Duratuf SENTRY SHEDS SS1515 User manual

Other Duratuf Outdoor Storage manuals

Duratuf

Duratuf Kapiti User manual

Duratuf

Duratuf SG2525 User manual

Duratuf

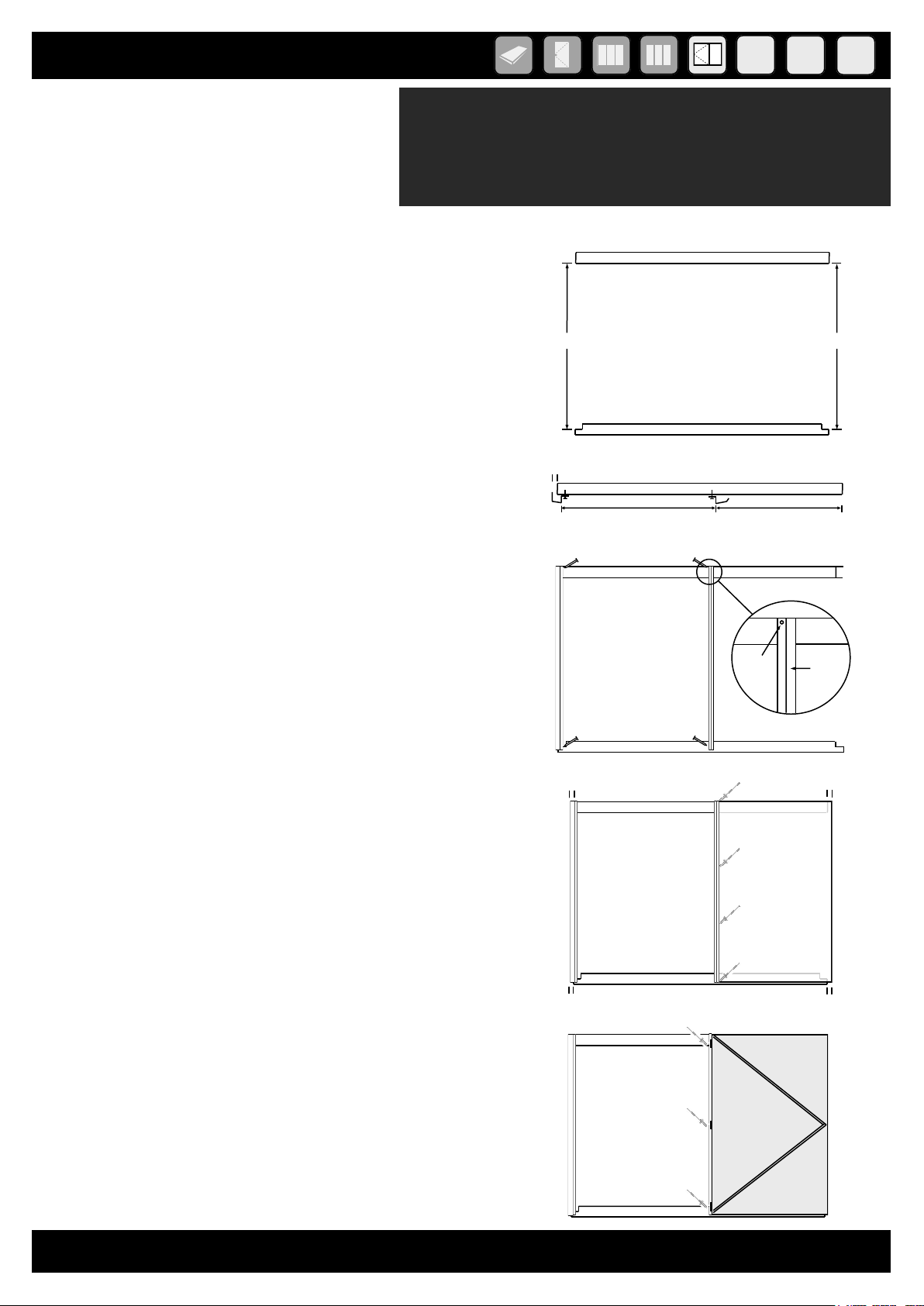

Duratuf PG88 User manual

Duratuf

Duratuf Guardian Sheds GS73 User manual

Duratuf

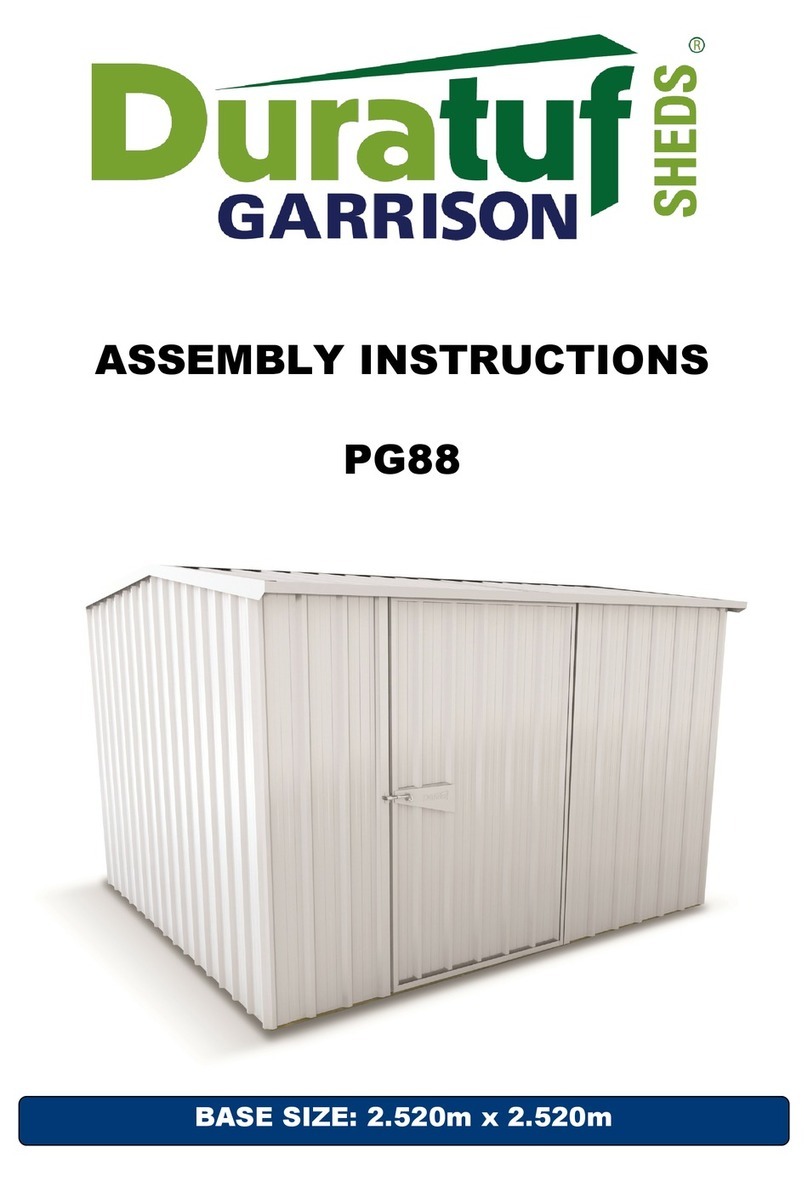

Duratuf GL95 User manual

Duratuf

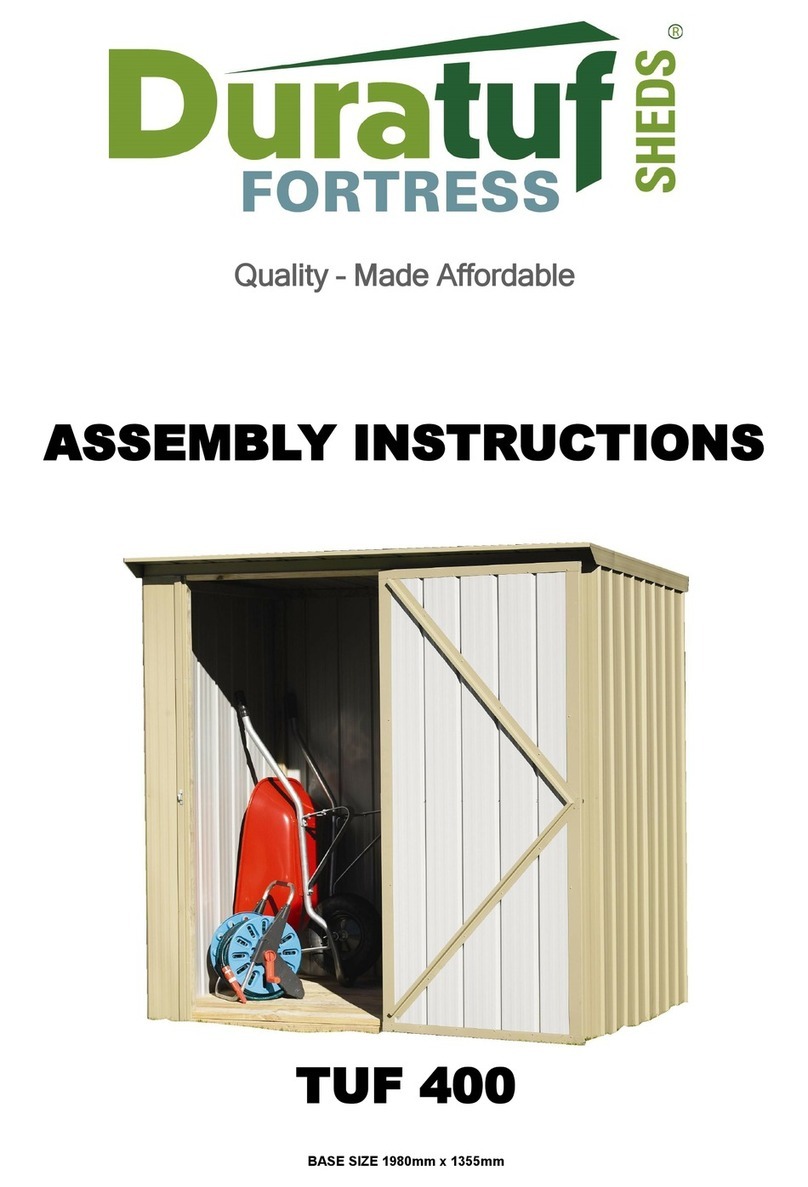

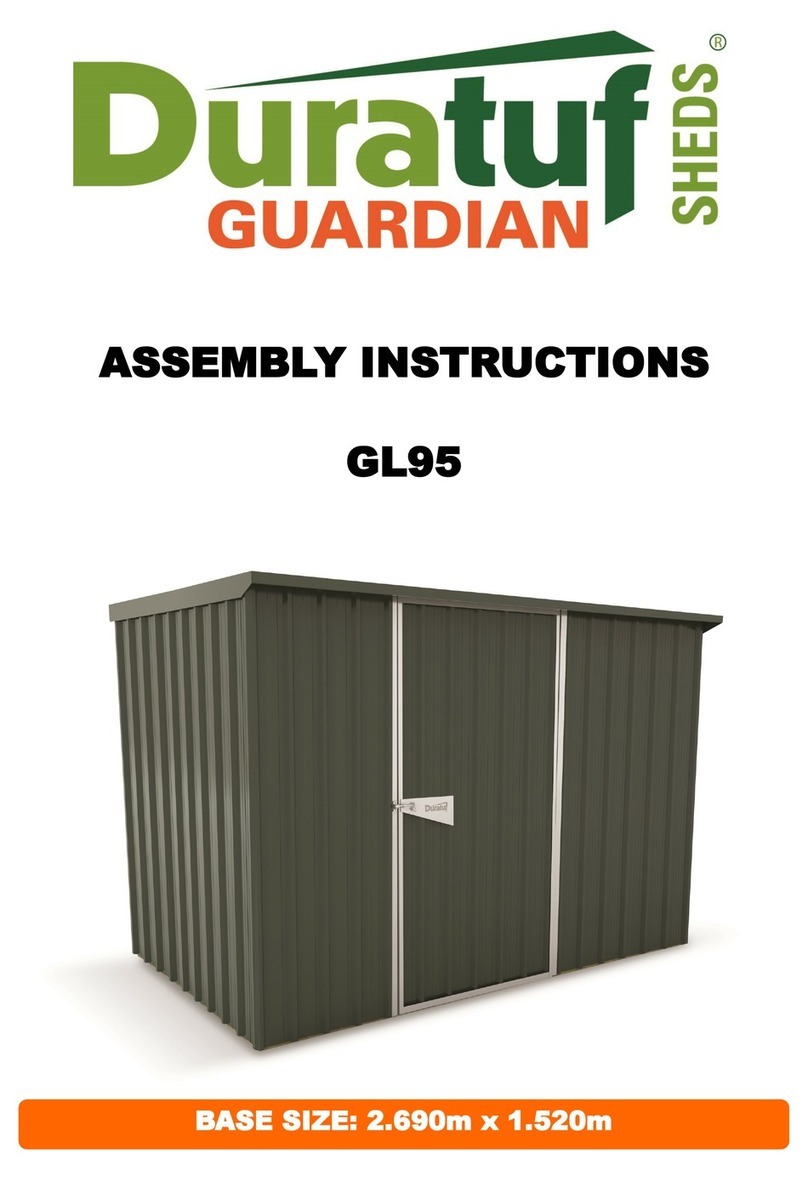

Duratuf TUF 100 User manual

Duratuf

Duratuf PL46 User manual

Duratuf

Duratuf GUARDIAN SHED GL37 User manual

Duratuf

Duratuf MK4C User manual

Duratuf

Duratuf GL75D User manual

Duratuf

Duratuf GG99 User manual

Duratuf

Duratuf Otago User manual

Duratuf

Duratuf TUF 800 User manual

Duratuf

Duratuf MARLBOROUGH User manual

Duratuf

Duratuf MK3B User manual

Duratuf

Duratuf SL1520 User manual

Duratuf

Duratuf GS62 User manual

Duratuf

Duratuf Sentry Shed SL1507 User manual

Duratuf

Duratuf PG98 User manual

Duratuf

Duratuf SS1510 User manual

Popular Outdoor Storage manuals by other brands

rollaway container

rollaway container ARPCA24 manual

X-METAL

X-METAL 4065 owner's manual

Outdoor Life Products

Outdoor Life Products FP2030 F Assembly instructions

Royalcraft

Royalcraft Faro 295L Storage Box Assembly instructions

Riverlea

Riverlea Duratuf KIWI KS3 Assembly instructions

Rubbermaid

Rubbermaid 5L45 manual