Dunster House AVON PVC E10-3040APVC-45 User manual

Other Dunster House Garden House manuals

Dunster House

Dunster House TERMINATOR E10-4030TM-45 User manual

Dunster House

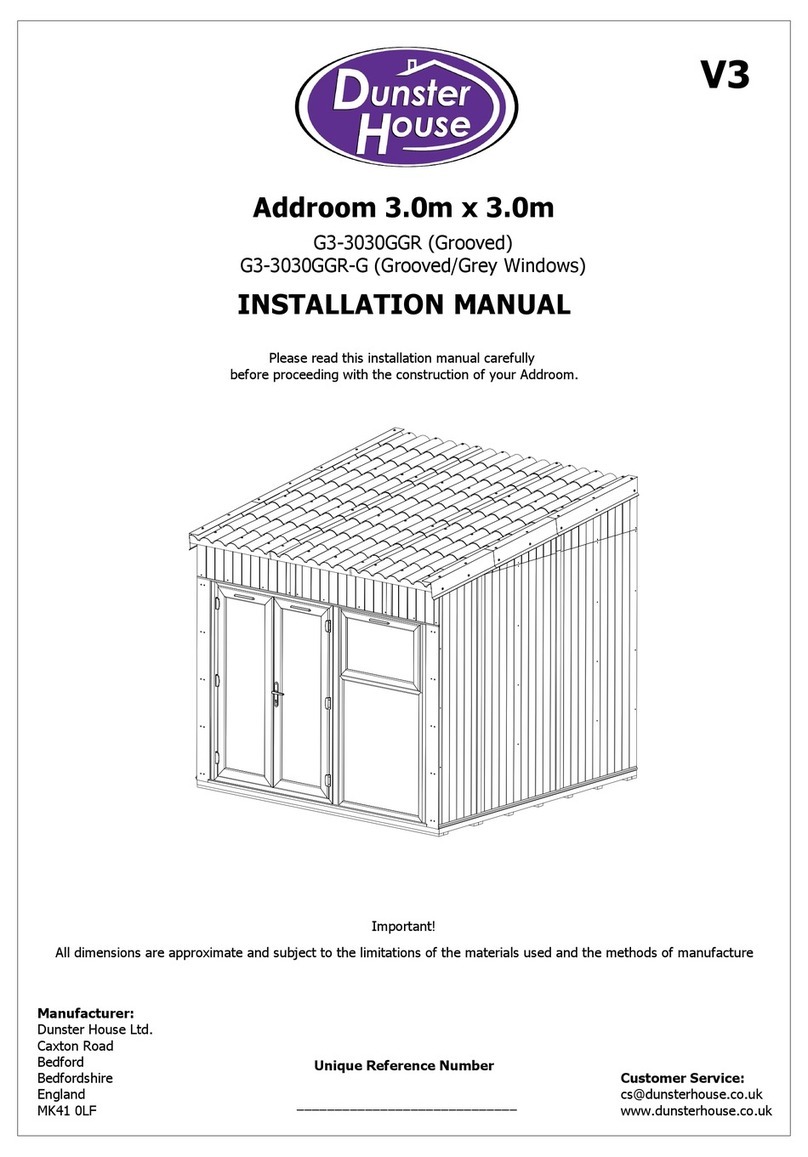

Dunster House Addroom G3-3030GGR User manual

Dunster House

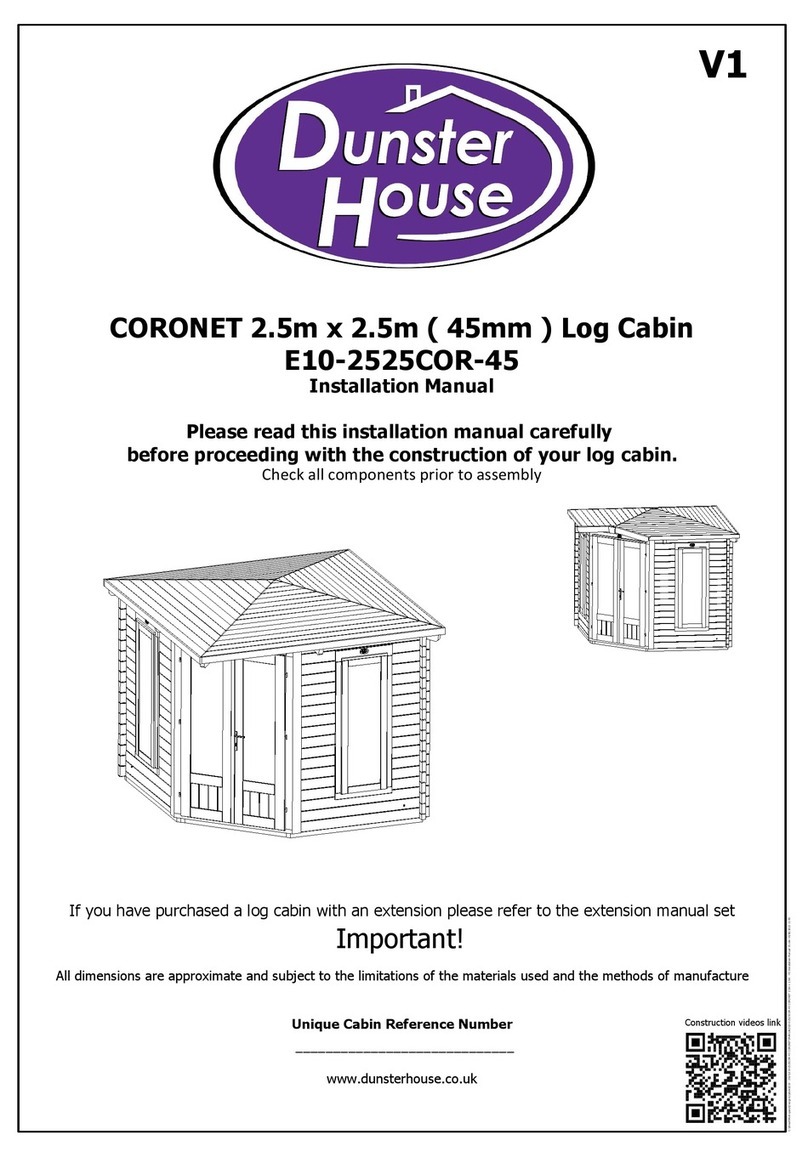

Dunster House CORONET E10-2525COR-45 User manual

Dunster House

