NORDAC ON / ON+ (SK 3xxP) – Manual with installation instructions

4 BU 0800 en-4521

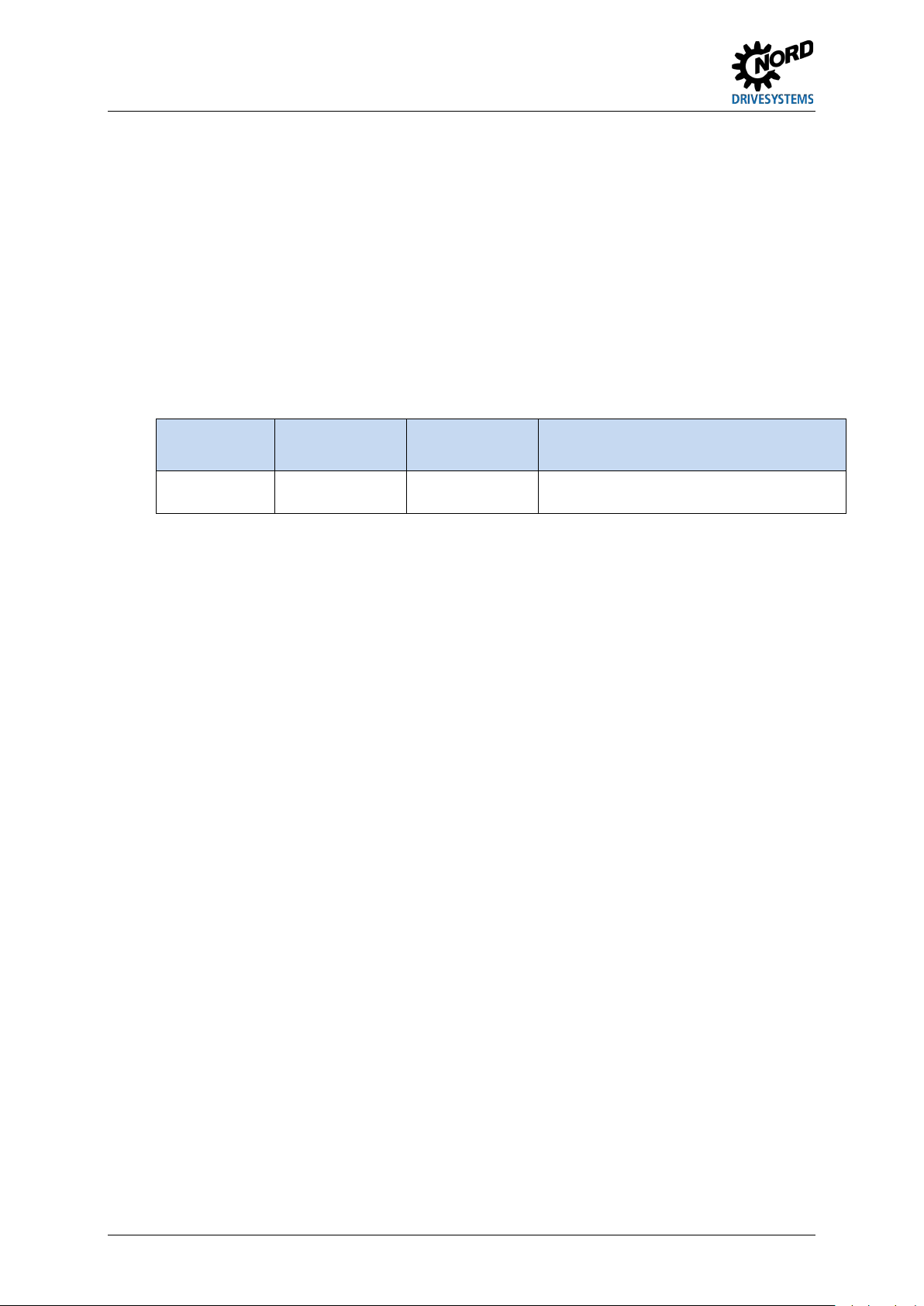

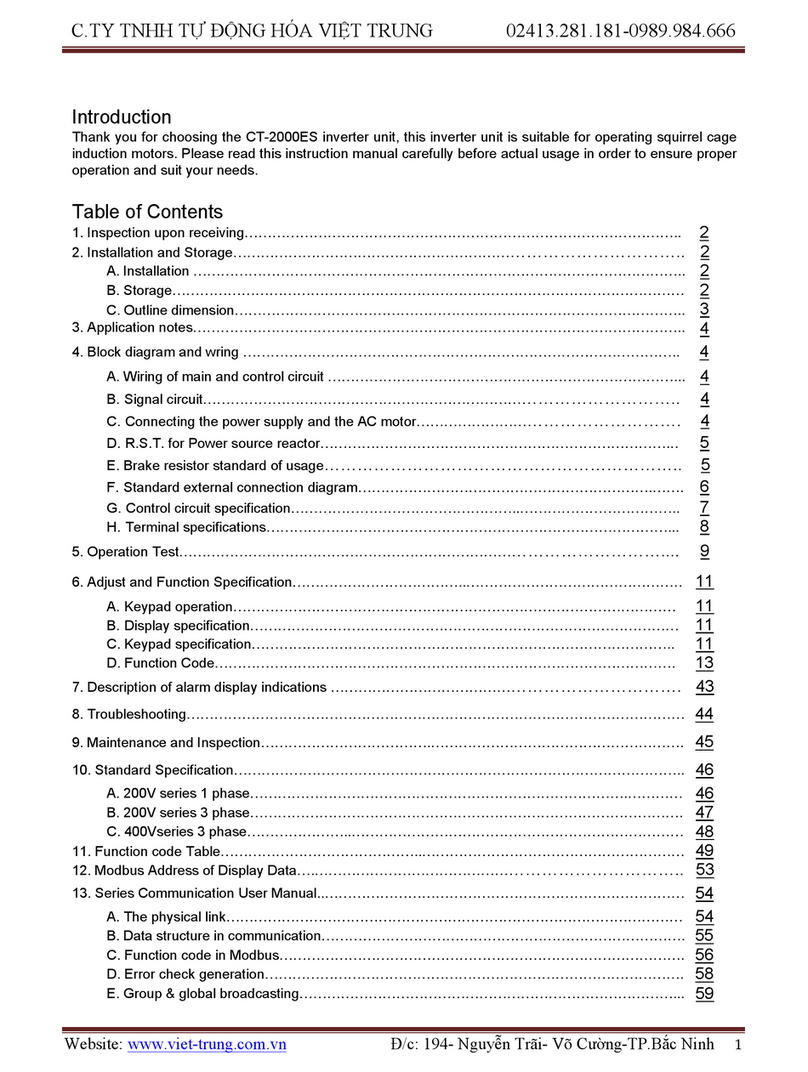

Table of Contents

1General.........................................................................................................................................................8

1.1 Overview ............................................................................................................................................9

