PAGE 7

4190-00 60706-169

The Automatic Transfer Switch connects the load (lights,

furnace, outlets, etc.) to the normal power line during

standby. When normal power fails, the A.T.S. starts the

engine generator set, disconnects the power line and then

connects the load to the standby generator set. When

normal power is restored, the automatic switch retransfers

the electrical load to the normal service and stops the

engine. The A.T.S. panel should be mounted as close to

the distribution panel as possible.

*************

***** WARNING *****

*************

All wiring must be done by a licensed electrician, and

must conform to the national electrical code and comply

with all state and local codes and regulations. Check with

your electrical inspectors before proceeding!

************

***** DANGER *****

*************

Be certain the operation selector switch on the front of the

A.T.S. Control is in the “stop” position and the main power

switch “off”. For your own protection, verify these impor-

tant safety precautions yourself with reliable instruments

before proceeding.

A.C. ELECTRICAL CONNECTIONS

*************

***** WARNING *****

*************

A FUSED DISCONNECT OR CIRCUIT BREAKER

MUST BE INSTALLED BETWEEN THE GENERATOR

AND THE A.T.S. PANEL TO PREVENT OVERLOADING

AND BURNING OUT THE GENERATOR. FAILURE TO

PROVIDE A FUSED DISCONNECT OR CIRCUIT

BREAKER, RATED AT GENERATOR RATING WILL

VOID YOUR WARRANTY IN CASE OF GENERATOR

FAILURE.

