You must perform the 2 point calibration in the order of pH7 rst and pH4 follows. You must complete all

calibration before proceeding to next installation step. 2 point calibrations must be performed every time

you attempt to recalibrate.

Please insert pH probe into pH4 solution of at least 1.5 cm deep.Press and hold number 1 and number

3 buttons simultaneously for 3 seconds until you hear a beep and release both buttons. Now the pH 4.0

calibration are complete.

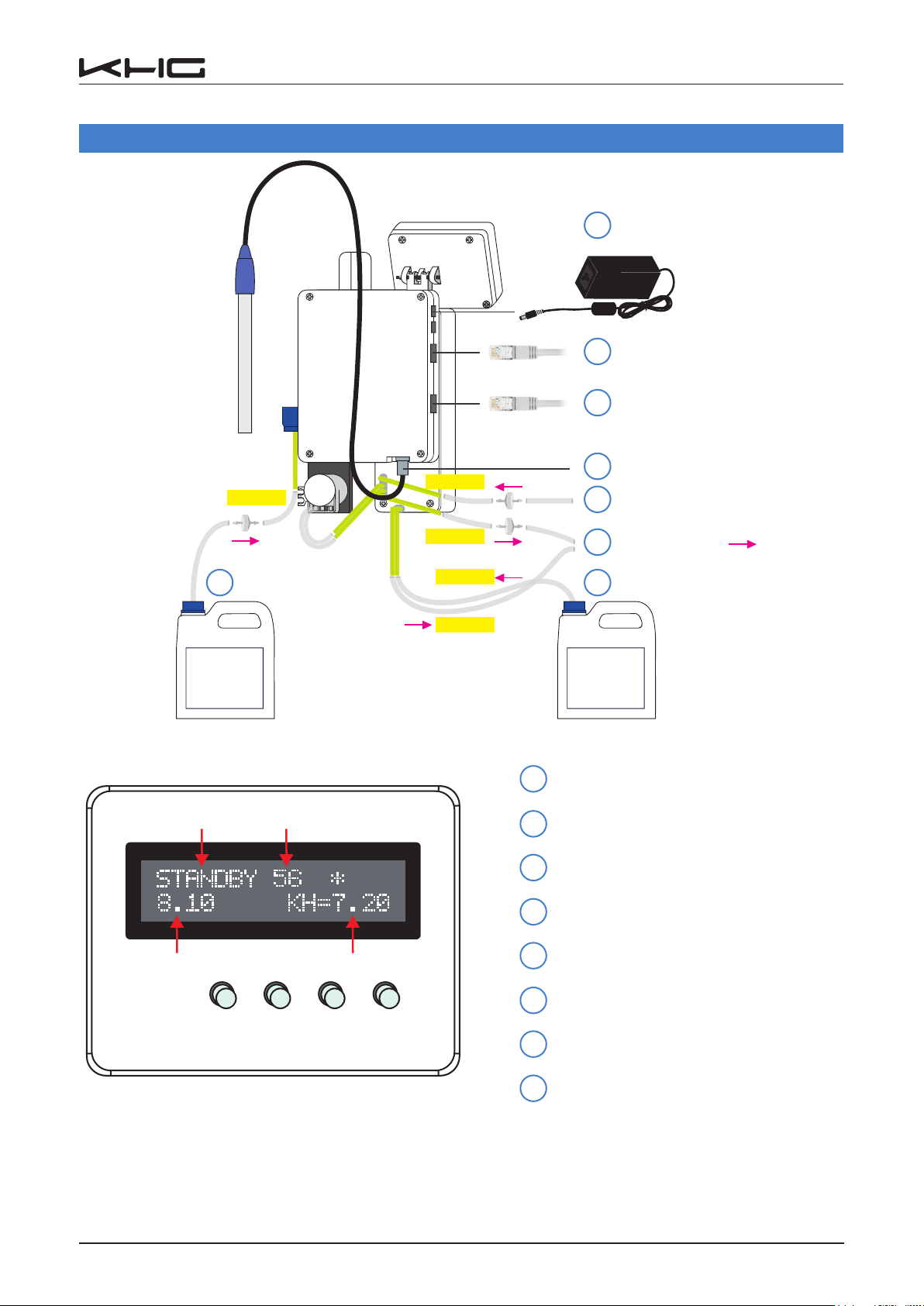

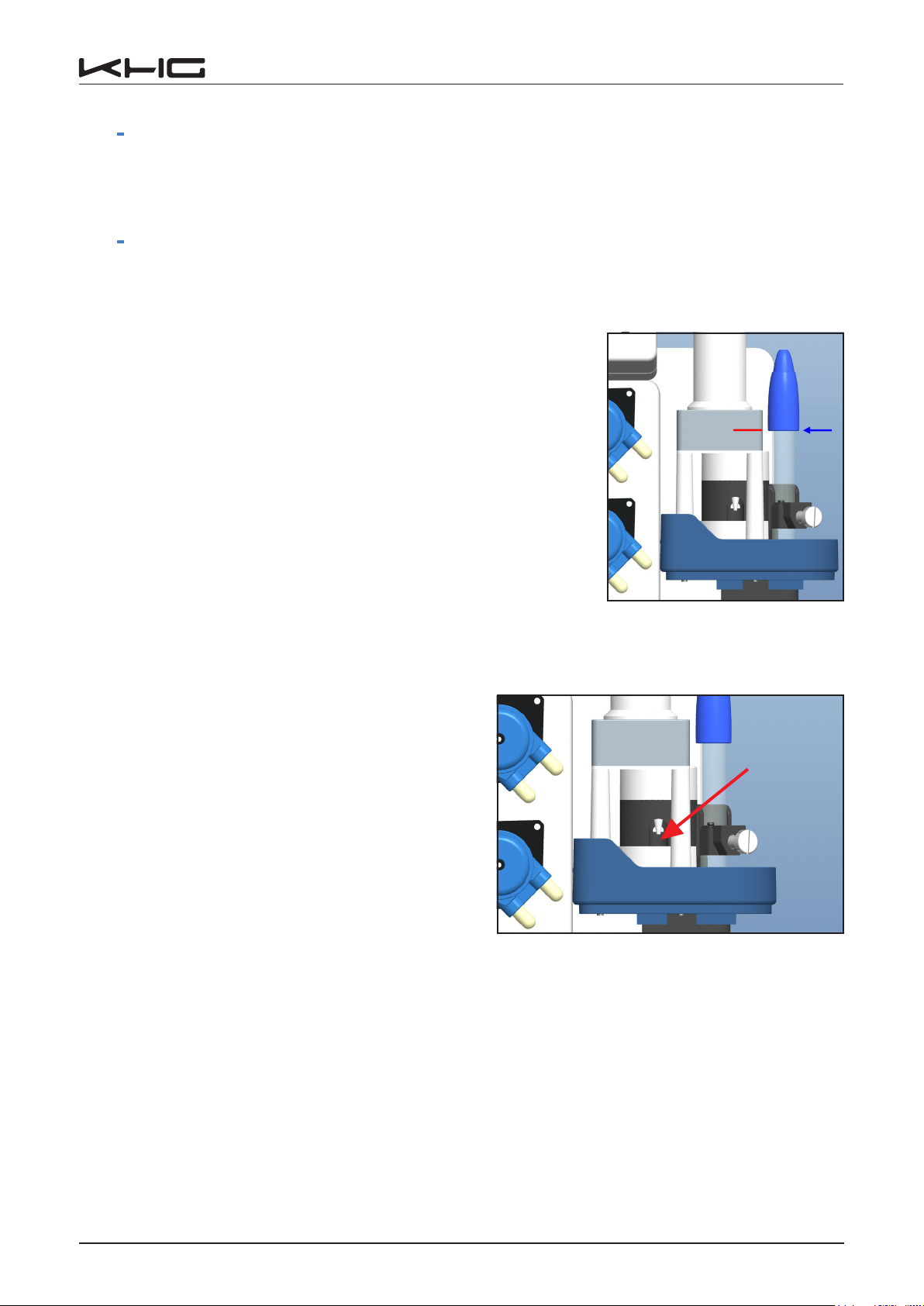

Please insert the calibrated pH probe until the cap of pH probe is

level with the Red line. (Figure 5) Hand tighten the white knob to

secure pH probe in place. Over tighten the white knob could break

the glass sleeve of pH probe.

Please recheck and make sure all tubes are connected as instructed

above. Go to your browser and click on “SW Tube De-Gas” to purge

air from your tank water inlet tube. First attempt to draw tank water

and purge air, KHG may show NSWE error message (No Salt Water

Entering). To cancel the error message, you should press and hold

the number 4 button until you hear a beep and release button.

Please click on the “SW Tube De-Gas” for as many times as out of

the inlet tube.

Please click on the “KS De-Gas” on your browser

to purge air from your KHG reagent solution tube.

Please look into the observation hole (Figure 6) until

you see reagent solution is dropping at the rate of

one drop per 3 seconds. Please let reagent solution

to drop at least 10 times before cancelling the air

purging by clicking on the “RESET” in your browser

screen, or press and hold number 4 button for 3

seconds to stop the purging procedure. If KHG shows

“KS_ERR”, there may be blockage in the tube and

KHG will force into areboot. At the same time please check if the tube is free from blockage and make sure

there are reagent solution in the storage bottle.

Next please key in your last known dKH value into the “Last KH (dKH)” under the “System Setup”. Please

also make sure the number you entered is not 1.5 dKH away from your desired alkalinity target level (“KH

Auto Correction”). Next click on “SAVE” to save your settings and KHG will enter a forced reboot.

After a successful reboot of KHG, the LCD display will show STANDBY. Please enter KHG main control

page in your browser, and click on “GET dKH”. KHG will perform a full test. After the test has been done,

KHG will return back to standby mode.

Page 4

6.

7.

8.

9.

10.

(Figure 6)

(Figure 5)

User Manual

required until tank water are owing

Observation hole