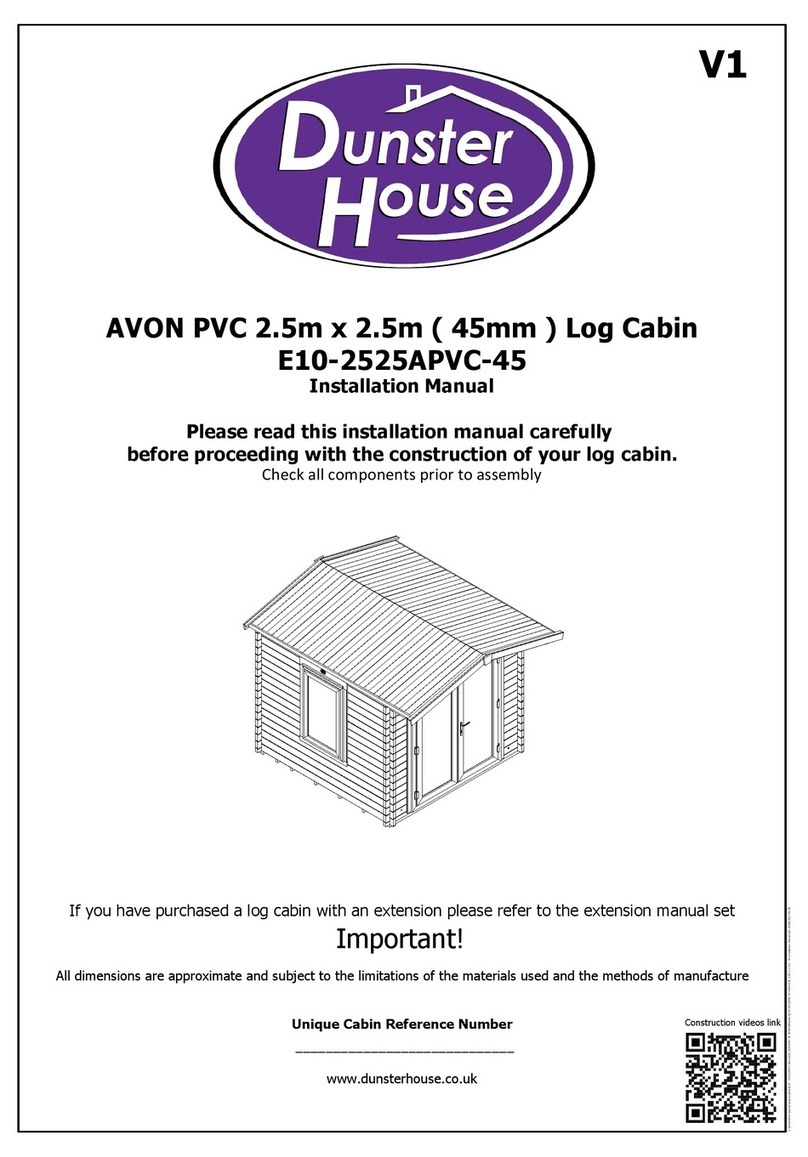

Dunster House AVON PVC E10-2525APVC-45 User manual

Dunster House

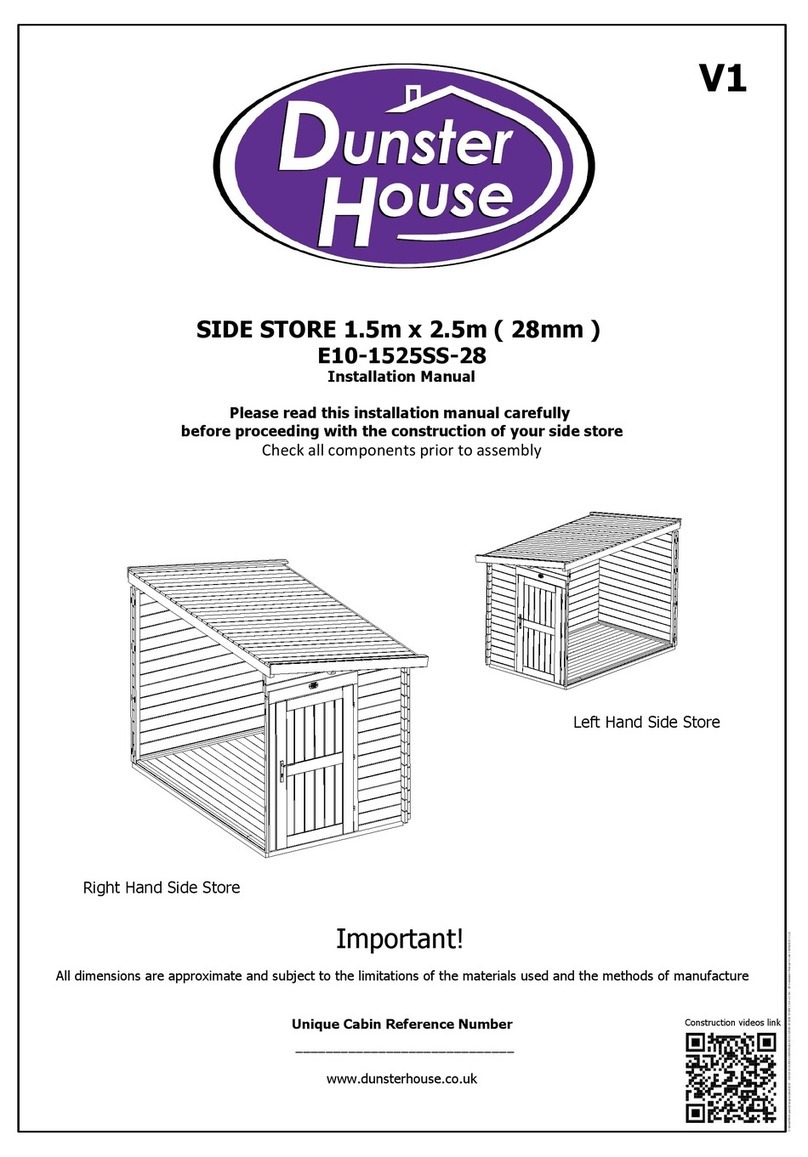

Dunster House E10-1525SS-28 User manual

Dunster House

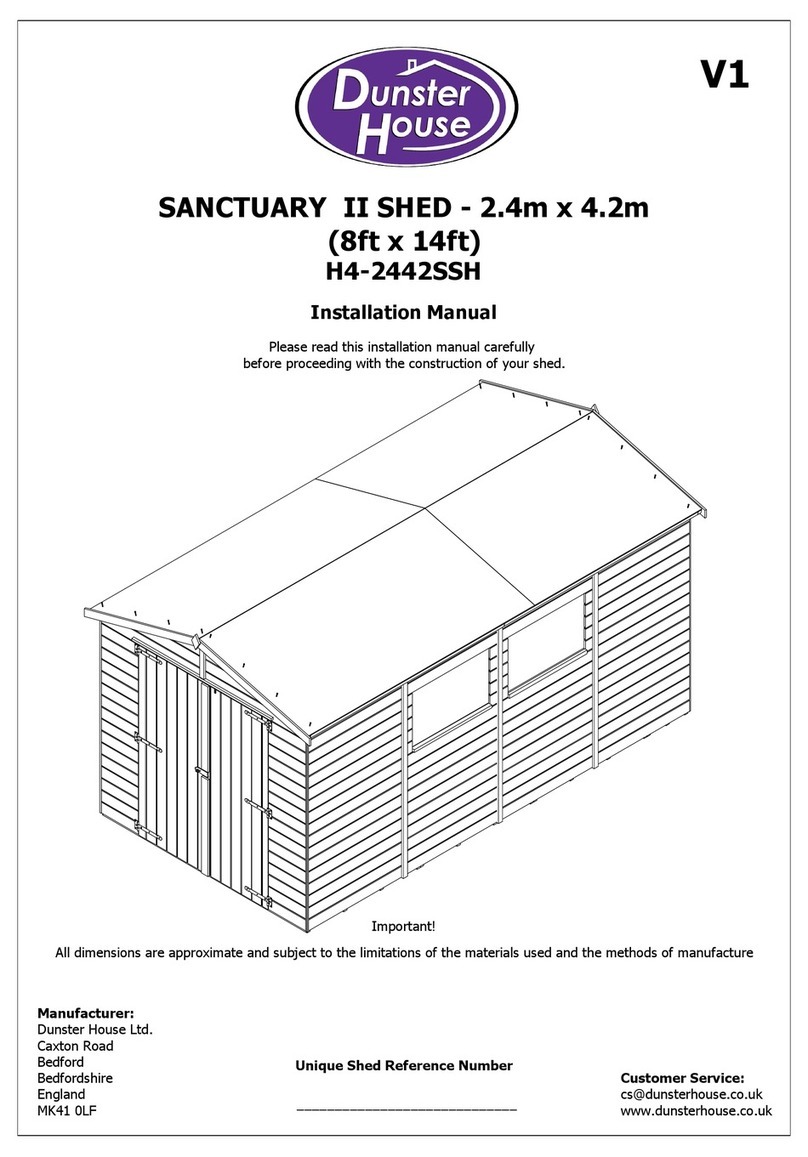

Dunster House H4-2442SSH User manual

Dunster House

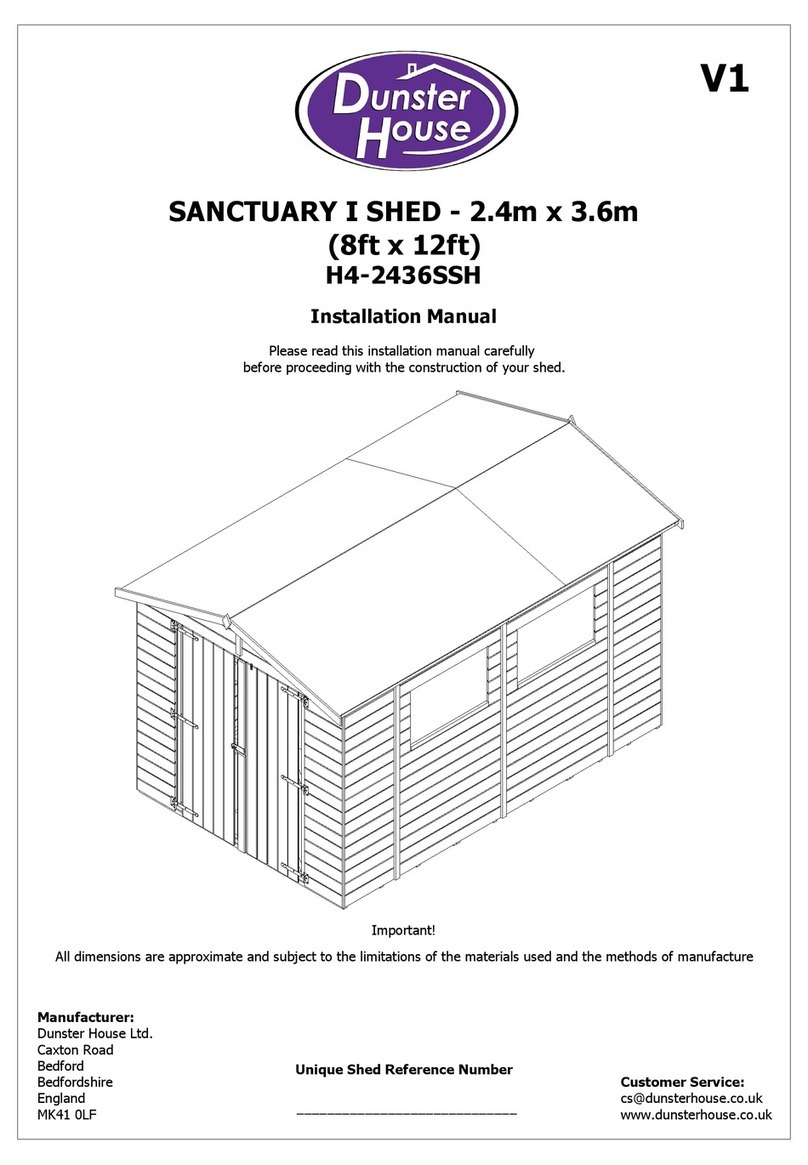

Dunster House H4-2436SSH User manual

