3

Table of Contents

Section 100 System Installation Instructions

Description Page

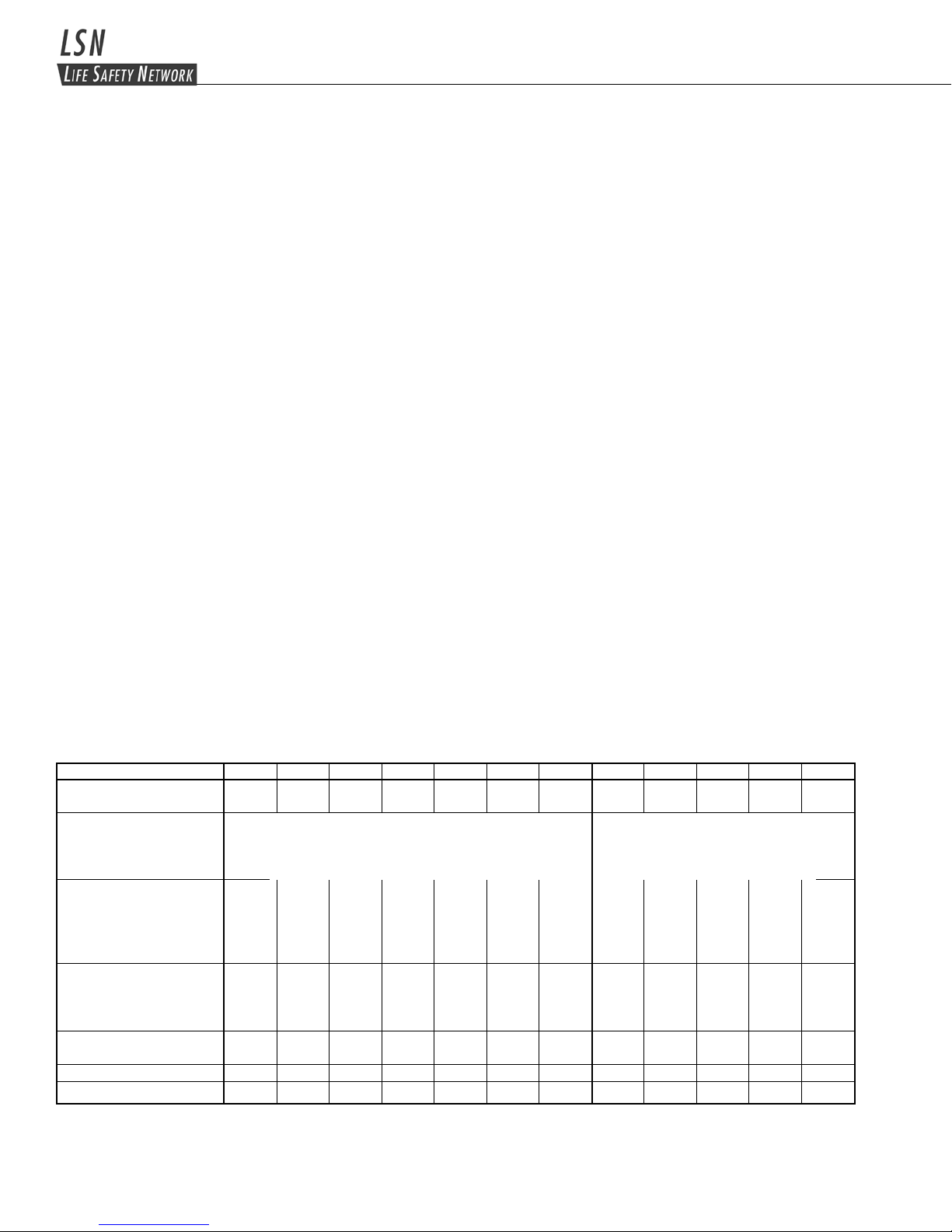

101. UnitSpecications ........................................................................................................................................................... 4

102. Receiving, Moving and Storing Systems and Batteries ............................................................................................... 5

102.1 Shipping Damage................................................................................................................................................................ 5

102.2 Moving Units and Batteries ................................................................................................................................................. 5

102.3 Temporary Storage of Units and Batteries .......................................................................................................................... 5

103. Installation Requirements................................................................................................................................................ 6

103.1 Operating Environment ....................................................................................................................................................... 6

103.2 High Altitude Operation ....................................................................................................................................................... 6

104. Cabinet Mounting (Physical) ........................................................................................................................................... 7

