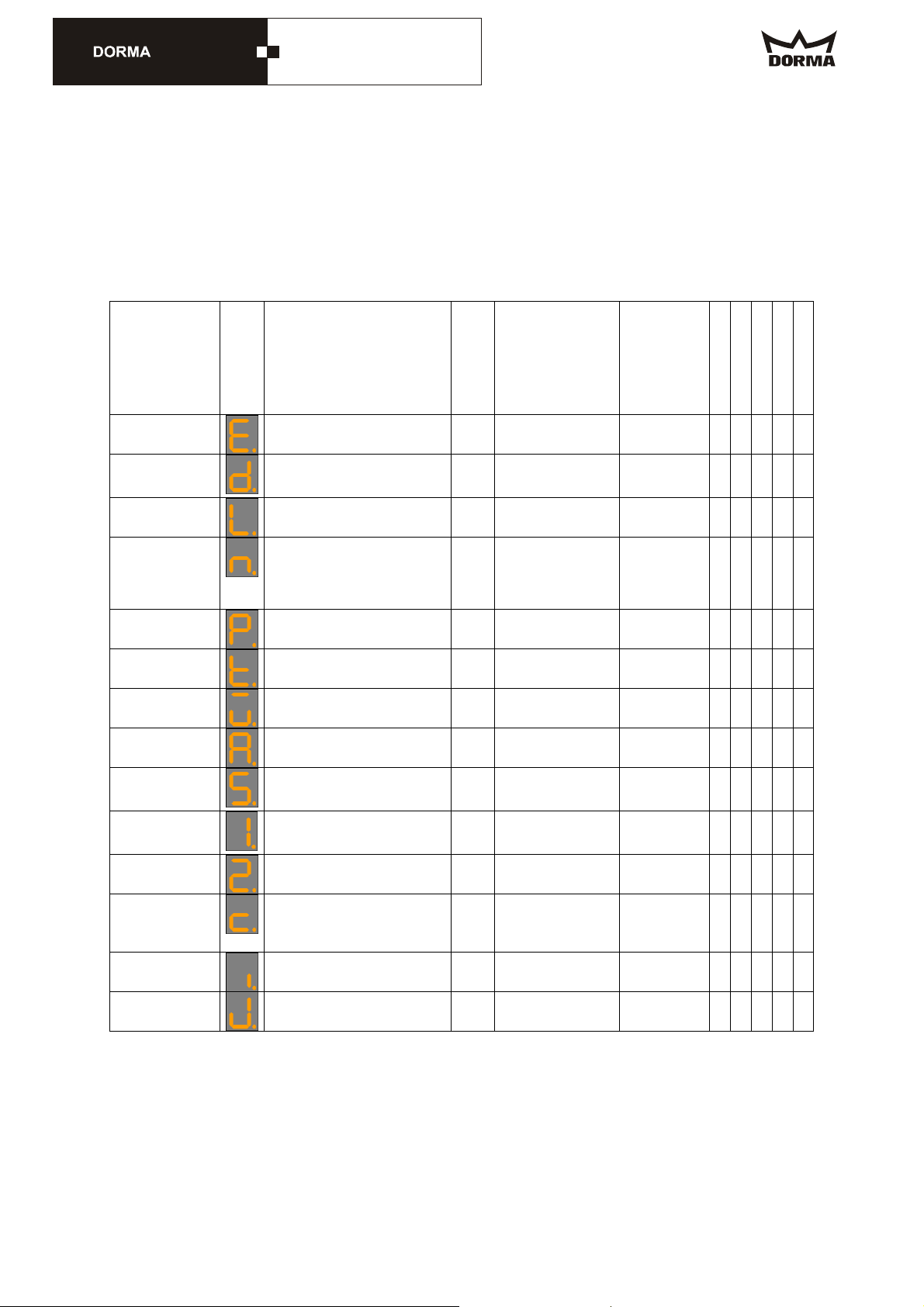

The following chart shows the setting entries:

The standard values are shown here, they may however vary.

