6

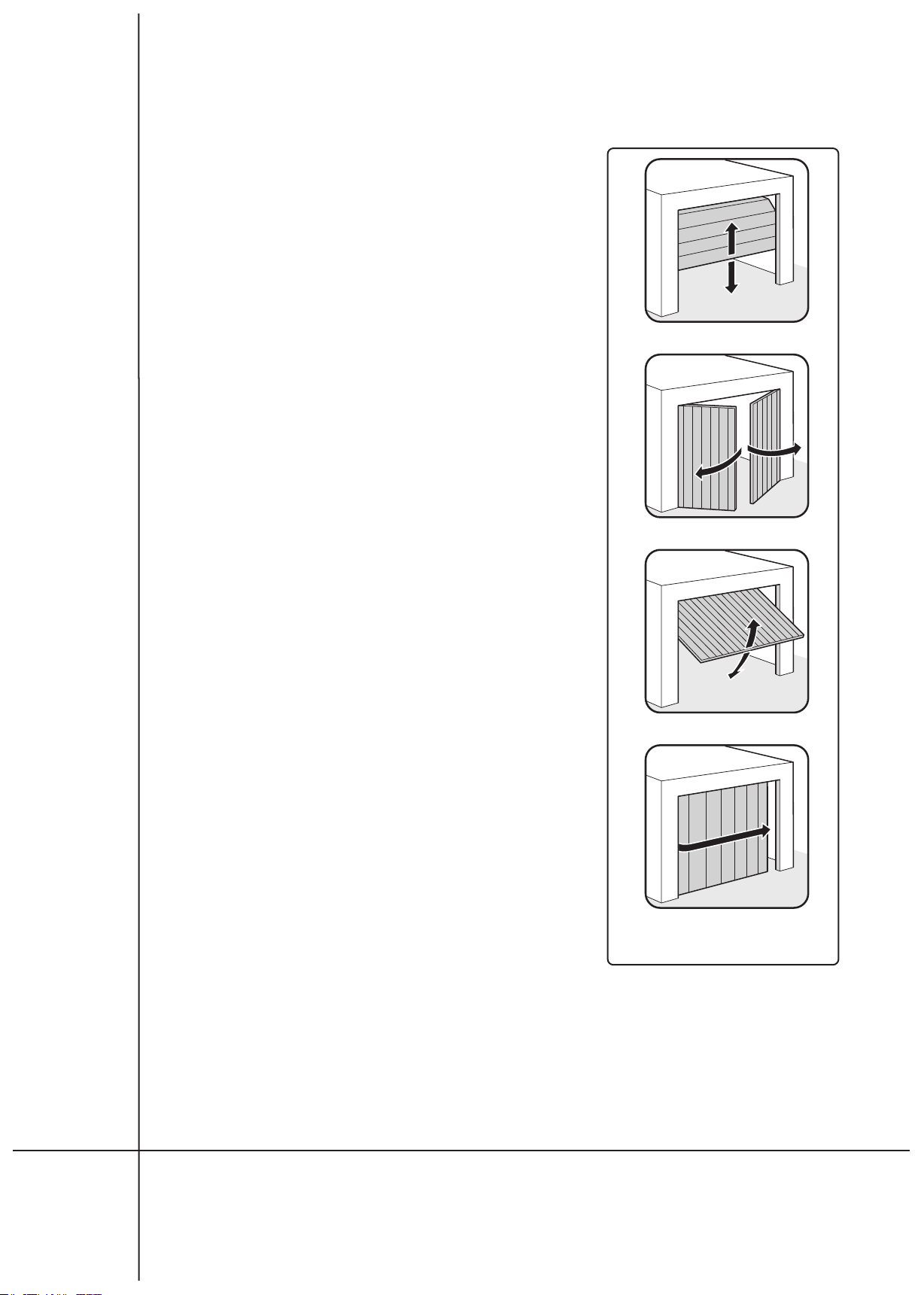

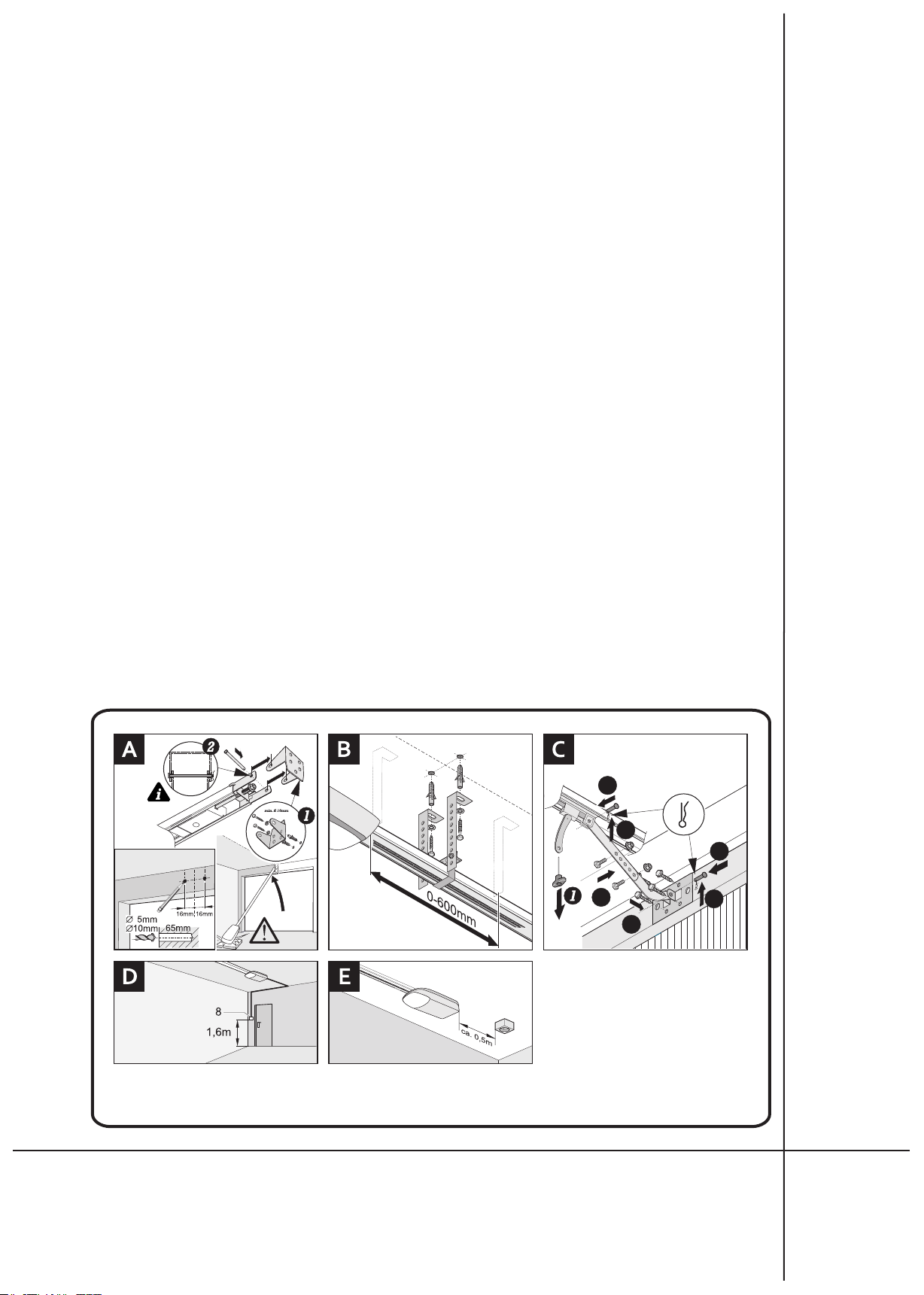

•The basic set allows you to automate sectional doors with an ordinary running rail - it is recommended to

use a "boomerang" type handle, with a double running rail - without a "boomerang", up-and-over gates -

without a "boomerang", and after adding an additional elements for side and swing gates (figure 2);

•The structural elements of the gate must meet the requirements of EN 12604 and EN 12605;

•The dimensions of the gate must not exceed the dimensions given

in the drive parameters;