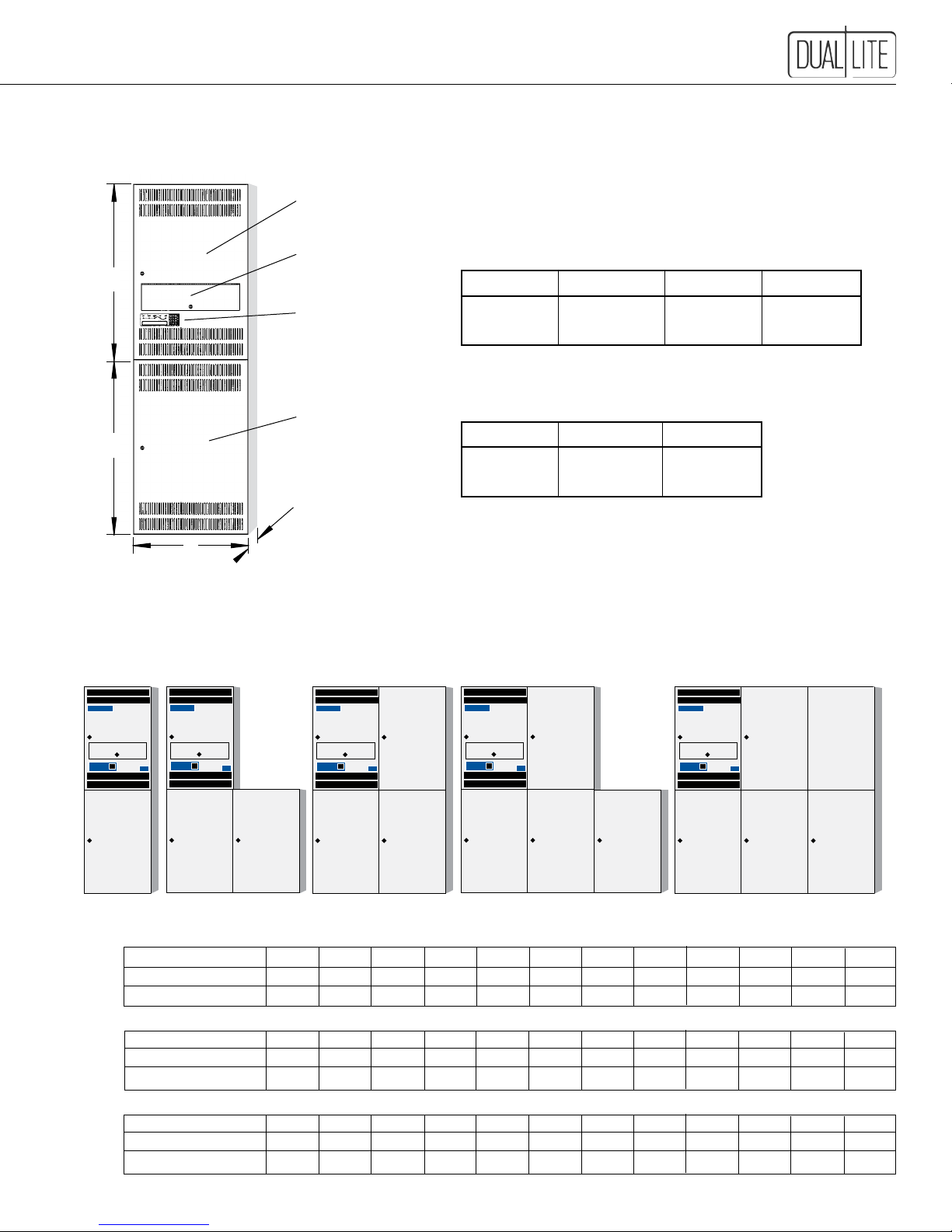

104.1 Dimensions ......................................................................................................................................................................... 7

104.2StandardCabinetCongurations........................................................................................................................................ 7