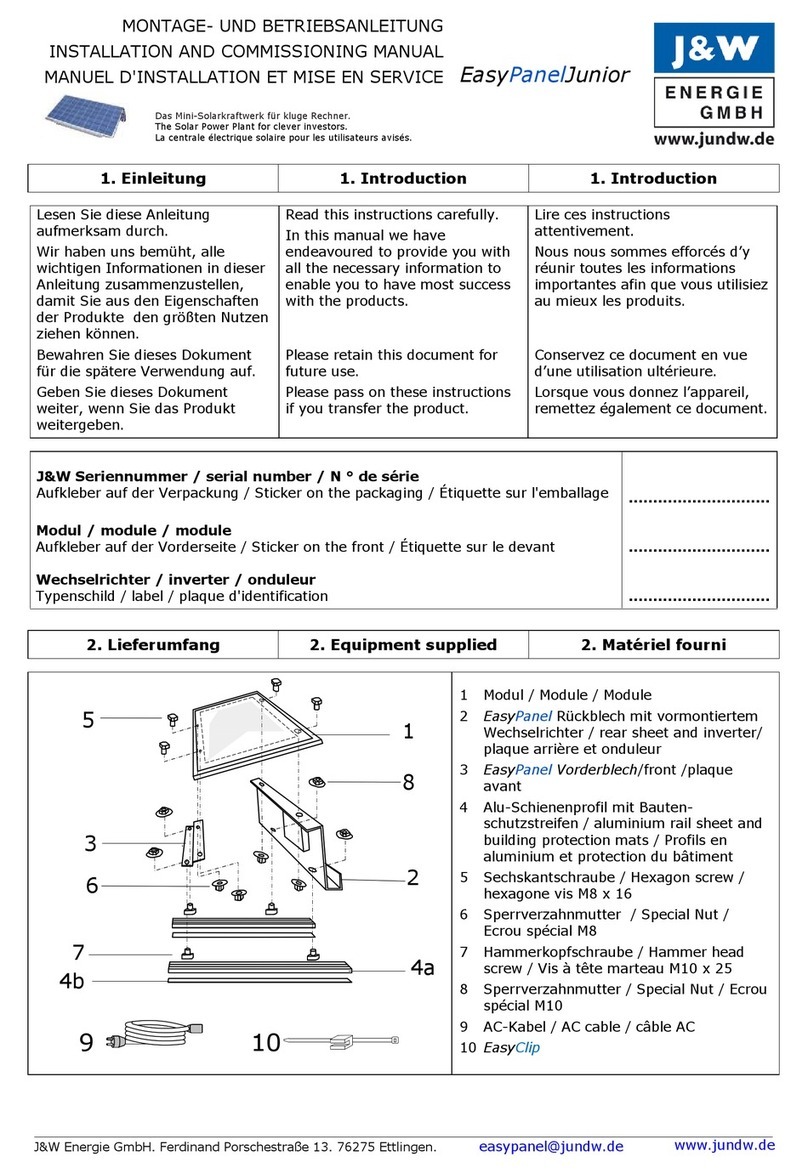

1.2 Delivery ............................................................................................................................................10

1.3 Scope of delivery..............................................................................................................................11

1.4 Presentation conventions.................................................................................................................11

1.4.1 Warning information ...........................................................................................................11

1.4.2 Other information................................................................................................................11

1.4.3 Text markings.....................................................................................................................11

1.5 Safety, installation and application information ................................................................................12

1.6 Warning and hazard information ......................................................................................................17

1.6.1 Warning and hazard information on the product.................................................................17

1.6.2 Warning information on the upper shell..............................................................................17

