D+H RZN 4404-K V2 User manual

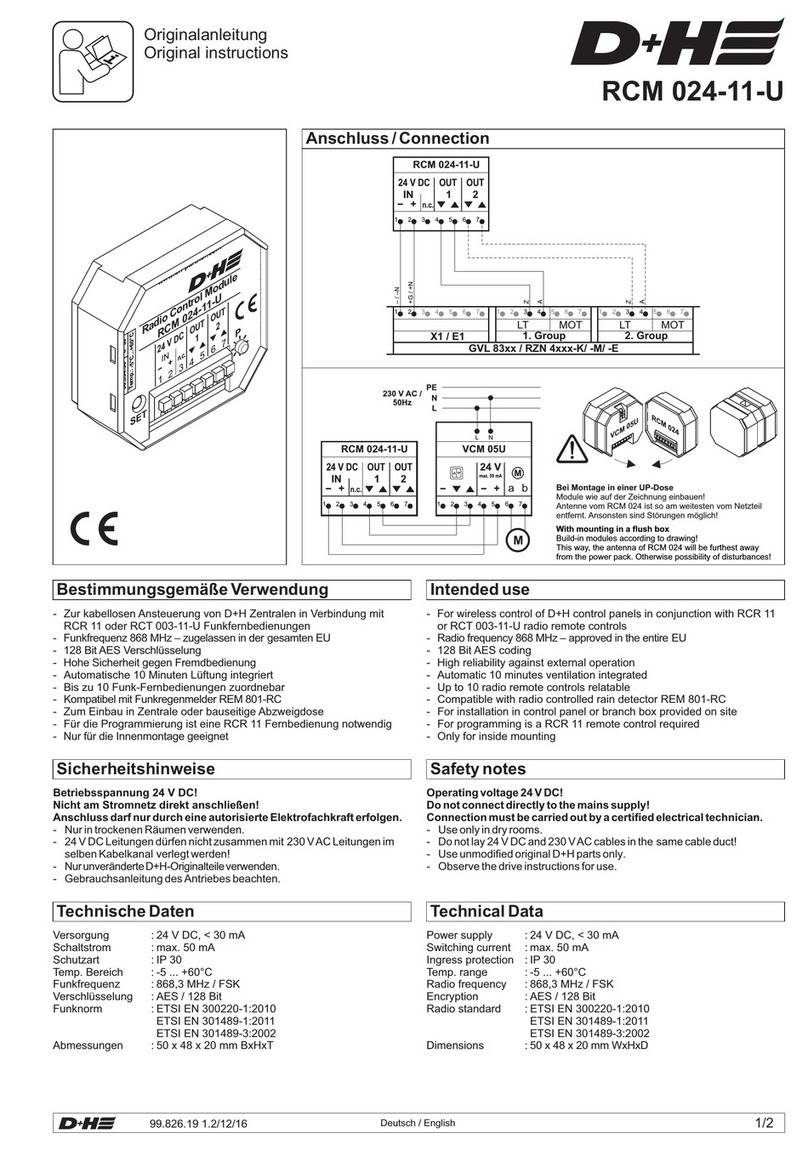

RZN 4404-K V2

RZN 4404-K V2

(ZP RZN 4404-K V2 + GEH-KST)

0786 - CPD - 50383

EN 12101-10 : 2005/AC:2007

conform

RZN 4404-KS V2

(ZP RZN 4404-K V2 + GEH-S-RWA)

Original instructions

Table of contents

Introduction / Assembly scheme.................................................................................................................3

Intended use / Safety notes........................................................................................................................4

SHEV opening ............................................................................................................................................4

Servicetimer................................................................................................................................................4

Important regulations / Repair and cleaning...............................................................................................4

Declaration of Conformity / Disposal ..........................................................................................................4

Technical data.............................................................................................................................................5

Emergency supply ......................................................................................................................................5

Pictogram explanation ................................................................................................................................5

Mounting of SHEV control panel with housing GEH-KST...........................................................................6

View motherboard.......................................................................................................................................7

DIP switch settings .....................................................................................................................................8

Cables for D+H smoke an heat vent systems / Wiring plan (Paragon) ......................................................9

230 V supply..............................................................................................................................................10

Connection overview .................................................................................................................................10

Connection of smoke vent buttons ............................................................................................................11

Connection of fire detector / Connenction of fire alarm system.................................................................12

Connection of magnetic clamps.................................................................................................................12

Drives ........................................................................................................................................................12

Information for starting...............................................................................................................................13

Operation...............................................................................................................................................14-16

Inspection / Maintenance...........................................................................................................................17

RZN 4404-K

99.823.80 3.7/06/1999.823.80 3.7/06/19

2/17 RZN 4404-K 3/36

Einleitung

D+H Service- und Vertriebspartner

Sicherheit im Gebäude entsteht nicht nur durch das

Produkt. Sicherheit entsteht vor allem durch

Kompetenz. Alle D+H Service- und Vertriebspartner

sind zertifizierte und regelmäßig geschulte RWA-

Fachbetriebe. Im engen Verbund mit der D+H

Mechatronic AG als Hersteller realisieren sie

umfassende Systemlösungen für RWA und

natürliche Gebäudelüftung. Mit ganzheitlicher

Betreuung und durchgängiger Qualitätssicherung in

allen Phasen des Projekts: von der Beratung,

Planung und Projektierung bis hin zu Installation,

Inbetriebnahme, Instandhaltung und Service. Somit

werden höchste nationale und internationale

Qualitätsstandards zuverlässig erfüllt.

Montage und Inbetriebnahme

Für die fachgerechte Montage und Inbetriebnahme

steht Ihnen das flächendeckende Netz der D+H

Service- und Vertriebspartner zur Verfügung. Unser

Partnersystem garantiert, dass D+H Produkte

ausschließlich durch ausgebildete und erfahrene

Monteure unter Beachtung der technischen

Richtlinien und Vorschriften installiert werden.

Persönliche Übergabe und die Einweisung der

Nutzer inbegriffen.

Wartung und Instandsetzung

Jeder Gebäudebetreiber ist für die Funktionssicher-

heit seiner Sicherheitseinrichtungen verantwortlich.

Die regelmäßige und fachgerechte Wartung sorgt für

die ständige Betriebsbereitschaft Ihrer Anlage. Als

RWA-Fachbetriebe sind die D+H Service- und

Vertriebspartner für die Wartung optimal qualifiziert.

Durch einen Wartungsvertrag kann der Betreiber

jederzeit nachweisen, dass er seiner Verpflichtung

nachgekommen ist.

Qualität mit Garantie

Für alle D+H RWA-Systeme, die durch einen D+H

Service- und Vertriebspartner installiert wurden und

regelmäßig gewartet werden, erhalten Sie erwei-

terte Garantieleistungen. Fragen Sie dazu Ihren

D+H Service- und Vertriebspartner vor Ort.

Immer in Ihrer Nähe

Mit unserem Netzwerk von eigenen Niederlassun-

gen und exklusiven Partnern sind wir weltweit

vertreten.

Sie suchen Ihren D+H Partner vor Ort?

Besuchen Sie einfach unsere Internetseite:

www.dh-partner.com

Linie

Gruppe

Fensterantrieb

RWA-Taster RWA-Zentrale

Lüftungstaster

Brandmelder

Regenmelder

Fremdansteuerung

OK

RWA-

Öffnung

Aufbauschema

Deutsch

RZN 4404-K 99.823.80 3.7/06/1999.823.80 3.7/06/19

18/36 RZN 4404-K 3/17

Line

Group

Window drive

SHEV button SHEV control panel

Ventilation button

Fire detector

Rain detector

External control

OK

SHEV opening

Assembly scheme

Introduction

D+H service and sales partners

Safety in the building not only comes from the

product. Above all, safety results from competence.

All D+H service and sales partners are certified and

regularly trained specialist SHEV businesses.

Working closely with D+H Mechatronic AG as the

manufacturer, they develop comprehensive system

solutions for SHEVs and natural building ventilation.

With integral customer support and continuous

quality assurance in all phases of the project: from

sales advice, planning and project management

through to installation, commissioning, repair and

service. The highest national and international

quality standards are therefore reliably fulfilled.

Installation and operation

The comprehensive network of D+H service and

sales partners is at your disposal to professionally

install your system and commission it. Our partner

system guarantees that D+H products are installed

exclusively by trained and experienced fitters, in

compliance with the technical guidelines and

specifications. Personal handover and training for

users is included.

Maintenance and repair

Every building operator is responsible for ensuring

that its safety equipment works reliably. Regular and

professional maintenance ensures that your system

is always operational. As specialist SHEV

businesses, the D+H service and sales partners are

best qualified to carry out maintenance. By taking out

a maintenance contract, operators can prove at all

times that they have fulfilled their obligations.