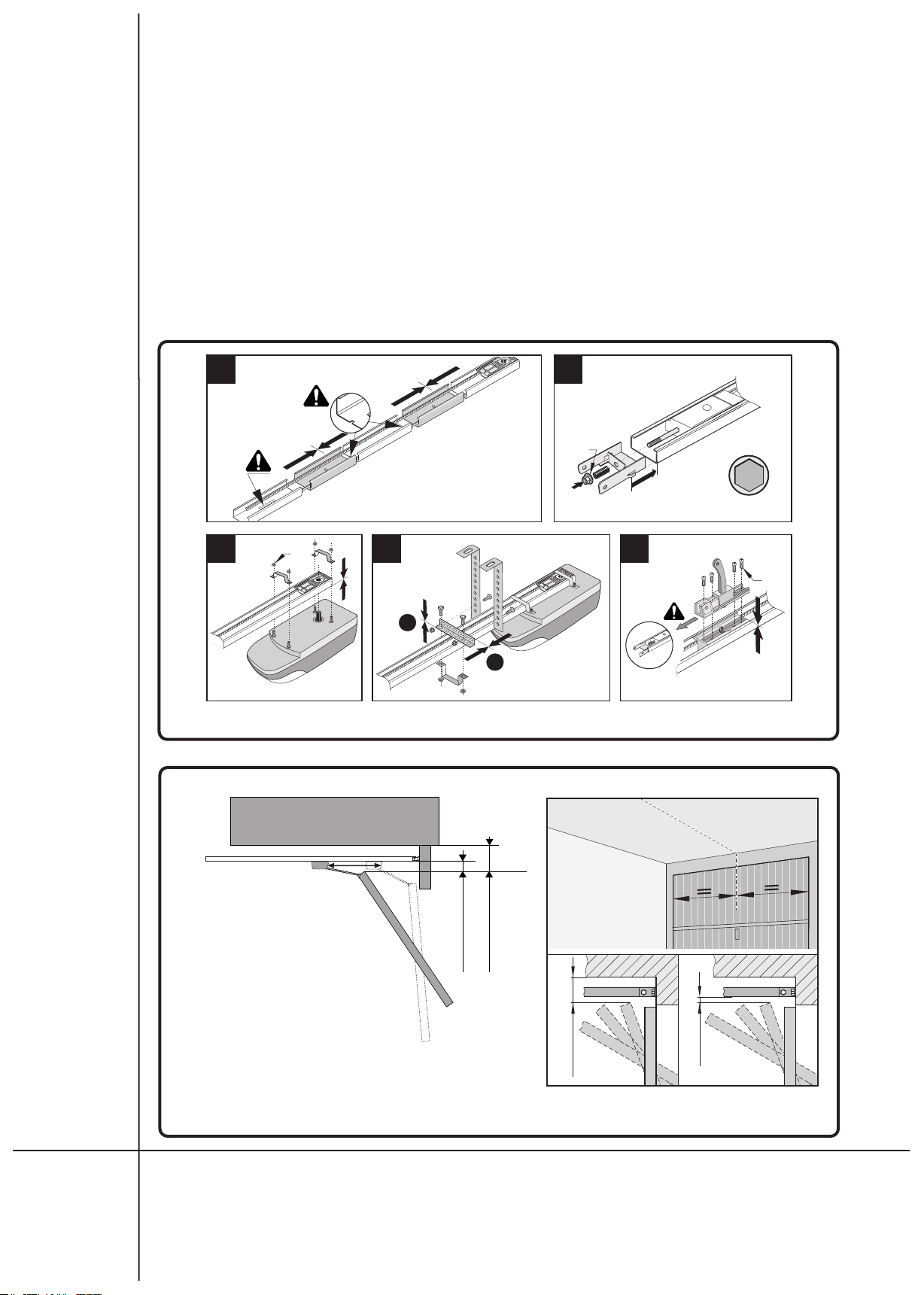

•Check the possibility of mounting the drive, taking into account

the installation dimensions;

•The drive mechanism requires sufficient space between the ceiling

and the door for mounting the running rail. It should also be

checked whether the part of the drive protruding beyond the load-

bearing structure of the gate has sufficient space.

•assembly of the automated system;

•The gate must move smoothly and freely throughout the entire

range of motion without any resistance;

•After opening the gate to half its height, the gate must remain in

this position, free movement up or down should be corrected by

appropriate adjustment of the gate;

•Check that the electrical installation allows the connection of the

drive. If this is not the case, qualified personnel must provide a

230VAC power socket at a distance of about 0.5m from the drive

head.

Notes on the gate and its surroundings:

•The area of the gate is an approximate parameter. However, the

maximum permissible door size should not be exceeded. The actual

force transmitted by the drive is influenced by: gate type, gate

weight, air movement around the gate;

•Low temperatures and high humidity may make it difficult or

impossible to start the automation;

•The drives are not designed for continuous operation, the maximum

operating frequency specified in the drive parameters must be

maintained;

•The gate must operate smoothly and without impact, movement

must be smooth and unobstructed;

•The drive cannot be used to operate emergency exits or gates on an

escape route (see escape routes);

•If there is a pedestrian door on the powered door, a safety switch

must be installed to prevent the automatic system from operating

when the door is open;

•The condition of the door structure has a direct impact on the

reliability and safety of use of the entire system

•It is recommended to complete the assembly of the steel structure

before installing the drive;

•Determine what materials are needed to install the kit and provide

them before starting the installation. This applies to anchors, bolts,

brackets, cables, electrical fixtures, tools.

2.2. Preparation of the gate

The type of gate determines the position in which the drive will be installed. The gate hardware should

be attached to the main frame or to the gate panel through a suitable holder. When the bracket is not sufficiently

stable, it must be strengthened. When we have a wooden gate, the gate hardware should be screwed "through".

In such cases, it is advisable to use the board from the outside so that the fastening cannot loosen over time.

Delicate aluminum, wooden gates must be additionally reinforced to withstand the stresses caused by the drive.

Fig. 2. Types of garage doors.

sectional gate

swing gate

up-and-over gate

side gate