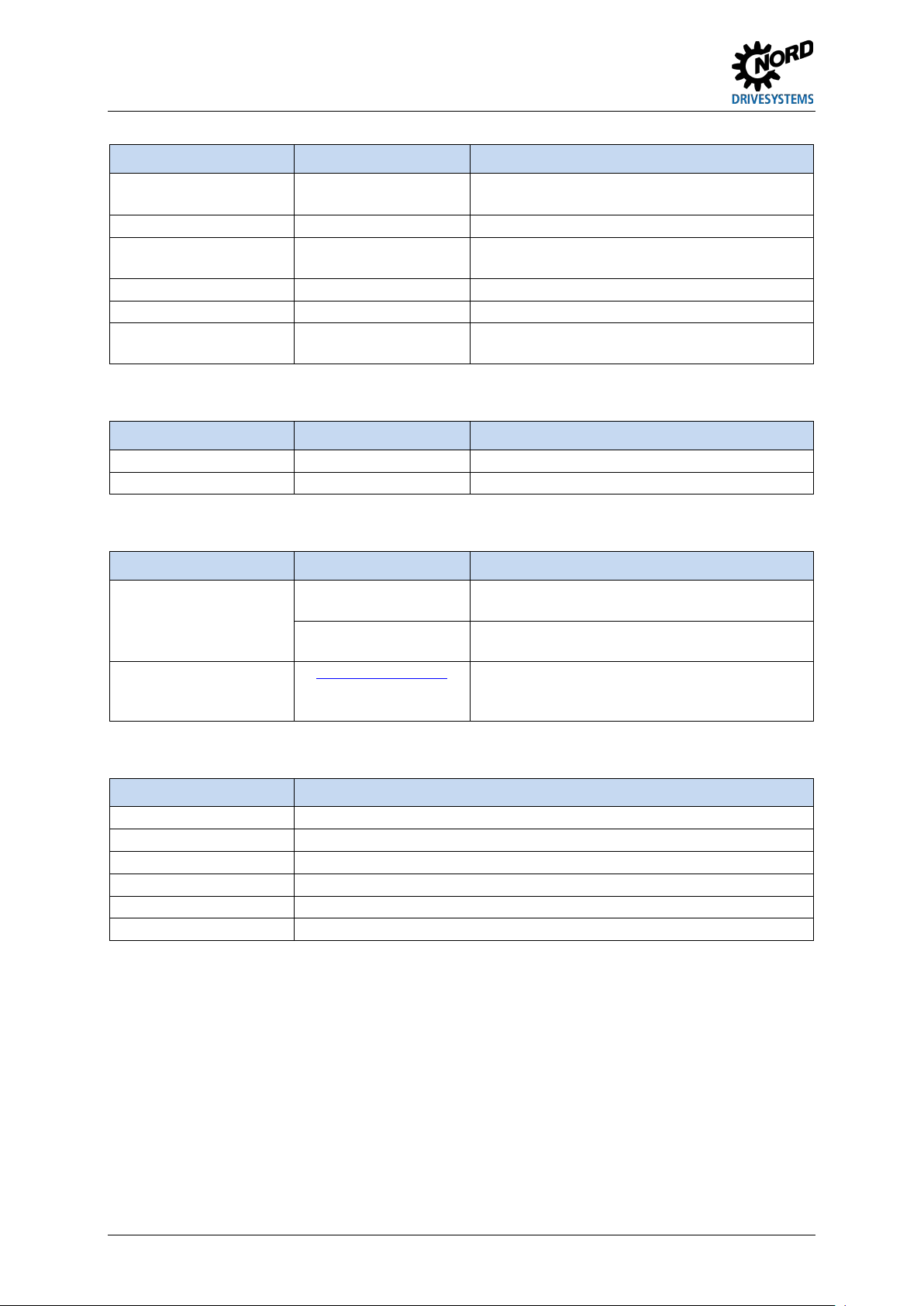

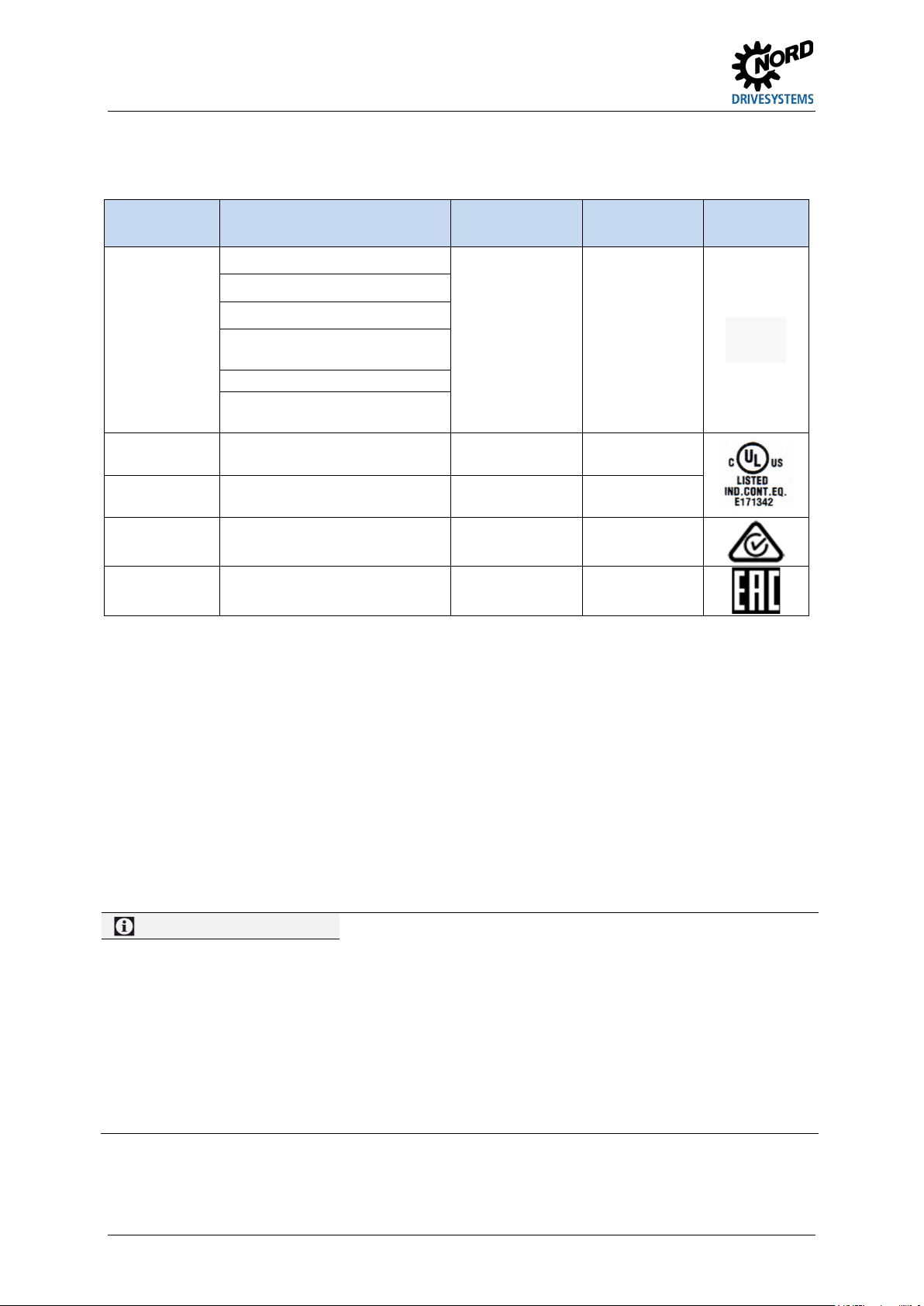

1.7 Standards and approvals .................................................................................................................18

1.7.1 UL and CSA approval.........................................................................................................18

1.8 Type code / nomenclature................................................................................................................20