Quality with guarantee

For all D+H SHEV systems, which have been

installed by a D+H service and sales partner and are

regularly serviced, you will receive extended

warranty services. Ask your local D+H service and

sales partner about this.

Always nearby

With the network of our own subsidiaries and

exclusive partners, we are represented nearly all

over the world.

Are you looking for your local D+H partner?

Simply visit our website:

www.dh-partner.com

English

RZN 4404-K

99.823.80 3.7/06/1999.823.80 3.7/06/19

4/17 RZN 4404-K 21/36

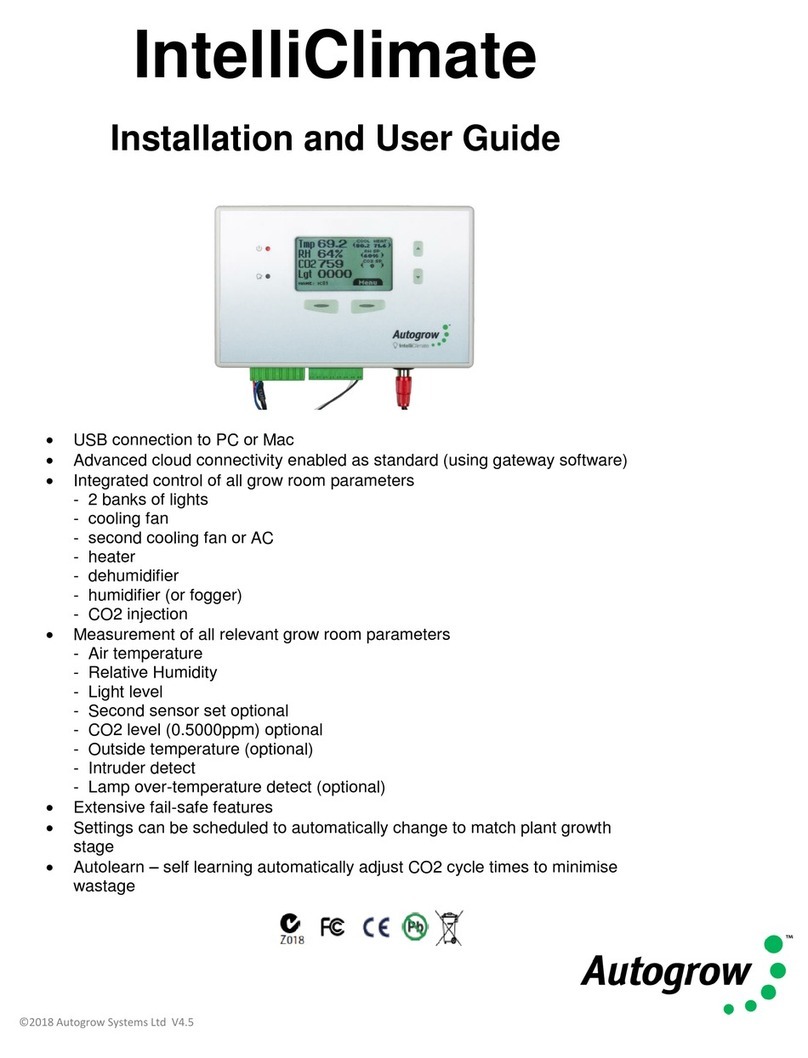

Intended use

- SHEV control panel in particular for staircases

- Microprocessor based control panel

- 1 line, 1 group

- 4A actuating current

- Comfort functions for daily ventilation

- Only for inside mounting

Operating voltage 230 V AC!

Risk of injury from electric shock!

- Connection has to be carried out only by an

authorized electrical specialist

- Only for inside mounting

- Just use unchanged original D+H parts

Safety notes

Smoke gases are to be carried off as unhindered

as possible through smoke and heat vent opening

in case of fire. Size, kind and arrangement of the

opening is of decisive significance for an optimal

effect of the smoke and heat vent system.

These requirements are defined in the relevant

regulations of the respective country.

More informations, are also available under

www.rwa-heute.de.

The SHEV opening should be coordinated with the

responsible fire protection authority.

SHEV opening

An overdue maintenance of the system will be

indicated by the control panel after about ca. 14 to

16 months.

The yellow LED in the smoke vent button will start

flashing.

A malfunction of the smoke vent system will be still

indicated by the extinction of the green LED in the

smoke vent button.

After the maintenance time is expired (approx. 14

to 16 months), the ventilation function OPEN can

be interrupted depending on the presetting of the

service timer.

Attention: Reset of the service timer can be

carried out by a specialist company only, who

has been authorized by the appliance

manufacturer.

Servicetimer

Inspection and maintenance has to be carried out

according to D+H maintenance notes. Only original

D+H spare parts may be used. Repair is to be

carried out exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Repair and cleaning

Observe regulations for danger warning systems

VDE 0833, guidelines for electrical systems VdS

2221, VDE 0100, DIN 18232 for smoke and heat

vent systems, regulations of the local fire-brigade

and of EVU for connection to mains supply.

Important regulations

Type ZP RZN 4404-K V2

Power supply 230 V AC, 50 Hz

Rated power 120 VA

Stand-by operating 5,8 W

Output voltage 24 V DC

Ripple 2 Vss, load-dependent

Output rated current 4 A

Number of lines / groups * 1 / 1

Fire detector per line max. 14 pcs.

SHEV button per line max. 8pcs.

Current per group ** max. 4 A

Mode of operation

- Monitoring Continuous duty

- Alarm / Ventilation Short-time duty (30 % DC)

Temperature range -5 ... +40 °C

* D+H Highspeed (HS) drives will be supported.

** The total current of the control panel must not be exceeded.

Housing GEH-KST GEH-S-RWA

Material Plastic with steel sheet door Steel sheet

Colour white light grey

Ingress protection IP 30 IP 54

Protection class II, with fuctional ground I

Dimensions WxHxD 310 x 310 x 100 mm 400 x 300 x 120 mm

Technical data

SHEV alarm

Malfunction

Mains existing

Vent button function "OPEN"

Smoke-/ vent button function "CLOSE"

Charging voltage regulator

Ground short

OPEN running time limitation

ventilation time limitation

Pictogram explanation

D+H window drive

OK Control panel O.K.

min

15

245

30

sec

20

260

40

English

WARNING

Read all safety warnings, instructions, illustrations

and specifications provided with this product.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

Electrical devices, accessories, batteries and packa-

ging should be sorted for environmental-friendly

recycling. Do not dispose electrical devices and

batteries into household waste!

Only for EC countries:

According the European Guideline 2012/19/EU for

waste electrical and electronic equipment and its

implementation into national right, electrcal devices

that are no longer usable must be collected separa-

tely and disposed of in an environmentally correct

manner.

Disposal

Declaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in

conformity with the following directives:

2014/30/EU, 2014/35/EU

Technical file at:

D+H Mechatronic AG, D-22949 Ammersbek

Dirk Dingfelder Maik Schmees

Member of the Board Authorized signatory, Technical Director

20.03.2018

24 V - Emergency supply

Emergency power supply for 72 hours.

Use VdS approved storage batteries only!

2x 12V / 2,2 Ah ±0,3Ah (Type 2)

With connection of D+H alarm devices:

2x 12V / 3,4 Ah ±0,3 Ah (Type 8)

If the control panel is only operated with a max.

output current of 2 A, the following batteries are

sufficient for the emergency supply:

2x 12V / 1,2 Ah ±0,2Ah (Type 1)

With connection of D+H alarm devices:

2x 12V / 2,2 Ah ±0,3 Ah (Type 2)

RZN 4404-K 99.823.80 3.7/06/1999.823.80 3.7/06/19

20/36 RZN 4404-K 5/17

Intended use

- SHEV control panel in particular for staircases

- Microprocessor based control panel

- 1 line, 1 group

- 4A actuating current

- Comfort functions for daily ventilation

- Only for inside mounting

Operating voltage 230 V AC!

Risk of injury from electric shock!

- Connection has to be carried out only by an

authorized electrical specialist

- Only for inside mounting

- Just use unchanged original D+H parts

Safety notes

Smoke gases are to be carried off as unhindered

as possible through smoke and heat vent opening

in case of fire. Size, kind and arrangement of the

opening is of decisive significance for an optimal

effect of the smoke and heat vent system.

These requirements are defined in the relevant

regulations of the respective country.

More informations, are also available under

www.rwa-heute.de.

The SHEV opening should be coordinated with the

responsible fire protection authority.

SHEV opening

An overdue maintenance of the system will be

indicated by the control panel after about ca. 14 to

16 months.

The yellow LED in the smoke vent button will start

flashing.

