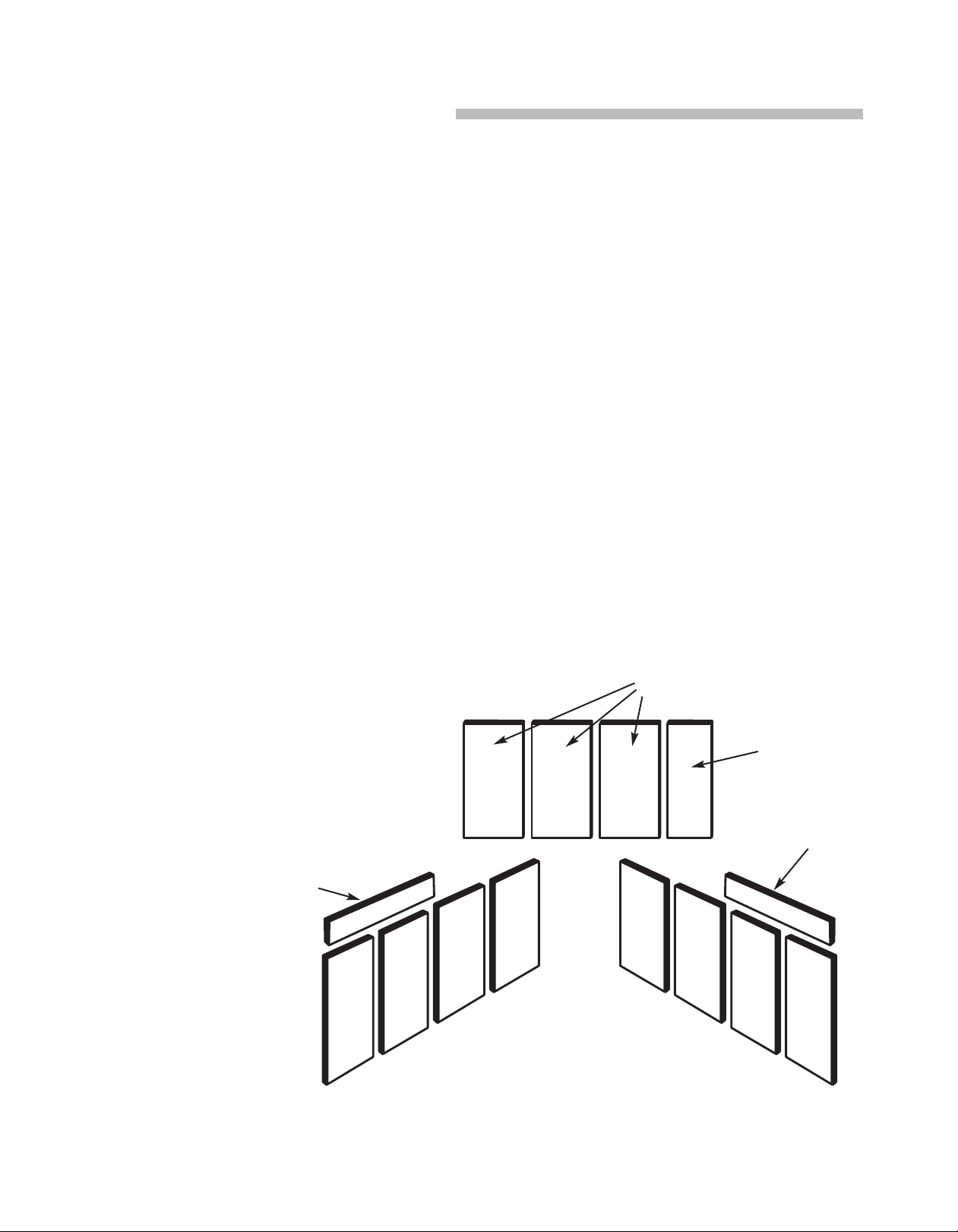

9

11/4 x 31/4x 81/4

Back

Left Side Right Side

11/4 x 11/4x 9

11/4 x 11/4x 9

Fire Brick List

8 pcs – 1-1/4 x 4-1/2 x 9 (sides bottom)

