Duratuf TUF 400 User manual

Other Duratuf Outdoor Storage manuals

Duratuf

Duratuf SL1520 User manual

Duratuf

Duratuf MK3B User manual

Duratuf

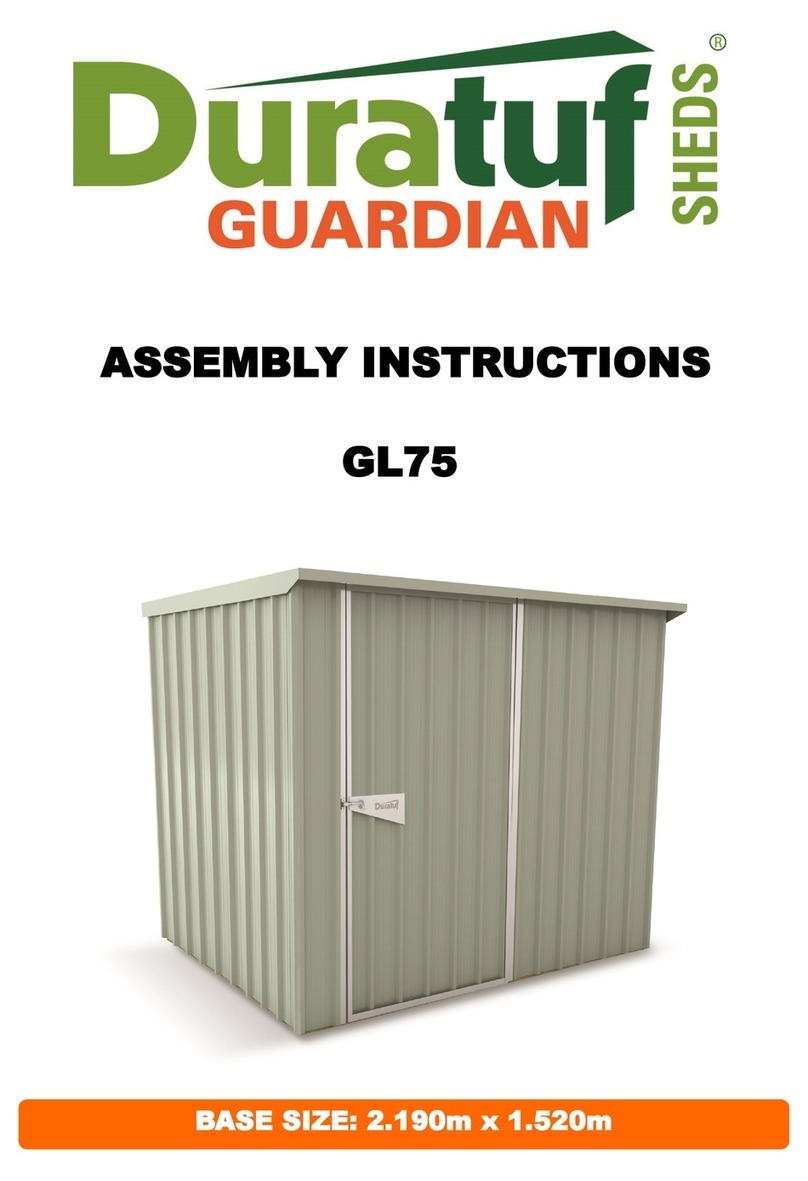

Duratuf GL75 User manual

Duratuf

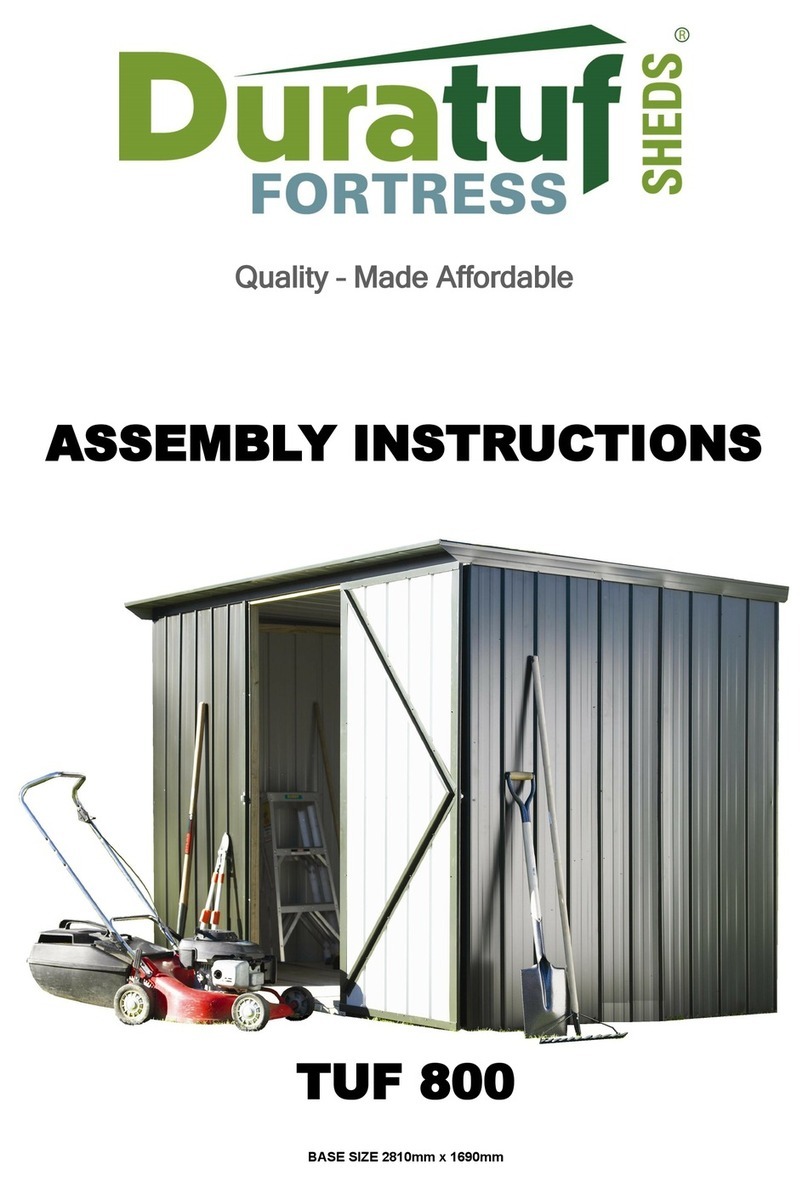

Duratuf TUF 800 User manual

Duratuf

Duratuf TUF 200 User manual

Duratuf

Duratuf GG97 User manual

Duratuf

Duratuf Sentry Sheds SL1515 User manual

Duratuf

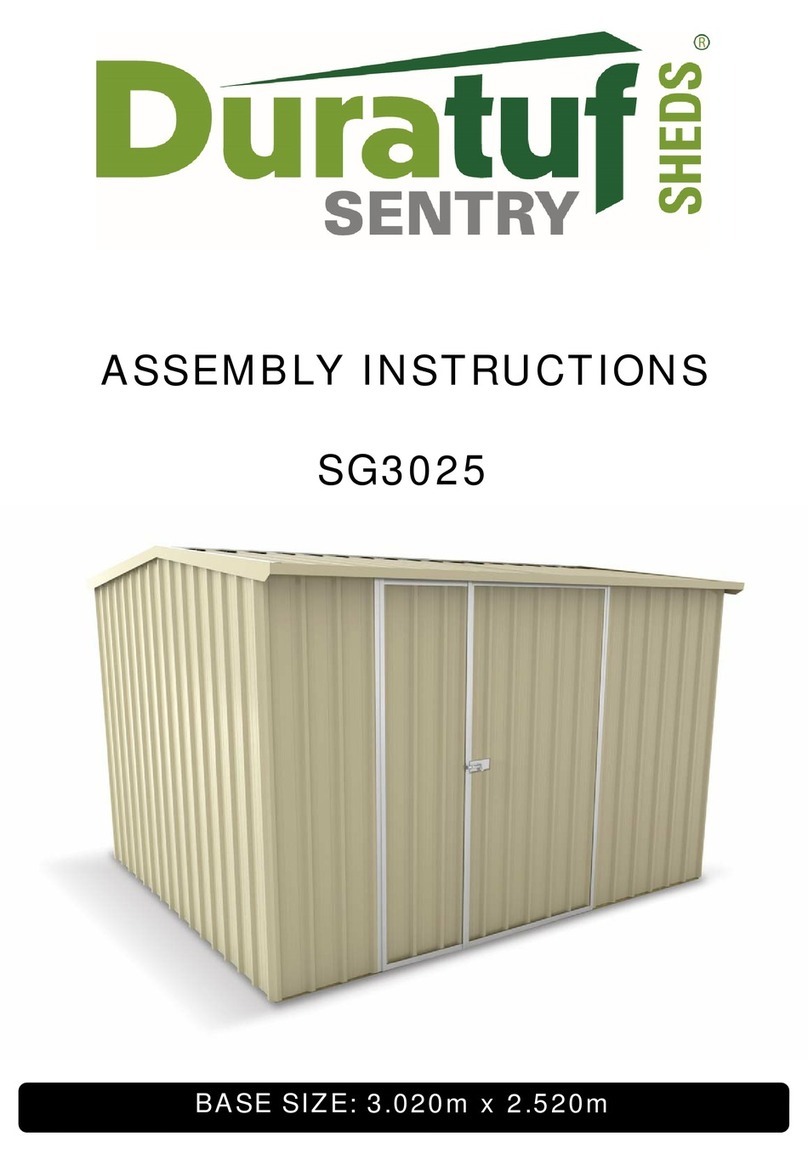

