2.0 Specifications

2.1 Materials of construction

Wetted components: Non-Wetted components:

Enclosure:

413 Aluminum (Polyester powder coated)

Pump Head:

q

Valox (PBT) thermoplastic

Pump Head Cover:

Polycarbonate for added strength and chemical resistance.

Permanently lubricated sealed motor shaft support ball bearing.

Cover Screws:

Stainless Steel

Roller Assembly:

q

Rotor:..................................Valox (PBT)

Rollers: ...............................PVDF/Nylon

Roller Bearings: .................SS Ball Bearings

Motor Shaft:

Chrome plated steel

TFD System Sensor pins:

Hastelloy C-276

Power Cord:

3 conductor, SJTW-A Water-resistant

Tube Installation Tool:

GF Nylon

Mounting Brackets and Hardware:

316 Stainless Steel

Power Cord Options:

115V60Hz = NEMA 5/15 (USA)

230V60Hz = NEMA 6/15 (USA)

220V50Hz = CEE 7/VII (EU)

240V50Hz = AS 3112 (Australia/New Zealand)

Motor:

Brushed DC, 1/8 H.P.

Duty cycle:

Continuous

Motor speed adjustment range 200:1:

0.5% - 100% motor speed (0.7 to 130 RPM)

Motor speed adjustment resolution:

0.1% increments

Display

Backlit LCD, UV resistant.

Keypad

Eight button positive action tactile switch keypad.

Enclosure:

NEMA 4X (IP66), Polyester powder coated aluminum.

Maximum Overall Dimensions:

7-1/2” W x 10-1/4” H x 14” D (19 W x 26 H x 35.6 D cm)

Approximate shipping wt:

25 lb. (12.0 Kg)

Maximum working pressure (excluding pump tubes):

125 psig (8.6 bar)

Note: see individual pump tube assembly maximum pressure

ratings.

Maximum Fluid temperature (excluding pump tubes):

o o

3/8” OD x 1/4” ID tubing connections: 130 F (54 C)

o o

M/NPT connections: 185 F (85 C)

Note: see individual pump tube assembly maximum temperature

ratings.

Maximum fluid viscosity:

12,000 Centipoise

Maximum suction lift:

30 ft. Water, 0 psig (14.7 m, 0 bar)

Ambient Operating Temperature

O O O O

14 F to 115 F (-10 C to 46 C)

Ambient Storage Temperature

O O O O

-40 F to 158 F (-40 C to 70 C)

Operating Voltage:

115VAC/60Hz, 1ph (1.5 Amp Maximum)

230VAC/60Hz, 1ph (0.7 Amp Maximum)

220VAC/50Hz, 1ph (1.0 Amp Maximum)

240VAC/50Hz, 1ph (1.0 Amp Maximum)

Pump Tube Assembly (Model Specific - 2 provided):

q q q

Tubing: . . . . . Flex-A-Prene or Flex-A-Chem or Flex-A-Thane

Adapter fittings: .PVDF

Injection / Back-flow Check valve (sold seperately):

Body & insert: ....................PVDF

Check Ball: .........................Ceramic

Spring: ................................Hastelloy C-276

Ball Seat O-ring:.................TFE/P (optional EPDM)

Static Seal O-ring:..............TFE/P (optional EPDM)

Recommended Ancillary Items (sold seperately):

With “S” tubing type connections only:

Suction Tubing: . . . . . 3/8” OD x 1/4” ID x 10’ Clear PVC

Discharge Tubing: . . . . 3/8” OD x 1/4” ID x 10’ Polyethylene

(LLDPE)

Suction Strainer: . . . . . PVDF

Suction Strainer:

Body:. . . . . . . . . . . PVDF

Check Ball: . . . . . . . . Ceramic

Ball Seat O-ring: . . . . . TFE/P (optional EPDM)

With “B” tubing and “M” M/NPT connections only:

Suction Strainer:

Body: . . . . . . . . . . . . . . . . . PVDF

Check Ball: . . . . . . . . . . . . Ceramic

Ball Seat O-ring: . . . . . . . . TFE/P (optional EPDM)

For “C” Tri-clamp and “Q” Quick Disconnect connections only:

(Available for ND, NEE, NGG, and G2G only)