Dunster House

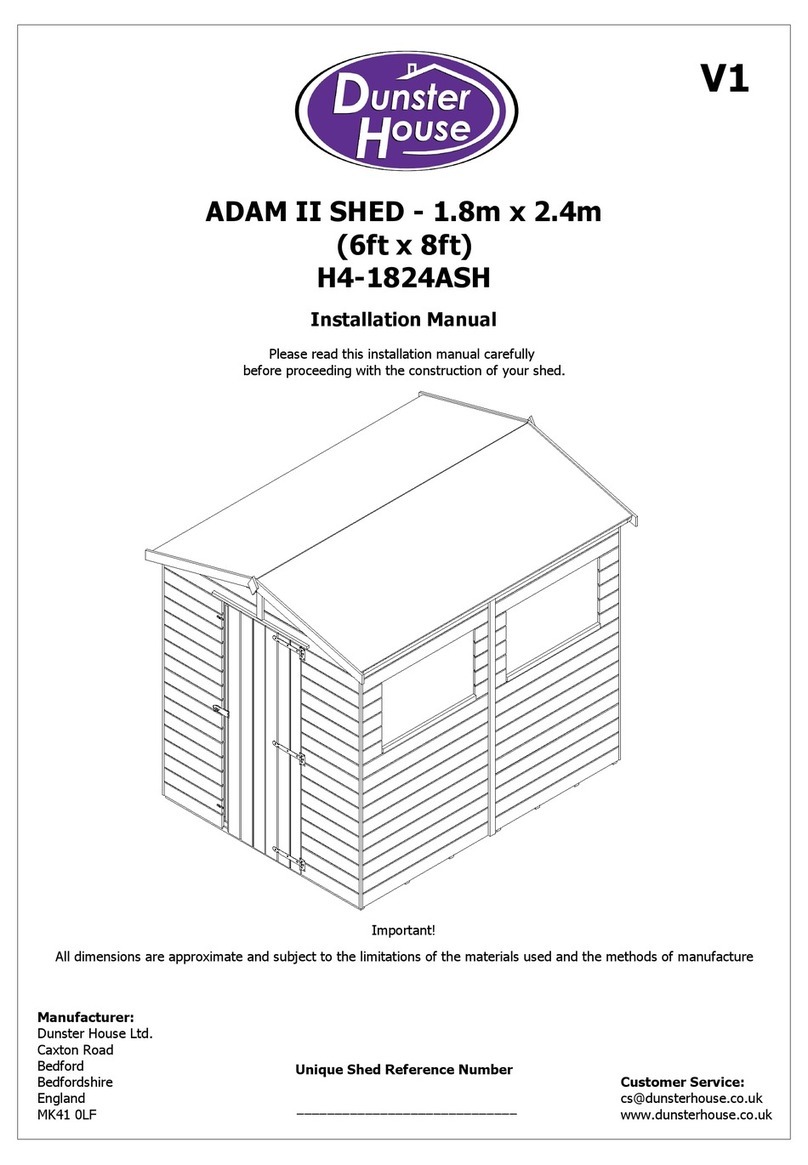

Dunster House ADAM II H4-1824ASH User manual

Dunster House

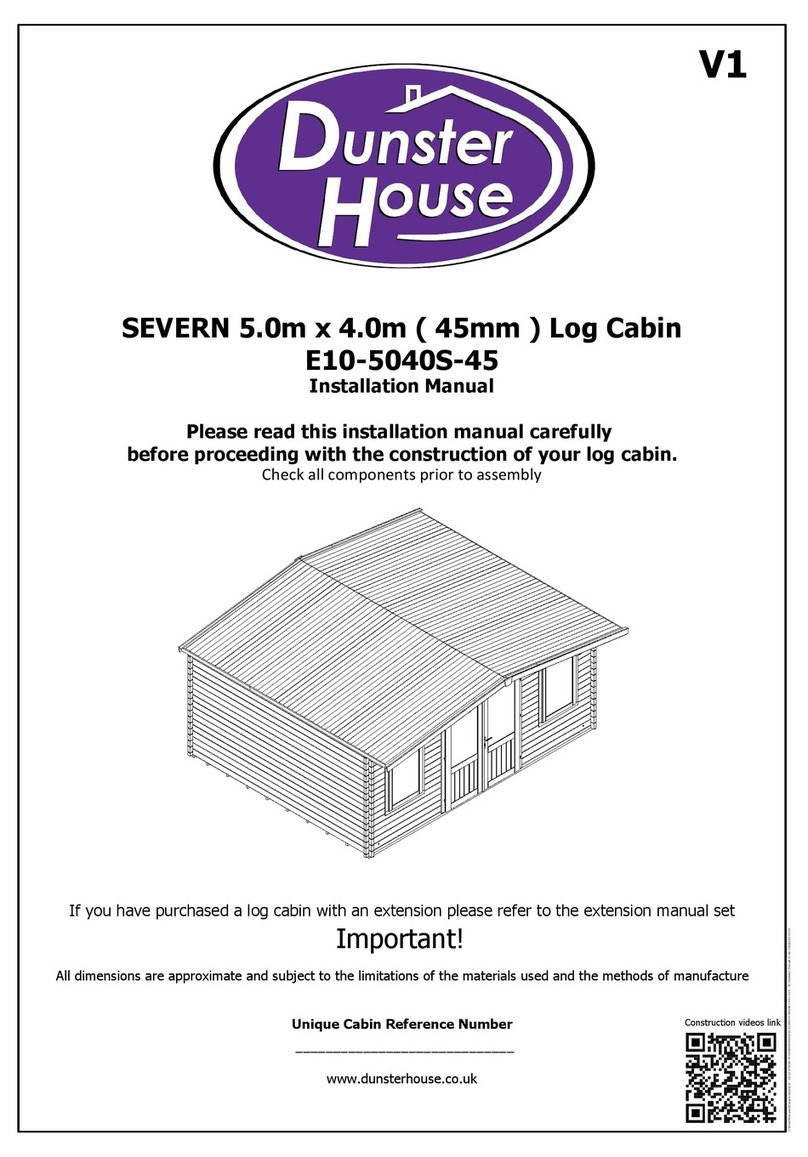

Dunster House SEVERN E10-5040S-45 User manual

Dunster House

Dunster House RHINE E10-4040R-45 User manual

Dunster House

Dunster House AVON User manual

Dunster House

Dunster House PETRUS E10-2530PW-28 User manual