A malfunction of the smoke vent system will be still

indicated by the extinction of the green LED in the

smoke vent button.

After the maintenance time is expired (approx. 14

to 16 months), the ventilation function OPEN can

be interrupted depending on the presetting of the

service timer.

Attention: Reset of the service timer can be

carried out by a specialist company only, who

has been authorized by the appliance

manufacturer.

Servicetimer

Inspection and maintenance has to be carried out

according to D+H maintenance notes. Only original

D+H spare parts may be used. Repair is to be

carried out exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Repair and cleaning

Observe regulations for danger warning systems

VDE 0833, guidelines for electrical systems VdS

2221, VDE 0100, DIN 18232 for smoke and heat

vent systems, regulations of the local fire-brigade

and of EVU for connection to mains supply.

Important regulations

Type ZP RZN 4404-K V2

Power supply 230 V AC, 50 Hz

Rated power 120 VA

Stand-by operating 5,8 W

Output voltage 24 V DC

Ripple 2 Vss, load-dependent

Output rated current 4 A

Number of lines / groups * 1 / 1

Fire detector per line max. 14 pcs.

SHEV button per line max. 8pcs.

Current per group ** max. 4 A

Mode of operation

- Monitoring Continuous duty

- Alarm / Ventilation Short-time duty (30 % DC)

Temperature range -5 ... +40 °C

* D+H Highspeed (HS) drives will be supported.

** The total current of the control panel must not be exceeded.

Housing GEH-KST GEH-S-RWA

Material Plastic with steel sheet door Steel sheet

Colour white light grey

Ingress protection IP 30 IP 54

Protection class II, with fuctional ground I

Dimensions WxHxD 310 x 310 x 100 mm 400 x 300 x 120 mm

Technical data

SHEV alarm

Malfunction

Mains existing

Vent button function "OPEN"

Smoke-/ vent button function "CLOSE"

Charging voltage regulator

Ground short

OPEN running time limitation

ventilation time limitation

Pictogram explanation

D+H window drive

OK Control panel O.K.

min

15

245

30

sec

20

260

40

English

WARNING

Read all safety warnings, instructions, illustrations

and specifications provided with this product.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

Electrical devices, accessories, batteries and packa-

ging should be sorted for environmental-friendly

recycling. Do not dispose electrical devices and

batteries into household waste!

Only for EC countries:

According the European Guideline 2012/19/EU for

waste electrical and electronic equipment and its

implementation into national right, electrcal devices

that are no longer usable must be collected separa-

tely and disposed of in an environmentally correct

manner.

Disposal

Declaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in

conformity with the following directives:

2014/30/EU, 2014/35/EU

Technical file at:

D+H Mechatronic AG, D-22949 Ammersbek

Dirk Dingfelder Maik Schmees

Member of the Board Authorized signatory, Technical Director

20.03.2018

24 V - Emergency supply

Emergency power supply for 72 hours.

Use VdS approved storage batteries only!

2x 12V / 2,2 Ah ±0,3Ah (Type 2)

With connection of D+H alarm devices:

2x 12V / 3,4 Ah ±0,3 Ah (Type 8)

If the control panel is only operated with a max.

output current of 2 A, the following batteries are

sufficient for the emergency supply:

2x 12V / 1,2 Ah ±0,2Ah (Type 1)

With connection of D+H alarm devices:

2x 12V / 2,2 Ah ±0,3 Ah (Type 2)

RZN 4404-K

99.823.80 3.7/06/1999.823.80 3.7/06/19

6/17 RZN 4404-K 23/36

01

02

03

04

05

06

07

08

09

10

11

12

13

14

01

02

03

04

05

06

07

08

09

10

11

12

13

14

A B C

ZP RZN 4404-K V2

ןשע תאצוה

ΕΞΑΕΡΙΣΜΟΣ ΚΑΠΝΟΥ

DUMAN ATIŞ

DŪMU NOVADIŠANA

RØYKVENTILASJON

SAVUNPOISTO

EVACUAZIONE FUMI

ДИМОВИДАЛЕННЯ

ДЫМОУДАЛЕНИЕ

LT

SUITSUEEMALDUS

DESENFUMAGEM

EVACUARE FUM

ROOKAFVOER

R Ø G L E M

ODDYMIANIE

EVACUACIÓN DE HUMOS

DESENFUMAGE

ODVOD KOUŘE

ODVOD DYMU

BRANDVENTILATION

2 x 1,2 Ah

2 x 3,4 Ah

Ø max. 5 mm

(not included)

4x

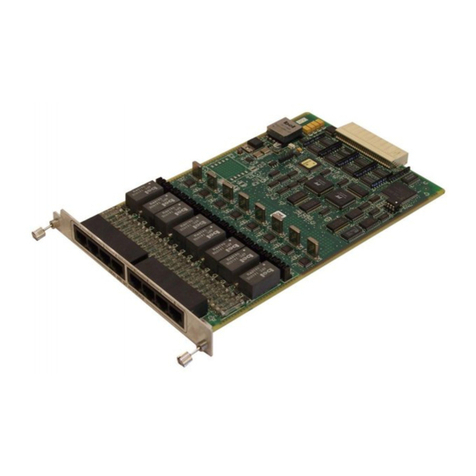

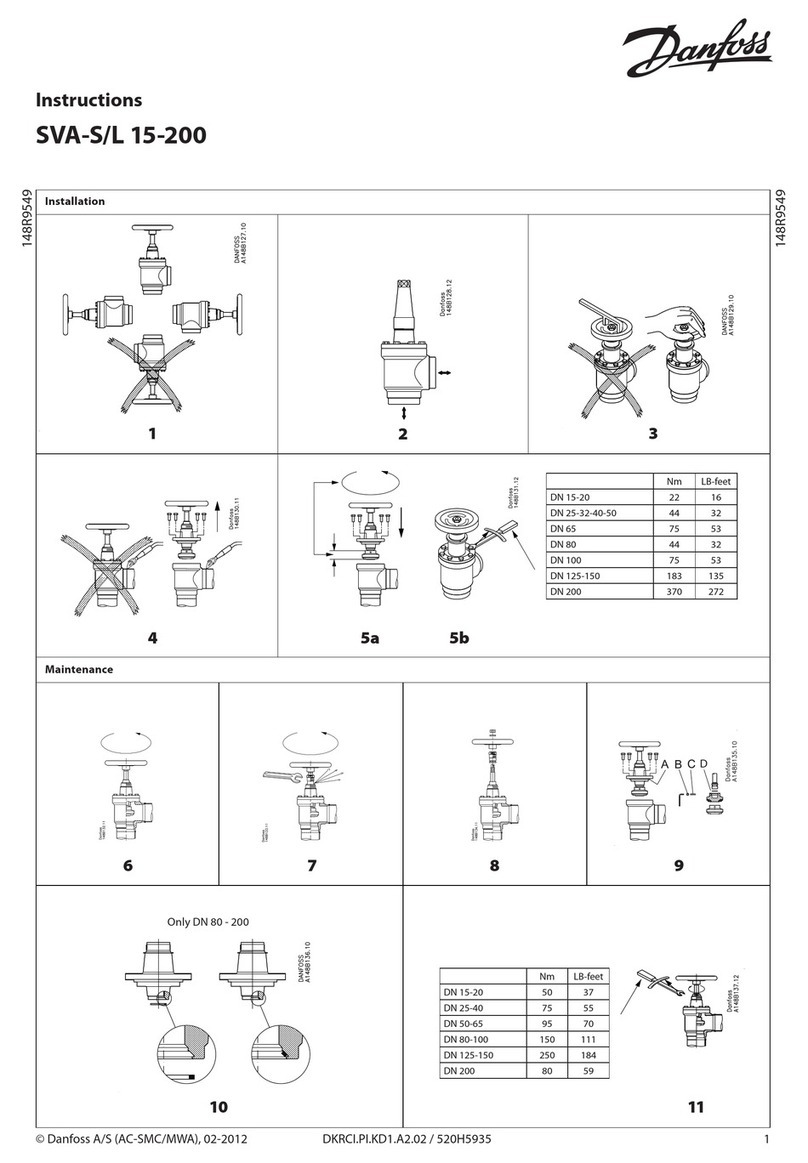

Install batteries: Position of the central pcb:

Mount control panel sheltered and easily accessible for

maintenance in proximity of drive.

Detailed installation instructions are supplied with the housing.