3 pcs – 1-1/4 x 4-1/2 x 8-1/4 (back)

2 pcs – 1-1/4 x 1-1/4 x 9 (sides top)

1 pc – 1-1/4 x 3-1/4 x 8-1/4 (back)

Assembly Instr ctions

Parts List – Fireplace Insert FP16

1-Right Side Sheet Metal . . . . . . . . . . . . . . . . . .FP16-RSS

1-Left Side Sheet Metal . . . . . . . . . . . . . . . . . . . .FP16-LSS

2-Surround Sides . . . . . . . . . . . . . . . . . . . . . . . . . .FP16-SSS

1-Surround Top . . . . . . . . . . . . . . . . . . . . . . . . . . .FP16-SST

2-Oversized Surround Sides (optional) . . . . .FP16-OSS

1-Oversized Surround Top (optional) . . . . . .FP16-OST

1-Back Sheet Metal . . . . . . . . . . . . . . . . . . . . . . . . .FP16-BS

1-Removable Coal Hopper (hopper only) . . . . . .FP-CH

1-Coal Hopper Door . . . . . . . . . . . . . . . . . . . . . . .FP16-HD

1-Right or Left Firebrick Angle . . . . . . . . . . . . . .FP16-FA

1-Ash Shaker Bar Assembly . . . . . . . . . . . . . . . . .FP-ASBA

4-Cast Iron 4” x 16” Grates . . . . . . . . . . . . . . . .4X16-C1G

2-Cast Iron Grate Rails for 2 – 4” grates . . . . . . . .44-GR

1-Cast Iron Fireplace Insert Fire Door . . . . . . . . . .X -FD

1-Cast Iron Ash Door 20” x 6” . . . . . . . . . . . . . . . . .20-AD

1 Ash Pan 15-1/2” wide x 21-1/2” long x 2-1/2”

deep . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155-215-25AP

1-Hopper Steel Lever w/wood handle . . . .FP16-HDH

2-Wood Door Handles for re and ash doors X -WDH

1-Wood Shaker Bar Handle . . . . . . . . . . . . . . .X -05WH

2-Wood Handles for Air Wash and Hopper

door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .X -03WH

2-Metal Door Handle (re and ash doors) . . .X -FDH

2-Door Latches (re and ash doors) . . . . . . . . . . .X -DL