Suction Strainer: . . . . . . . . . PVDF

*Quick Disconnect Valves sold separately

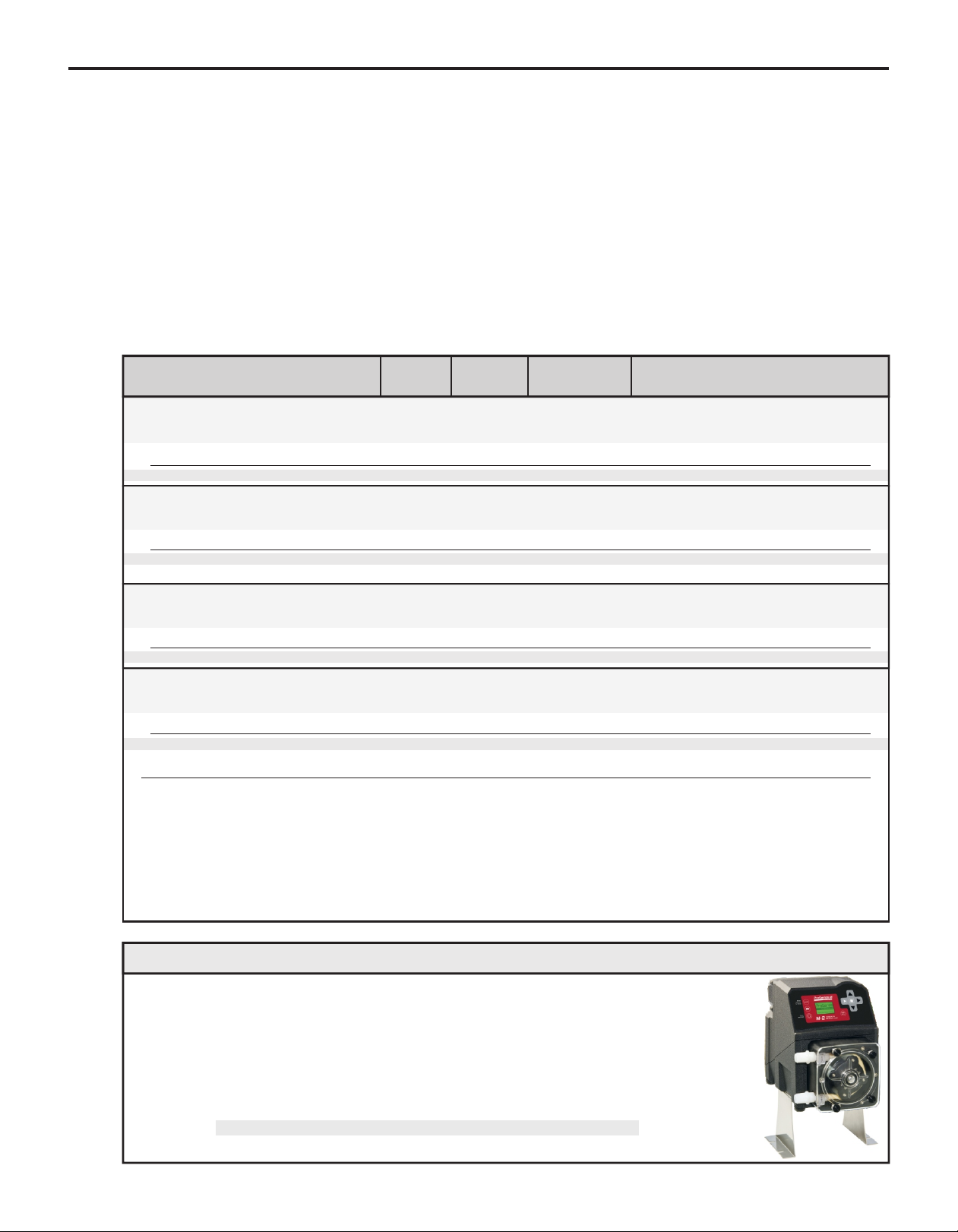

Congratulations on purchasing Flex-Pro variable speed Peristaltic Metering Pump. A peristaltic pump is a type of

positive displacement pump used for pumping a variety of fluids.

Your Flex-Pro pump is pre-configured for tubing that shipped with your metering pump. Tubing assembly has an

Identification number printed on tube for easy re-order; such as ND, NH, etc.

Please Note: Your new pump has been pressure tested at factory with clean water before shipping. You may

notice trace amounts of clean water in pre-installed tube assembly. This is part of our stringent quality assurance

program at Blue-White Industries.

