D+H LSC-M Series User manual

Instruction for use

Lift Smoke Control LSC-M

System for Lift Shaft and

Staircase Smoke Vent

01/48

LSC 44-M4

99.823.35 1.2/06/09

Index

1.0 ......................................................................................3

2.0 .......................................................................6

3.0 System Overview .............................................................................................8

4.0 ...................................................................................................15

Lift Shaft Smoke Vent

Introduction to SHEV Systems

Tube System

1.1 Legal Aspects.........................................................................................................................3

1.2 One System many Advantages..............................................................................................4

1.3 Solutions for every Case of Application .................................................................................5

2.1 Details to the Product.............................................................................................................6

2.2 Details about Mounting ..........................................................................................................6

2.3 Safety Notes ..........................................................................................................................6

2.4 Maintenance ..........................................................................................................................7

2.5 Guarantee ..............................................................................................................................7

3.1 Functional Principle................................................................................................................9

3.2 Why Smoke Suction?...........................................................................................................10

3.3 Wiring Plan Lift Shaft............................................................................................................11

3.4

3.5 Cable for D+H Smoke and Heat Vent Systems ...................................................................13

3.6 Line lenghts and Cross sections ..........................................................................................13

3.7 Project Planning of Smoke Suction System.........................................................................14

4.1 Mounting of Tube System ....................................................................................................16

4.2 Mounting of Reflux Valve at Suction Tube End ....................................................................17

4.3 Pipe Clamps.........................................................................................................................18

4.4 Checking of Tube System ....................................................................................................18

4.5 Tube Project Planning Guideline..........................................................................................19

4.6 Suction Openings.................................................................................................................20

4.7 Air Filter LF-AD ....................................................................................................................21

4.8 Free-Blowing Device............................................................................................................22

Wiring Plan Staircase...........................................................................................................12

4.9 Titanus Pipe-Clean...............................................................................................................22

02/48

LSC 44-M4

99.823.35 1.2/06/09

Index

5.0 .......................................................................23Central Appliance LSC 44-M4

5.1 Mounting Place LSC 44-M4 .................................................................................................23

5.2 Inside Design of Control Center...........................................................................................24

5.3 SHEV Control Panel of Type RZN 4404-M VdS ..................................................................25

5.5 .................................................................................27

5.6 .......................................................................................28

5.7 Codification of

5.8 Codification of Lin

5.9 Codification of Control Panel

5.12 LSC-System for ventilating purposes as well.......................................................................33

5.13 Emergency Power Accumulators .........................................................................................33

5.14 Smoke Suction System of Type MICRO-SENS ..................................................................34

5.16 Central Module LSM 44 .......................................................................................................36

5.17 View motherboard LSM 44...................................................................................................36

5.20 Connection Signalling Lift / External Signals .......................................................................38

5.21 Connection BMS/ RM/ RT....................................................................................................39

5.22 Connection REM/ LT/ MOT/ BZ/ BL .....................................................................................40

6.1 Louvre Drive.........................................................................................................................41

6.2 Domelight.............................................................................................................................41

6.3 Informations for Mounting of Louvres / Domelight ...............................................................42

6.4 Display Panel EF 43-LSC ....................................................................................................42

6.5 Key-operated vent button SLT 42 ........................................................................................43

6.7 Smoke vent button RT 43-H-LSC ........................................................................................46

6.8 Smoke vent button RT 43-H/-N............................................................................................47

6.10 Flashing light BL 41..............................................................................................................48

6.11 General display panel SF 43................................................................................................48

5.4 View motherboard RZN 4404-M VdS...................................................................................26

Standard Connection with RT 43-H/-N

Parallel Connection of RT 43-H/-N

Group 1 and 2 ..............................................................................................29

e 1 and 2 .................................................................................................30

...............................................................................................31

5.10 Factory preset of the DIP-Switch .........................................................................................32

5.11 Delivery Condition................................................................................................................32

5.15 Plug and Play-Initiation-Airflow Alignment ...........................................................................35

5.18 DIP-Switch S1......................................................................................................................37

5.19 DIP-Switch S2......................................................................................................................37

6.6 Fire detector FO 1362.....................................................................................................44-45

6.9 Alarm Series B/SE 24 ..........................................................................................................48

6.0 Smoke Vent Device / Connecting Elements ................................................41

®

1.0

1.1

03/48

LSC 44-M4

99.823.35 1.2/06/09

Lift Shaft Smoke Vent

The State Building Regulations demand, that

smoke vent in lift shafts is ensured in case of fire. By

the Energy Saving Regulation EnEV is

simultaneously demanded, that building external

areas must be constructed in such a way, that they

are permanent air-tight according to the state of the

art.

With LSC D+H offers a special system, which will

provide smoke vent of lift shafts in case of fire by

© 2009 D+H MechatronicAG,Ammersbek,

Rights to technical modifications reserved.

All sizes in millimetre.

Observe protection mark ISO 160 16!

For details see document O00110!

All trade marks used in this form are unreserved

subject to the respective valid trademark right and

possessory right of the respective owner. By

omission of an express marking of the trade name

shall not be given the impression, that the

tradename was not protected by a third party.

Legal Aspects

Legal Aspects

using electric motor controlled louvres, windows or

domelights. The smoke vent flaps, normally closed,

will simultaneously prevent an unnecessary loss of

thermal energy, caused by uncontrolled escaping

of heated air out of the building.

Consequently energy can be saved, ventilation

controlled and smoke vent ensured in case of fire.

