5. HEALTH & SAFETY INFORMATION

Have this tool repaired by a qualified person. This tool is designed to confirm to the relevant

international and local standards and as such should be maintained and repaired by someone

qualified; using only original parts supplied by the manufacturer: This will ensure the tool

remains safe to use.

5.2 SPECIFIC SAFETY INSTRUCTION FOR BANDSAW USE

Do not use saw bands which are damaged or deformed.

Replace table insert when worn.

Connect bandsaws to a dust collecting device when sawing wood.

Do not operate the machine when the door or guard protecting the saw band is open.

Take care; the selection of the saw band and the speed depends on the material to be cut.

Do not clean the saw band whilst it is in motion.

Wear suitable personal protective equipment, when necessary; this could include:

Hearing protection to reduce the risk of Induced hearing loss.

Respiratory [breathing] protection to reduce the risk of inhalation of harmful dust;

Gloves for handling the saw band and rough material.

Always keep hands and fingers away from the saw band, especially when coming to the end

of a cut.

Use a push stick or piece of scrap wood to do the pushing and guiding when sawing small

pieces which require the fingers to be close to the saw band.

Switch the machine off and let the blade come to a stop before removing scrap pieces from

the table.

Make all adjustments and set up with the power off and plug removed from power supply.

This includes tilting the table, adjusting the saw band guards, guide, tension and tracking.

Guards must be in place and securely fastened when performing any operation.

Securely lock all adjustable parts so they cannot move during operation. This will prevent

distraction from the operation.

When sawing curves, make relief cuts to allow removal of scrap material. This will help

prevent undue twisting or binding of the saw blade. The relief cuts are made before starting

the curved saw cut.

Hold material firmly and feed into the band at a moderate speed.

Be sure to use the correct band size and type for the application.

Do not saw any material that does not have a flat surface, unless a suitable support is used.

Permanently fix the bandsaw to a bench or stand before performing cutting operations.

Use in a well ventilated area to minimise airborne dust. Use of a suitable extraction device

and PPE equipment is required.

Before freeing any jammed material turn switch off, disconnect from power supply and wait

for all moving parts to stop.

Before starting to cut, watch and listen to the saw while it runs. If it makes an unfamiliar

noise or vibrates excessively, stop immediately. Turn the saw off and disconnect from the

power supply. Do not attempt to use the saw until the problem has been identified and

rectified.

13. MAINTENANCE

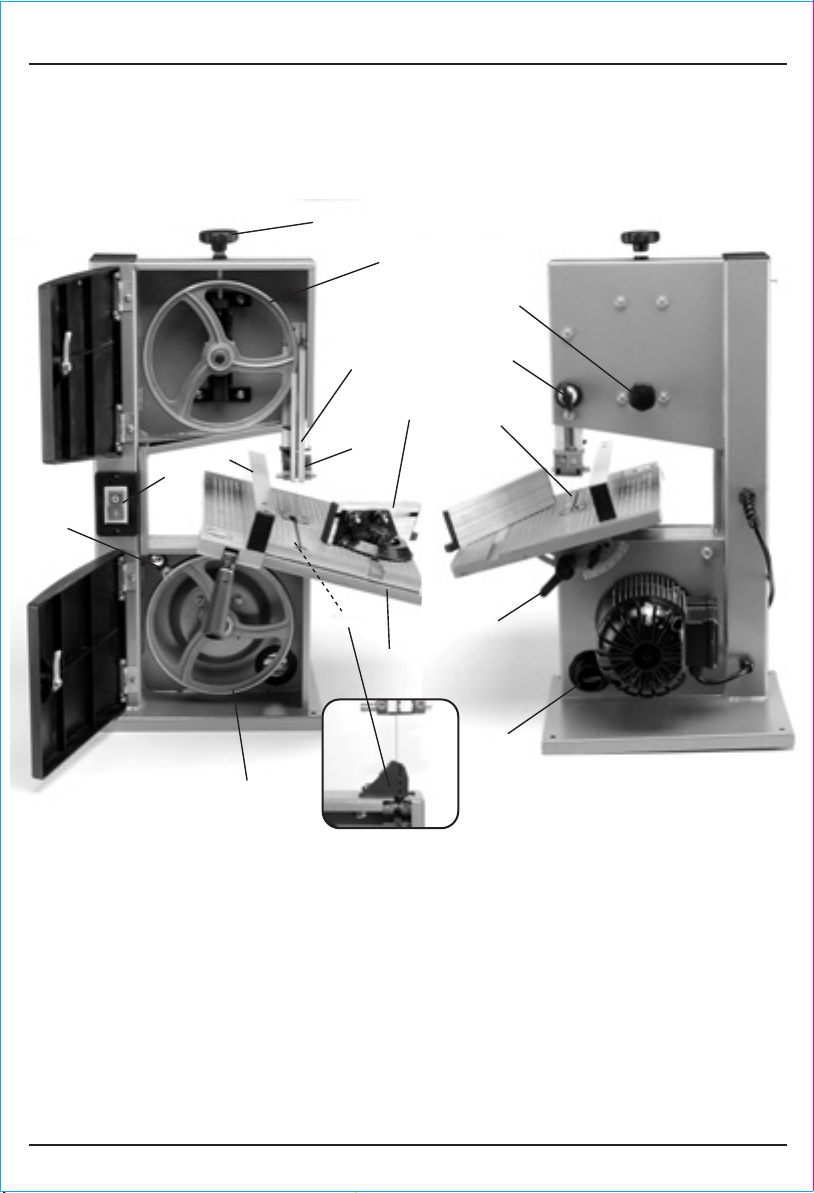

13.1 SLIDE ADJUSTMENT – FIG. 12

WARNING For your own safety turn switch off and remove plug from power supply before

attempting any adjustment or repairs.

CHANGING TYRES

Eventually the rubber tyres on the bandsaw wheels will wear due to the constant contact of

the sharp teeth of the blade. Lift the edge of the tyre with a small screwdriver and the tyre

can be worked off the wheel easily. We recommend that the two tyres be changed at the

same time. (See Spare Parts Listing/Drawing).

BLADE GUIDES

Blade guides should be inspected regularly for wear or chipping. When replacing guides

replace all guides at the same time, both upper and lower. (See Spare Parts Listing/Drawing).

BEARINGS

All bearings used in the construction of your bandsaw and its motor are sealed and

lubricated for life.

CLEAN OUT

Remove the plug from the socket before carrying out adjustment, servicing or maintenance.

Accumulated dust and chips should be removed from inside the bandsaw frequently. Open

the front covers and use a brush or vacuum cleaner. At the end of every work session clean

sawdust away from the motor vents.

Regular inspection and cleaning reduces the necessity for maintenance operations and will

keep your tools in good working condition.

The motor must be correctly ventilated during the tools operation. For this reason avoid

blocking the air inlets.

If the replacement of the supply cord is necessary, this has to be done by the manufacturer or

his agent in order to avoid a safety hazard.

21

8