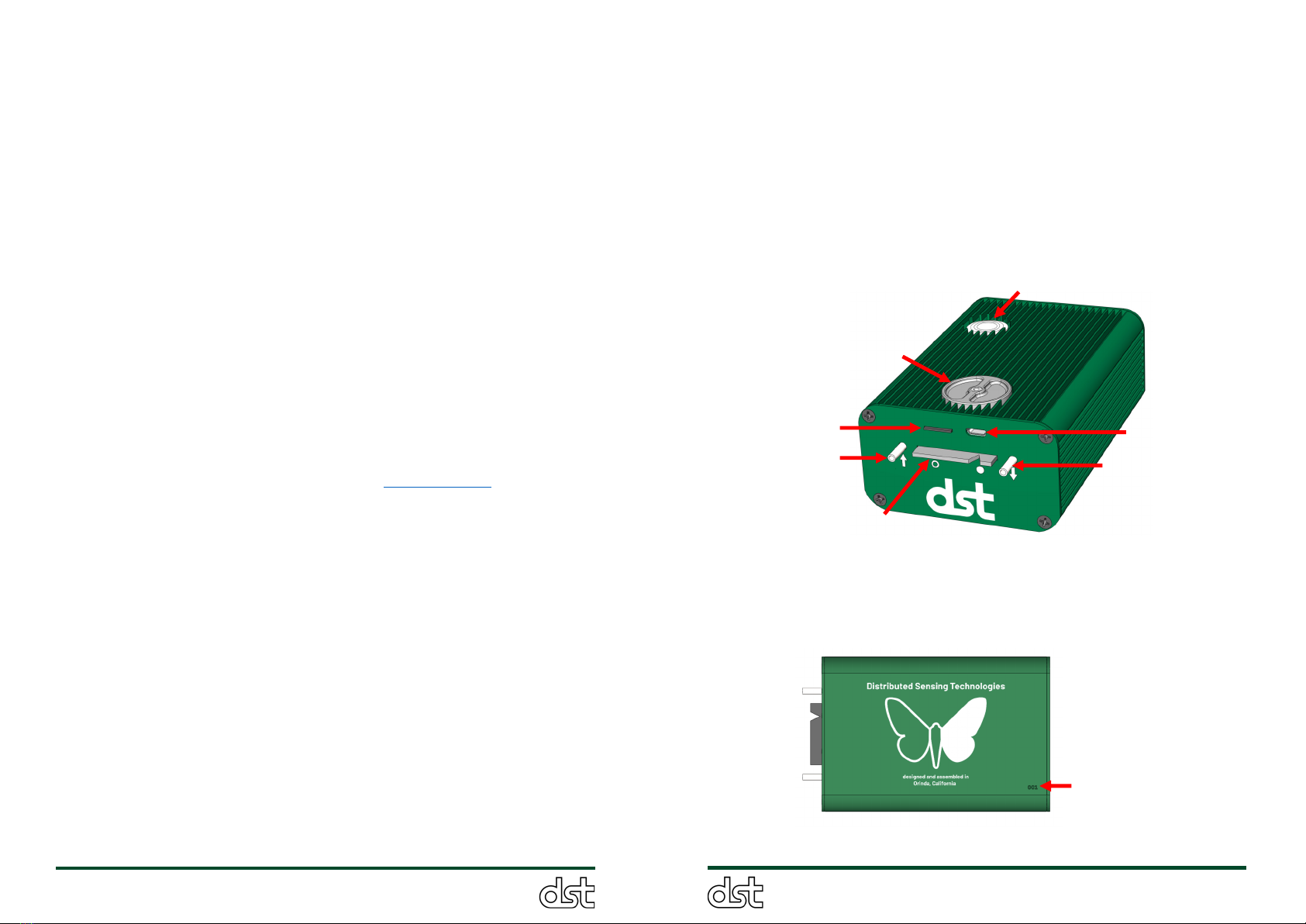

Each ObservAir comes with a magnetic cover, shown in Figure 6, that

mounts to the front panel and covers the USB port, SD card slot, and filter

tab to protect the sensor from moisture and dust penetration. The cover

simply slips over the inlet and outlet nozzles, and magnetically adheres to

the front panel. When not in use, the magnetic cover conveniently sticks to

the rear of the sensor for storage. Figure 7 shows the magnetic cover both

in use and in the storage position. The magnetic cover is also used to hard

reset the sensor as described in Section 6.2.

Figure 6. Magnetic cover being mounted to front plate.

Figure 7. Magnetic cover (a) in use on the front panel and (b) in the

storage position on the rear of the sensor.

3.2. Interactive LED button: Sensor display and control

The ObservAir’s interactive LED button is used to control basic operational

settings and display errors, pollutant concentrations, and other messages.

3.2.1. Sensor startup

To turn on the sensor, press and hold the button for 5 seconds until the

LED flashes green, and then release the button. The LED will shine yellow

while initializing the bootup sequence then briefly flash red, green, and blue

in sequence to indicate that it is starting normal operating mode. If no

errors or alarms are detected, the LED will begin to indicate current

pollutant concentrations by ‘breathing’ slowly (see Section 3.2.2 below).

The sensor should be allowed to warm up for 15 minutes before measuring

black carbon concentrations, and 30 to 60 minutes before monitoring

gaseous pollutants. For every new start up event, a new data file is created

on the SD card (.txt file) and is assigned a filename that contains the

sensor’s ID number and the start-up time/date (Section 3.5.1).

3.2.2. Default LED mode: Pollutant concentration display

When the sensor is operating normally (no errors or faults to report), the

LED slowly glows on and off in a ‘breathing’ pattern. By default, the color of

the breathing LED ranges from green to red to indicate the current BC

concentration. Green corresponds to a BC concentration of 0 µg/m3, and

red represents concentrations that are higher than or equal to a user

defined maximum setting (factory default is 5µg/m3). LED colors are scaled

according to BC concentration between these two limiting values. For

example, yellow corresponds to a BC concentration of 2.5 µg/m3with the

default settings. The LED can also be configured to display gaseous

pollutant concentrations. After 20 minutes, the LED turns off automatically

to conserve battery power. The LED can be turned back on by pressing the

button briefly, and it will breathe to indicate pollutant concentrations for

another 20 minute period. This LED timeout period can also be set by the

user. For instructions on configuring the LED display settings, please see

Section 3.6.3.

3.2.3. Sensor menu Interface

To interact with the sensor, press and hold the button. The LED will cycle

through flashes of different colors and patterns that correspond to the

menu items listed in Table 5. When holding the button, the LED cycles

through the menu options in the order listed with two seconds in between

each option. After reaching the desired menu item, release the button, and

the LED will flash the menu item color to confirm the selection. To exit the

menu, press and hold the button through the entire menu selection, the

LED will start breathing normally, and you can release the button.