1. Important Safety Information

4

1. Important Safety Information

1.1 Health & Safety at Work Act 1974

Section 6(a) of this Act requires manufacturers to advise their customers on the safety and the handling

precautions to be observed when installing, operating, maintaining and servicing their products. The user’s

attention is therefore drawn to the following:

• The appropriate sections of this manual must be read before working on the equipment.

• Installation, operating and maintenance must only be carried out by suitably trained/qualified personnel.

• Normal safety precautions must be taken and appropriate procedures observed to avoid accidents.

Refer to Dutypoint for any technical advice or product information. It is the responsibility of the customer and/or

the contractor:

• To ensure that anyone working on the equipment is wearing all necessary protective gear/clothing;

• Is aware of appropriate health & safety warnings and to read the information in this manual.

1.2 Safety Messages and Hazard Statement

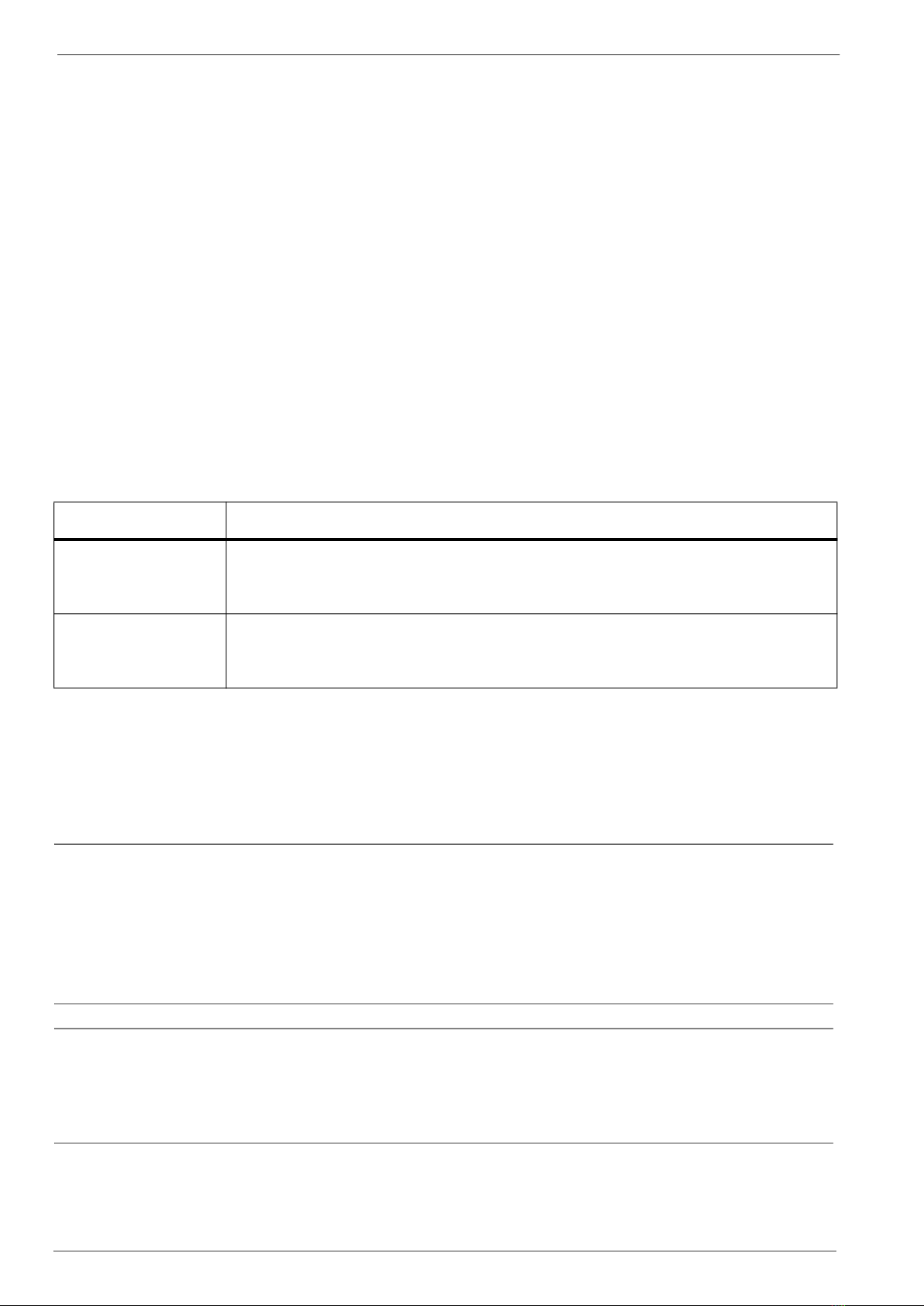

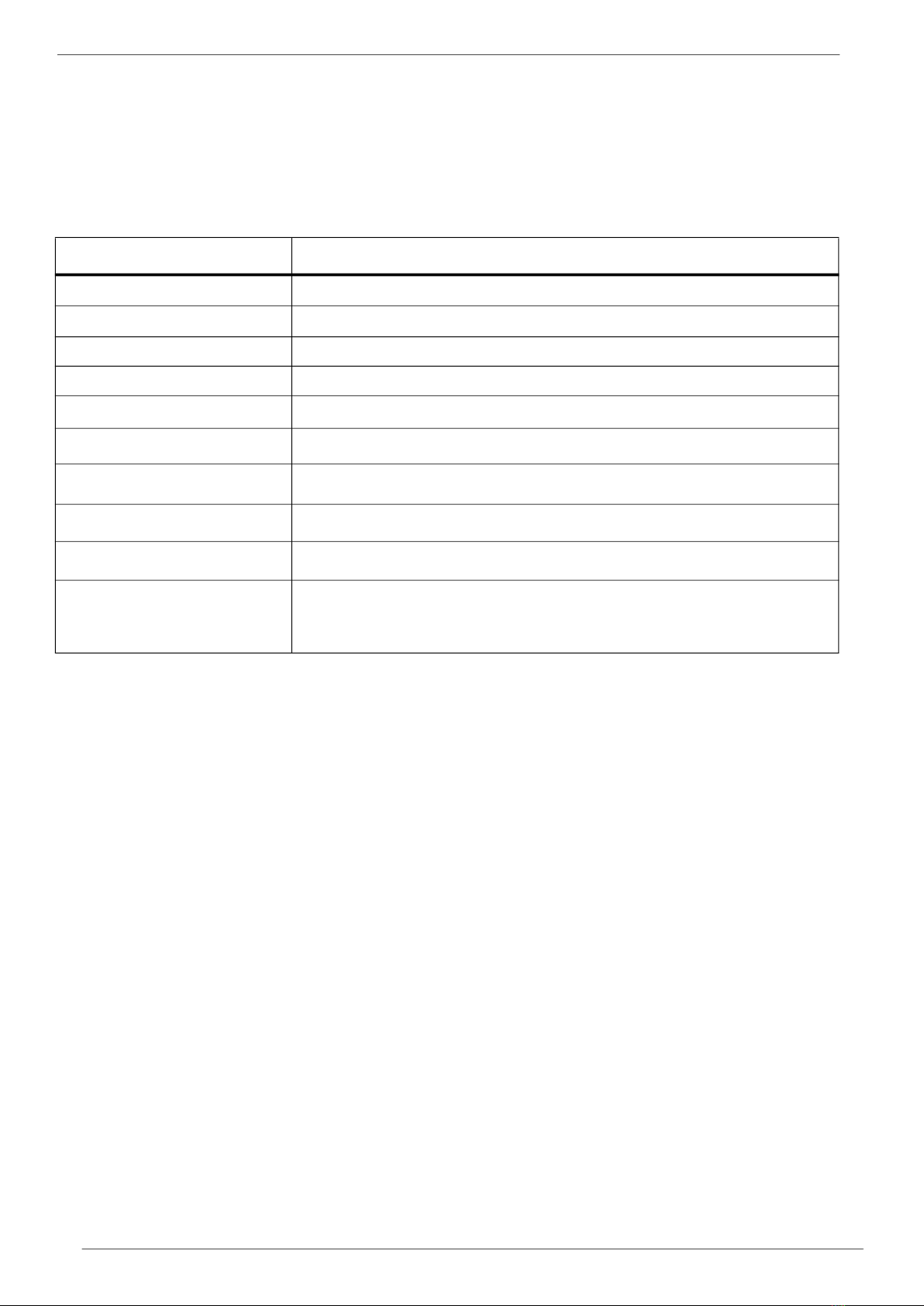

Table 1.1: Hazard Notice Definitions

1.3 Qualified Personnel

WARNING

This product is intended for operation by qualified personnel only

• Only qualified personnel are allowed to install or operate this equipment

• Qualified personnel are defined as trained staff, who are authorised to install, commission and maintain

equipment, systems and circuits in accordance with relevant laws and regulations. Personnel must be

familiar with the instructions and safety procedures described in this document.

• This product should not be used by anyone with mental disabilities, or anyone without the relevant

experience and knowledge, unless they have received instructions on using the equipment and on the

associated risks, or are supervised by a responsible person.

• Children must be supervised to ensure they do not play on or around the equipment.

1.4 Environmental Protection

All local regulations and codes regarding emissions and waste disposal must be followed. This may include:

• Reporting of emissions to appropriate authorities

Message Level Definition

DANGER A hazardous situation which, if not avoided, will result in death or serious injury

WARNING A hazardous situation which, if not avoided, could result in death or serious injury

CAUTION A hazardous situation which, if not avoided, could result in minor injury

or moderate injury

ELECTRICAL HAZARD Risks associated with electricity will cause hazards if not properly avoided

Note A situation which may arise resulting in undesirable conditions and/or will

not cause direct hazards to persons