Energy Saving Regulation EnEV 10/2007

Operational Safety Regulation

State Building Regulations (LBO)

Lift Guideline 95/16 of the EC

DIN VDI 6017 Behaviour of Lifts in case of Fire

EU guideline DIN V 18599

§ 6 tightness, minimum change of air

(1) Buildings to be erected must be constructed in such a way,

that the heat transfering external area, including the joints, will be

permanently airtight sealed according to the state of art. (…)

energetic valuation of buildings

1.2

04/48

LSC 44-M4

99.823.35 1.2/06/09

One System many Advantages

LSC -Lift Control is an energy-optimized system

for smoke vent and ventilation of lift shafts.

Less draught in a staircase

Early Evacuation

Maintenance direct at Control System

The closed smoke vent openings will lessen the

draught in the staircase and thereby the thermal

comfort will be improved for the user.

Possible whistling sounds will be additionally

avoided, caused by a too high flow of air.

A fire will be already recognized during a fire

formation through the smoke suction system used.

People in the lift can be moved earlier therefore to

the smokefree evacuating level.

The mechanic will not need access to the shaft for

maintenance and cleaning. This will be directly

carried out at the control system.

Lower Thermal Energy Costs

Better Building-Energy Pass

Operators and users must rethink their attitude

towards energy consumption forced by the

continous high oil price as well as generally

increasing energy costs.

The D+H system LSC avoids unnecessary losses

of energy, because a permanent opening in the top

end area of the lift shaft is avoided and with this, an

uncontrolled ventilation of the building will be

prevented.

The result:

Operating expenses will be noticeably reduced.

An optimized thermal insulation will lead as well to

better values in the building-energy pass, which will

be successively prepared for all buildings.

This will have a positive effect on the image of a

building.

From this will result better rentability, not least

because of lower additional costs. This will have a

positive influence on the building value as well.

New!

Integrated Staircase SHEV-System

The flexible SHEV-compact control system

combines simultaneously two functions:

the lift shaft smoke vent

the staircase SHEV-system

Both the requirements will be met with this

intelligent control unit. Both the fire lobbies will be

triggered and monitored separately from one

another.

This system is a compact unit in one housing with

low mounting expenditure and at reasonable

maintenance costs. It has a high degree of

equipment and operating convenience.

-

-

1.3

LSC LSC

05/48

LSC 44-M4

99.823.35 1.2/06/09

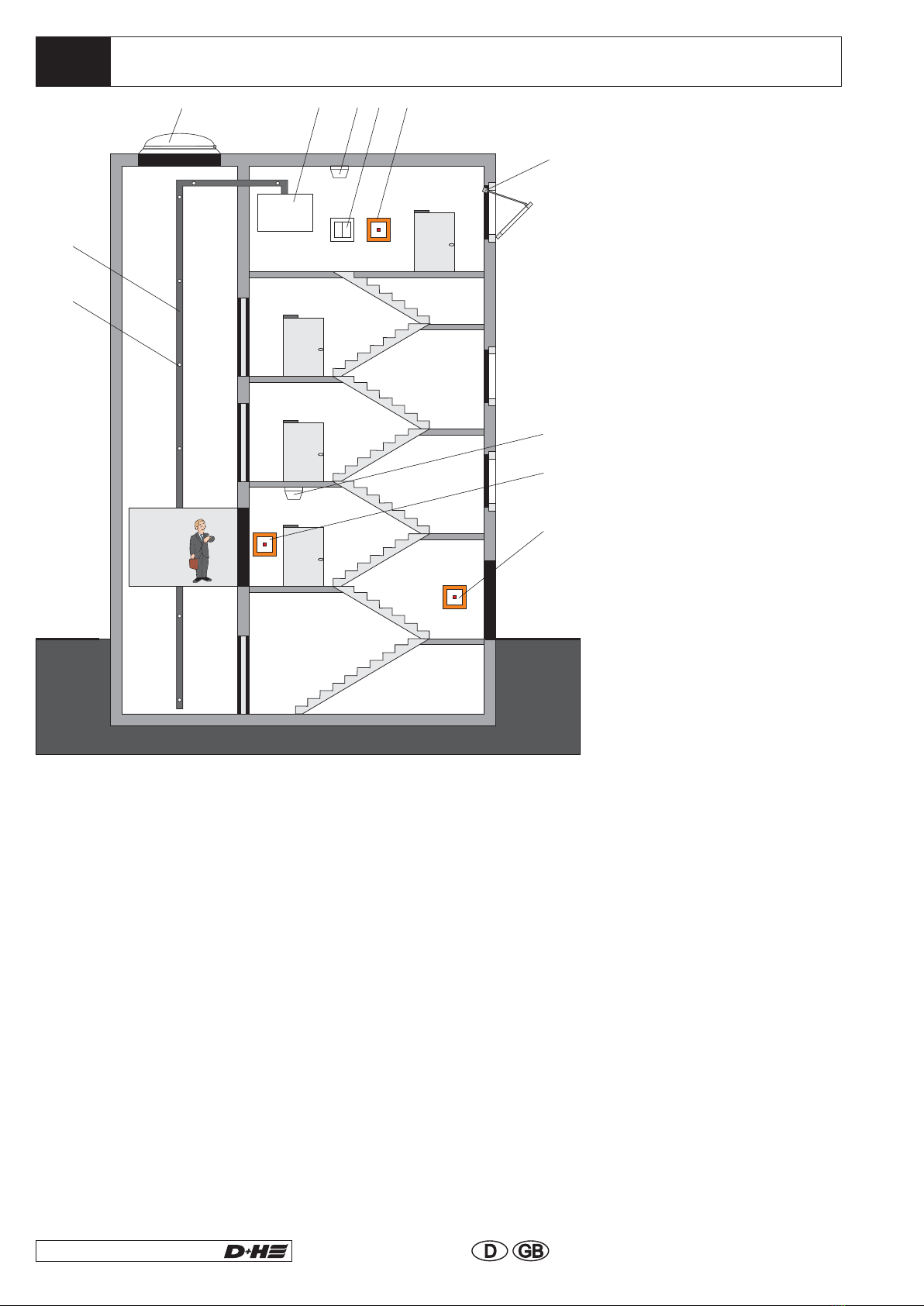

Solution for every Application

Detection of a fire will occur by a

in

the

For the a smoke suction system has been

connected by the Lift Smoke Control System

LSC 44-M4. The entire lift shaft will be constantly

monitored through a tube with suction openings,

vertically installed in the lift shaft.

