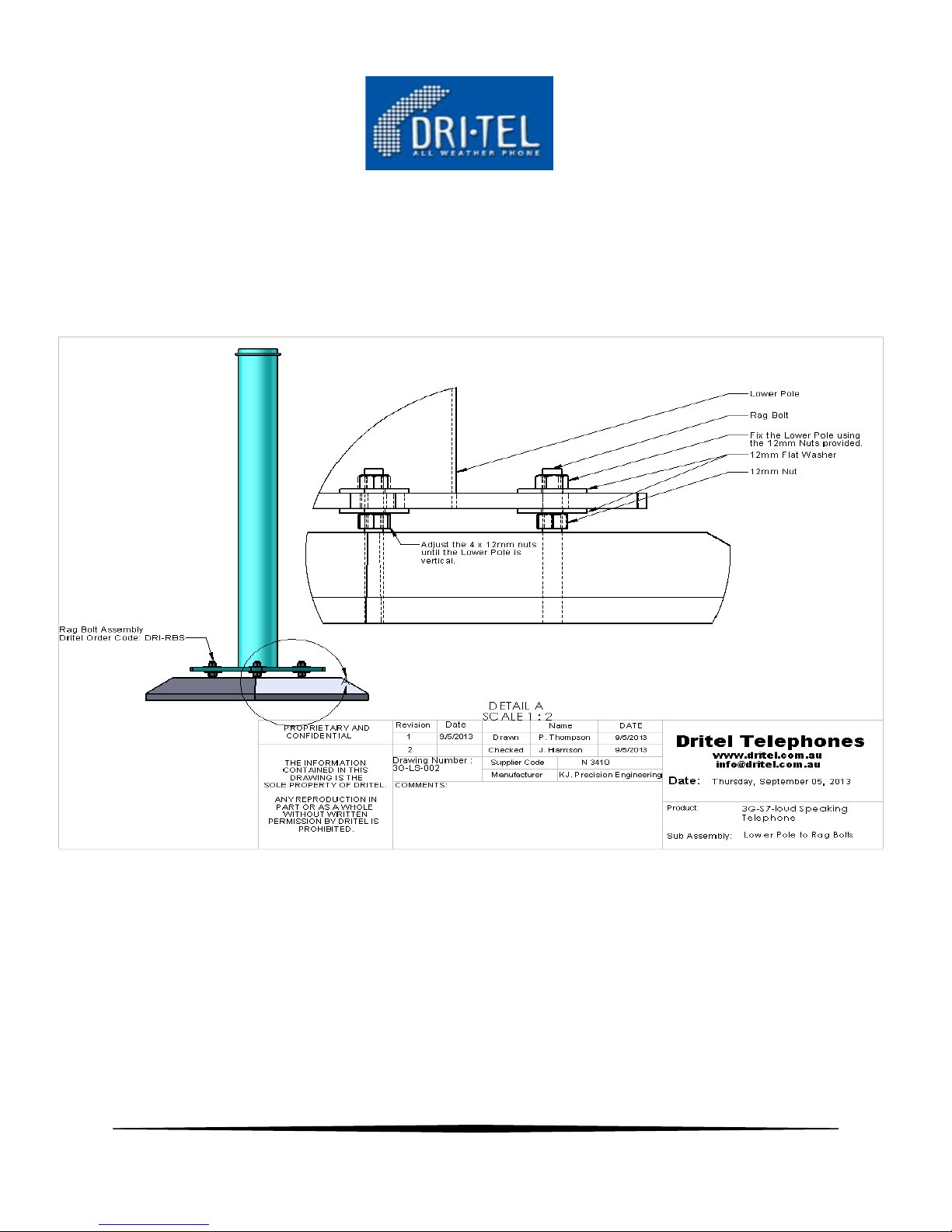

4

Manual Version 2/2013

INTRODUCTION

Thank you for selecting the Dritel Series 7 3G Solar Powered Telephone. Each unit is thoroughly tested and

inspected at our factory before delivery. We take particular pride in producing one of the finest quality products

available today. Please take a few minutes to familiarize yourself with this step by step manual before

commissioning the unit.

This phone is designed to meet all relevant specifications set out for safe and correct operation regarding its

application. We strongly advise against modifying or changing the method of installation as this may render the

phone unsuitable for its application. Incorrect installation procedure may render the warranty null and void.

Dritel believes service and backup of our products is paramount. Any questions or problems not covered in the

manual can be referred directly to the manufacturer, or to your local distributor for a quick resolution.

Please use the following contacts for assistance:

Manufacturer

KJ Precision Engineering, 16/388 Newman Rd Geebung, Brisbane, Australia, 4034,

Tel: +61 (7) 3265 3240 Email sales@kjeng.com.au for technical information regarding phones

info@kjeng.com.au for general inquiries