Page 1of 27

CR300 Vers: 2.1

Table of Contents

Introduction ............................................................................................................................................ 3

Important Health and Safety Information ....................................................................................... 3

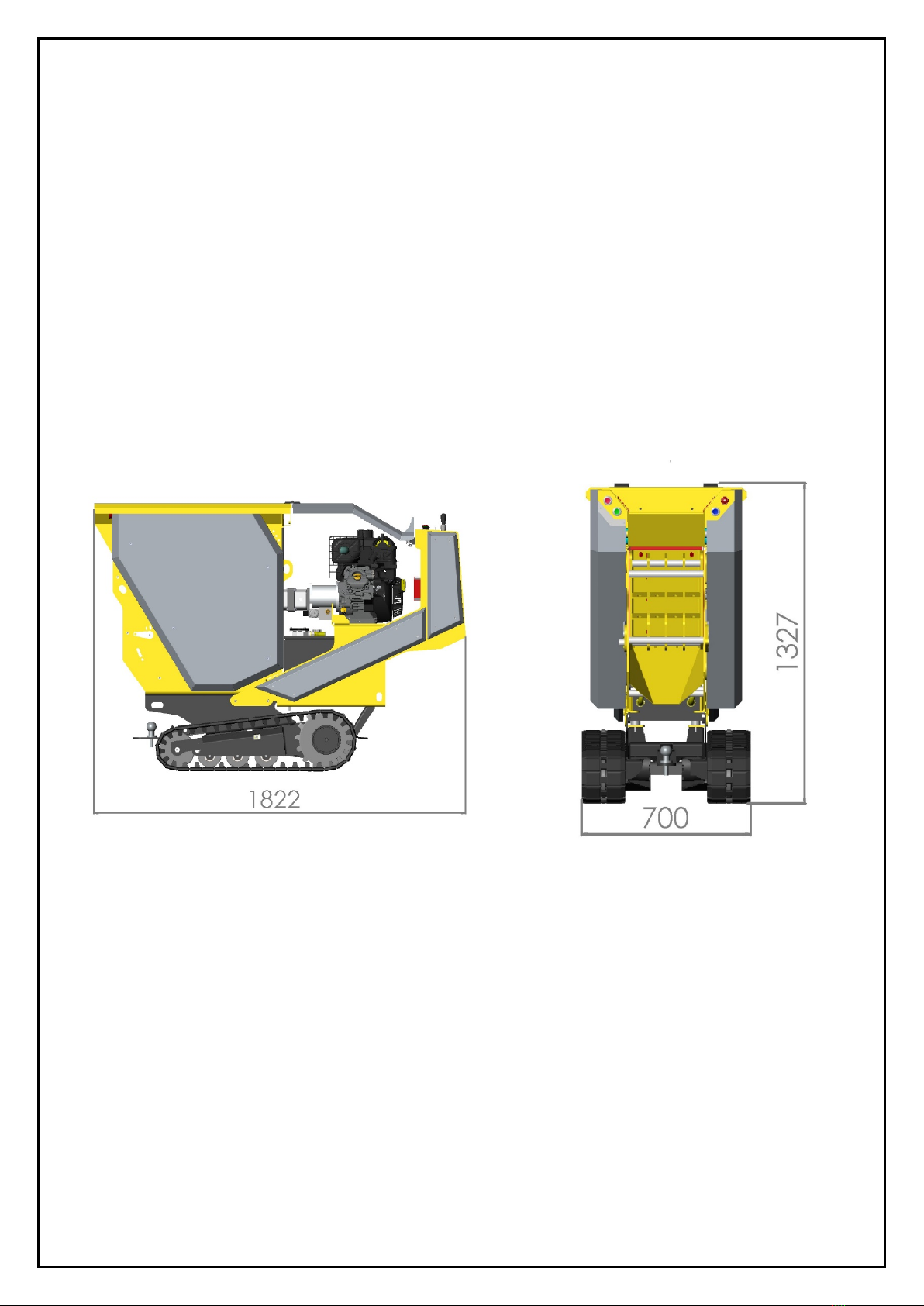

Specifications................................................................................................................................. 4

