8704013 RC.50M 14/03/06 – R.0

Pag. 8 D.V.P. Vacuum Technology s.r.l. – MSH Techno Ltd. – www.msht.ru

ɇɚɫɨɫ ɞɨɥɠɟɧ ɛɵɬɶ ɭɫɬɚɧɨɜɥɟɧ ɜ ɩɪɨɜɟɬɪɢɜɚɟɦɨɣ ɤɨɦɧɚɬɟ

ɱɬɨɛɵɝɚɪɚɧɬɢɪɨɜɚɬɶɟɝɨɩɪɚɜɢɥɶɧɭɸɪɚɛɨɬɭ Ⱦɨɥɠɟɧɛɵɬɶ

ɨɛɟɫɩɟɱɟɧ ɫɜɨɛɨɞɧɵɣ ɨɬɯɨɞ ɬɟɩɥɨɝɨ ɜɨɡɞɭɯɚ ɨɬ ɧɚɫɨɫɚ

ɧɢɤɚɤɢɟɩɪɟɞɦɟɬɵɧɟɫɬɨɢɬɩɨɦɟɳɚɬɶɪɹɞɨɦɫɜɟɧɬɢɥɹɬɨɪɨɦ

ɞɥɹɩɪɟɞɨɬɜɪɚɳɟɧɢɹɧɚɪɭɲɟɧɢɹɟɝɨɪɚɛɨɬɵ

The pump should be placed in a ventilated room in order to

ensure its proper working. Make sure warm air is let out of the

installation room. No elements should be placed near the motor

cooling fan as this may inhibit regular air flow.

ɇɚɫɨɫ ɞɨɥɠɟɧ ɛɵɬɶ ɭɫɬɚɧɨɜɥɟɧ ɬɚɤ ɱɬɨ ɛɵ ɛɵɥɢ ɞɨɫɬɭɩɧɵ

ɦɚɫɥɨɡɚɥɢɜɧɨɟ ɢ ɦɚɫɥɨɫɥɢɜɧɨɟ ɨɬɜɟɪɫɬɢɹ ɫɦɨɬɪɨɜɨɟ

ɨɤɨɲɤɨ ɀɟɥɚɬɟɥɶɧɨ ɢɫɩɨɥɶɡɨɜɚɬɶ ɞɟɩɮɟɪɧɵɟ ɧɨɠɤɢ ɞɥɹ

ɭɫɬɚɧɨɜɤɢ ɧɚɫɨɫɚ ɇɚɞɟɠɧɨ ɡɚɤɪɟɩɢɬɟ ɧɚɫɨɫ ɇɚɫɨɫ ɞɨɥɠɟɧ

ɛɵɬɶɭɫɬɚɧɨɜɥɟɧɧɚɝɨɪɢɡɨɧɬɚɥɶɧɭɸɩɨɜɟɪɯɧɨɫɬɶ

Place pump so that oil filler and drain plugs as well as Oil sight

glass are well visible and easily accessible.

The pump is fitted with vibration-damping feet that are also used

to fasten it. Secure the pump so it will not fall aside should the

system be relocated. The pump should be installed on a perfectly

level surface.

3.5 Ɂɚɩɨɥɧɟɧɢɟɧɚɫɨɫɚɦɚɫɥɨɦ 3.5 Filling the tank.

ɉɪɢ ɡɚɩɨɥɧɟɧɢɢ ɧɚɫɨɫɚ ɦɚɫɥɨɦ ɧɢɤɨɝɞɚ ɧɟ

ɩɪɟɜɵɲɚɣɬɟɞɨɩɭɫɬɢɦɵɣɭɪɨɜɟɧɶ.When filling the oil tank never exceed allowed

maximum level.

Fȼɫɟ ɧɚɫɨɫɵ ɩɨɫɬɚɜɥɹɸɬɫɹ ɧɟɡɚɩɨɥɧɟɧɧɵɦɢ

ɂɫɩɨɥɶɡɭɣɬɟɬɨɥɶɤɨɪɟɤɨɦɟɧɞɨɜɚɧɧɵɟɦɚɫɥɚ FAll pumps are shipped out dry.

Use DVP oil only.

