DH9116 Initial Basic Swashplate Leveling Procedure & Mechanical

Trimming / Adjustment of the Servo Arms & Linkages

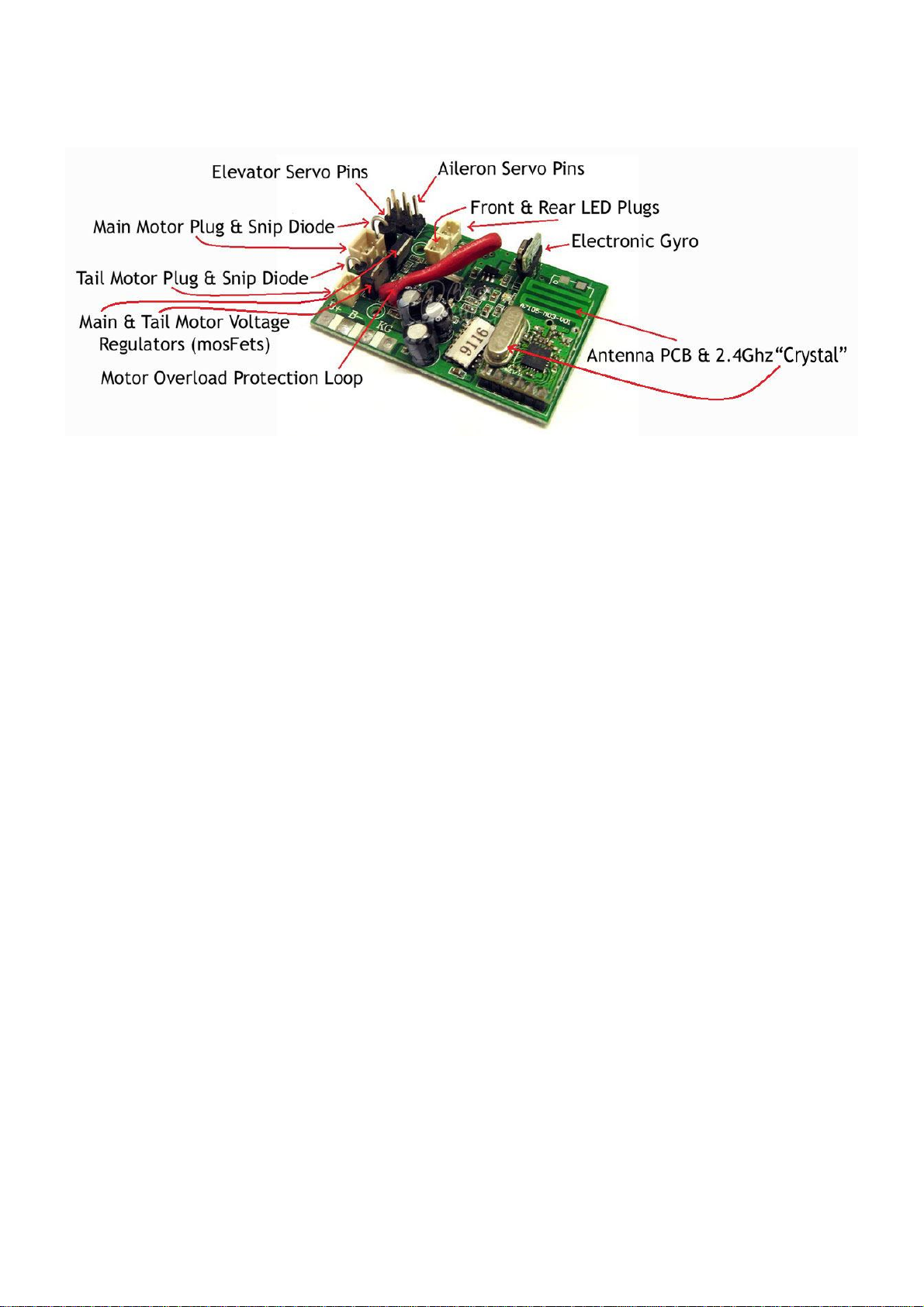

Remove the canopy and find the plugs to the tail motor and main motor on the pcb and pull them out (making

note of where they go), therefore disconnecting both the motors from the helicopter's battery power source.

Connect the battery to the helicopter, turn on your transmitter and switch on / power up the helicopter and

allow the helicopter to bind or sync with the transmitter, the servo's should flutter when it is bound. Centre all

the trims on the sticks on the TX and center all the sticks.

