General recommendations

INTRODUCTION

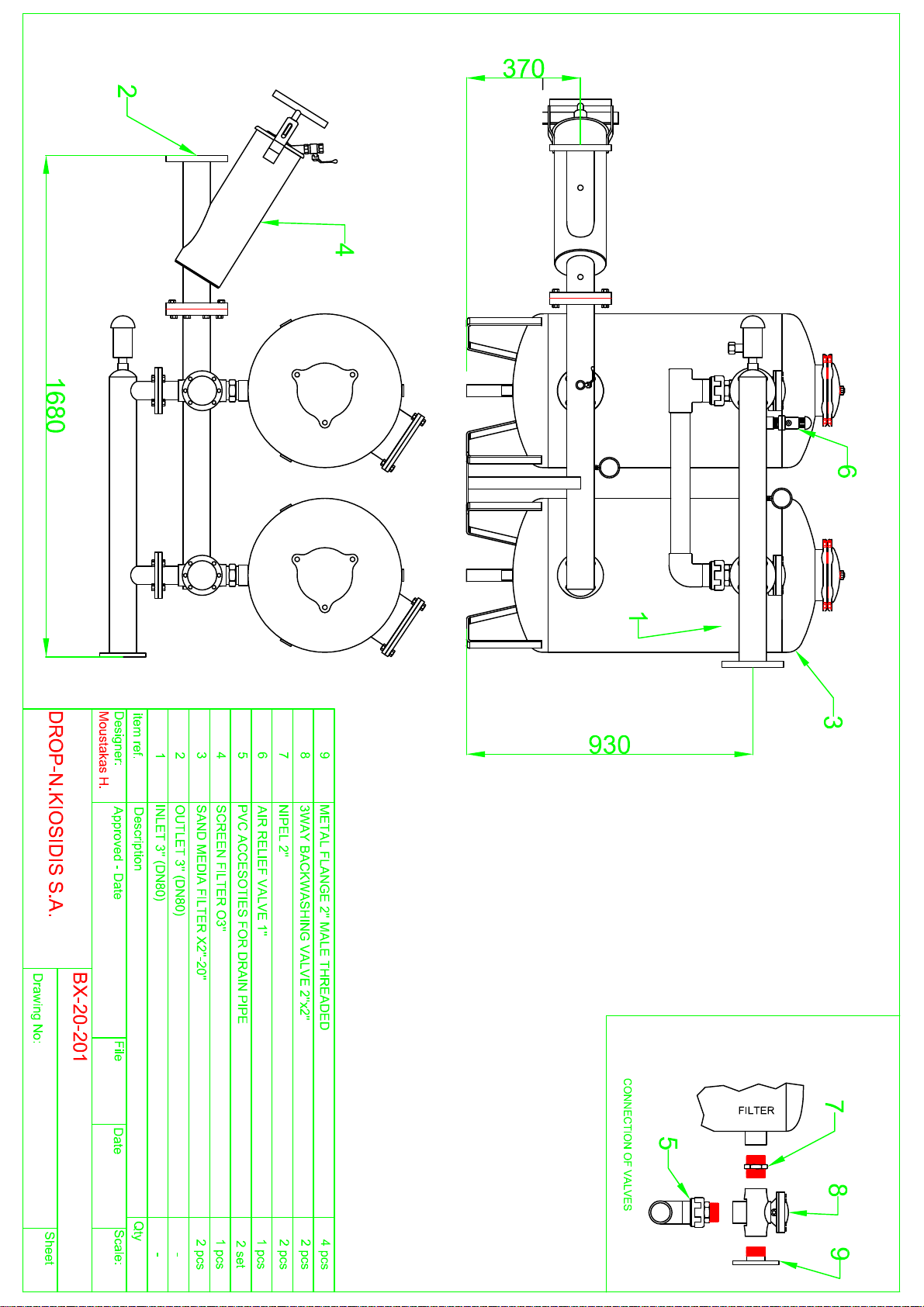

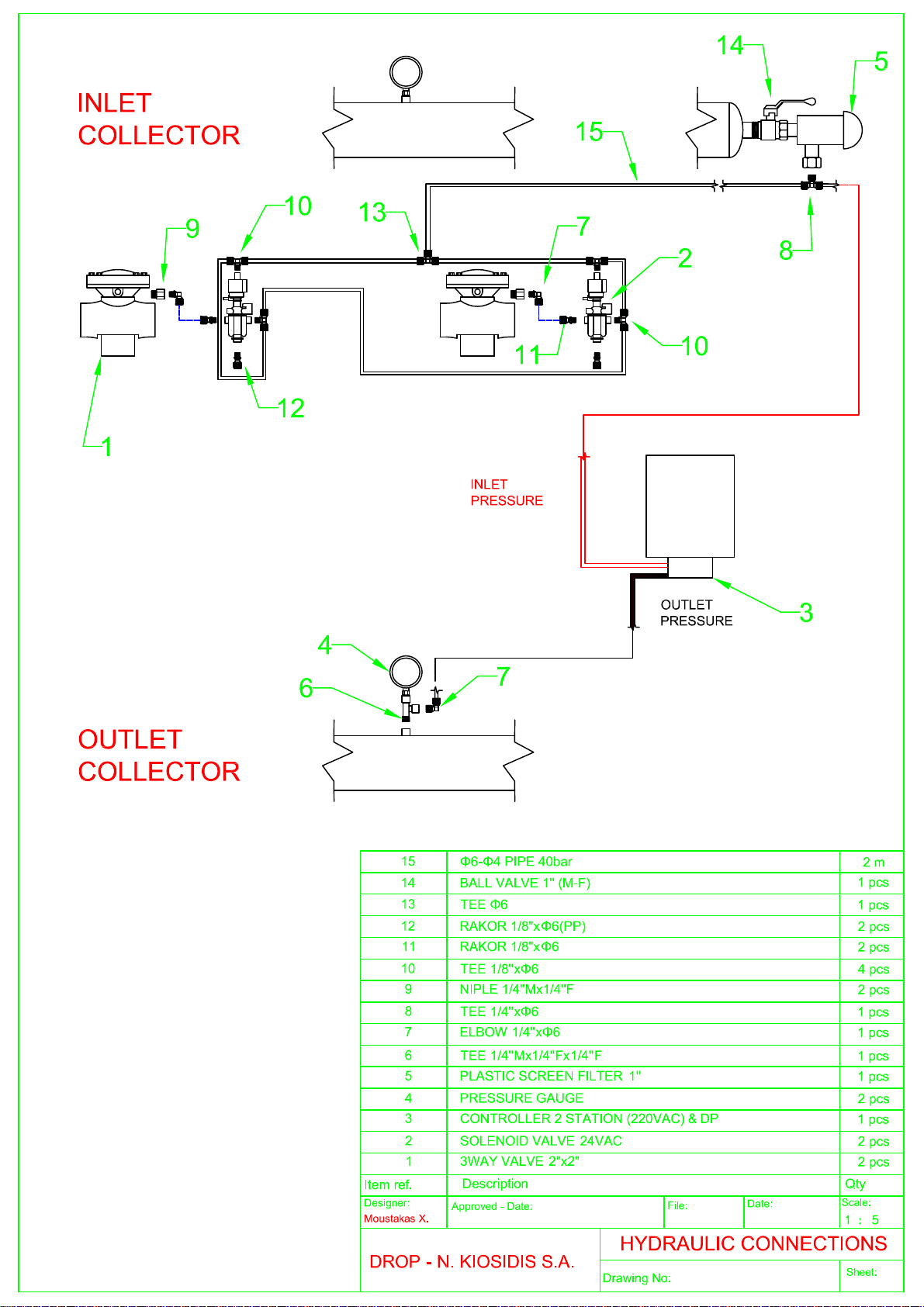

• In small facilities, with few filter elements, it is

recommendable to install a sustaining pressure

valve under the filtrate system, with the purpose of

guaranteeing sufficient pressure for the backwash

process of. This valve must go provided with a

control mechanism (electrical

or hydraulic) that manages its total opening during

the filtration process.

• In any case, whenever the installation does not

allow to maintain necessary the sufficient pressure

for the backwash one, it is advisable to place a

manual valve when coming out (of butterfly),

regulated properly to stabilize the pressure.