Parameters

Parameter

designation

Symbo

l

Description Unit Range Original

setting

Palm

Central system

Learning cycle

Original setting

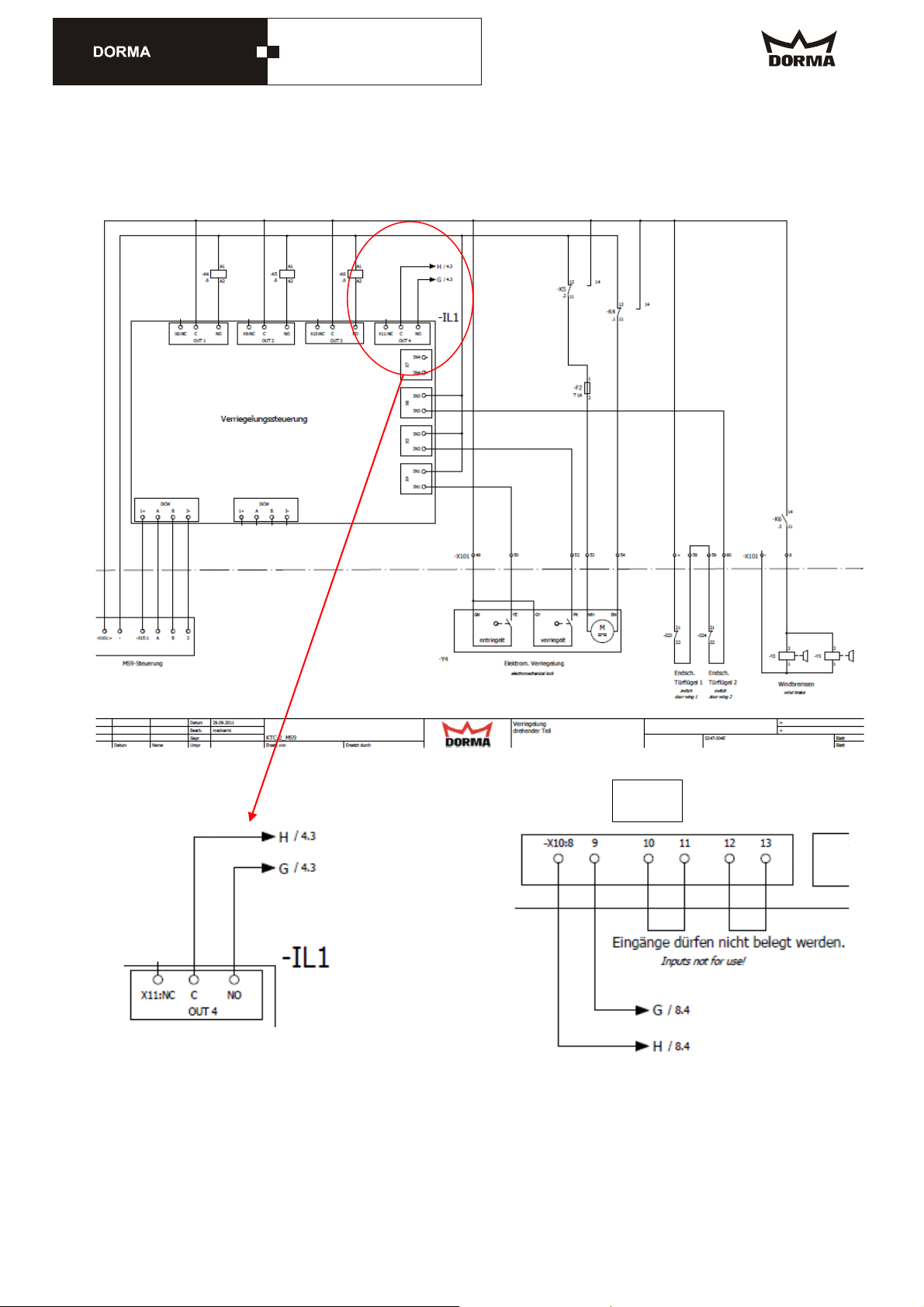

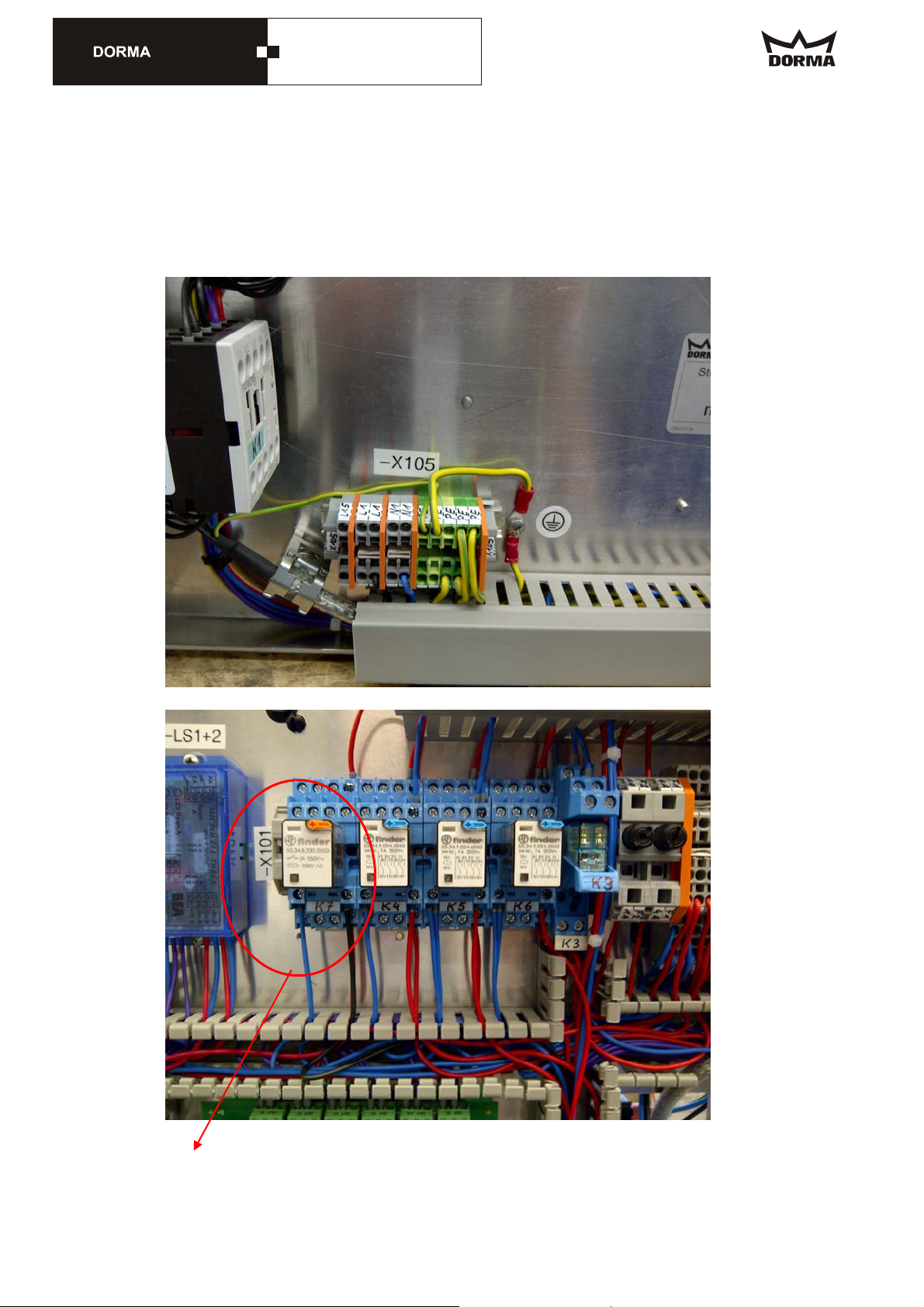

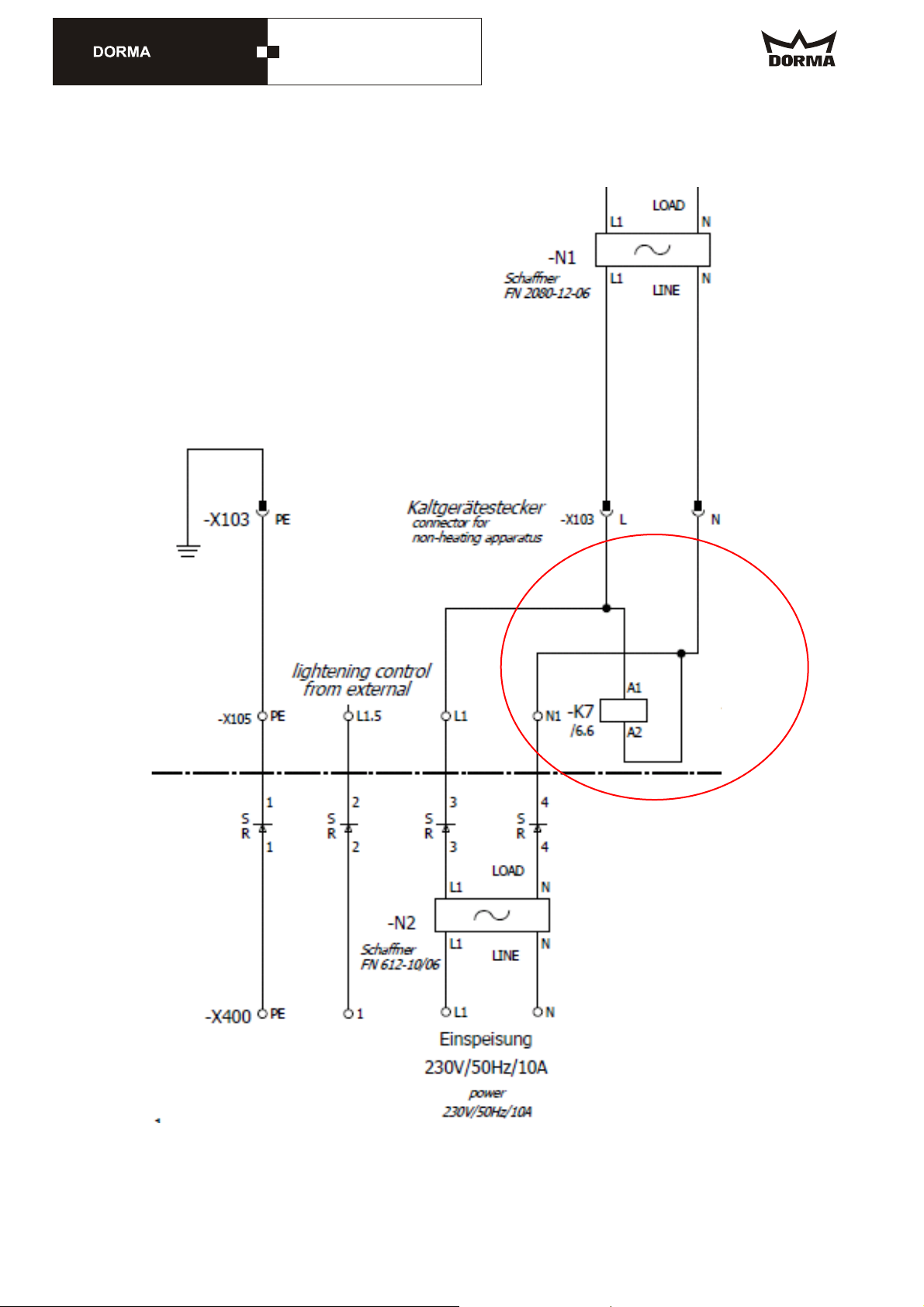

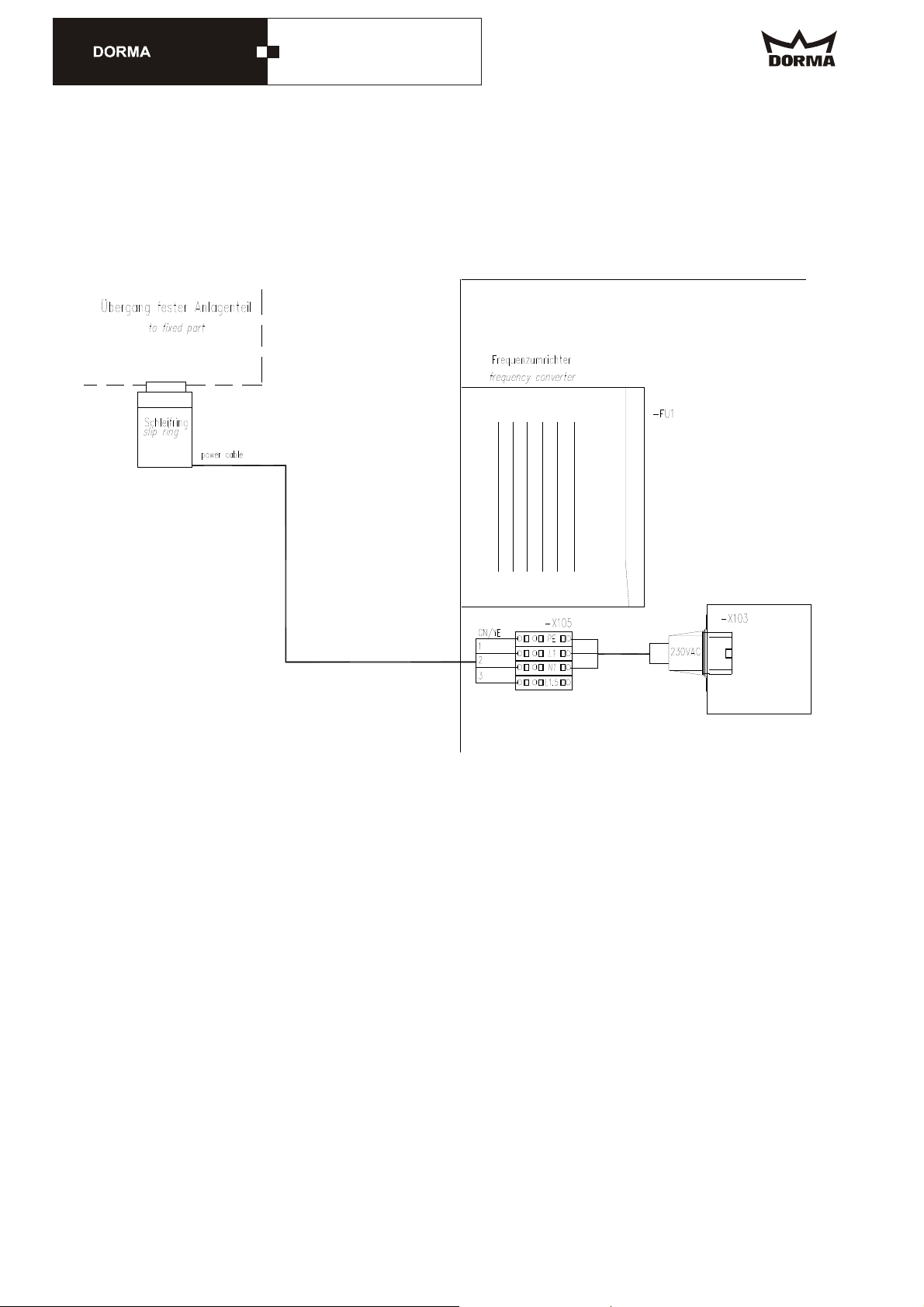

Wiring

Current error

status

Error list - - - - -

Door diameter

Door diameter mm 2000 .. 6500 (system

learns

diameter)

- - C - -

#el. locking