Mounting of SHEV control panel with housing GEH-KST

2x 2,2 Ah

2x 1,2 Ah /

2x 3,4 Ah

GEH-KST

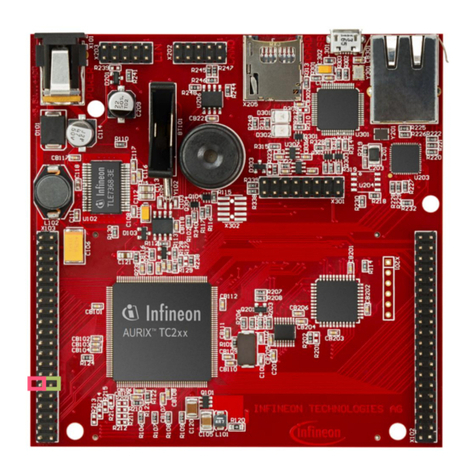

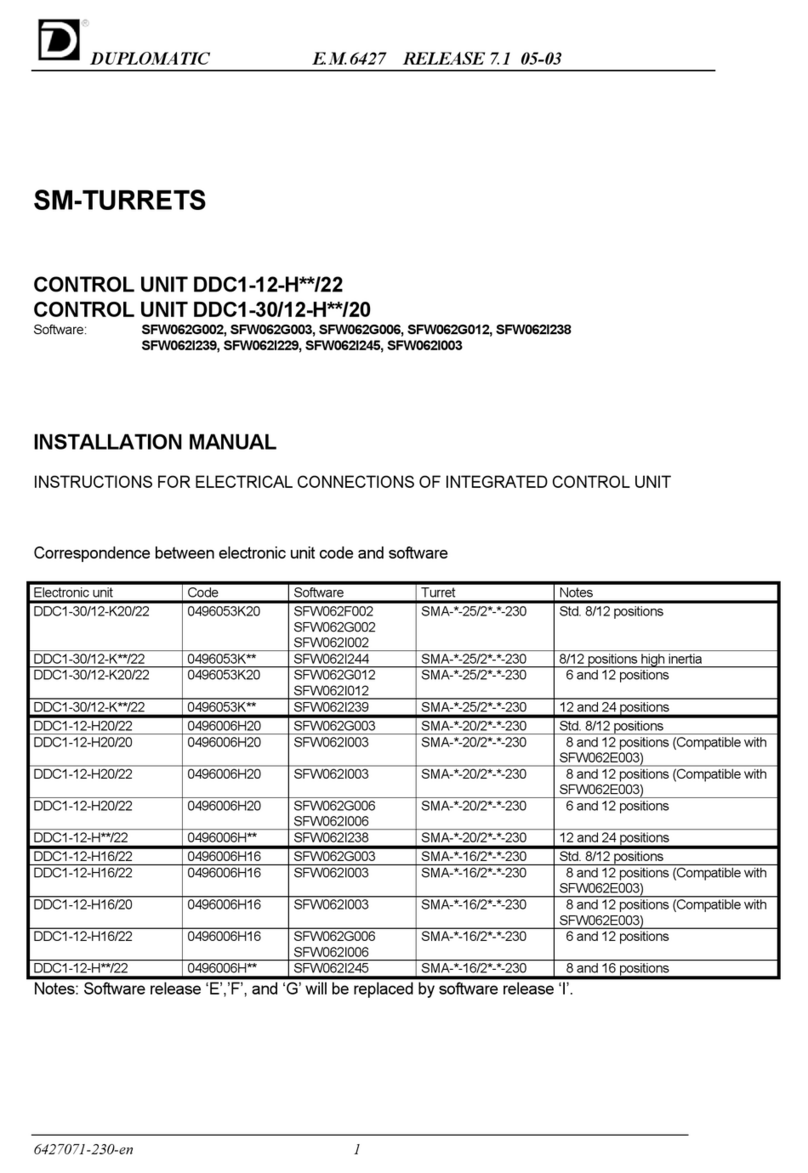

View motherboard

sec

20

260

40

min

15

245

30

F1.25A

Reset

0

I

S 1

Ext.

Signals Ventilation System

Line Group

U

F.315A

Fx.xA

Battery

Rauchabzugszentrale

Smoke Vent Controller

2x12V/

x.xAh

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7

www.dh-partner.com

D+H Mechatronic - Germany - +49 40 605 65 0

IP

30

VDS-Nr.:

RZN 4404-K/KS V2

IN :

OUT :

Temp. -5°C...40°C

Mains supply

Fire recognation

element*

Fuse drive

LED malfunction

group

LED control

LED alarm

line

LED malfunction

line

LED mains

Fuse ext. signal

DIP switch S1

Fuse mains

Battery charging

voltage regulator

Battery

connection

LED battery fault

Fuse battery

OPEN running

time limitation

Ventilation

time limitation

Line ON-

OFF-RESET

D1

D47 D42 D20 D79

D14

– +

– : Emergency-supplied potential -

+ : Emergency-supplied potential +

N– : Not emergency-supplied potential -

N+ : Not emergency-supplied potential +

A : General alarm

K : Control

S : General fault

M : Magnetic clamp control

Z : Input, central function, closing of group

* For monitoring of the internal temperature of the control device. If the

internal temperature is exceeding 72°C (caused by radiant heat of a

fire in immediate vicinity of the mounting place), the entire smoke and

heat vent system will be emergency opened under alarm conditions.

English

RZN 4404-K 99.823.80 3.7/06/1999.823.80 3.7/06/19

22/36 RZN 4404-K 7/17

01

02

03

04

05

06

07

08

09

10

11

12

13

14

01

02

03

04

05

06

07

08

09

10

11

12

13

14

A B C

ZP RZN 4404-K V2

ןשע תאצוה

ΕΞΑΕΡΙΣΜΟΣ ΚΑΠΝΟΥ

DUMAN ATIŞ

DŪMU NOVADIŠANA

RØYKVENTILASJON

SAVUNPOISTO

EVACUAZIONE FUMI

ДИМОВИДАЛЕННЯ

ДЫМОУДАЛЕНИЕ

LT

SUITSUEEMALDUS

DESENFUMAGEM

EVACUARE FUM

ROOKAFVOER

R Ø G L E M

ODDYMIANIE

EVACUACIÓN DE HUMOS

DESENFUMAGE

ODVOD KOUŘE

ODVOD DYMU

BRANDVENTILATION

2 x 1,2 Ah

2 x 3,4 Ah

Ø max. 5 mm

(not included)

4x

Install batteries: Position of the central pcb:

Mount control panel sheltered and easily accessible for

maintenance in proximity of drive.

Detailed installation instructions are supplied with the housing.

Mounting of SHEV control panel with housing GEH-KST

2x 2,2 Ah

2x 1,2 Ah /

2x 3,4 Ah

GEH-KST

View motherboard

sec

20

260

40

min

15

245

30

F1.25A

Reset

0

I

S 1

Ext.

Signals Ventilation System

Line Group

U

F.315A

Fx.xA

Battery

Rauchabzugszentrale

Smoke Vent Controller

2x12V/

x.xAh

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7

www.dh-partner.com

D+H Mechatronic - Germany - +49 40 605 65 0

IP

30

VDS-Nr.:

RZN 4404-K/KS V2

IN :

OUT :

Temp. -5°C...40°C

Mains supply

Fire recognation

element*

Fuse drive

LED malfunction

group

LED control

LED alarm

line

LED malfunction

line

LED mains

Fuse ext. signal

DIP switch S1

Fuse mains

Battery charging

voltage regulator

Battery

connection

LED battery fault

Fuse battery

OPEN running

time limitation

Ventilation

time limitation

Line ON-

OFF-RESET

D1

D47 D42 D20 D79

D14

– +

–: Emergency-supplied potential -

+: Emergency-supplied potential +

N– : Not emergency-supplied potential -

N+ : Not emergency-supplied potential +

A : General alarm

K : Control

S : General fault

M : Magnetic clamp control

Z : Input, central function, closing of group

* For monitoring of the internal temperature of the control device. If the

internal temperature is exceeding 72°C (caused by radiant heat of a

fire in immediate vicinity of the mounting place), the entire smoke and

heat vent system will be emergency opened under alarm conditions.