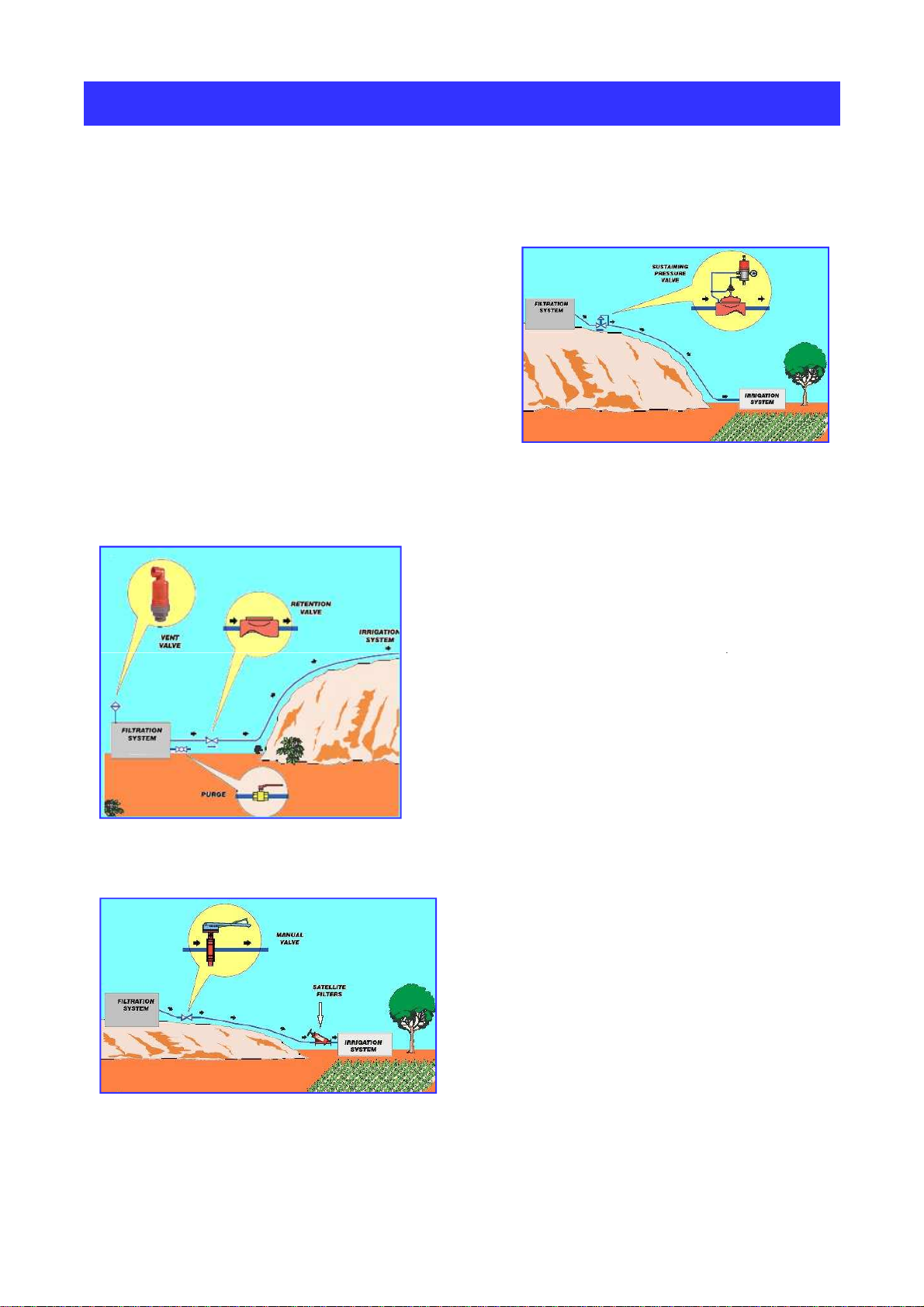

• With the purpose of eliminating the air that

could arrive at the filter elements, he is

recommendable to place a vent valve in an

advisable place of the system.

irrigation towards the filtrate, before a

shutdown of the pumping system, the

installation of a retention valve is advisable, in

cases in that the height waters down is greater

than where the

pressure system is located.

• With the purpose of being able to eliminate

the water of the system for operations of

maintenance one is due to have a purge valve.

• The use of satellites filters in the water

takings of the irrigation sectors

eliminates risks of cloggings of emitters.

These cloggings could be caused by the

grain formation by agglutinations of

dissolved substances that precipitate

throughout the conduction. Also risk of

clogging by a possible accidental

breakage of the conduction is run.

• As protection against overpressures

safety valves can be installed in the

system.