In addition to fire detection in the lift shaft, the

different exit levels will be monitored here by smoke

detectors.

In case of fire (or for ventilation purposes) a smoke

vent opening in the upper area of the lift shaft will be

opened by an electric motor driven drive.

A signal will be additionally given to the lift control,

apart from the release of the SHEV function, which

will run the lift to the predetermined main

evacuating level. This will be usually the main

entrance area.

smoke suction

system in the lift shaft and a smoke detector

staircase.

lift shaft

The integrated will

monitor the adjacent staircase. The smoke

detector, installed at the top end area of the

staircase, will detect the fire smoke in the staircase

and open automatically the smoke vent flap in the

staircase.

The SHEV-function can be triggered additionally as

well via two manually operated SHEV-buttons.The

staircase SHEV-system will run absolutely

independent from the lift shaft smoke vent.

Consequently, fire smoke will be early and reliably

recognized even under difficult conditions.

Evacuating of persons, who possibly are in a lift, is

of particular significance in public buildings, where

a lot of people are coming and going.

SHEV staircase system

2.0

2.2

2.1

2.3

06/48

LSC 44-M4

99.823.35 1.2/06/09

Safety system for protecting human life and

material assets! Once a year functional testing

by a specialist company authorized by the

manufacturer.

Connection, mounting and functional testing by a

specialist company authorized by the

manufacturer.

Green control diodes in the buttons must constantly

lighten, otherwise see “Informations for Starting”.

Repair power failure at once. Instructions of the fire

protection authorities must be always observed.

This SHEV-system has been constructed in

accordance with the latest state of the art and

science. In case of professional mounting and

maintenance it is of high operating safety.

Nevertheless, there can dangers arise from the

product, if by unqualified personell used inexpertly

or not in accordance with the regulations.

Introduction to SHEV Systems

Details about Mounting

Details to the Product

Safety Notes

Danger of Injury or Life!

central appliance

switched idle

Working on the is only allowed, if

this is . This includes distribution

voltage with 230V alternating voltage as well as

emergency power supply with 24V direct voltage.

Only electrical specialist companies are authorized

to install these systems, who have electrical

specialist staff with relevant experiences in

installing danger alarm systems or smoke and heat

vent systems. Only these ones can take on

responsibility for functioning, and can ensure

product liability for the whole system (see product

liability law BGBL.I S.2198 and BGB (bodily injury,

compensation for damage). Therfore, regular

maintenance and checking of functional readiness

is imperative and has to be ensured. These

Smoke and heat vent systems (SHEVs) are very

important elements of structural preventive fire

protection.

Smoke and heat vent systems are appliances of

preventive fire protection. They fulfil important

functions in case of fire as there are: protection of

human life by creating a smokefree layer, by which

escape and rescue routes will be kept free for the

fire brigade. Consequential damages by

conflagration gases are reduced and therefore

considerable material assets are often protected

from destruction. Precondition for this is, that the

system will function absolutely reliable in a case of

fire.

standard requirements are demanded according to

regulations of the DIN, of the Association of

German Insurer against damage of property (VdS)

and the respective local authorities.

In spite of greatest possible care we can not accept

responsibility for this document. All informations

given are no warranted qualification in the sense of

§ 434 BGB.

Current directions of the authorities and the VDE-

regulations must be taken into account during the

entire mounting and installation of the system.

Regulations of the local EVU must be additionally

observed. Furthermore, individual working steps

must be coordinated with the management of

works.

Should special problems arise during mounting or

operation, with which is not extensively enough

dealt with in the operating instructions, so please for

your own safety do not hesitate to consult with the

manufacturer.

Apart from suction tubes with reflux valve and air

recirculation,

nomical maintenance

warranted.

no components will be installed in

the lift shaft! Acceptance by an expert can be can

be only obtained with this precondition as well as

with simple and eco

Unauthorized modifications and alterations at the

SHEV-system are for safety reasons.

This operating instruction must be

before installation.

Keep to the instruction.

not allowed

read through

carefully

Please observe in any case the safety notes.

2.5

2.4

07/48

LSC 44-M4

99.823.35 1.2/06/09

Guarantee

Maintenance

Smoke and heat vent systems must be maintained

at annual intervals by authorized specialist

companies according to DIN 18232 section 2

paragraph 10.2, and VDE 0833 section 1

paragraph 5.3.4 for alarm systems and

manufacturer guidelines.

Renew test badge, keep control book.

The respective current D+H maintenance

instruction is decisive.

D+H authorized expert companies have been

specially trained by D+H for carrying out expertly

this maintenance, and they get automatically the

latest maintenance instructions.

Following tests must be carried out in the course of

maintenance:

- Outside examination/ inspection of system

components

- Measuring of insulation resistances

- Checking of all relevant power supply units

- Functional testing of connected system

components

- Record of competent carrying-out of

maintenance, and designation according

to directions

Once a year by a specialist company, who is

authorized by the appliance manufacturer.