Dunster House

Dunster House RHINE PVC E10-4030RPVC-45 User manual

Dunster House

Dunster House PADDINGTON GROOVE EFFECT GARDEN OFFICE User manual

Dunster House

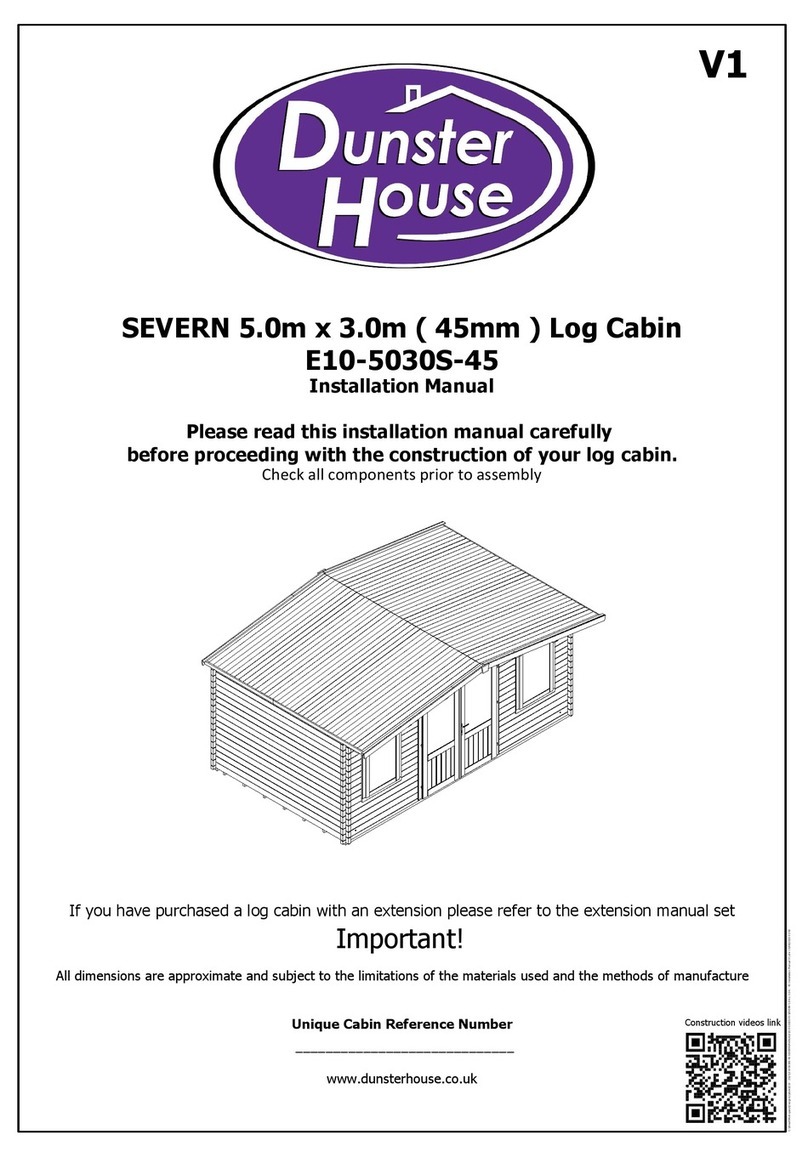

Dunster House SEVERN User manual

Dunster House

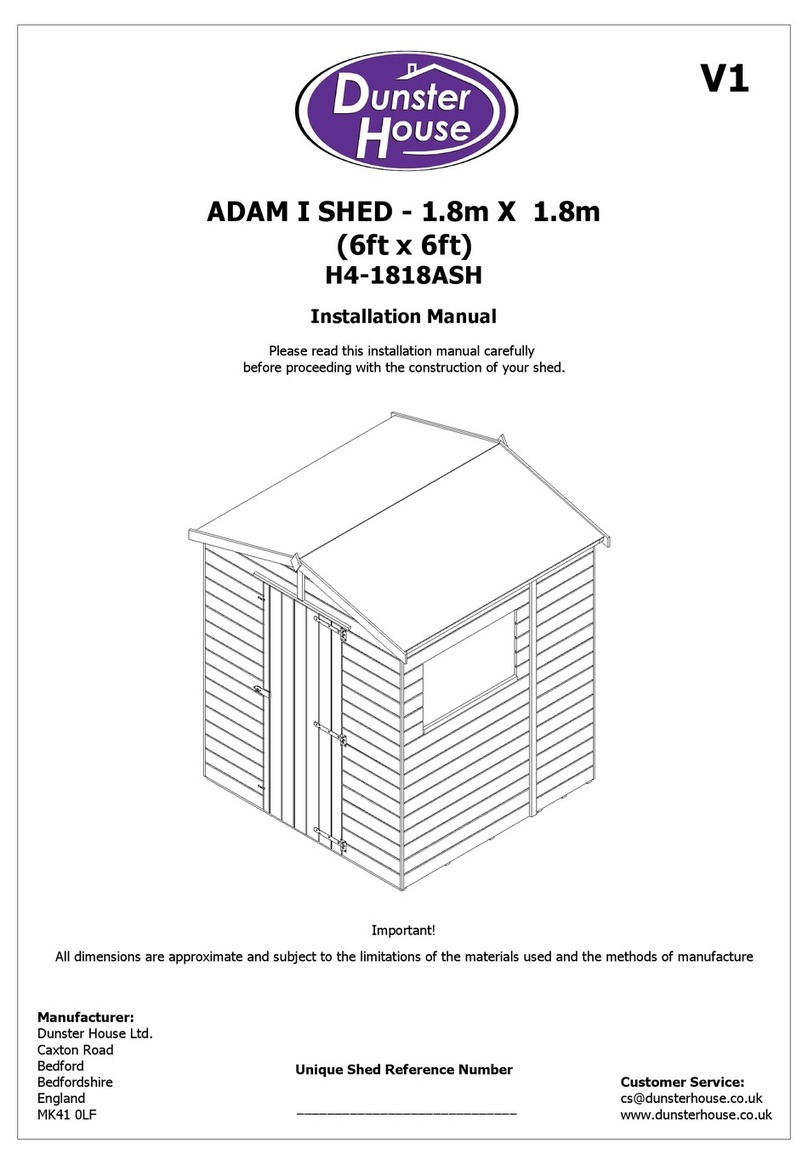

Dunster House H4-1818ASH User manual

Dunster House

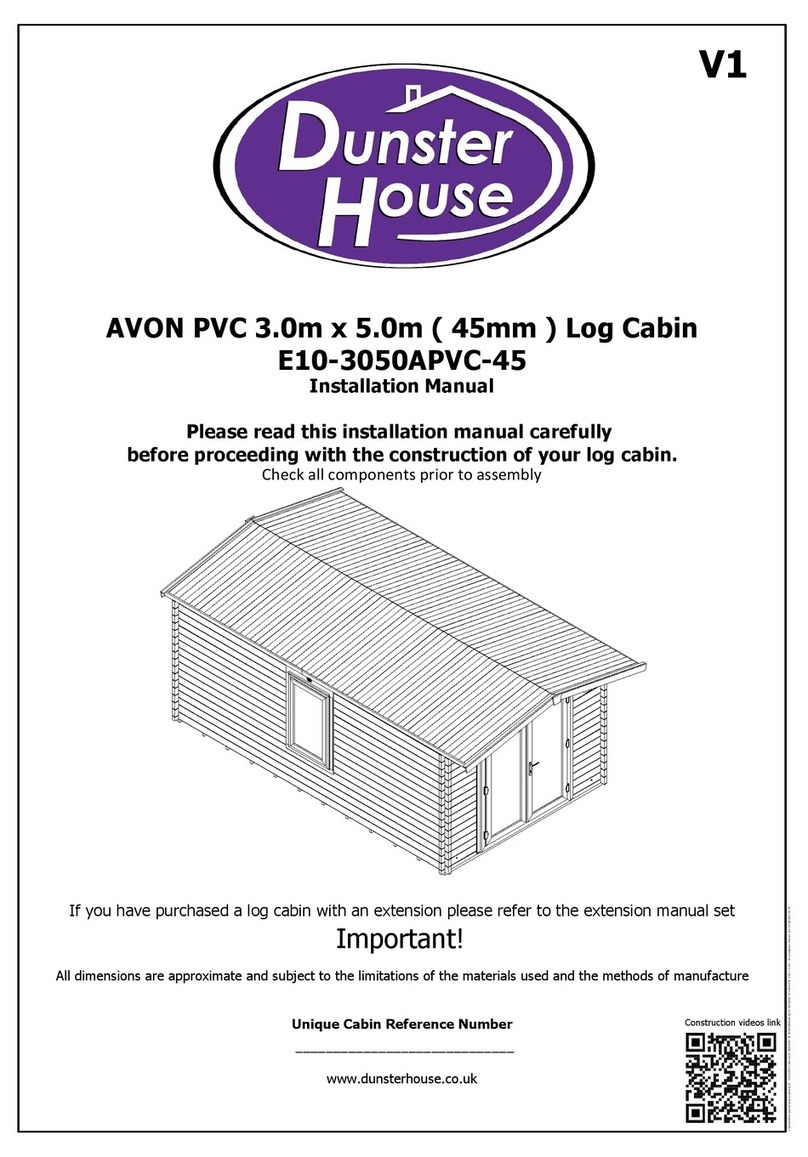