Place the helicopter on a level surface and in a position, so you can see it comfortably, you are going to be

doing this for 20 minutes or so. Make sure all the blades are in their shortest throw positions and the balance

bar is level (a small line level fixed to the balance bar is perfect for achieving this). Look at the swashplate and

ascertain if the top plate of the swash is at right angles or perpendicular to the main shaft. I find putting a long

thin knitting needle or a bamboo "satay" skewer stick on the top plate exaggerates the angle and makes it

more obvious. I have also found if you draw a thick horizontal and vertical line in the shape of a cross ("+") on

an "A4" sheet of paper, then temporarily position it on a wall (making sure it is perfectly horizontally and

vertically level before you fix it) directly behind the helicopter it can be used as reference marks for maintaining

the alignment of the main shaft and the swashplate leveling "stick". Adjust both servo arm linkages until the

swashplate is level along the length of the helicopter, re-attach the linkages to the swashplate, and re-connect

the tail and main motors and re-attach the canopy (re-attaching the canopy is important, because the weight of

the canopy will affect the balance of the helicopter and if it isn't on, hovering without it will give a false drift

backward).

Test fly / hover the helicopter. This must be done on a perfectly calm day or indoors well away from walls, etc.,

like a large shed or gym. Any slight breezes will influence or over-exaggerate any fine mechanical adjustments

you make, and you will be "chasing your own tail" trying to get it perfect.

Adjusting the position of the Servo arms.

Make sure first that you have fully re-charged the battery, then place the heli on a flat, level surface, like a

table or workbench top, and connect the battery and turn on the heli and the tx, allow then to bind and set the

throttle to zero, make sure all the stick trims on the tx are centred. This is to allow the servo's to stay at their

midpoint settings, because if the heli was switched off, you can move the servo and arms and knock them out

of central alignment. Unscrew the centre screw from the central pivot point on the servo arm and remove it,

pull the servo arm straight off (it might need prying or wriggling off), then re-align the inside grooves of the

servo arm with the corresponding grooves on the servo axle, so the arm is now horizontally level with the table

top (if you can't get it spot on, don't worry, it just needs to be as close as possible to 90°) and re-attach the

screw. Repeat the same procedure to the opposite side servo arm.

Servo Arm to Swashplate Link Adjustments.

To adjust the servo arm links to obtain a near perfect hands free hover, start with the swashplate levelling

procedure and re-set the servo arm links back to the factory lengths (but if you haven't adjusted them

previously, skip that bit, as they should be set to those lengths already). That is your starting point. At this

setting, the heli should take off with a bias to the rear and to the right. Once you get the heli airborne, attempt

to get it into a nose in hover, as close as to you as you can, so you can see the servo links rise and fall above

the top edge of the canopy, as you try to get the heli to hover stably with the sticks. If the heli wants to shoot

off to the left or right, as you are moving the sticks to counter it's movements, take note of which way the

servo link is going, if it goes down, that link needs to be shortened (screw in a clockwise direction) if it rises, it

needs to be lengthened (screw out in a counter-clockwise direction). Bring the heli down and pop off that link

from the swashplate ball, by placing your fingernail behind the "ring" of the servo link and giving it a good

"flick". Screw in or out the servo link as required, in one full or one half turn increments, then press fit it back

on and go through the test hover procedure again. Only work on one direction at a time. Obviously, if the heli

wants to scoot off in a diagonal direction, you need to adjust both servo arm links, but only adjust one link at a

time, so to bring it back to a straight line drift (so it only wants to drift forwards or backwards, for instance).

For sliding/banking left or right ,you adjust the aileron servo (right hand side, looking from the tail). For

backward/forward drift, you adjust both servo links in equal amounts, but only after you've eliminated any side

to side drifting first.

A trimming in flight must be done on a 0 wind free day or a large indoor venue and it should take at least 1

fully charged battery, maybe 2 (so it should take about 30 - 45 minutes to do, maybe less, if you've got your

head around what you need to do first), to get it hovering close to perfect, because taking off and hovering

constantly requires optimum battery capacity. Ideally, the heli should take off near vertically and it should self-

level into a stable hover about 1.5 metres (head height) from the ground. So punch the throttle to get it

airbourne as quickly as possible, then get it into a hover. If the heli starts to loose altitude, even with a full

throttle stick, bring it down and re-charge it as soon as possible after you've let the battery cool down for 5 -

10 mins.