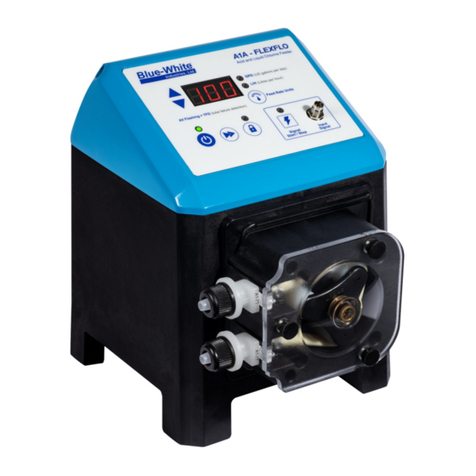

1.1 Available Models

nRaise metering pump 4-1/2 inches (11.43 cm) off ground or a surface.

nMade out of tough Stainless Steel.

nProvides a stable mounting surface.

Stainless Steel extended brackets allow pump to be securely mounted to most any surface; floor,

shelf, or skid. Brackets lift pump up 4-1/2 inches (11.43 cm), for easy pump access in hard to reach

areas.

Model #

72000-380

Description

Extended Mounting Bracket, 1 Pair, SS, 4 SS Screws

Optional Extended Brackets

1.0 Introduction

®

Flex-A-Thane M2 Tube Pumps

Meets FDA criteria for food | Resistant to oils, greases and fuels

GPH

.02 - 4.0

.05 - 9.3

.07 - 14.98

LPH

.08 - 15.2

.17 - 35.2

.03 - 56.7

ML/Min

1 - 253

3 - 587

4.7 - 945

RPM

130

130

130

115V AC

M-224-*GE

M-224-*GG

M-224-*G2G

230V AC

M-225-*GE

M-225*GG

M-225*G2G

220V AC

M-226-*GE

M-226-*GG

M-226-*G2G

®

Flex-A-Chem M2 Tube Pumps

Meets FDA criteria for food | Superb chemical resistance

LPH

.27 - 54

230V AC

M-225-*TH

115V AC

M-224-*TH

GPH

.07 - 14.3

220V AC

M-226-*TH

ML/Min

4.5 - 900

RPM

130

®

Flex-A-Prene M2 Tube Pumps

Meets FDA criteria for food | Excellent chemical resistance | CIP | SIP

LPH

.03 - 6.5

230V AC

M-225-*ND

115V AC

M-224-*ND

GPH

.01 - 1.7

220V AC

M-226-*ND

ML/Min

.54 - 108

Feed Rate

RPM

130

Max

Speed M2 Model Numbers

PSI (bar)

65 (4.5)

65 (4.5)

65 (4.5)

Max

Pressure

PSI (bar)

125 (8.6)

PSI (bar)

50 (3.4)

Max

Temperature

F (C)

185 (85)

F (C)

130 (54)

F (C)

130 (54)

130 (54)

130 (54)

!Flex-Pro Pumps motor speed is linear over entire 1% to 100% adjustment range.

!Output versus pressure is nearly linear in all models. Larger tubes exhibit greater losses.

!For optimum tube life, specify pump to operate at lowest possible RPM and pressure.

!Feed rates taken in laboratory environment with clean water after 20 minute tube break-in period with a 3 foot (1 meter) suction lift.

®

Flex-A-Prene M2 Tube Pumps

Meets FDA criteria for food | Excellent chemical resistance | Extra long tube life

LPH

.084 - 16.8

.325 - 65.1

230V AC

M-225-*NEE

M-225-*NGG

115V AC

M-224-*NEE

M-224-*NGG

GPH

.07 - 4.44

.086 - 17.2

220V AC

M-226-*NEE

M-226-*NGG

ML/Min

1.4 - 280

5.4 - 1085

RPM

130

130

PSI (bar)

110 (7.6)

110 (7.6)

F (C)

185 (85)

185 (85)

* Inlet/outlet connection type

S = 3/8” OD x 1/4” ID tubing compressions type connections

M = 1/²” male NPT

B = 1/²” Hose barb, Natural PVDF (Kynar), (ND, NEE, NGG, and G2G only)

C = 1/²” - 3/4” tri-clamp connections (ND, NEE, NGG, and G2G only)

Q = Quick Disconnect (ND, NEE, NGG, and G2G only) (Valves sold separately)

Page 4 ®

FLEXFLO M2 ®

FLEXFLO M2 Page 5