Duratuf Glenburn User manual

Other Duratuf Outdoor Storage manuals

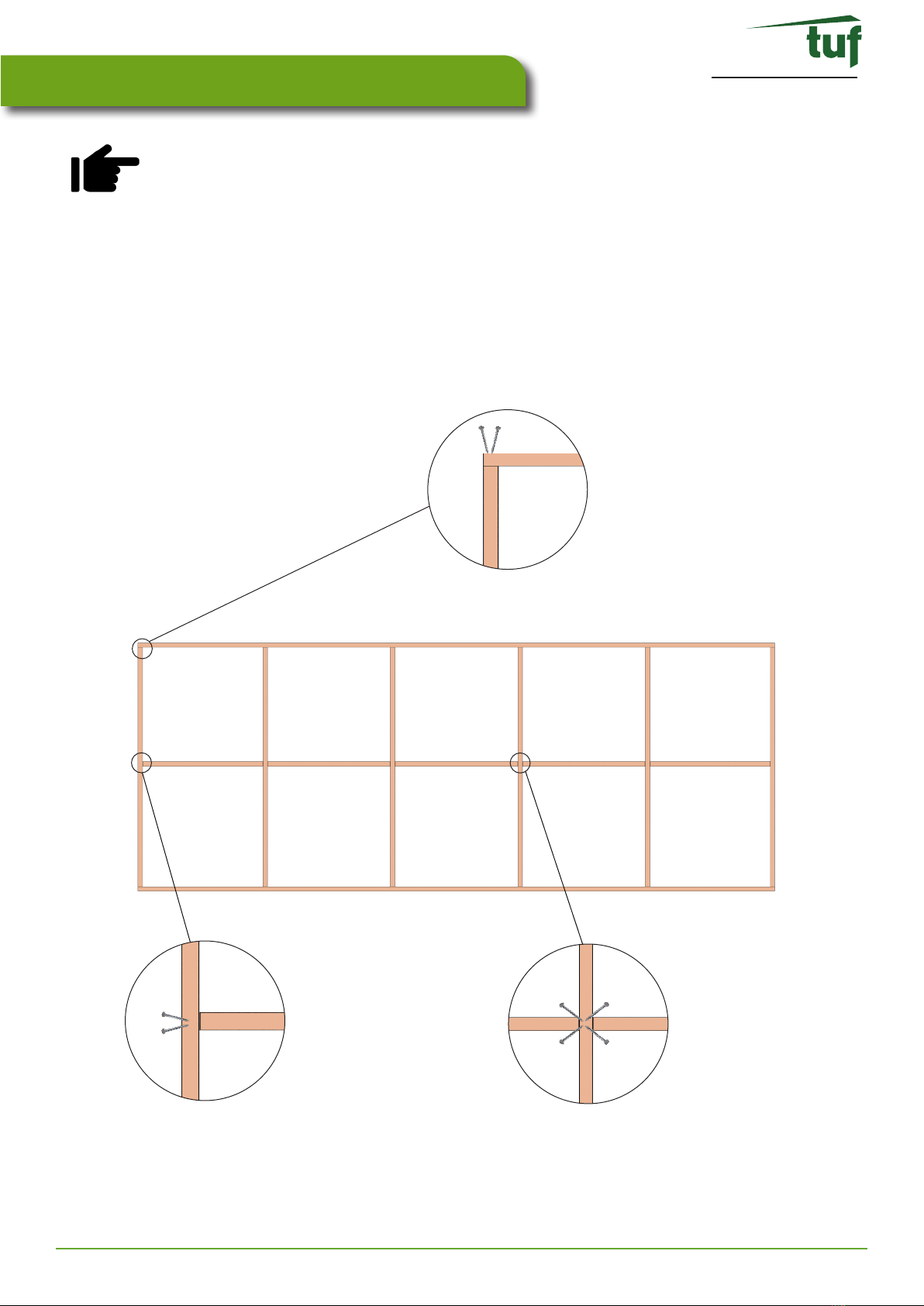

Duratuf

Duratuf GUARDIAN SHED GL37 User manual

Duratuf

Duratuf SG2525 User manual

Duratuf

Duratuf MK4 User manual

Duratuf

Duratuf SENTRY SHEDS SS1515 User manual

Duratuf

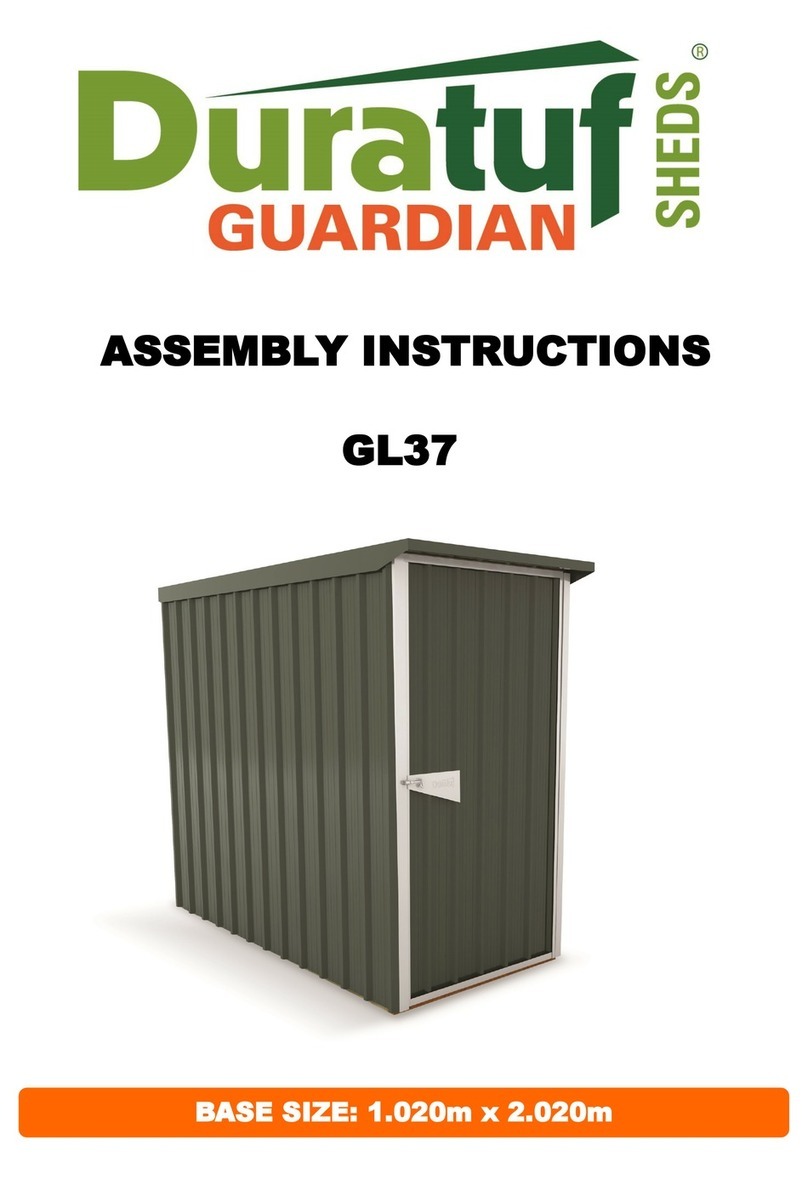

Duratuf SG2020 User manual

Duratuf

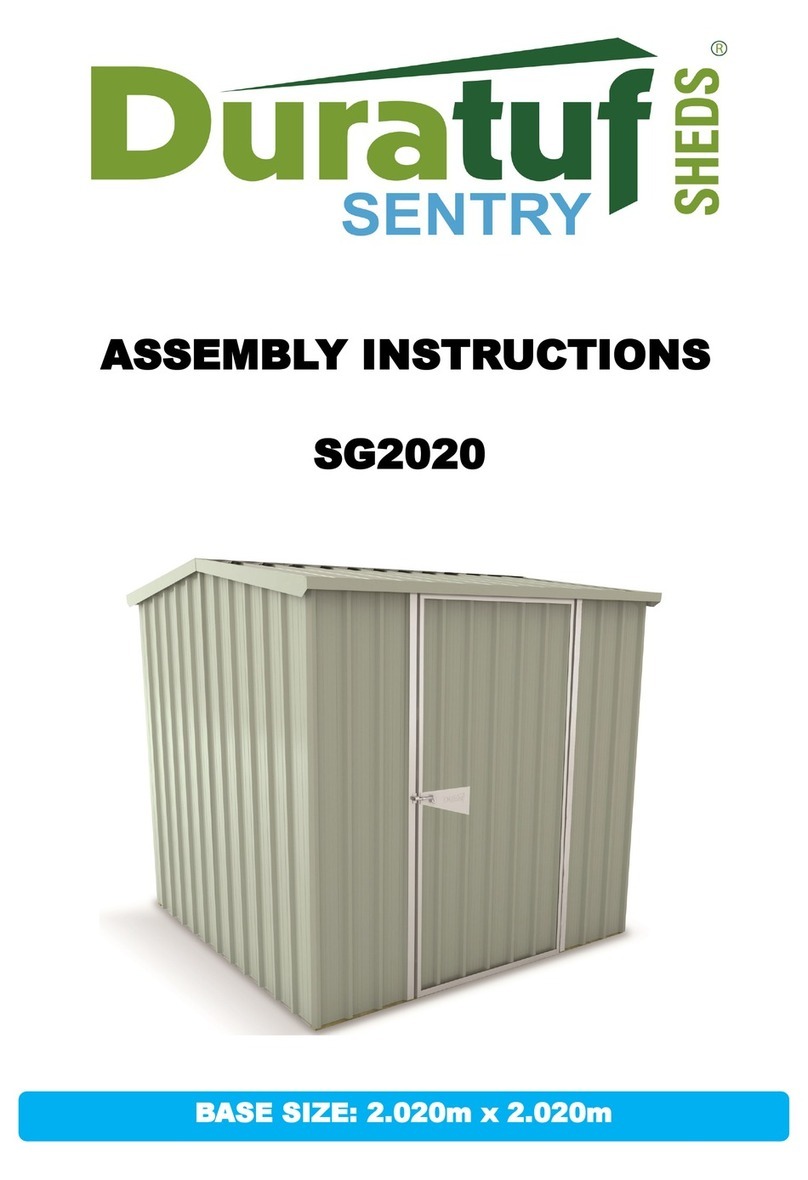

Duratuf PG98 User manual

Duratuf

Duratuf Garrison PL36 User manual

Duratuf

Duratuf GL105 User manual

Duratuf

Duratuf SL2515 User manual

Duratuf

Duratuf PL46 User manual

Duratuf

Duratuf SL3015 User manual

Duratuf

Duratuf TUF 500 User manual

Duratuf

Duratuf SG3020 User manual

Duratuf

Duratuf KL3 User manual

Duratuf

Duratuf GS62 User manual

Duratuf

Duratuf Garrison PL84 User manual

Duratuf

Duratuf Garrison Sheds PL64 User manual

Duratuf

Duratuf GG97 User manual

Duratuf

Duratuf PG88 User manual

Duratuf

Duratuf TUF 100 User manual

Popular Outdoor Storage manuals by other brands

rollaway container

rollaway container ARPCA24 manual

X-METAL

X-METAL 4065 owner's manual

Outdoor Life Products

Outdoor Life Products FP2030 F Assembly instructions

Royalcraft

Royalcraft Faro 295L Storage Box Assembly instructions

Riverlea

Riverlea Duratuf KIWI KS3 Assembly instructions

Rubbermaid

Rubbermaid 5L45 manual