Dunster House E10-3050APVC-45 User manual

Dunster House

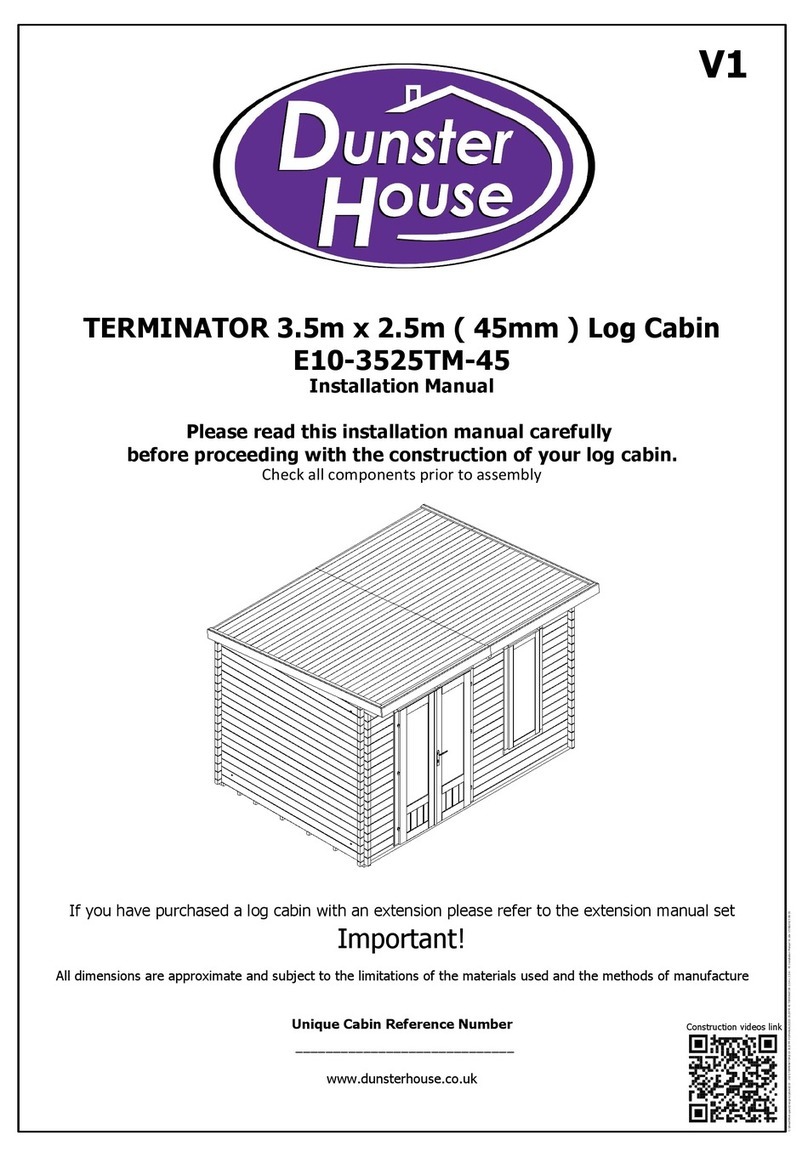

Dunster House E10-3525TM-45 User manual

Dunster House

Dunster House E9-3042DBPP-45 User manual

Dunster House

Dunster House TERMINATOR E10-3830TWLPVC-62 User manual

Popular Garden House manuals by other brands

Yardmaster

Yardmaster 66 ZGEY Assembly instructions

