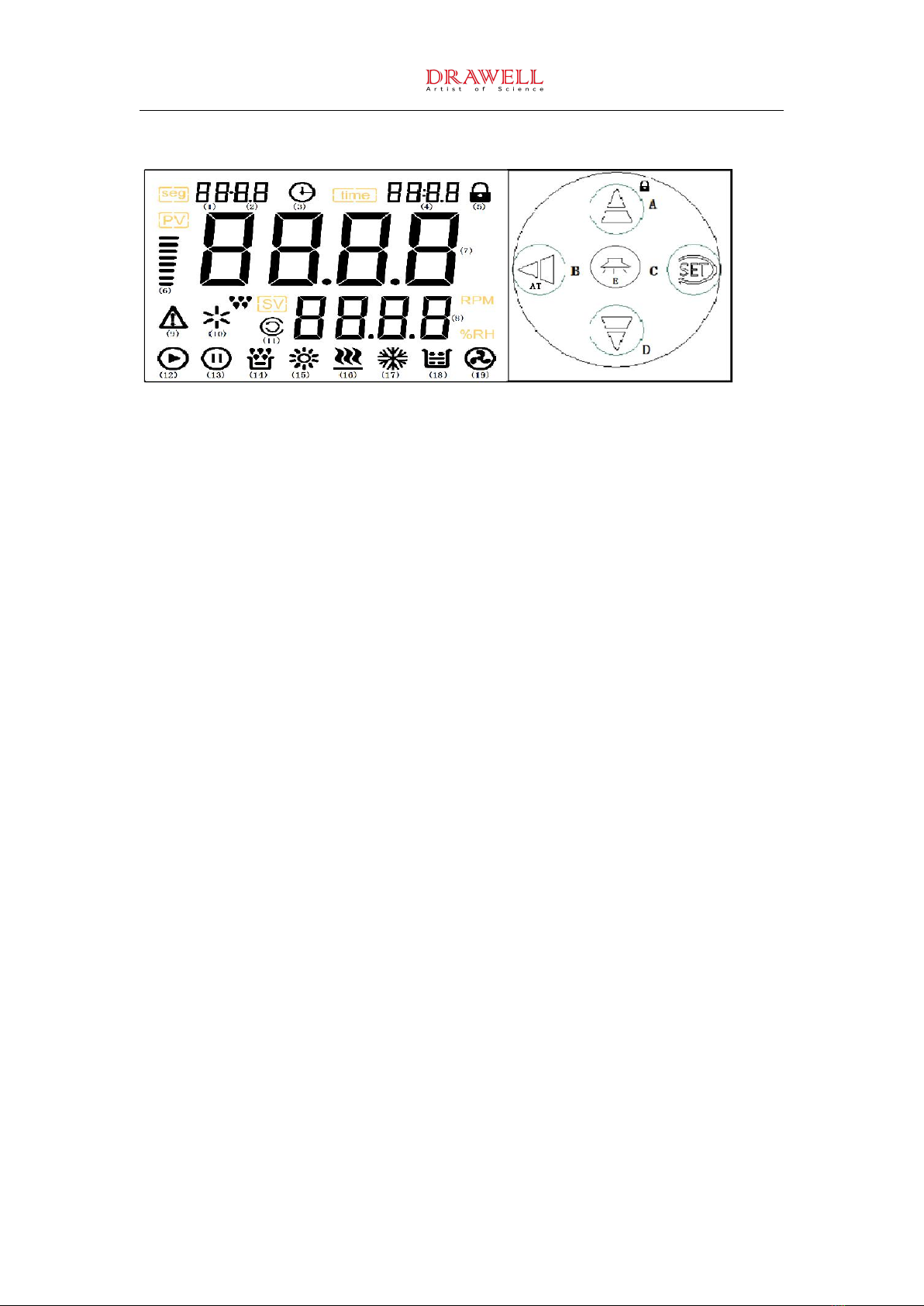

Panel:

2) Controller instructions:

(1) Cycles: display the number of cycles when it is a program segment;;

(2) Program segments: display the number of segments in program mode;

(3) Appointment time indicator: it lights when the appointment is turned on;

(4) Time: program segment time or fixed value timing time;

(5) Key lock;

(6) Reminder of temperature rise or fall;

(7) Measuring temperature;

(8) Set temperature;

(9) Alarm indicator: flashes when the machine is shut down or abnormal;

(10) Standby;

(11) Spare lights;

(12) Fan running indicator: it lights up when it starts running;

(13) Stop indicator: it turns on when the machine stops;

(14) Standby;

(15) Ultraviolet or illuminating lamp indicator: always on for illumination, flashing for UV

disinfection;

(16) Heating indicator light: on when heated;

(17) The refrigeration indicator: lights when there is refrigeration output and flashes when

refrigeration is delayed;

(18) Standby;

(19) Fan indicator light: lights up when the fan is workingt; ℃symbol: lights up when the

temperature unit is Celsius, ℉symbol: lights up when it is Fahrenheit;

3) Keyboard operation instructions

A: Key ∧: modify the parameter value; (long press for 5S to modify the existing running

time, with program has this function). Tap Lock or Unlock.

B: Shift key: Shift modification of parameter value, long press to start/stop temperature

auto-tuning, click to query ambient temperature.

C: SET key: Enter parameter setting,long press for 5 seconds to enter LK or exit

parameter setting.

D: Key ∨: Modify the parameter value, long press for 5 seconds to enter manual UV