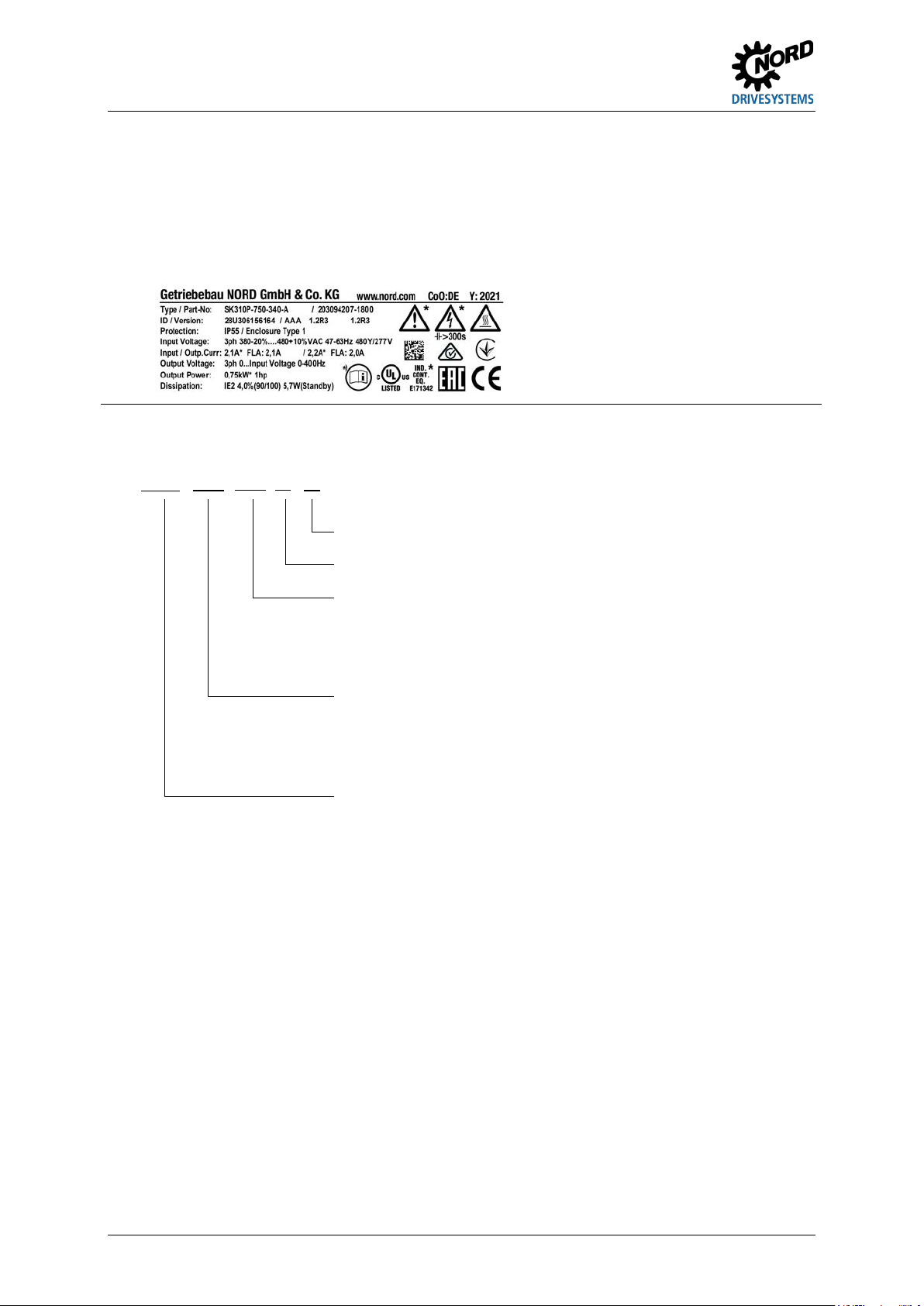

1.8.1 Name plate .........................................................................................................................20

2Assembly and installation ........................................................................................................................21

2.1 Installation........................................................................................................................................21

2.2 Dimensions NORDAC ON, motor-mounted .....................................................................................22

2.3 Dimensions NORDAC ON+, motor-mounted ...................................................................................23

2.4 Dimensions NORDAC ON and NORDAC ON+, wall-mounted ........................................................24

2.5 Connections .....................................................................................................................................25

2.5.1 NORDAC ON motor-mounted, Size 1 ................................................................................25

2.5.2 NORDAC ON motor-mounted, Size 2 ................................................................................26

2.5.3 NORDAC ON+ motor-mounted, Size 2 ..............................................................................27

2.5.4 NORDAC ON wall-mounted, Size 1 ...................................................................................28

2.5.5 NORDAC ON and NORDAC ON+, wall-mounted, Size 2...................................................29

2.6 Electrical Connection .......................................................................................................................30

2.6.1 Mains connection................................................................................................................30

2.6.2 Daisy chain connection.......................................................................................................30

2.6.3 Motor connection ................................................................................................................31

2.6.4 Wiring guidelines ................................................................................................................32

2.6.5 Electrical connection of power unit .....................................................................................33

2.6.5.1 Mains connection 33

2.6.5.2 Motor cable 34

2.6.5.3 Braking resistor (optionally with size 2 and above) 34

2.6.5.4 Electromechanical brake (optionally with size 2 and above)) 34

2.6.6 Electrical connection Ethernet communication and digital input/outputs ............................36

2.6.6.1 Control connection details 38

2.7 Diagnostic connection......................................................................................................................39

2.8 Encoder............................................................................................................................................40

3Display .......................................................................................................................................................43

3.1 LEDs ................................................................................................................................................43

3.1.1 Display of M1 and M2 when using EtherCAT.....................................................................43

3.1.2 Display of M1 and M2 when using EthernetIP....................................................................44

3.1.3 Display of M1 and M2 when using PROFINET...................................................................45

3.1.4 Display M3..........................................................................................................................45

3.1.5 Display of M4 and M5.........................................................................................................46

3.2 Diagnostic LED ................................................................................................................................46

4Commissioning .........................................................................................................................................47

4.1 Starting up the device ......................................................................................................................47

4.2 Selecting the operating mode for motor control ...............................................................................48

4.2.1 Explanation of the operating modes (P300) .......................................................................48

4.2.2 Overview of controller parameter settings ..........................................................................50

4.2.3 Motor control commissioning steps ....................................................................................51

5Parameter...................................................................................................................................................52

5.1 Parameter overview .........................................................................................................................55