Operating and Maintenance Instructions

EN

LB.5WR – LC.25WR – LB.40WR – LB.60WR – LC.105WR

8 0203 – 01/01/2011 – R.0 www.dvp.it

1

INDEX

1 INTRODUCTION....................................................................................................................................................2

1.1 GENERAL

INFORMATION .............................................................................................................................................. 2

1.2 MANUFACTURER

INFORMATION ................................................................................................................................. 2

1.3 METHOD

OF

CONSULTATION ....................................................................................................................................... 2

1.4 PERSONNEL

QUALIFICATIONS .................................................................................................................................... 2

1.5 PERSONAL

PROTECTION

EQUIPMENT ....................................................................................................................... 2

1.6 INFORMATION

PLATE.................................................................................................................................................... 3

2 SAFETY .................................................................................................................................................................3

2.1 GENERAL

WARNINGS ................................................................................................................................................... 3

2.2 RESIDUAL

RISKS ........................................................................................................................................................... 3

2.3 PICTOGRAMS................................................................................................................................................................. 4

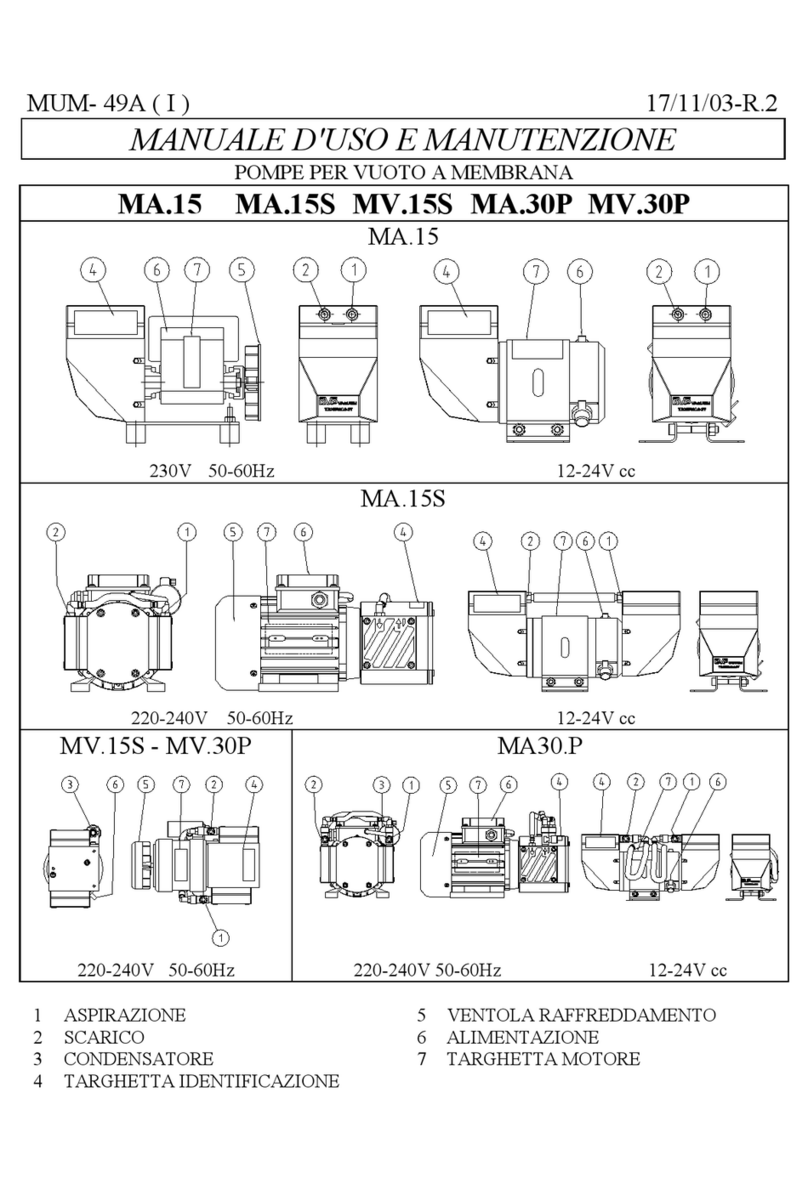

3 PUMP DESCRIPTION ...........................................................................................................................................4