Only regular and professional maintenance

warrants the necessary and permanent

functional safety.

Only authorized specialist companies are allowed

to install and maintain smoke and heat vent

systems and system components, constructed and

distributed by . All

partners belong to these

authorized specialist companies, who regularly

undergo an in-house training to ensure their

qualification and experience.

According to DIN VDE 0108 section 1 paragraph

9.1.1 accumulators for emergency supply (lead

accumulators) must be checked every six months

by a person, who has been introduced to this task,

and once a year, maintenance must be carried out

by specialist companies.

Accumulator types, which are used for

smoke and heat vent systems

must be VdS approved, and must be released by

to use in smoke and heat

vent systems.

According to DIN 18232 section 2 paragraph 10.2

the tests must be put down in an operational book,

which the operator/ building owner must present to

the building supervision authority on request.

This operational book is available at

(Ord.-No.: 68.700.15)

Executed maintenance must be proved by a

maintenance/ and testing

confirmation.

Observe regulations for danger warning systems

VDE 0833, guidelines for electrical systems VdS

2221, DIN 18232 for smoke and heat vent systems,

regulations of the local fire-brigade and of EVU for

connection to mains supply.

D+H Mechatronic AG D+H

Mechatronic AG

D+H

Mechatronic AG

D+H Mechatronic AG

D+H

Mechatronic AG

D+H

Mechatronic AG

You will get guarantee for all D+H products

from date of verified handing over of the system up

to maximal 3 years after date of delivery, when

mounting and starting has been carried out by a

D+H authorized .

2 years

distributor

D+H guarantee is expired, with connection of D+H

components with external systems or with mixing of

D+H products with parts of other manufacturers.

3.0

Rauchabzug

08/48

LSC 44-M4

99.823.35 1.2/06/09

Louvre

window

with drive

in lift shaft

Acoustical + optical

alarm devices *

Smoke detector

*Main evacuating level

Smoke vent button

230V / 50Hz

Mains supply

Lift

shaft

Domelight

with drive

on lift shaft

Tube system

with accessories

<or>

rain detector

VRS 10*

key-operated

ventilation button *

Signal contact

to Lift control

* optional

System Overview

Smoke vent button

RT 43-H-LSC

key-operated

ventilation button *

Smoke

detector

window

with drive

StaircaseLift Shaft

Signal contact to

BMS/ MSR

(measurement

and control)