English

RZN 4404-K

99.823.80 3.7/06/1999.823.80 3.7/06/19

8/17 RZN 4404-K 25/36

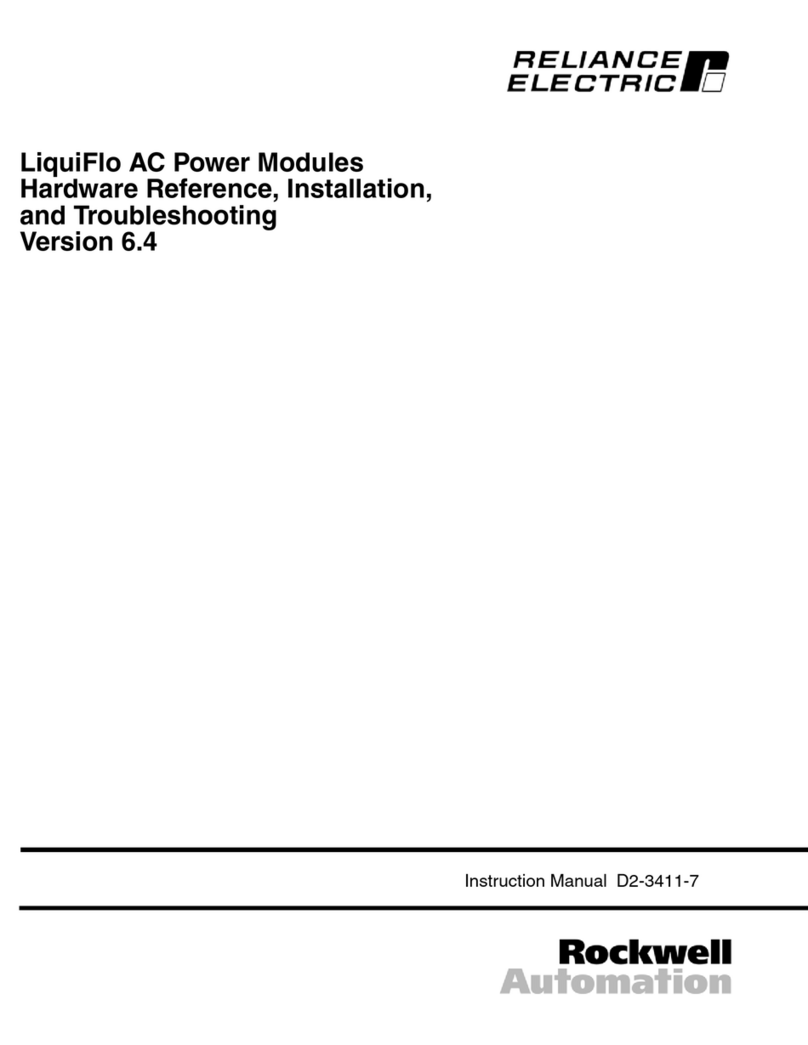

DIP switch settings

Delivery condition S1

123456789

10

ON

1 = ON OPEN-running time limitation in ventilation operation (Only if DIP switch 6 = ON).

Using a potentiometer, running time in OPEN direction can be limited.

If the vent button is actuated in OPEN direction, the drive will run open as long as

the running time is set.

2 = ON Ventilation time limitation (Only if DIP switch 5 = ON).

Using a potentiometer, ventilation tim can be set.

Drives will automatically close again, after the adjusted time has expired.

3 = ON OPEN-retriggering (Only if DIP switch 1 = ON)

The OPEN-running time limitation can be retriggered again.

4 = ON Power failure "CLOSE" (Only if DIP switch 5 = ON).

In case of power failure the drives will close.

5 = ON Drives CLOSE up to final position by single pressing on vent button

5 = OFF Drives are closing only so long as the vent button or the button "close SHEV" in the

smoke vent button is pressed. OPEN-display on vent button is no longer possible then!

The function power failure-CLOSE will be ineffective (see DIP switch 4).

6 = ON Drives OPEN up to final position by single pressing on vent button.

6 = OFF Drives are opening only so long as the vent button is pressed.

7 = ON In case of a line fault (e.g. at an interrupted detector line or short circuit) the control panel

will be switched on alarm, that means the smoke vent opens.

8 = ON In case of a group fault (e.g. in case of an interrupted monitoring line) the control panel will

be switched on alarm, that means the smoke vent opens.

DIP switch must be on ON in conjunction with a ground in thermal maximal detector (e.g.

THE4).

9 = ON Smoke detector alarm can not be reset by single pressing on the button "close SHEV" in

the smoke vent button.

9 = OFF Smoke detector alarm will be reset by pressing on the button "close SHEV" in the smoke

vent button.

10 = ON SHEV retriggering on. The smoke vent is triggered for a duration of 30 minutes in intervals

of 2 minutes according to VdS 2581.

min

15

245

30

sec

20

260

40

Cables for D+H smoke an heat vent systems

When selecting and installing the cables, the

regional electrical installation regulations

concerning wiring systems and the necessary

safety equipment, or guidelines on integrity

maintenance of electric lines are observed (e.g.

MLAR).

Notice:

No type designation is given for these cables,

because of a large variety on the market.

Please consult your D+H partner.

Wiring plan (Paragon)

Line lenghts and cross sections

Cross section (mm²) = Cable lenght (m) x Total current

80

RZN 4404 - K

0,5

240

400

1

120

200

1,5

80

130

2

60

100

2,5

48

80

3

40

65

3,5

34

55

4

30

50 m

m

Type

Total current

3 x 1,5 mm²

3 x 2,5 mm²

Group cable (control panel - drive)

At least three wire design:

- 2 wires for the supply of the drive

- 1 wire for line monitoring, on which also the

SHEV high speed (HS) signal is transmitted to the

drive. If group DIP switch 8 is ON, the group will in

case of a fault automatically triggered and opens.

Line cable (control panel - detector)

The cables are monitored for short circuit and for

interruption. If line DIP switch 7 is ON, the group

will in case of a fault automatically triggered and

opens.

230 V, 50 Hz

Seperate electric circuit.

Mark fuse.

to further ones

see line lenghts and cross sections

Drive at smoke

vent opening SHEV control panel

Vent button

approx. 1,2 m

above upper edge

firm flooring Smoke vent button

approx. 1,5 m above

upper edge firm flooring

External control

4x 0,8 Ø

6x 0,8 Ø (RT 45)

10x 0,8 Ø (RT 45-LT)

6x 0,8 Ø (RT 45)

10x 0,8 Ø (RT 45-LT)

2x 0,8 Ø

2x 0,8 Ø

OK

OK

Rain detector

3x 0,8 Ø

System voltage 24 V!

Do not run cables with together power lines!

In case of a cable with ground wire (green /

yellow) this must not be used!

Cable and terminal boxes have to be labeled.

English

Fire detector

SD-O 371 or FD-T 271

RZN 4404-K 99.823.80 3.7/06/1999.823.80 3.7/06/19

24/36 RZN 4404-K 9/17

DIP switch settings

Delivery condition S1

123456789

10

ON

1 = ON OPEN-running time limitation in ventilation operation (Only if DIP switch 6 = ON).

Using a potentiometer, running time in OPEN direction can be limited.

If the vent button is actuated in OPEN direction, the drive will run open as long as

the running time is set.

2 = ON Ventilation time limitation (Only if DIP switch 5 = ON).

Using a potentiometer, ventilation tim can be set.

Drives will automatically close again, after the adjusted time has expired.

3 = ON OPEN-retriggering (Only if DIP switch 1 = ON)

The OPEN-running time limitation can be retriggered again.

4 = ON Power failure "CLOSE" (Only if DIP switch 5 = ON).

In case of power failure the drives will close.

5 = ON Drives CLOSE up to final position by single pressing on vent button

5 = OFF Drives are closing only so long as the vent button or the button "close SHEV" in the

smoke vent button is pressed. OPEN-display on vent button is no longer possible then!

The function power failure-CLOSE will be ineffective (see DIP switch 4).

6 = ON Drives OPEN up to final position by single pressing on vent button.

6 = OFF Drives are opening only so long as the vent button is pressed.

7 = ON In case of a line fault (e.g. at an interrupted detector line or short circuit) the control panel

will be switched on alarm, that means the smoke vent opens.

8 = ON In case of a group fault (e.g. in case of an interrupted monitoring line) the control panel will

be switched on alarm, that means the smoke vent opens.

DIP switch must be on ON in conjunction with a ground in thermal maximal detector (e.g.

THE4).

9 = ON Smoke detector alarm can not be reset by single pressing on the button "close SHEV" in

the smoke vent button.

9 = OFF Smoke detector alarm will be reset by pressing on the button "close SHEV" in the smoke

vent button.

10 = ON SHEV retriggering on. The smoke vent is triggered for a duration of 30 minutes in intervals

of 2 minutes according to VdS 2581.

min

15

245

30

sec

20

260

40

Cables for D+H smoke an heat vent systems

When selecting and installing the cables, the

regional electrical installation regulations

concerning wiring systems and the necessary

safety equipment, or guidelines on integrity

maintenance of electric lines are observed (e.g.

MLAR).

Notice:

No type designation is given for these cables,

because of a large variety on the market.

Please consult your D+H partner.

Wiring plan (Paragon)

Line lenghts and cross sections

Cross section (mm²) = Cable lenght (m) x Total current

80

RZN 4404 - K

0,5

240

400

1

120

200

1,5

80

130

2

60

100

2,5

48

80

3

40

65

3,5

34

55

4

30

50 m

m

Type

Total current

3 x 1,5 mm²

3 x 2,5 mm²

Group cable (control panel - drive)

At least three wire design:

- 2 wires for the supply of the drive

- 1 wire for line monitoring, on which also the

SHEV high speed (HS) signal is transmitted to the

drive. If group DIP switch 8 is ON, the group will in

case of a fault automatically triggered and opens.