1-62” 3/4” Rope Gasket (re door) . . . . . . . . . . . .34-GR

1-50” 3/4” Rope Gasket (ash door) . . . . . . . . . . . .34-GR

1-29” 5/8” Rope Gasket (hopper door) . . . . . . . . .58-GR

1-Fire Door Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . .X -GL

1-Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . .RB-312 Blower

1-9 Foot Power Cord . . . . . . . . . . . . . . . . . . . . . . . . .KK9SC

1-Left Baffle Re-burn . . . . . . . . . . . . . . . . . . . . . .FP16-LBR

1-Right Baffle Re-burn . . . . . . . . . . . . . . . . . . . . .FP16-RBR

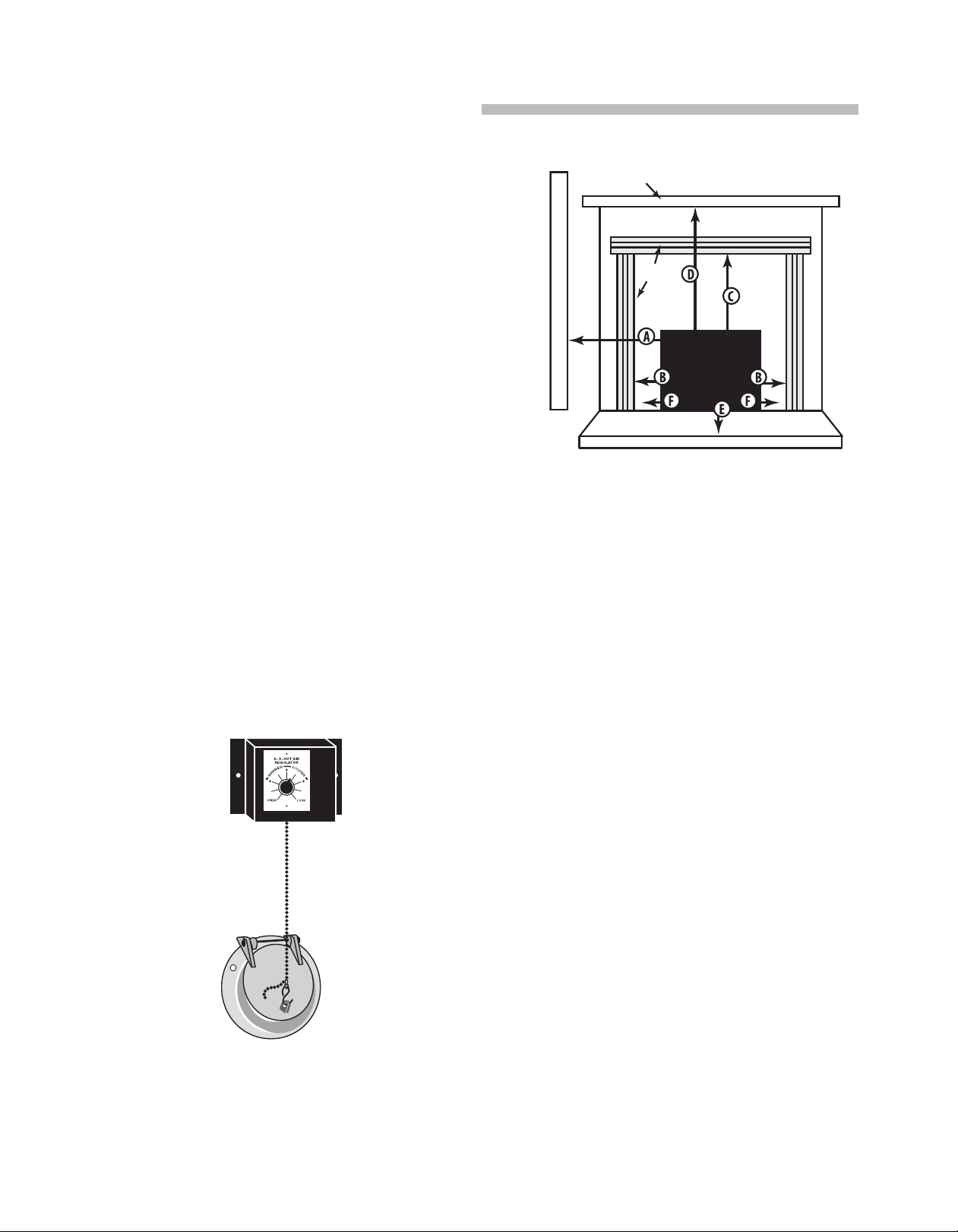

1-Hot Air Regulator . . . . . . . . . . . . . . . . . . . . . .FP16-HAR

1-Hot Air Regulator Chain . . . . . . . . . . . . .Hot A-Chain

1-Hot Air Regulator Fittings . . . . . . . . . .Hot A-Fittings

1-Hot Air Regulator Knob . . . . . . . . . . . . . .Hot-A-Knob

1-Draft Cover Plate . . . . . . . . . . . . . . . . . . . . . . .FP16-DCP

1-Draft Intake Cover Lid . . . . . . . . . . . . . . . . . . .FP16-DIC

1-Back Baffle Insulation (for top back of

re-burn baffle) . . . . . . . . . . . . . . . . . . . . . . . . .FP16-BBI

2-Side Baffle Insulation (for top sides of

re-burn baffles) . . . . . . . . . . . . . . . . . . . . . . . .FP16-BSI

1-Ash Pan Back Insulation

(for behind ash pan) . . . . . . . . . . . . . . . . . .FP16-APBI

1-Firebox Back Insulation

(blanket insulation) . . . . . . . . . . . . . . . . . . . .FP16-FBI

1-Firebrick Heat Deector

(11ga.SS 8-1/4 x 16-1/4 . . . . . . . . . . . . . .FP16-FBHD

1-Blower Speed Controller . . . . . . . . . . . . . . . .FAB-1100

11/4 x 41/2x 81/4

4 - 11/4 x 41/2x 9 4 - 11/4 x 41/2x 9