3.1

1 2

3 4

LSC LSC

LSC LSC

09/48

LSC 44-M4

99.823.35 1.2/06/09

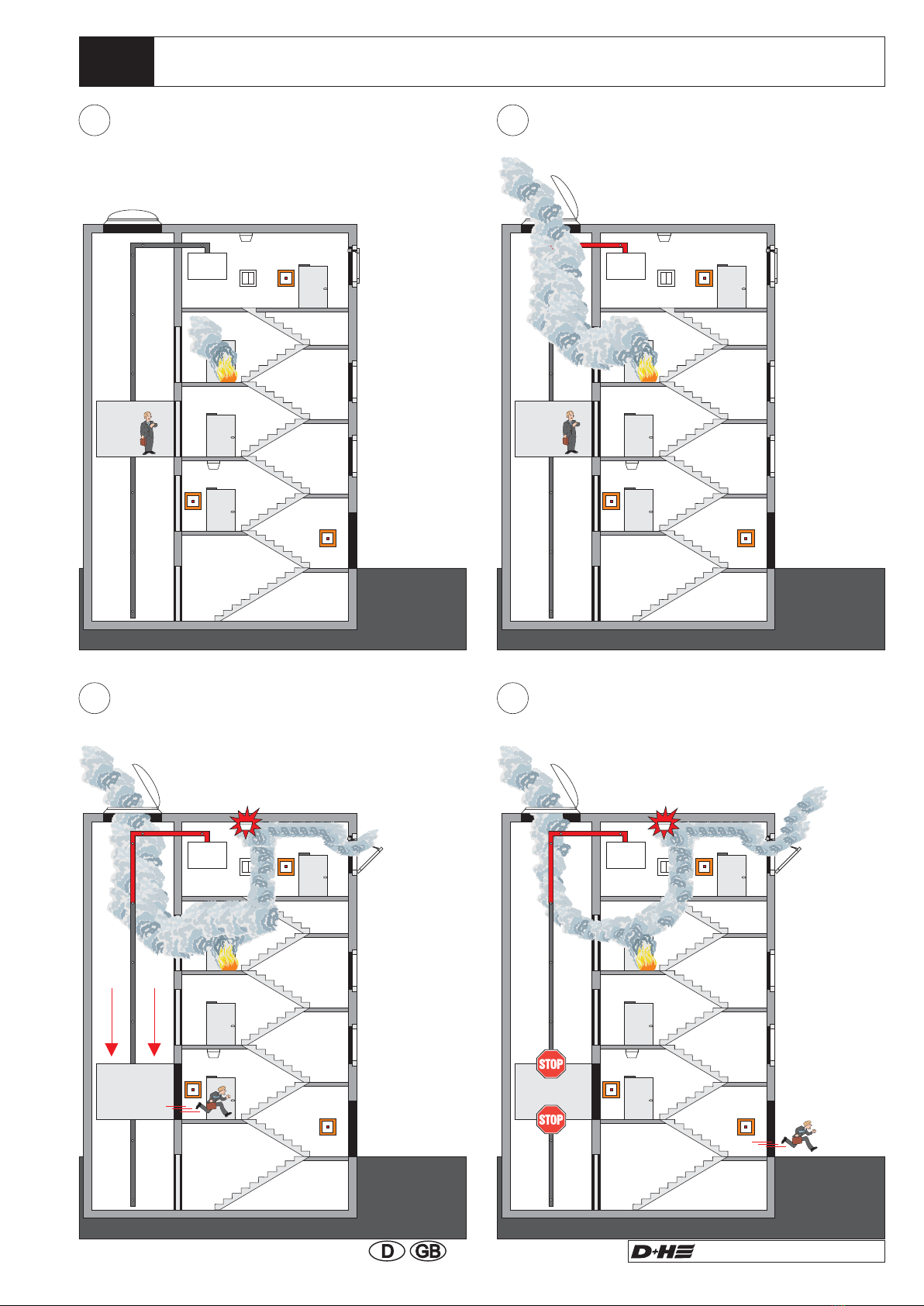

Functional Principle

Smoke recognition Opening of the

smoke vent flap

Evacuating travels

of lift car and activation

of the staircase smoke vent

Prevention of

further lift car travels

3.2

LSC

1

2

3456 7

8

9

10

11

10/48

LSC 44-M4

99.823.35 1.2/06/09

Taking samples of air through smoke suction over

the complete height of the lift shaft will prevent

spurious release and allow earlier reliably detecting

of smoke.

Optical smoke detectors ca

e

suction on the individual floor levels and the lift will

be automatically run to the main evacuation level.

No interruption of lift operation necessary during

maintenance.

In the LSC-system is an “extended fire control”

integrated. In this process, the predetermined main

evacuation level will be monitored by an optical

n not be used, because

of whirling caused by the lift car, and danger of dirt

accumulation in the lift shaft, as the danger of

spurious release would be very high.

Smoke will be recorgnized earlier through selectiv

On top of that,

a smoke detector according to the standard DIN

VDE 0833-2 + EN 54-7 in the elevator shaft can not

used, because the inflow of the smoke detector can

not occur freely!

Why Smoke Suction?

1 Suction opening

2 Suction tube

3 Domelight

4 Control panel

5 Smoke detector

6 Ventilation button

7 Smoke vent button

RT 43-N

8 Window drive

9 Smoke detector

10 Smoke vent button

RT 43-LSC

11 Smoke vent button

RT 43-H

smoke detector in front of the landing entrance. If

this smoke detector will release, the lift will be run to

the second evacuation level (will be defined by

customer from the operating authority and the local

fire protection)

Furthermore, SHEV-alarm can be triggered as well

by the smoke detector on the main evacuating level

and the smoke vent flap in the lift shaft will be

opened. Release will be effected in dependence of

the DIP-switch setting (S1) on pcb LSM 44. In case

of SHEV-alarm the electric motor driven opening

drive will be triggered by a re-clocking operation.

With this the drives will be triggered again and again

in regular intervals. Consequently the opening

drives, which may have been blocked first, for

example by icing or sticked seals, will be

nevertheless opened.

The same functionality is ensured also for the

control part of the staircase SHEV-system.

3.3

M

M

JY (St) Y

4x2x0,6

230VAC

24VDC

JY (St) Y

2x2x0,6

JY (St) Y

2x2x0,6

JY (St) Y

2x2x0,6

JY (St) Y

2x2x0,6

JY (St) Y

2x2x0,6

JY (St) Y

2x2x0,6

JY (St) Y

4x2x0,6

JY (St) Y

4x2x0,6

JY (St) Y

4x2x0,6

11/48

LSC 44-M4

99.823.35 1.2/06/09

fire

detector

Key-

operated

vent button

external control

BMS

signal contact

lift

Signal contact

BMS/MSR

smoke

vent button

RT 43-LSC

230V 50Hz

not possible to switch off

control

panel

drive

rain

detector

acoustical signal

transmitter

flashing

light

signal

indicating board

Symbol Description

Wiring Plan Lift Shaft

LSC 44-M4 surface type

600x600x210 (230VAC/ 24VDC)

near the lift shaft

Smoke vent button (RT 43-LSC)

surface 24 VDC circa 1,5m above

upper edge firm flooring (by customer

55mm flush socket)

Vent button 24 VDC (e.g. LT 43) circa

1,2 above upper edge firm flooring (at

flush type by others 55mm flush

socket)

Fire detector 24 VDC

(e.g. FO 1362 or FT 1262)

230V- Power supply

Weak Current Lines

Provide for separate electric circuit.

Mark fuses.

Connecting cable

Install and feed separately from supply mains.

Mark cable and terminal box red.

: NYM-I 3x1.5

Connecting load : RZN 4404-M = 120 VA

flashing

light

acoustical

signal transmitter

signal

indicating board

rain

detector

Drive 24 VDC at smoke vent flap (lines

must end in flush mounted distribution

box, see symbols above).

see cable

wiring table

230VAC

24VDC

3.4

12/48

LSC 44-M4

99.823.35 1.2/06/09

Wiring Plan Staircase

M

JY (St) Y

4x2x0,6

230VAC

24VDC

JY (St) Y

2x2x0,6

JY (St) Y

2x2x0,6

JY (St) Y

2x2x0,6

JY (St) Y

4x2x0,6

key-operated

vent button

smoke

vent button

RT 43-H

smoke

vent button

RT 43-N

see cable

wiring table

to further ones

to further ones

fire

detector

contact

external control

230V 50Hz

not possible to switch off

control

panel

drive

M

Symbol Description

LSC 44-M4 surface type

600x600x210 (230VAC/ 24VDC)

near the lift shaft

Smoke vent button (RT 43-H/N)

surface 24 VDC circa 1,5m above

upper edge firm flooring (by customer

55mm flush socket)

Vent button 24 VDC (e.g. LT 43) circa

1,2 above upper edge firm flooring (at

flush type by others 55mm flush

socket)

230V-Power supply

Weak Current Lines

Provide for separate electric circuit.