devices

Electromechanical bolt locking

device no = 0, yes = 1

0 .. 1 0 U U - C -

Hold after stop

Time until the el. brake is

released after an Emergency

Stop

0 = brake never released, 1 - 9

= after... sec.

sec (0 .. 9) sec 1 U U - C -

#X-Pos Auto

1 - 2

Number of starting positions in

Automatic 1 or 2

2 .. 5 2 U U - C -

SlowStop canopy

SlowStop time of canopy-

integrated sensors

sec (0 .. 15) sec

16 = ∞16 U U - C -

SlowStop wing

SlowStop time of wing sensor 0.1

sec

(0 .. 15.9) sec

16.0 = ∞16.0 U U - C -

Hold after stop

Time until the door starts after a

safety stop

0.1

sec

(0 .. 9.9) sec 1.0 U U - C -

Sec. area stop

Detection range of canopy-

integrated sensor in security

area for SlowStop

mm (d * (pi/3)

.. 500) mm 700 U U - C -

Summer

configuration

Starting-positions: 0°/180° (system

reads X-

positions)

- - - - U

Starting position

Summer

Starting-positions: 90°/270° [0],

60°/240° [1]

0 .. 1 0 U U - C -

PosV after safety

stop

Time system operates in

positioning speed after leaving

the stationary position following

a safety stop

0.1

sec

(0.0 .. 2.9) sec 1.0 U U - C -

A/M lighting

Automatic/manual lighting

control

0 ... 1 0 (auto) U U - C -

FUT warm air

curtain

Follow-up time of warm air

curtain

sec 0 ... 600 10 U U - C -

Caption:

U = adjustable value

C = resettable value

- = non-adjustable value