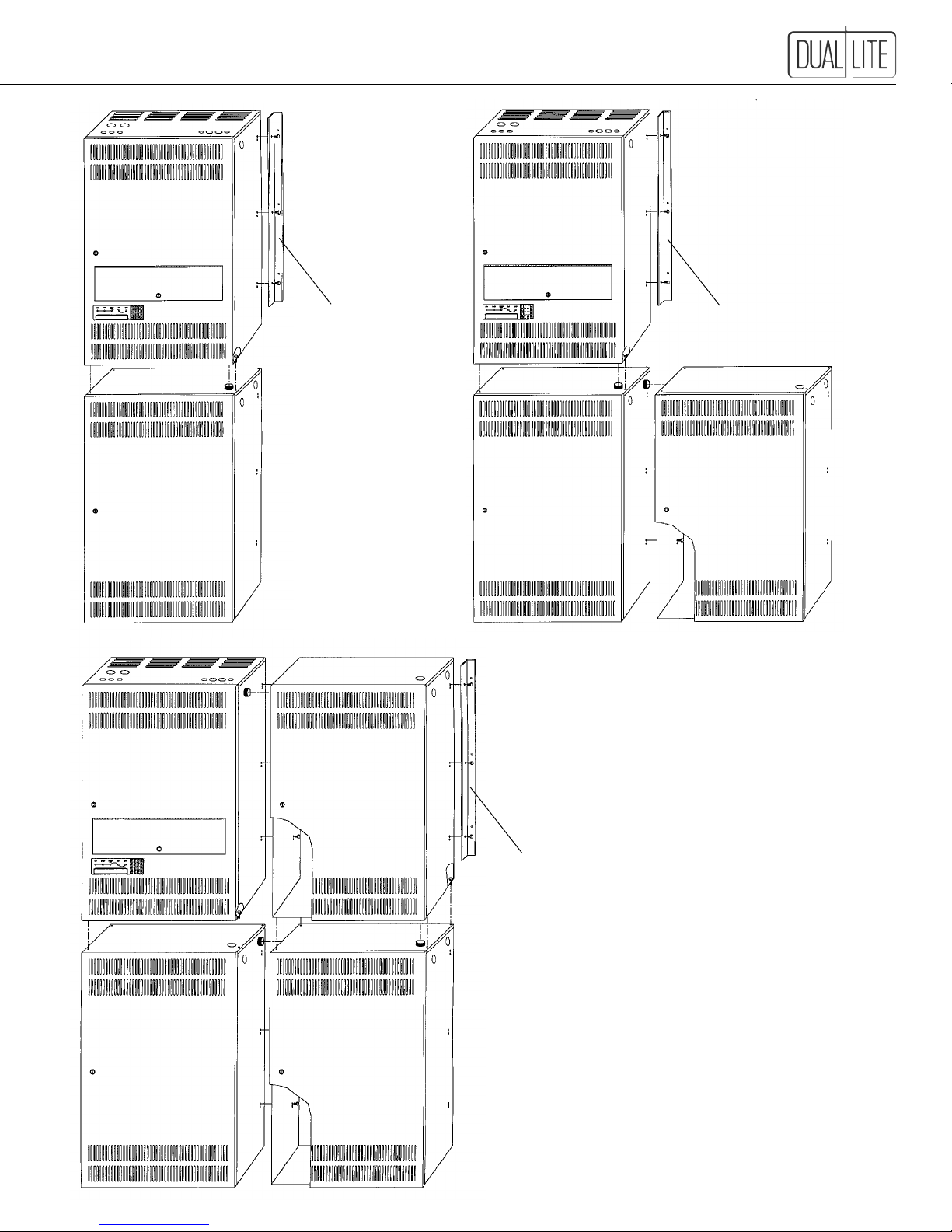

104.3 Cabinet Installation........................................................................................................................................................... 8,9

105. Battery Installation and Connection............................................................................................................................. 10

105.1 Tools...................................................................................................................................................................................11

105.2 Installation Considerations ................................................................................................................................................ 12

105.3 Battery Installation Procedure...................................................................................................................................... 12-16

105.4 DC Fuse Installation.......................................................................................................................................................... 17

105.5 Electronics Cabinet Voltage Check................................................................................................................................... 17

106. AC Connections.............................................................................................................................................................. 18

106.1 AC Wiring Preparations..................................................................................................................................................... 18

106.2 AC Input and AC Output Connections............................................................................................................................... 19

107. RS-232 Communications Connections ........................................................................................................................ 20

108. Final Installation Checklist ............................................................................................................................................ 20

109. Maintenance Bypass Switch Phase Check.................................................................................................................. 21

110. System Start-Up Procedure........................................................................................................................................... 22

111. SystemVerication ........................................................................................................................................................ 22

Section 200 User Manual

Description ...........................................................................................................................................................................Page