Mark fuses.

Connecting cable : NYM-I 3x1.5

Connecting load : RZN 4404-M = 120 VA

Install and feed separately from supply mains.

Mark cable and terminal box red.

Drive 24 VDC at smoke vent flap in the

staircase (lines must end in flush mounted

distribution box, see symbols above).

Rain detector 24VDC (FO 1362) at the top

end of the staircase

230VAC

24VDC

3.5

3.6

LSC 44-M4

13/48

LSC 44-M4

99.823.35 1.2/06/09

Cable for D+H Smoke and Heat Vent Systems

The smoke vent control panel is designed for

opening smoke vent devices, which operate by

thermal ascending force and by automatic fire

recognition devices (thermal detector, smoke

detector), and they release either self-acting or

manual by smoke detectors at an early stage of a

fire, and remain in opened position without further

power consumption. In these cases, functioning

preservation of the electrical line system is required

only at an early stage of fire. Protected wiring is

required with protection against mechanical

damages according to DIN 18232 section 2.7.2.4.

Cable from the smoke vent control panel to

connection of drive (drive lines have a monitoring

wire, in which fire recognition devices (thermal

maximal detector e.g. THE) can be looped-in):

- Safety line, with functional conservation

... E30, according to DIN 4102* or standard

guidelines for line systems MLAR.

Control Cable (Group):

Detector Cables (Line):

Cables through areas not monitored:

The detector cables are monitored for short circuit

and for break.

The opening device is automatically triggered and

opens up in case of fault, when DIP-switch 3 is on

ON.

Smoke vent button cable and cable of automatic

detectors:

- weak current sheathed flexible cable YR 6 x 0.8

or

- house wiring cable IY(ST)Y 4 x 2 x 0.6

An increased time of functioning of the cable can be

required, when drive lines are installed through

building parts, which are not monitored.

- Safety line with functional conservation

... E90, according to DIN 4102* or standard

guidelines for line systems MLAR.

(see supplementary sheet 1 to DIN VDE 0108)

* Notice: No type designation is given for these

cables, because of a large variety on the market.

Please consult your D+H distributor about these.

plain cable length (m) x number of drives

80 **

Line lengths and Cross sections

Number of wires and cross-sections indicated, refer to required lines only. In case of using a line with

earthed conductor (green/ yellow), this one will not be counted in and must not be wired.

*

**

connect in parallel 2 wires for each drive line

only valid for drives with 1A actuating current. Use „160“ for drives with 0,5A actuating current

and „230“ for drives with 0,35Aactuating current.

cross section (mm²) =

Type

drive 0,5A 1 2 345678

1A 1 2 3 4

3 x 1,5mm² 240 120 80 60 48 40 34 30

3 x 2,5mm² 400 200 130 100 80 65 55 50

5 x 2,5mm² 800 400 260 200 160 130 110 100

3.7

14/48

LSC 44-M4

99.823.35 1.2/06/09

Project Planning of Smoke Suction System

Regulations

The following project planning regulation is orientated to the system limitations of TITANUS MICRO-

SENS. In this connection, respective national regulations of the states in the valid version each must be

observed. The project planning must be adapted to these standards.

In Germany

With VdS-Systems

DIN VDE 0833 part 1 and 2 “alarm systems for

fire, burglary and raid”.

Additional provisions for construction of fire alarm

systems, which are issued from the fire

management of the fire brigades, from the

inspection of works or from the building right

authorities, which are only of local validity.

“Guideline for automatic fire alarm systems,

planning and installation” VdS Schadenverhütung

GmbH (VdS 2095).

With CEA-Requirement

With Project Planning Limitations

The CEA-guideline 4022 “Requirements and test

methods for aspirating smoke detectors”

demands a recognition of an airflow disturbance,

if a 50% change of the main airflow arises. In

addition, the size of suction openings has been

laid down on at least 2.0 mm Ø.

The project planning limitations according to

chapter 4.5 have to be taken into account within

this project planning.

Maximum monitoring area of a suction opening

corresponds to the monitoring area of a point

indicator according to the regulations of the

respective national standards.

4.0

Ø 25mm

E

D

C

B

A

10

9

8

7

6

5

4

3

2

1

E

D

C

B

A

10

9

8

7

6

5

4

3

2

1

min.

max.

2m

20m

min.

max.

4m

10m

max.

25cm

15/48

LSC 44-M4

99.823.35 1.2/06/09

ultimate

suction

opening

max. number per tube

system 6 units

max. total tube length

(Ø 25mm) 40m

first suction

opening

first suction

opening

LSC control center

smoke

suction

device

smoke

suction

device

Recirculation in shaft

Shaft

Ceiling

1 x 40 m PVC tube 25x1.9 red

1 x air filter

1 x reflux valve

20 x PVC sleeves

50 x pipe clamps

6 x PVC angles 90°

2 x PVC bends 90°

4 x PVC angles 45°

6 x suction reducing foil

1 x tube of PVC adhesive agent 125 ml

1 x bottle of PVC purifying agent

There is a 25 m Tube-Set optionally

available!

The tube system serves for a defined air sampling

from the monitoring area and consists of different

components.

Tube System

A simplified project planning will be applied in

equipment protection and in conveniences of small

dimensions.

Air Filter

The control panel can also be mounted in the

basement of course, so that the air will be

removed by using suction from the shaft to the

bottom. In this case the reflux valve will be

situated on the lift shaft head.