Generator Connections

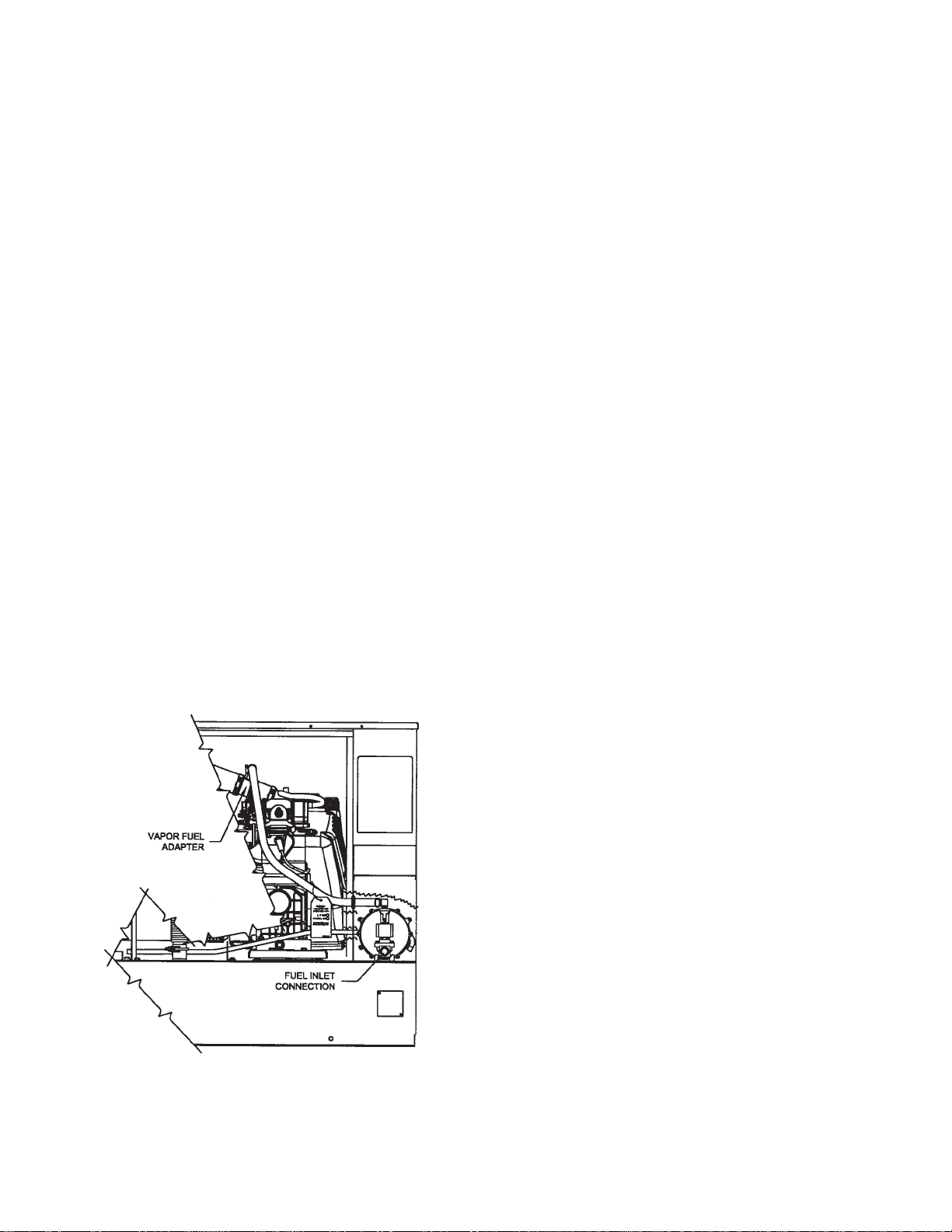

To gain access to the customer connections Remove

the end panel opposite the air dischage. All connections

including AC & DC connections to the ATS, 120 Volt

power connection for battery charger, fuel line connection

and battery installation are made behind this panel. After

removing the end panel you will need to remove the cover

over the connection box in the upper right hand corner.

Knockouts are provided on the outside of the enclosure

for your convenience. Three AC power leads are required

between the generator and the A.T.S. Two hot leads

connected generator leads G1 and G3 and a neutral lead

connected to generator leads N. A ground wire is also

required, which is connected to the ground lug mounting

bolt. These units are shipped with no neutral to

ground bond. You will need to run both the neutral and

ground leads in addition to the two power leads all the

way back to your distribution panel. Your distribution

panel should contain your only neutral to ground bond.

All power leads from the generator to the A.T.S. must

be sized to handle rated generator output amperage at a

minimum, the type of wire you use will determine the

gauge required. Consult your local wire supplier for proper

gauge and type for your area.

In addition to the power leads you will also need to run a

three wire 120 volt, 15 amp circuit from your distribution

panel to the generator. This circuit will be used to power

the battery charger and the optional block heater and

battery heater

The last two wires you will need are the DC control

leads for the start circuit in the A.T.S. These last two

connections wil be discussed later in more detail.

A.T.S .Connections - for standard Non-UL WINCO ATS

The standby generator terminals in the A.T.S are

marked “GENERATOR - G1, G-N, G3”. The “hot” leads

G1 and G3 from the generator are wired to the generator

side contactor, terminals G1 and G3.

The line terminals in the A.T.S. are marked “LINE - L1,

L-N, L3”. The “hot” line leads L1 and L3 are wired to the

line side contactor, terminals L1 and L3.

The load terminals in the A.T.S. are marked “LOAD - T1,

T-N, T3”. The “hot” leads T1 and T3 are wired to the

bottom side of both the line side and the generator side

contactor.

If you are using a separate ground lead it is routed to

the ground lug in the A.T.S.

ASCO UL ATS (165 & 300 Series)

See the ASCO operator manual shipped with the

transfer switch for proper wiring instructions.

INSTALLATION NOTES

The load current carrying wires (L) and (T) must be

sized to handle the maximum load current without

excessive voltage drop. By code, the wire must be heavy

enough to handle the full current rating of the main line

circuit-breaker (or fuse) in the entrance (or sub-panel)

protecting the contactor switch.

All wires should be installed in rigid or flexible conduit.

(Knockouts are provided in the control box)

Because of the many different types of service, feeder,

and distribution equipment, no specific wiring instructions

can be provided. It is, however, recommended that only

copper wire be used. In all cases it is essential that while

the load is connected to the generator, there can be

absolutely no feedback from the generator to the power

line or the power line to the generator. When properly

installed, the normal A.T.S. control and safety systems will

eliminate all paths for feedback. Check with your local

electrical inspector on applicable local, state and federal

codes.