Duratuf SG3025 User manual

Duratuf

Duratuf GUARDIAN SHED GL37 User manual

Duratuf

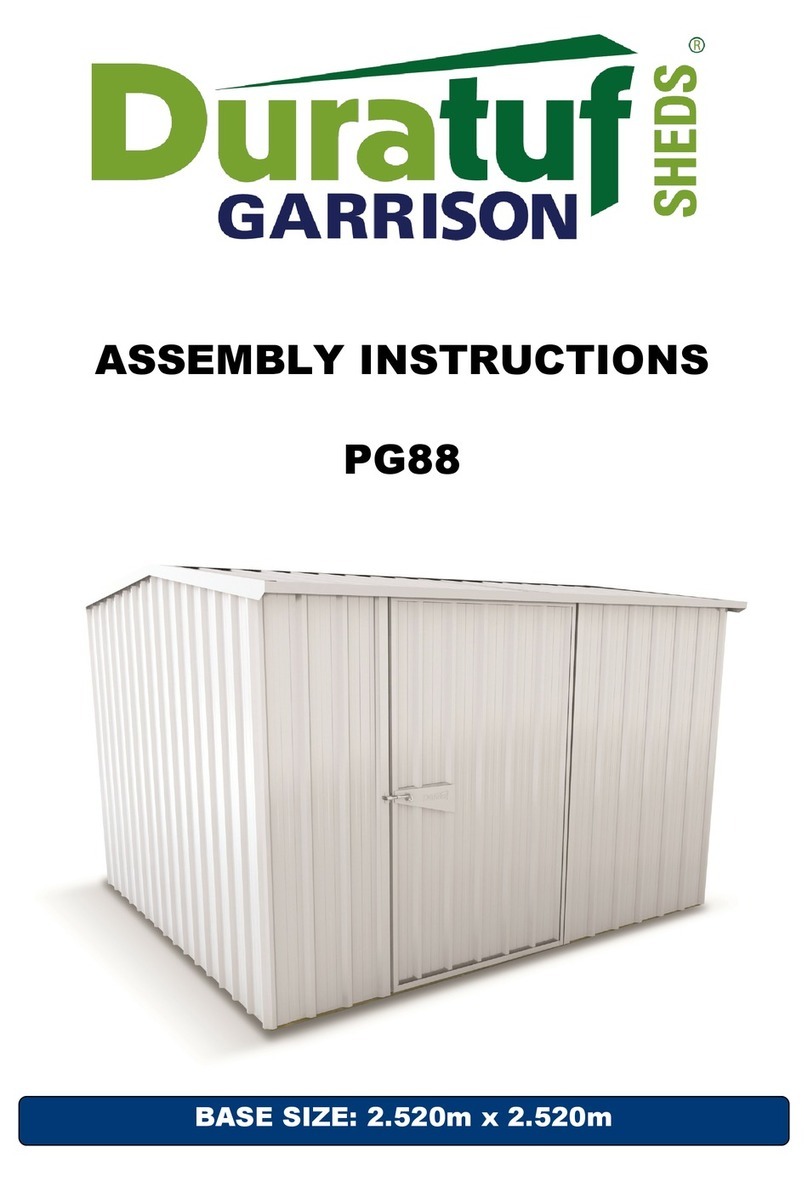

Duratuf PG96 User manual

Duratuf

Duratuf GL95D User manual

Duratuf

Duratuf PG99 User manual

Duratuf

Duratuf Guardian Sheds GS73 User manual

Duratuf

Duratuf PG98 User manual

Duratuf

Duratuf SG2020 User manual

Duratuf

Duratuf TUF 400 User manual

Duratuf

Duratuf SG3020 User manual

Duratuf

Duratuf SL3015 User manual

Duratuf

Duratuf Paihia User manual

Duratuf

Duratuf Otago User manual

Popular Outdoor Storage manuals by other brands

rollaway container

rollaway container ARPCA24 manual

X-METAL

X-METAL 4065 owner's manual

Outdoor Life Products

Outdoor Life Products FP2030 F Assembly instructions

Royalcraft

Royalcraft Faro 295L Storage Box Assembly instructions

Riverlea

Riverlea Duratuf KIWI KS3 Assembly instructions

Rubbermaid

Rubbermaid 5L45 manual