4.1

1

2

4

3

16/48

LSC 44-M4

99.823.35 1.2/06/09

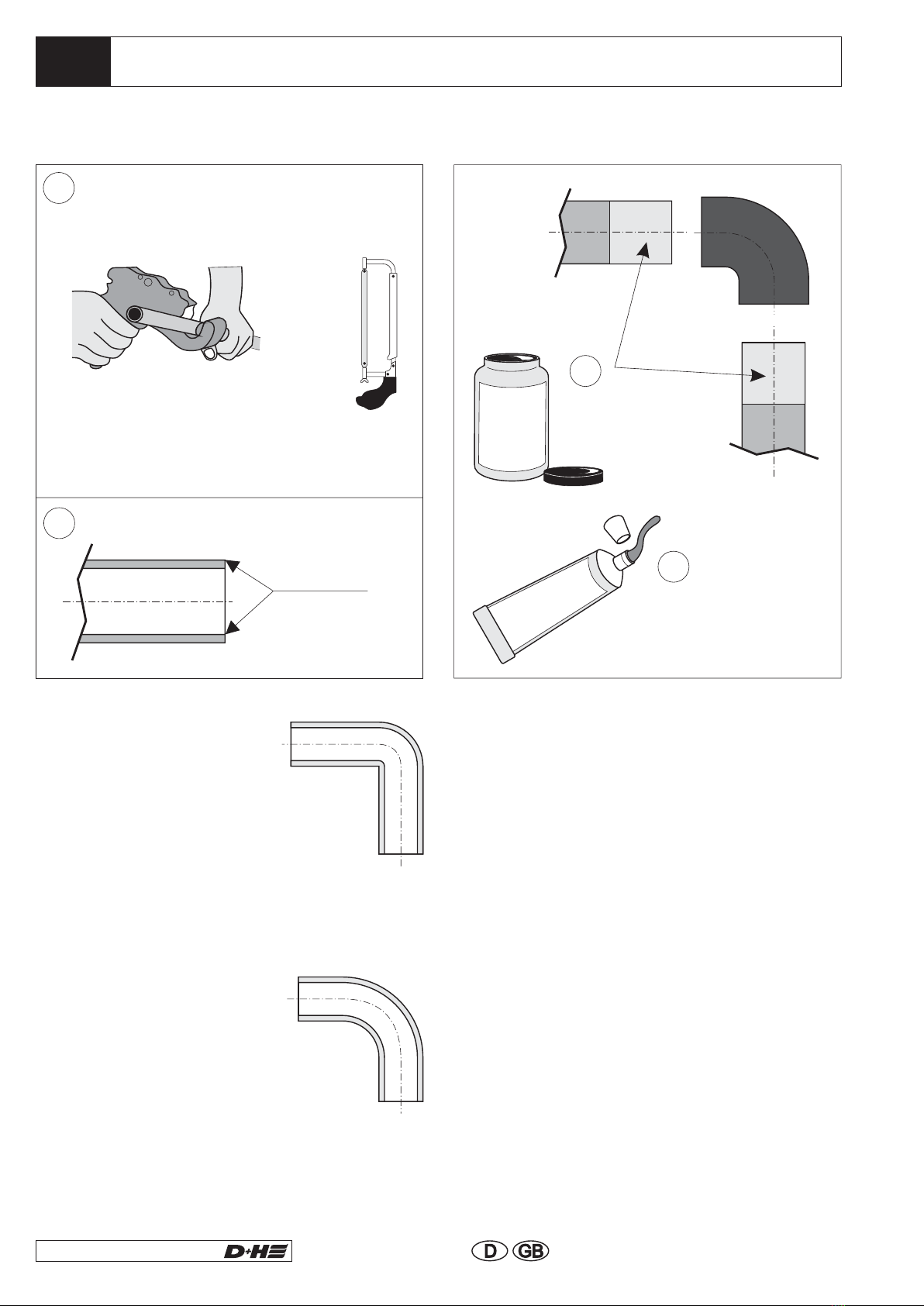

Mounting of Tube System

Burring

fig. 1

fig. 2

Cut tubes to length

(pipe cutter or pipe shears 38mm/

metal cutting saw)

The tube system shall be put together according to the requisition by the project and with observance of

the project planning guidelines.

Burring

Suction tube (PVC)

Suction tube halogen free

(optional available)

R-2519, R-3218, R-4019)

ABSR-2518, ABSR-3220, ABSR-4025

After cleaning, glue

tube street fittings

airtight together!

Clean tube

Street fittings!

Minimize tube lengths and

changes of direction.

(see fig. 1 on the right) have an

extremely high air flow

resistance. Therfore use these

only at places, where they are

inevitable for structural

reasons. If necessary, the tube

length must be reduced in

proportion to the angles used.

(see fig. 2 on the right)

shall be always prefered to

angles. A too high number of

bends and angles will lessen

the velocity of air in the suction

tube and by this, detection time

will be increased.

Angles

Bends

If angles and bends are used, the maximum

total length of the tube system will be reduced.

Standard Value

- a bend corresponds to a straight tube length

of 0,3m.

- an angle corresponds to a straight tube length

of 1,5m.

