SPA Actuator with Intelli-Motion™ Technology Manual R00

May 2022

Page 3 of 48

Section 1

General Information

1.1 General

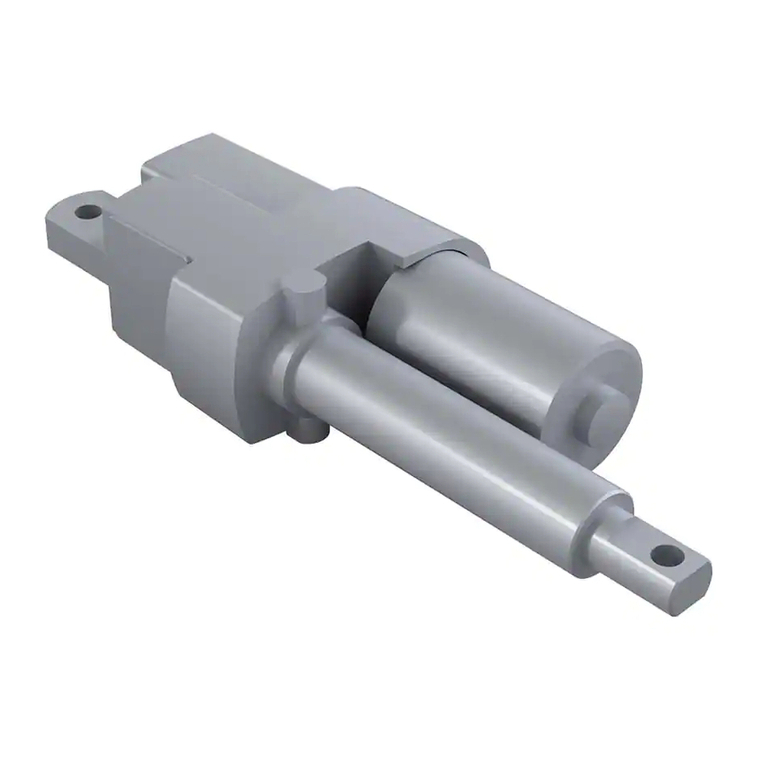

This manual provides instructions for the installation, operation, and maintenance of the Duff-Norton SPA with Intelli-

Motion Actuator. It includes proper procedures for the disassembly, cleaning, inspection, rebuilding and assembly of the

actuator. To ensure efficient, long, satisfactory use of this unit, follow these instructions closely.

1.2 Applications

The actuators described and illustrated in this manual are intended for industrial use only and should not be used to lift,

support or otherwise transport people (unless you have a written statement from Duff-Norton Company that authorizes

this actuator unit, as used in your application, as suitable for moving people).

1.3 Factory Preparation

Each actuator is carefully assembled and tested at the factory to ensure that the motor and the mechanical components

will function properly, and that the actuator will lift its rated load.

The brake is preset at the factory and no further adjustment is required. With proper maintenance, this brake prevents the

actuator from self-lowering. The actuator is pre-lubricated at the factory and thus requires minimum maintenance.

Limit switches are checked at the factory for proper functioning.

1.4 Warranty

Subject to the conditions stated herein, Duff-Norton will repair or replace, without charge, any parts proven to Duff-

Norton’s satisfaction to have been defective in material or workmanship. Claims must be made within one year after date

of shipment. Duff-Norton will not repair or replace any parts that become inoperative because of improper maintenance,

eccentric loading, overloading, chemical or abrasive action, excessive heat, or other abuse.

Equipment and accessories not of Duff-Norton’s manufacture are warranted only to the extent that they are warranted by

the manufacturer, and only if the claimed defect arose during normal use, applications and service.

Equipment which has been altered or modified by anyone without Duff-Norton’s authorization is not warranted by Duff-

Norton. EXCEPT AS STATED HEREIN, DUFF-NORTON MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

If you have any questions concerning warranty repair, please contact Duff-Norton Customer Service. Authorization for

return must be received from Duff-Norton before returning any equipment for inspection or warranty repair.