iii

TABLE OF CONTENTS

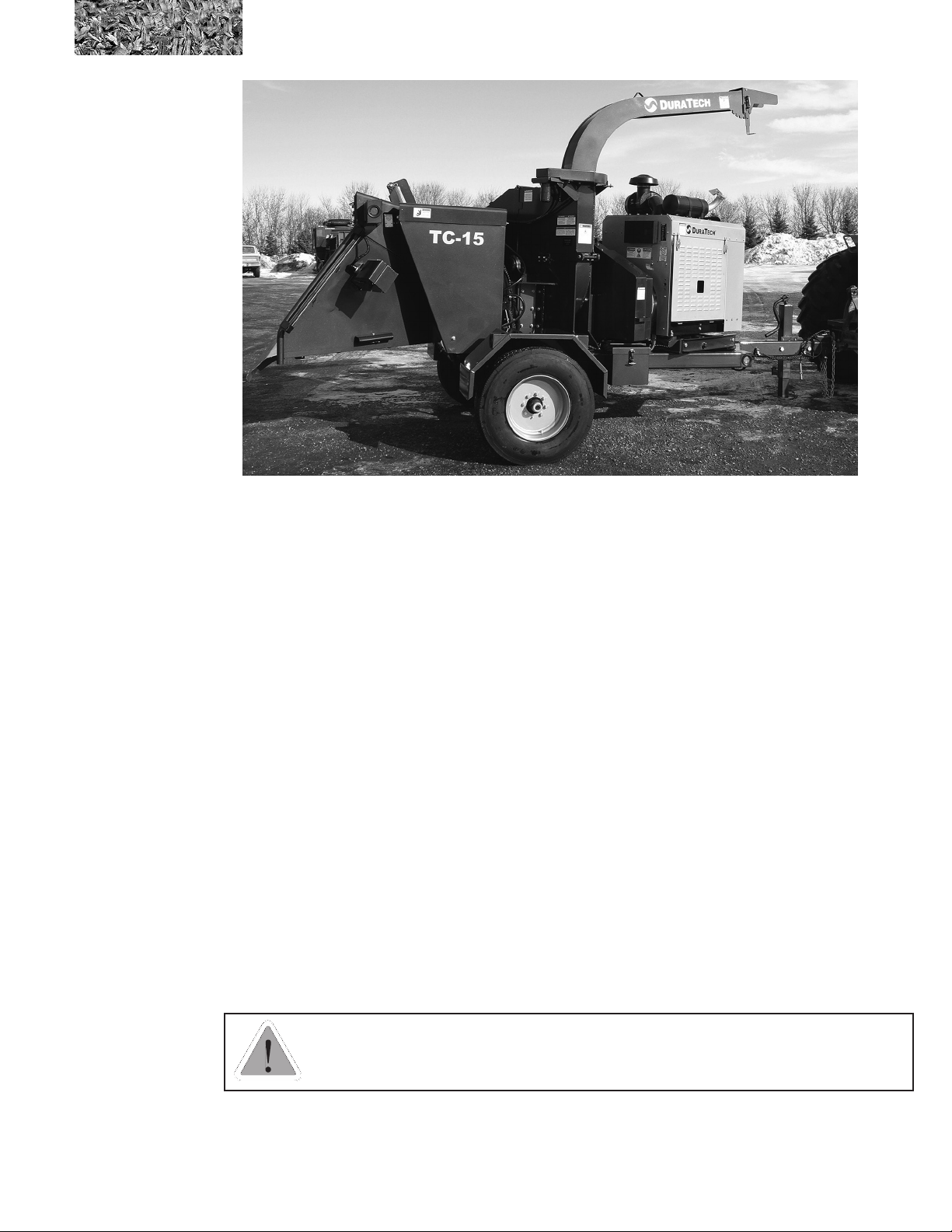

TC-15 TREE CHIPPER OPERATING INSTRUCTIONS

Section 5: General Maintenance ............................................. 27

5.1 Welding Procedure ........................................................................................... 27

5.2 Batteries............................................................................................................ 28

5.3 Hydraulic system.............................................................................................. 28

5.4 Clutch system ................................................................................................... 29

5.5 Axle, wheels, and tires...................................................................................... 30

5.6 Lubrication ....................................................................................................... 30

5.7 Wear parts......................................................................................................... 32

5.8 Checking and setting belt tension procedures .................................................. 33

5.9 Spring tensioner for feed wheel ....................................................................... 35

5.9A Torquing the feed wheel motor nut................................................................ 35

5.10 Anvil adjustment ............................................................................................ 36

5.11 Changing knives ............................................................................................. 37

6.0 Troubleshooting the TC-15 .................................................. 38

6.1 General trouble shooting .................................................................................. 38

6.2 Troubleshooting the feed control and electronic monitoring system (PLC) ... 39

Appendix A: WARRANTY............................................................ 43

Appendix B: TC-15 Specications ............................................. 44

Part 2: Parts Reference .................................................45

TRAILER ASSEMBLY ......................................................................................... 46

CAT ENGINE ASSEMBLY (FOR S.N. UP TO 0010) .......................................... 48

CAT ENGINE ASSEMBLY - TIER 3 (FOR S.N. 0011 AND UP)........................ 50

DISC ASSEMBLY ................................................................................................. 52

INFEED ASSEMBLY VIEW 1.............................................................................. 54

INFEED ASSEMBLY VIEW 1 - DETAILS A,B, & C .......................................... 56

INFEED ASSEMBLY VIEW 2 (FOR S.N. UP TO 0010) ..................................... 58

INFEED ASSEMBLY VIEW 2 (FOR S.N. 0011 AND UP).................................. 60

INFEED ASSEMBLY VIEW 3.............................................................................. 62

INFEED ASSEMBLY VIEW 4.............................................................................. 64

DISCHARGE ASSEMBLY VIEW 1 ..................................................................... 66

DISCHARGE ASSEMBLY VIEW 2 ..................................................................... 68