Tangit

cleaner

Tangit

Adhesive agent

X.x

4.2

1

2

4

3

17/48

LSC 44-M4

99.823.35 1.2/06/09

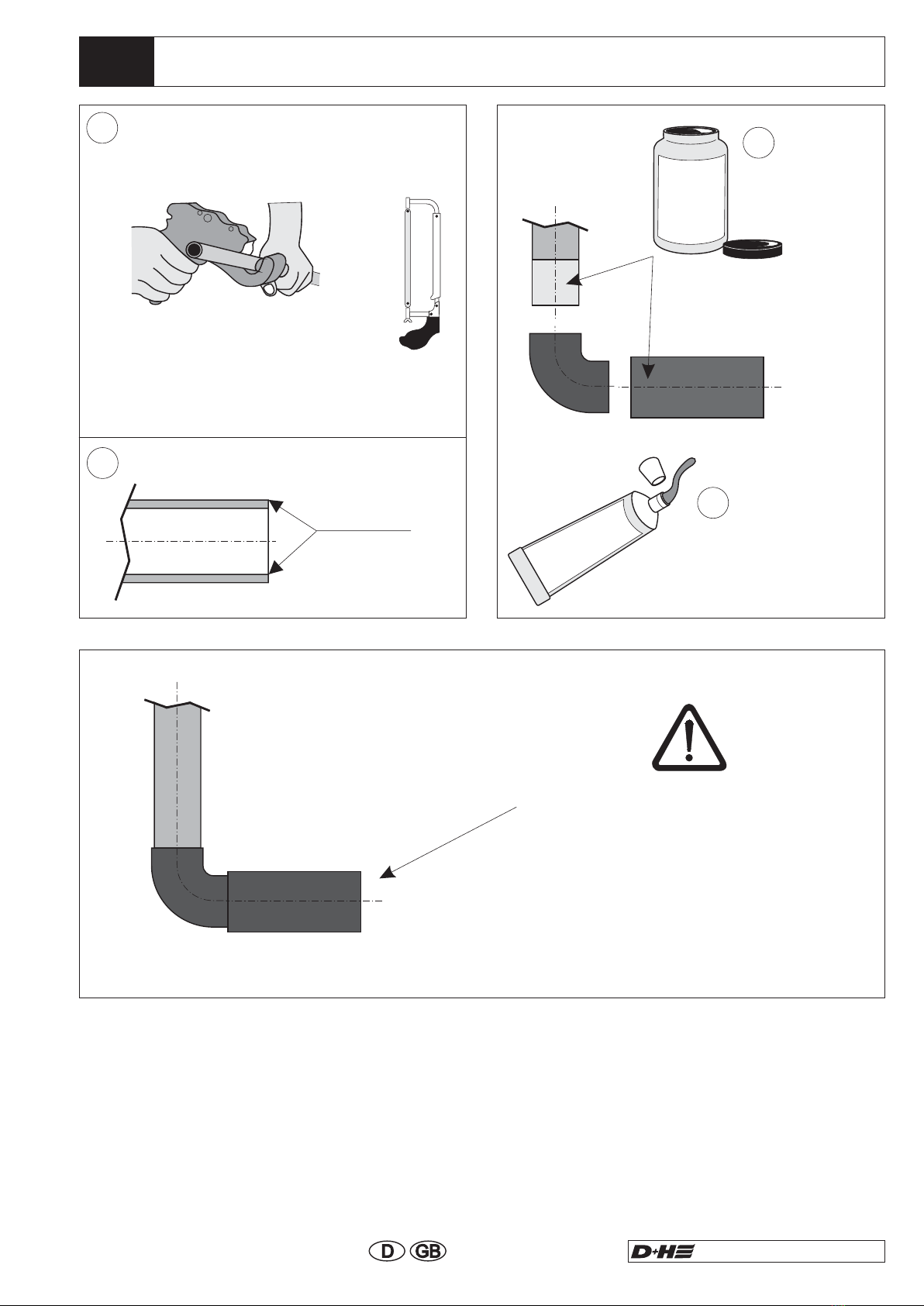

Mounting of Reflux Valve at Suction Tube End

Mount reflux valve,

always horizontally

if used in lift shaft,

that dust and dirt will

not be uncessarily whirled up

in the shaft pit with blowing

through of the tube system.

Cut tubes to length

(pipe cutter or pipe shears 38mm /

metal cutting saw)

Burring

Burring

Suction tube (PVC-red)

Suction tube halogen free

R-2519, R-3218, R-4019

ABSR-2518, ABSR-3220, ABSR-4025

(optional available)

After cleaning,

glue tube street

fittings airtight

together!

Clean tube

street fittings!

Tangit

cleaner

Tangit

Adhesive agent

4.3

4.4

E

D

C

B

A

10

9

8

7

6

5

4

3

2

1

18/48

LSC 44-M4

99.823.35 1.2/06/09

SHEV-control panel

Checking of Tube Systems

- for leakages (e.g. by damages)

- for faulty connections

- for correct project planning of suction openings

- check with critical applications safe detection

with response tests apart from this check,

whether an air throughput is available on the

individual suction openings.

- The ventilator voltage can be infinitely

increased from 9V (standard) up to 13.5V in

order to increase the velocity of air flow in the

tube system in critical areas.

- If the tube system does not meet the project

planning guidelines, as described here,

because of structural facts, it must be

separately calculated by D+H for the respective

conditions.

Pipe Clamps

Smoke

suction

device

For the of the tube system,

after tube connection at TITANUS

a type has to be used,

which

Plastic pipe clamps of type NG 23 are

used as standard for installation of the

tube system (Ø 25mm). They do not

allow linear extensions.

first clamp

does not allow linear extension.

MICRO SENS ,

®

(with high

variations

in temperature

max. 30cm)

max. 80cm

Fasten tubes with

pipe clamps without

rubber ply.

Lay tube system firmly.

It must neither hang sagging

nor must it be possible that it

is moved out of place.

Air Filter

This manual suits for next models

1

Table of contents