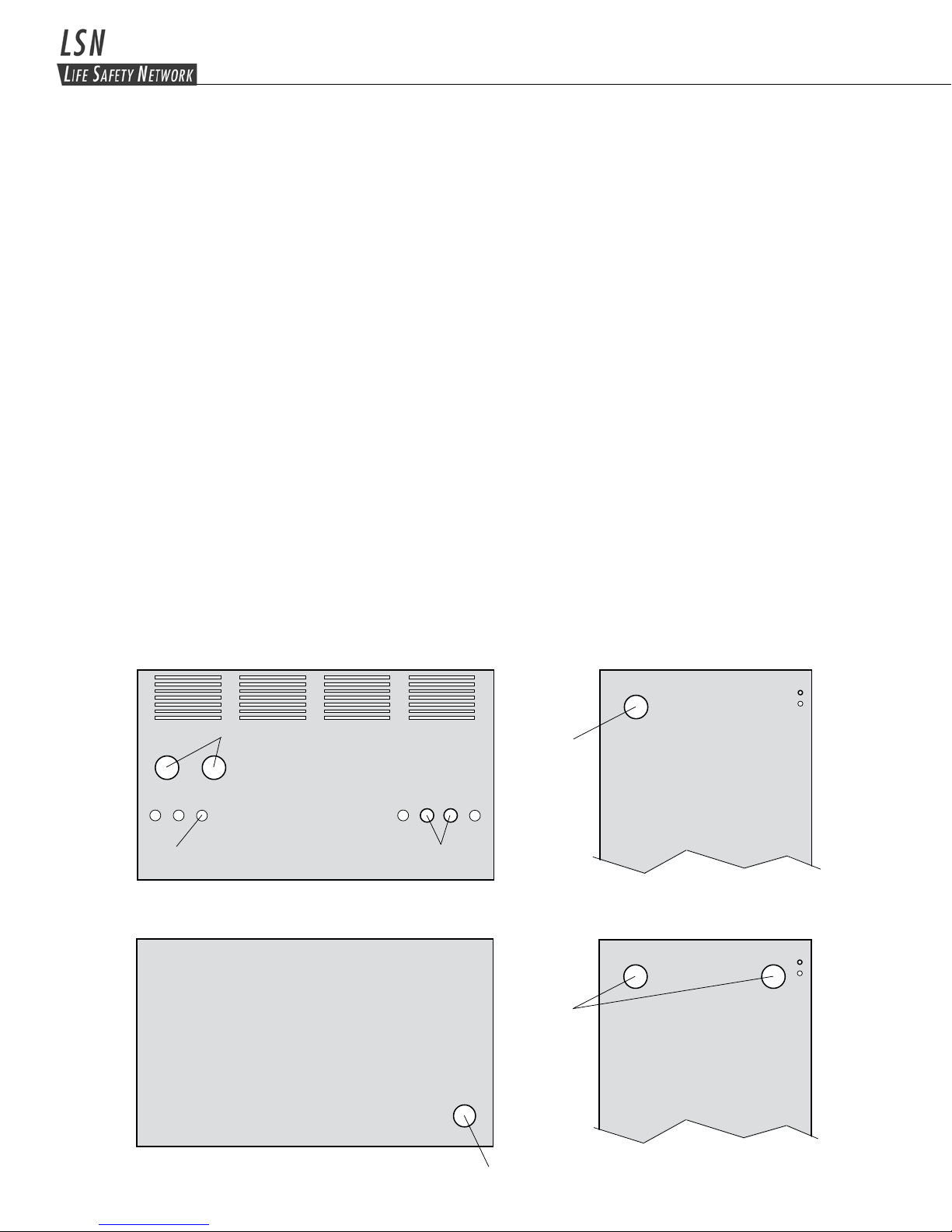

201. User Interface Panel....................................................................................................................................................... 23

201.1 User interface Panel Basics.............................................................................................................................................. 23

201.2 Using The Interface Panel................................................................................................................................................. 24

201.3 How To Display A Parameter............................................................................................................................................. 24

201.4 How to Clear A User Password ......................................................................................................................................... 24

201.5 How o Change A Parameter Value.................................................................................................................................... 24

201.6 How to Change Operating Modes..................................................................................................................................... 25

201.7 Parameter "Hot Key" Listing By Function..................................................................................................................... 26,27

202. System Diagnostics ....................................................................................................................................................... 28

203. System Auto Testing ...................................................................................................................................................... 28

203.1 Weekly Test....................................................................................................................................................................... 28

203.2 Monthly Test ...................................................................................................................................................................... 28

203.3 Annual Test........................................................................................................................................................................ 28

203.4 Extended Power Outages ................................................................................................................................................. 28

203.5 Performing A Manual Test ................................................................................................................................................. 29

204. Stored Test Results (Logs)............................................................................................................................................ 29

205. Alarms ............................................................................................................................................................................. 31

206. Communications ............................................................................................................................................................ 33

207. Unit Communication Options........................................................................................................................................ 33

208. Service Options .............................................................................................................................................................. 34

Section 300 Maintenance, Warranty and Technical Support

300. Maintenance.................................................................................................................................................................... 35

300.1 Safe Shut Down Procedure............................................................................................................................................... 35

300.2 Routine System Maintenance ........................................................................................................................................... 36

300.3 Changing Air Filters........................................................................................................................................................... 36

300.4 Battery Maintenance and Replacement....................................................................................................................... 37-39

301. Warranty Information ..................................................................................................................................................... 39

302. Technical Service and Support ..................................................................................................................................... 39

Appendix 1 ...................................................................................................................................................................... 40