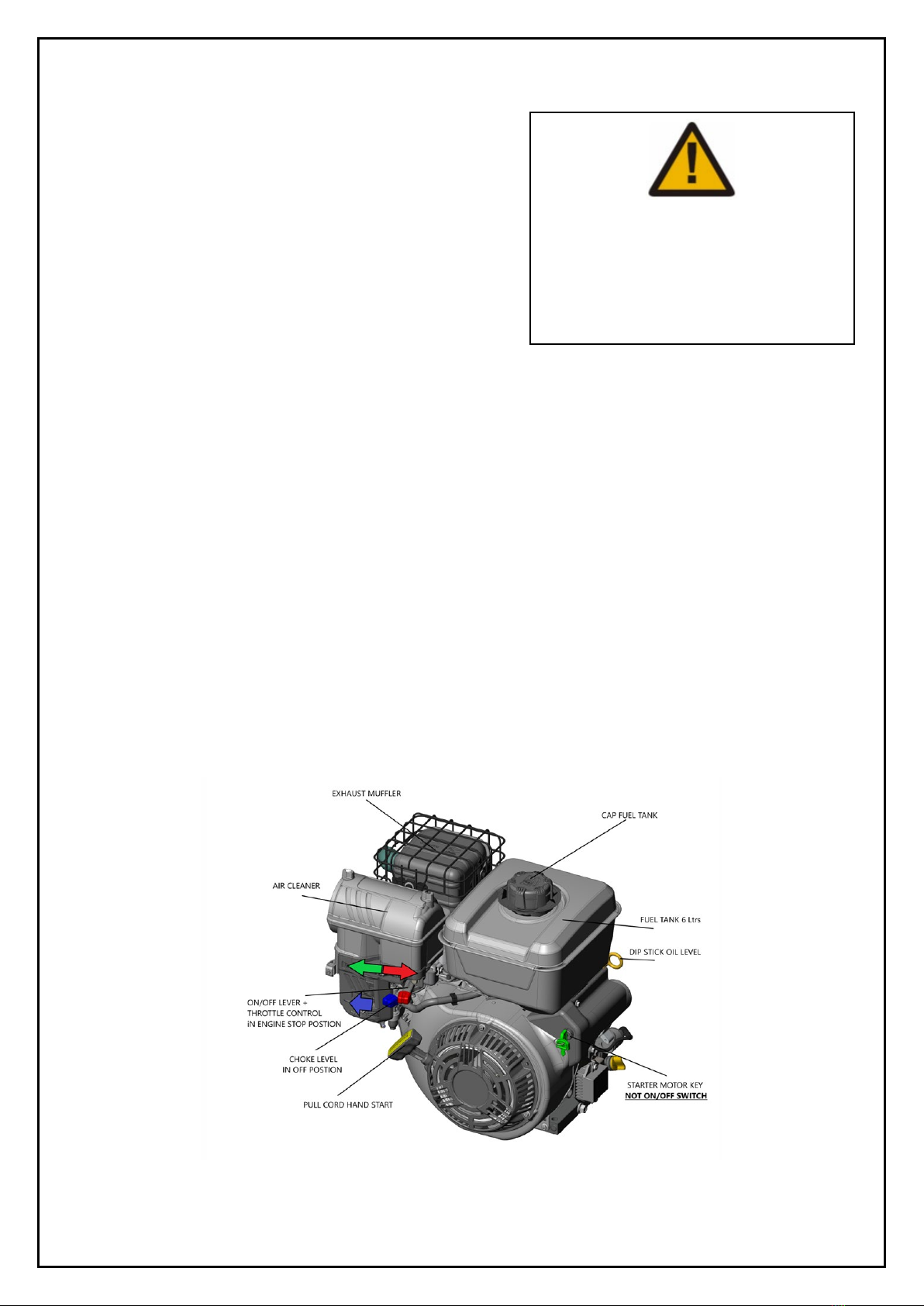

Parts Locator ................................................................................................................................. 5

Safe Working...........................................................................................................................................6

Operator’s Personal Protective Equipment (PPE)............................................................................ 6

Basic Crushing Operation Safety..................................................................................................... 6

General Safety Matters .................................................................................................................. 6

Engine Noise.................................................................................................................................. 7

Refuelling ...................................................................................................................................... 7

Operating Instructions ............................................................................................................................ 8

Storage and Parking ....................................................................................................................... 8

Starting the Engine ........................................................................................................................ 9

Stopping the Engine..................................................................................................................... 10

Crawler Tracking Controls ............................................................................................................ 11

Tracking....................................................................................................................................... 11

Crushing Controls ........................................................................................................................ 13

Crushing ...................................................................................................................................... 13

Troubleshooting .......................................................................................................................... 14

Service Instructions...............................................................................................................................15

Service Schedule.......................................................................................................................... 16

Check Fittings .............................................................................................................................. 18

Hazardous Materials and End of Machine Life .............................................................................. 18

Battery Safety Information ........................................................................................................... 19

Tension Drive Belts ...................................................................................................................... 20

Engine Servicing........................................................................................................................... 20

Hydraulic Servicing....................................................................................................................... 21

Warranty Statement .............................................................................................................................22

Declaration of Conformity ....................................................................................................................24

Identification Plate................................................................................................................................25

Circuit Diagram .....................................................................................................................................26