P

ANDORA

(

REV-C

), www.dpcav.com Page 7

©2007-2008 Jun-11-2008

Final Assembly:

1. Install the top Stringer (item 5) on the chassis at Slots DD. Use a small amount of epoxy or

solder. Use it sparingly since it may be necessary to remove the stringer for repairs or perhaps

to upgrade to the optional 5VDC Voltage Regulator in the future.

2. Using two 2-56 x 3/8" machine screws and nuts (with Loctite), install the HS-81 pan servo

(with rubber grommets and metal eyelets) to the Base Plate (item 10). Using the retaining

screw supplied with the servo, attach the servo to the chassis mounted servo wheel. Be sure

to install it so that servo center results in a forward looking camera pan position. For best

results, set your R/C transmitter’s EPA/ATV mix for maximum servo travel. Verify that the pan

servo is able to rotate without hitting any chassis obstructions. By the way, the Pan Backing

Plates (items 14 and 15) are used to help strengthen the model where the Pan Base is

installed in it.

3. While using your R/C transmitter, adjust the tilt linkage for best servo movement. Ensure that

the servo is not allowed to stall or it will be damaged. It will be necessary to adjust your R/C

transmitter’s EPA/ATV mix feature to set the maximum lower and upper travel ranges.

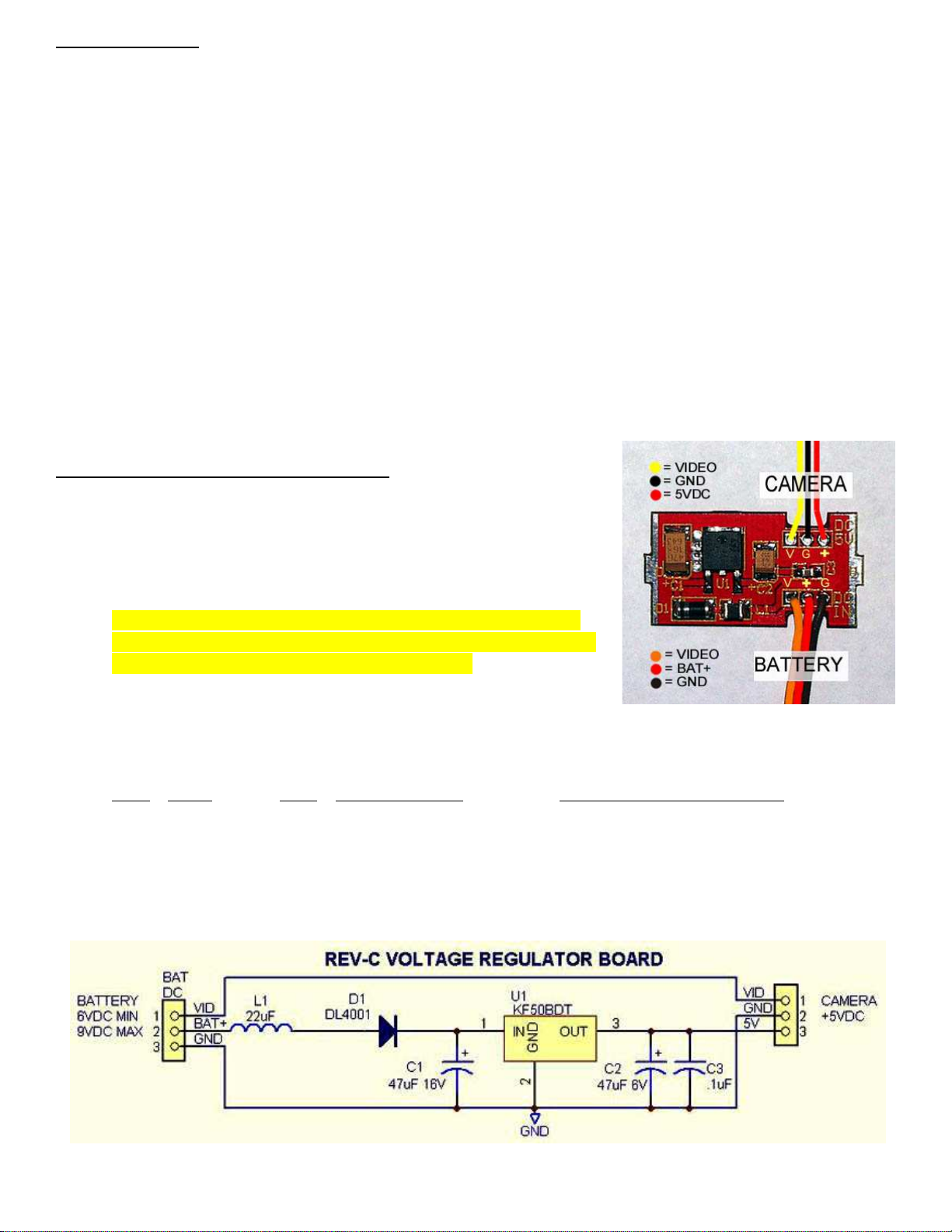

Revision-C Voltage Regulator Option:

The top Stringer (item 5) can be replaced with the optional

5VDC voltage regulator board. It is compatible with the 5-volt

KX-131 (KPC-S226CB) board camera. The input voltage

may range from 6.0VDC to 9.0VDC.

Note: On the Rev-C board, the 3-wire signal order on the

Battery input is NOT the same as the Camera side. Please

consult the photo on the right for full details.

1. The Voltage Regulator requires assembly. It uses SMD

components so advanced soldering skills are needed. The electronic components are

available from mouser.com for about $10.

QTY ITEM REF DESCRIPTION MOUSER PART NUMBER

1 .1uF C3 Capacitor 80-C0805C104J5R

1 47uF 6V C2 Capacitor 80-T491B476K006

1 47uF 16V C1 Capacitor 80-T491C476K016

1 22uH L1 Inductor 80-CBC3225T220MRK

1 DL4001 D1 Diode 833-DL4001-TP

1 KF50BDT U1 LDO VREG IC, 5V 511-KF50BDT