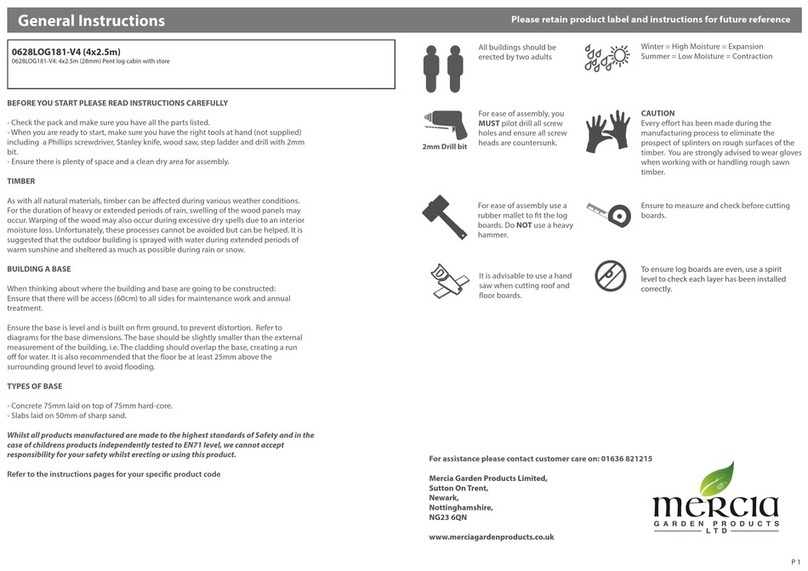

Mercia Garden Products

Mercia Garden Products 0628LOG181-V4 manual

Lemeks

Lemeks Palmako PA120-5930-6 Assembly, installation and maintenance manual

Rion

Rion Hobby Gardener Assembly instructions

Select

Select ISAAC E9682 Assembly manual

Palmako

Palmako Saale installation manual

Palmako

Palmako Roger FR44-5953-2 installation manual

Lemeks