Line cable (control panel - detector)

The cables are monitored for short circuit and for

interruption. If line DIP switch 7 is ON, the group

will in case of a fault automatically triggered and

opens.

230 V, 50 Hz

Seperate electric circuit.

Mark fuse.

to further ones

see line lenghts and cross sections

Drive at smoke

vent opening SHEV control panel

Vent button

approx. 1,2 m

above upper edge

firm flooring Smoke vent button

approx. 1,5 m above

upper edge firm flooring

External control

4x 0,8 Ø

6x 0,8 Ø (RT 45)

10x 0,8 Ø (RT 45-LT)

6x 0,8 Ø (RT 45)

10x 0,8 Ø (RT 45-LT)

2x 0,8 Ø

2x 0,8 Ø

OK

OK

Rain detector

3x 0,8 Ø

System voltage 24 V!

Do not run cables with together power lines!

In case of a cable with ground wire (green /

yellow) this must not be used!

Cable and terminal boxes have to be labeled.

English

Fire detector

SD-O 371 or FD-T 271

RZN 4404-K

99.823.80 3.7/06/1999.823.80 3.7/06/19

10/17 RZN 4404-K 27/36

Connection overview

230 V, 50 Hz

Seperate electric circuit..

Mark fuse.

230 V supply

Protective earth (PE)

Only with KS-Version.

Protection cap:

Place enclosed protection cap

over supply terminal after mains

cable has been connected.

L

N

PE

2

8

316475

RT 45

28316475

RT 45

28316475

OK

Line

T

R– A– K EA aZ bS

RZN 4404-K V2

Line

–

N–

Control

Alarm

CLOSE

Mot.b

Mot.a

Monitoring

OPEN

CLOSE

Open signal (only with LT 43U-SD)

RM LT

10kW

Failure

Alarm

Control

–

Line

CLOSE

Failure

n.c.

RT MOT

10kW

OK

L N– Z

LT 84-U (-SD)

LP

EM 47 K

2x47kW

(BK)

(BK)

(OG)

Mot.b

Mot.a

HS

Drive

Mot.b

Mot.a

HS

Connection of smoke vent buttons

Max. 8 buttons per line connectable.

Standard connection Parallel connection

Parallel connection of 2x 2 buttons

2

8

316475

RT 45

first to penultimate

button

28316475

RT 45

28316475

OK

last button

Line

345678

RZN 4404-K V2

Line

–

Control

Alarm

CLSOE

RM

10kW

Failure

Alarm

Control

–

Line

CLOSE

Failure

n.c.

RT

Line

n.c.

Failure

345678

RZN 4404-K V2

Line

–

Control

Alarm

CLOSE

RM

10kW

Alarm

Control

–

Line

Line

CLOSE

Failure

**

* Shunt connection by customer

Alarm

Control

–

Line

CLOSE

Failure

n.c.

RT

28316475

RT 45

28316475

OK

28316475

RT 45

28316475

OK

2

8

316475

RT 45

2

8

316475

RT 45

first to penultimate

button each

last button each

Line

n.c.

Failure

345678

RZN 4404-K V2

Line

–

Control

Alarm

CLOSE

RM

Alarm

Control

–

Line

Line

CLOSE

Failure

**

Alarm

Control

–

Line

CLOSE

Failure

n.c.

RT

* Shunt connection by customer

10kW

28316475

RT 45

28316475

OK

28316475

RT 45

28316475

OK

English

32

5

SD-O 371

32

SD-O 371

5

RZN 4404-K 99.823.80 3.7/06/1999.823.80 3.7/06/19

26/36 RZN 4404-K 11/17

Connection overview

230 V, 50 Hz

Seperate electric circuit..

Mark fuse.

230 V supply

Protective earth (PE)

Only with KS-Version.

Protection cap:

Place enclosed protection cap

over supply terminal after mains

cable has been connected.

L

N

PE

2

8

316475

RT 45

28316475

RT 45

28316475

OK

Line

T

R– A– K EA aZ bS

RZN 4404-K V2

Line

–

N–

Control

Alarm

CLOSE

Mot.b

Mot.a

Monitoring

OPEN

CLOSE

Open signal (only with LT 43U-SD)

RM LT

10kW

Failure

Alarm

Control

–

Line

CLOSE

Failure

n.c.

RT MOT

10kW

OK

L N– Z

LT 84-U (-SD)

LP

EM 47 K

2x47kW

(BK)

(BK)

(OG)

Mot.b

Mot.a

HS

Drive

Mot.b

Mot.a

HS

Connection of smoke vent buttons

Max. 8 buttons per line connectable.

Standard connection Parallel connection

Parallel connection of 2x 2 buttons

2

8

316475

RT 45

first to penultimate

button

28316475

RT 45

28316475

OK

last button

Line

345678

RZN 4404-K V2

Line

–

Control

Alarm

CLSOE

RM

10kW

Failure

Alarm

Control

–

Line

CLOSE

Failure

n.c.

RT

Line

n.c.

Failure

345678

RZN 4404-K V2

Line

–

Control

Alarm

CLOSE

RM

10kW

Alarm

Control

–

Line

Line

CLOSE

Failure

**

* Shunt connection by customer

Alarm

Control

–

Line

CLOSE

Failure

n.c.

RT

28316475

RT 45

28316475

OK

28316475

RT 45

28316475

OK

2

8

316475

RT 45

2

8

316475

RT 45

first to penultimate

button each

last button each

Line

n.c.

Failure

345678

RZN 4404-K V2

Line

–

Control

Alarm

CLOSE

RM

Alarm

Control

–

Line

Line

CLOSE

Failure

**

Alarm

Control

–

Line

CLOSE

Failure

n.c.

RT

* Shunt connection by customer

10kW

28316475

RT 45

28316475

OK

28316475

RT 45

28316475

OK

English

32

5

SD-O 371

32

SD-O 371

5

-+

-+

N– N+ Z + M D1 D2

Cutout

button

Magnetic

clamps

RZN 4404-K

99.823.80 3.7/06/1999.823.80 3.7/06/19

12/17 RZN 4404-K 29/36

Connection of magnetic clamps

Magnetic clamps 24V (max. 500 mA overall power)

No output voltage during power failure! Group output:

While an alert, a possible group disturbance will

not notified. Only after reset the alarm, a fault

message will be indicated.

High-speed function (HS):

All D+H drives with SHEV high-speed function are

supported. In daily ventilation operation, a consi-

derable noise reduction is achieved through the

reduced drive speed. In case of SHEV the drives

run with a very high speed to reach the OPEN

position defined within 60 seconds at the most.

SHEV retriggering:

(When DIP switch S1.10 = ON)

The smoke vents will be triggered with an OPEN-

impulse every 2 minutes for a duration of 30

minutes according to VdS 2581. For this, the

drives must be blockage safe. All D+H drives meet

this precondition. Otherwise the DIP switches has

to be switched on OFF.

Mounting of the drives:

Please take mounting informations from the

relevant instruction for use of the respective drive,

because of varied possibilities for choosing drives.

Drives

Connection of fire detector

Max. 14 fire detectors connectable.

Only D+H approved detectors must be used.

* Terminal resistors for line monitoring

It is pinched in control panel for transport.

Take it off there and connect according to plan.

Terminal resistor must remain at terminal RM 1,2,

when no fire detector or external control exists!

Connection of fire alarm system

English

Informations for starting

Carry out following sight and performance checks for switching-on the smoke and heat vent

control panel.

All cables

connected?

Factory set?

(DIP switch)

10kΩ resistor in

smoke vent

button?

End module

2x47kΩ

in junction box?

Connect mains.

LED mains lightens?

Connect battery

lines. Control l

ightens?

Smoke vent flap opens

and closes?

All necessary moving loads connected?

Smoke vent components are line-monitored.

A malfunction is connected as alarm in delivery condition of

control panel. The smoke vent opens self-acting and can be

reset under special conditions only.

yes

yes

yes

yes

yes

yes

yes

Performance check alarm/reset and ventilation

yes

Partial or incomplete connection of

components can cause malfunction.

Check following connections: mains 230 V,

drives, smoke vent buttons, when necessary

fire detectors and vent buttons.

See wiring an connection plans pages 26-28.

Delivery condition of DIP switch see page 24.

Resistor must be cramped in electric last

button on terminal 3/8 (RT 45).

See connection plan pages 26-27.

Resistor must be cramped in last or only fire

detector on terminal 3 and 5 (type SD-O/FD-T).