3.1 INTENTED

USE

AND

CONTRAINDICATIONS................................................................................................................ 4

3.1.1 INTENTED USE ....................................................................................................................................................... 4

3.1.2 CONTRAINDICATIONS............................................................................................................................................ 4

3.2 FKM

VERSION ................................................................................................................................................................ 4

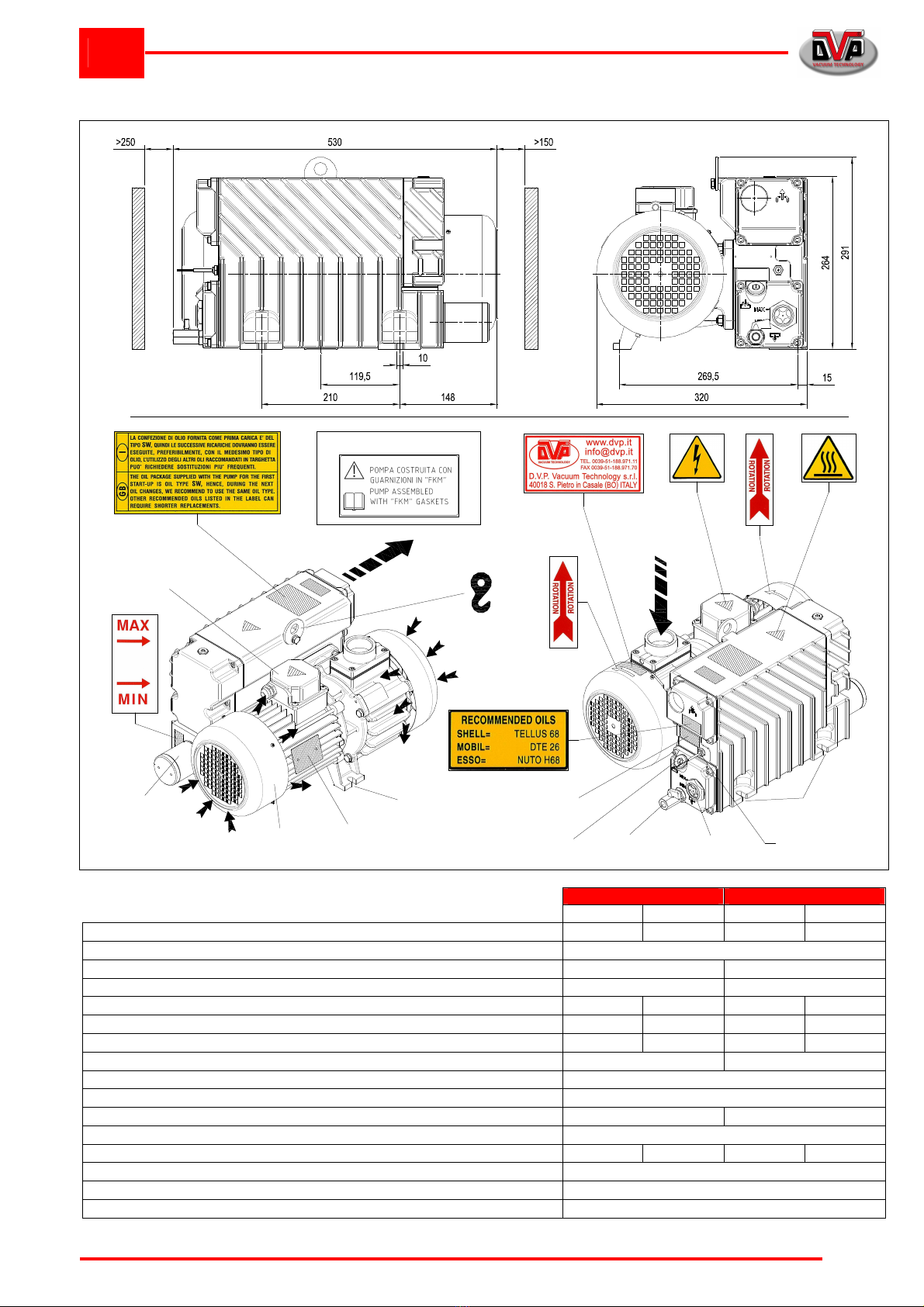

3.3 DIMENSIONS

AND

CHARACTERISTICS........................................................................................................................ 5

3.3.1 Mod l: LB.5WR ....................................................................................................................................................... 5

3.3.2 Mod l: LC.25WR ..................................................................................................................................................... 6

3.3.3 Mod l: LB.40WR – LB.60WR.................................................................................................................................. 7

3.3.4 Mod l: LC.105WR ................................................................................................................................................... 8

3.4 NOISE

EMISSION ........................................................................................................................................................... 9

4 INSTALLATION .....................................................................................................................................................9

4.1 RECEIPT

AND

CONTENT

VERIFICATION ..................................................................................................................... 9

4.2 PACKAGING.................................................................................................................................................................... 9

4.3 TRANSPORT

AND

HANDLING ....................................................................................................................................... 9

4.4 STORAGE ....................................................................................................................................................................... 9

4.5 ENVIRONMENTAL

CONDITIONS ................................................................................................................................... 9

4.6 PUMP

INSTALLATION .................................................................................................................................................. 10

4.7 MOTOR

INSTALLATION

(ONLY

LC.105WR) ................................................................................................................ 10

4.8 USER

SYSTEM.............................................................................................................................................................. 10

4.9 CONNECTION............................................................................................................................................................... 10

4.9.1 ASSEMBLING THE INTAKE FILTER (ONLY LB.5WR).......................................................................................... 10

4.9.2 INTAKE AND OUTLET CONNECTIONS................................................................................................................ 10