Lemeks Palmako Grace PM56-4529 Assembly, installation and maintenance manual

Mercia Garden Products

Mercia Garden Products 03WES0808-V1 General instructions

Mercia Garden Products

Mercia Garden Products 03DTSHHP1206HGD4MW-V1 General instructions

Shire

Shire Salcey Assembly

Pergola kits USA

Pergola kits USA PREMIUM VINYL PAVILION Assembly manual

G21

G21 Boston 882 manual

Mercia Garden Products

Mercia Garden Products 05DTMBPN0503DD-V1 Assembly instructions

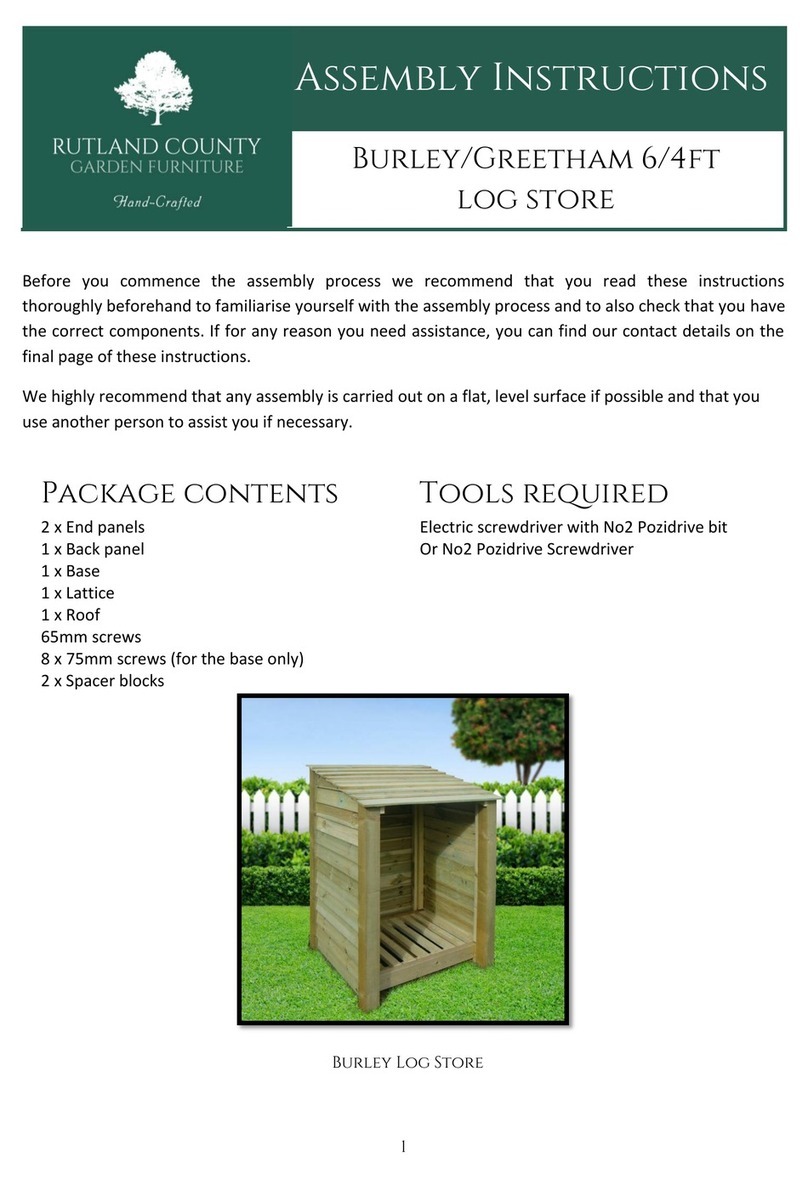

Rutland County

Rutland County Burley 6ft Assembly instructions

Palmako

Palmako Roger 27,7 installation manual

Mercia Garden Products

Mercia Garden Products 01PTOSBA0306DDNW-V1 General instructions

Gartenhaus-King

Gartenhaus-King Valery manual