Resistor remains in control panel between

terminal RM "R" and "–", when no fire

detector is connected.

See connection plan page28.

10kΩ resistor in fire

detector?

yes

End module on last or only drive in junction

box on wire 5 orange, 6 black, 7 black.

See connection plan page 26.

Check line safety fuse in distribution box and

fuse mains in control panel.

Mains still not available or line switch on "0"

or one of fuses faulty.

Possibly change poles in drive.

no

no

no

no

no

no

no

no

R

Operating contact

Alarm resistor

1kW

BMZ / BMA

Terminal resistor*

10kW

RZN 4404-K V2

RM RT

1 2

–

first to penultimate

fire detector

last

fire detector

SD-O 371

or

FD-T 271

RZN 4404-K V2

RM RT

1 2

–

R

EP 6

EM 2

1

C 3

IN 4

OUT 5

EP 6

EM 2

1

C 3

IN 4

OUT 5

< optional >

10 kW

-+

-+

N– N+ Z + M D1 D2

Cutout

button

Magnetic

clamps

RZN 4404-K 99.823.80 3.7/06/1999.823.80 3.7/06/19

28/36 RZN 4404-K 13/17

Connection of magnetic clamps

Magnetic clamps 24V (max. 500 mA overall power)

No output voltage during power failure! Group output:

While an alert, a possible group disturbance will

not notified. Only after reset the alarm, a fault

message will be indicated.

High-speed function (HS):

All D+H drives with SHEV high-speed function are

supported. In daily ventilation operation, a consi-

derable noise reduction is achieved through the

reduced drive speed. In case of SHEV the drives

run with a very high speed to reach the OPEN

position defined within 60 seconds at the most.

SHEV retriggering:

(When DIP switch S1.10 = ON)

The smoke vents will be triggered with an OPEN-

impulse every 2 minutes for a duration of 30

minutes according to VdS 2581. For this, the

drives must be blockage safe. All D+H drives meet

this precondition. Otherwise the DIP switches has

to be switched on OFF.

Mounting of the drives:

Please take mounting informations from the

relevant instruction for use of the respective drive,

because of varied possibilities for choosing drives.

Drives

Connection of fire detector

Max. 14 fire detectors connectable.

Only D+H approved detectors must be used.

* Terminal resistors for line monitoring

It is pinched in control panel for transport.

Take it off there and connect according to plan.

Terminal resistor must remain at terminal RM 1,2,

when no fire detector or external control exists!

Connection of fire alarm system

English

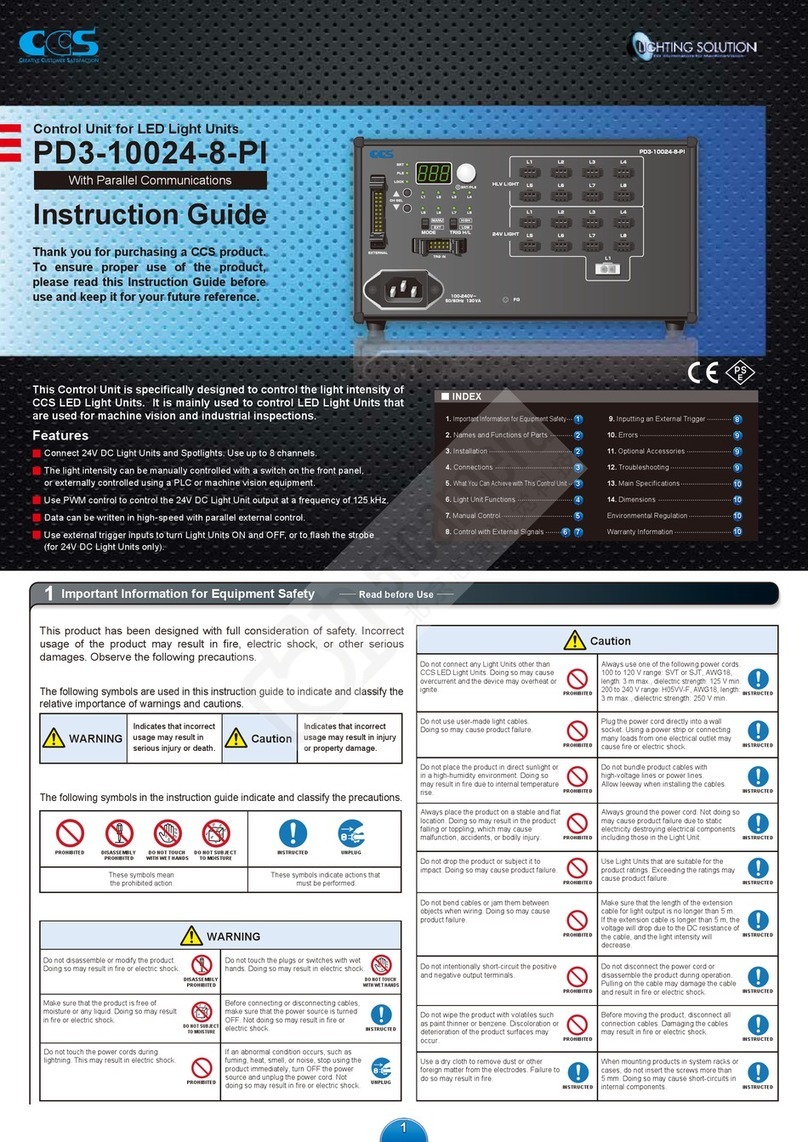

Information for starting

Carry out following sight and performance checks for switching-on the smoke and heat vent

control panel.

All cables

connected?

Factory set?

(DIP switch)

10kΩ resistor in

smoke vent

button?

End module

2x47kΩ

in junction box?

Connect mains.

LED mains lightens?

Connect battery

lines. Control l

ightens?

Smoke vent flap opens

and closes?

All necessary moving loads connected?

Smoke vent components are line-monitored.

A malfunction is connected as alarm in delivery condition of

control panel. The smoke vent opens self-acting and can be

reset under special conditions only.

yes

yes

yes

yes

yes

yes

yes

Performance check alarm/reset and ventilation

yes

Partial or incomplete connection of

components can cause malfunction.

Check following connections: mains 230 V,

drives, smoke vent buttons, when necessary

fire detectors and vent buttons.

See wiring an connection plans pages 26-28.

Delivery condition of DIP switch see page 24.

Resistor must be cramped in electric last

button on terminal 3/8 (RT 45).

See connection plan pages 26-27.

Resistor must be cramped in last or only fire

detector on terminal 3 and 5 (type SD-O/FD-T).

Resistor remains in control panel between

terminal RM "R" and "–", when no fire

detector is connected.

See connection plan page28.

10kΩ resistor in fire

detector?

yes

End module on last or only drive in junction

box on wire 5 orange, 6 black, 7 black.

See connection plan page 26.

Check line safety fuse in distribution box and

fuse mains in control panel.

Mains still not available or line switch on "0"

or one of fuses faulty.

Possibly change poles in drive.

no

no

no

no

no

no

no

no

R

Operating contact

Alarm resistor

1kW

BMZ / BMA

Terminal resistor*

10kW

RZN 4404-K V2

RM RT

1 2

–

first to penultimate

fire detector

last

fire detector

SD-O 371

or

FD-T 271

RZN 4404-K V2

RM RT

1 2

–

R

EP 6

EM 2

1

C 3

IN 4

OUT 5

EP 6

EM 2

1

C 3

IN 4

OUT 5

< optional >

10 kW

RZN 4404-K

99.823.80 3.7/06/1999.823.80 3.7/06/19

14/17 RZN 4404-K 31/36

Operation - Release in case of alarm

click

External control

Manual opening by smoke vent button:

Automatic opening by fire detector:

Automatic opening by external control (e.g. fire alarm system):

OK

SMOKE VENT

OK

Reset

0

I

System

Line

D47 D42 D20

OK

OK

RT

RZN

Reset

0

I

System

Line

D47 D42 D20

OK

OK

RT

RZN

Reset

0

I

System

Line

D47 D42 D20

OK

OK

RT

RZN

English

OK

~ 1 Sec.

see DIP

switch

page 24

OK

~ 1 Sec.

OK

Emergency closing in case of non-resettable alarm:

Reset =

OFF / ON

Reset

0

I

System

Line

OK

click

OFF

Reset

0

I

System

Line

OK

With manual release:

In case of automatic release by fire detector or external control:

External control

or

Operation - Closing after alarm

Open the housings (control panel and buttons) using the enclosed keys.