4.9.3 WIRING .................................................................................................................................................................. 11

4.9.4 ELECTRICAL OIL LEVEL GAUGE......................................................................................................................... 11

5 OPERATING INSTRUCTIONS............................................................................................................................12

5.1 OPERATION.................................................................................................................................................................. 12

5.1.1 FILLING THE OIL TANK......................................................................................................................................... 12

5.1.2 START-UP.............................................................................................................................................................. 12

5.1.3 PUMPING WATER VAPOUR................................................................................................................................. 12

5.1.4 INTAKE FILTER (ONLY LB.5WR).......................................................................................................................... 12

5.1.5 STOP...................................................................................................................................................................... 13

6 MAINTENANCE...................................................................................................................................................13

6.1 GENERAL

WARNINGS ................................................................................................................................................. 13

6.2 MAINTENANCE

TABLE................................................................................................................................................. 13

6.2.1 CHECK THE OIL LEVEL AND THE ABSENCE OF WATER VAPOUR CONDENSED IN THE TANK .................. 14

6.2.2 CHECK THE STATUS OF THE INTAKE FILTER (ONLY LB.5WR) ....................................................................... 14

6.2.3 CHANGE OIL.......................................................................................................................................................... 14

6.2.4 INTAKE FILTER CARTRIDGE REPLACEMENT (ONLY LB.5WR) ........................................................................ 14

6.2.5 CLEAN MOTOR FAN GUARD AND CLEAN THE PUMP....................................................................................... 14

6.2.6 CHANGE THE AIR EXHAUST FILTER .................................................................................................................. 14

6.2.7 CHANGE VANES ................................................................................................................................................... 14

6.3 SPARE

PARTS .............................................................................................................................................................. 15

7 HOW TO RETURN THE PUMP...........................................................................................................................15

8 DISMANTLING ....................................................................................................................................................15

9 TROU LESHOOTING.........................................................................................................................................16