Service

RZN 4404-K 99.823.80 3.7/06/1999.823.80 3.7/06/19

30/36 RZN 4404-K 15/17

Operation - Release in case of alarm

click

External control

Manual opening by smoke vent button:

Automatic opening by fire detector:

Automatic opening by external control (e.g. fire alarm system):

OK

SMOKE VENT

OK

Reset

0

I

System

Line

D47 D42 D20

OK

OK

RT

RZN

Reset

0

I

System

Line

D47 D42 D20

OK

OK

RT

RZN

Reset

0

I

System

Line

D47 D42 D20

OK

OK

RT

RZN

English

OK

~ 1 Sec.

see DIP

switch

page 24

OK

~ 1 Sec.

OK

Emergency closing in case of non-resettable alarm:

Reset =

OFF / ON

Reset

0

I

System

Line

OK

click

OFF

Reset

0

I

System

Line

OK

With manual release:

In case of automatic release by fire detector or external control:

External control

or

Operation - Closing after alarm

Open the housings (control panel and buttons) using the enclosed keys.

Service

RZN 4404-K

99.823.80 3.7/06/1999.823.80 3.7/06/19

16/17 RZN 4404-K 33/36

ST OP ST OP ST OP

Operation - Day-to-day ventilation

Open: Close: Stop:

or

Ventilation button or SHEV button with ventilation function RT 45-LT required.

or

or

STOP

OKOK

OK

Only if wind detector or rain detector available.

Upon triggering of the corresponding sensor, the

group of the control panel is closed.

If alarm is released by a smoke and heat vent

system, the system will open also in case of wind

and rain.

Do not ventilate via smoke vent button,

because otherwise there would be a danger of

damage by wind or water.

The weather automatic can be switched-off via an

optional automatic switch, if gap ventilation is

required in case of bad weather.

Gap ventilation is not possible in case of bad

weather, if no automatic switch available.

If the weather automatic is switched on , the

system will automatically

close in case of wind or rain.

The system will not

automatically open again,

if wind or rain has stopped.

Opening of the system for

ventilation via vent button.

Operation - Weather automatic

Automatic

on/off

LT 84-U-W

SMOKE VENT SMOKE VENT SMOKE VENT

English

Once a year by a specialist company, who is

authorized by the appliance manufacturer.

Renew test badge, keep log book.

The respective current D+H maintenance

instruction is decisive.

D+H authorized expert companies have been

specially trained by D+H for carrying out expertly

this maintenance, and they get automatically the

latest maintenance instructions.

Maintenance

Following tests must be carried out in the course of

maintenance:

- Outside examination / inspection of system

components

- Checking of all relevant power supply units

- Functional testing of connected system

components

- Record of competent carrying-out of

maintenance, and designation according to

directions

Inspection

Regular visual inspection between maintenance by the operator or a trained person.

Immediately correct any defects.

Indicators:

- Green LEDs in the buttons must illuminate.

- Yellow LEDs in the buttons and the control panel

are not allowed to illuminate or flash (fault).

- If the green LEDs do not illuminate or if the

yellow LEDs illuminate or flash, contact After

Sales service.

Examination:

- Check all appliances and cable connections for

outer damage and dirt accumulation.

- Fire detectors, smoke vent buttons, smoke vents

and so on must not be impaired in their function

by goods in storage or structural changings.

RZN 4404-K 99.823.80 3.7/06/1999.823.80 3.7/06/19

32/36 RZN 4404-K 17/17

ST OP ST OP ST OP

Operation - Day-to-day ventilation

Open: Close: Stop:

or

Ventilation button or SHEV button with ventilation function RT 45-LT required.

or

or

STOP

OKOK

OK

Only if wind detector or rain detector available.

Upon triggering of the corresponding sensor, the

group of the control panel is closed.

If alarm is released by a smoke and heat vent

system, the system will open also in case of wind

and rain.

Do not ventilate via smoke vent button,

because otherwise there would be a danger of

damage by wind or water.

The weather automatic can be switched-off via an

optional automatic switch, if gap ventilation is

required in case of bad weather.

Gap ventilation is not possible in case of bad

weather, if no automatic switch available.

If the weather automatic is switched on , the

system will automatically

close in case of wind or rain.

The system will not

automatically open again,

if wind or rain has stopped.

Opening of the system for

ventilation via vent button.

Operation - Weather automatic

Automatic

on/off

LT 84-U-W

SMOKE VENT SMOKE VENT SMOKE VENT

English

Once a year by a specialist company, who is

authorized by the appliance manufacturer.

Renew test badge, keep log book.

The respective current D+H maintenance

instruction is decisive.

D+H authorized expert companies have been

specially trained by D+H for carrying out expertly

this maintenance, and they get automatically the

latest maintenance instructions.

Maintenance

Following tests must be carried out in the course of

maintenance:

- Outside examination / inspection of system

components

- Checking of all relevant power supply units

- Functional testing of connected system

components

- Record of competent carrying-out of

maintenance, and designation according to

directions

Inspection

Regular visual inspection between maintenance by the operator or a trained person.

Immediately correct any defects.

Indicators:

-Green LEDs in the buttons must illuminate.

-Yellow LEDs in the buttons and the control panel

are not allowed to illuminate or flash (fault).

- If the green LEDs do not illuminate or if the

yellow LEDs illuminate or flash, contact After

Sales service.

Examination:

- Check all appliances and cable connections for

outer damage and dirt accumulation.

- Fire detectors, smoke vent buttons, smoke vents

and so on must not be impaired in their function

by goods in storage or structural changings.

This manual suits for next models

1

Table of contents

Other D+H Control Unit manuals

Popular Control Unit manuals by other brands

Peak

Peak PCAN-GPS user manual

ARI-Armaturen

ARI-Armaturen BR 012 ZESA Operating and installation instruction

Specified Controls

Specified Controls SC-BN Series Configuration guide

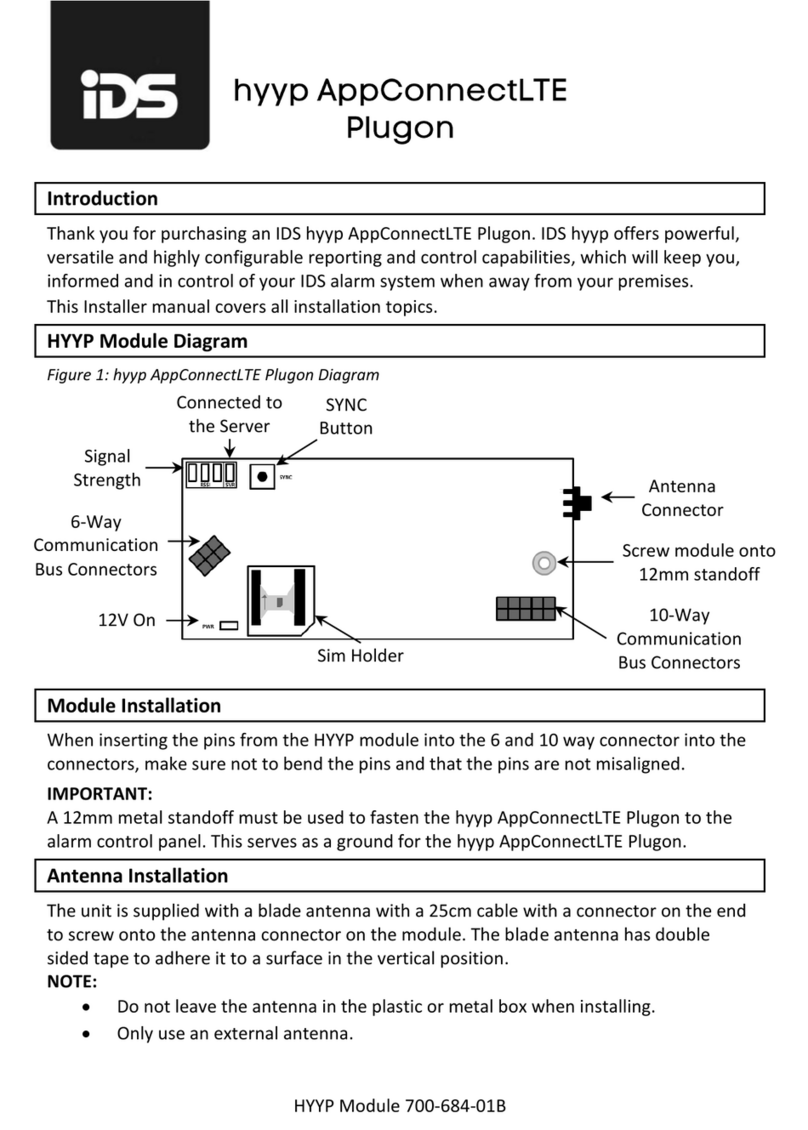

IDS

IDS hyyp AppConnectLTE Plugon quick start guide

ABB

ABB NCAN-02 Installation and startup guide

Bosch

Bosch FLM-420/4-CON-S installation guide