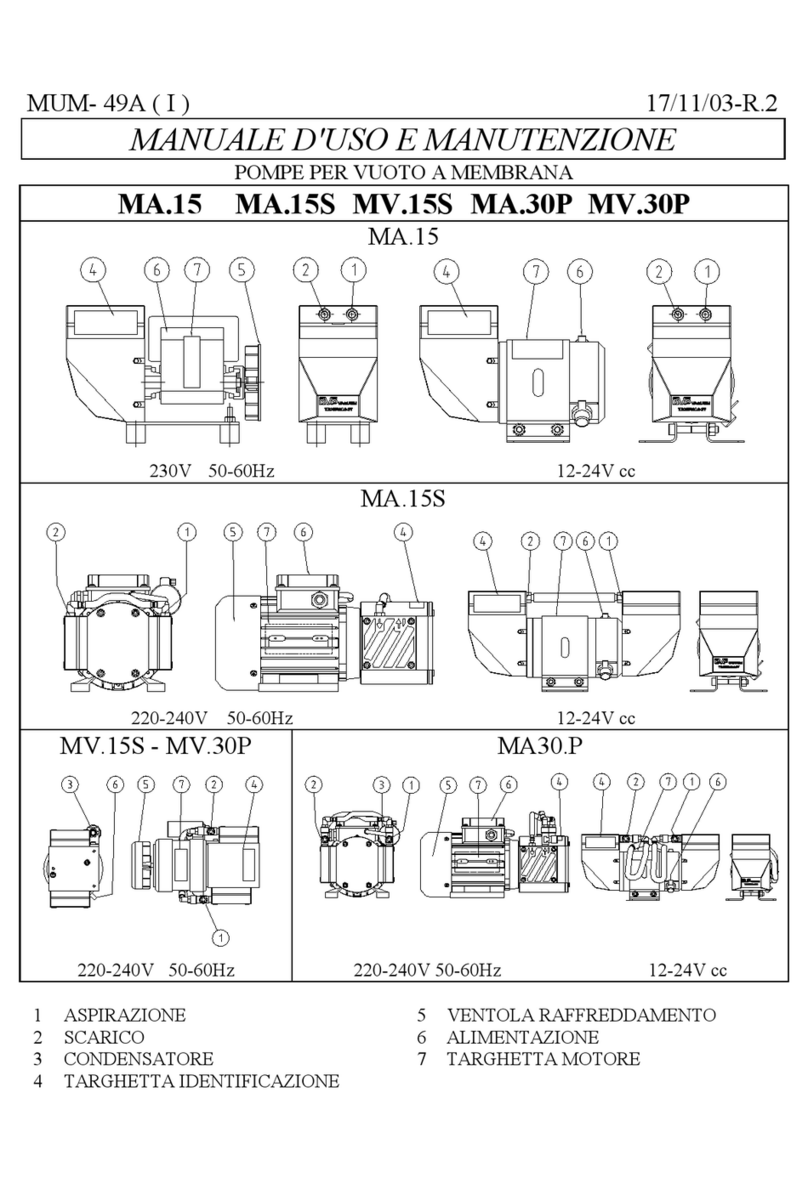

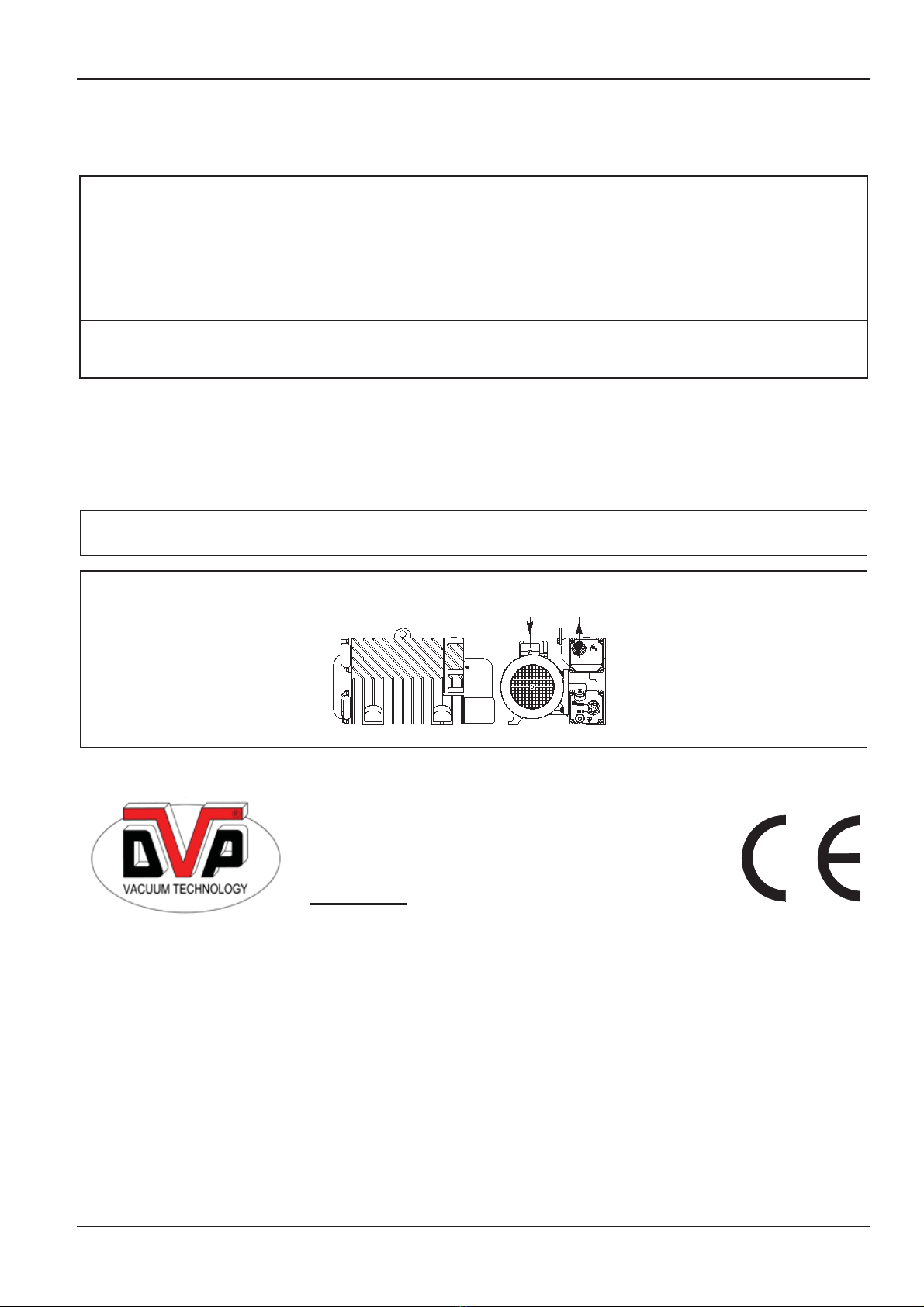

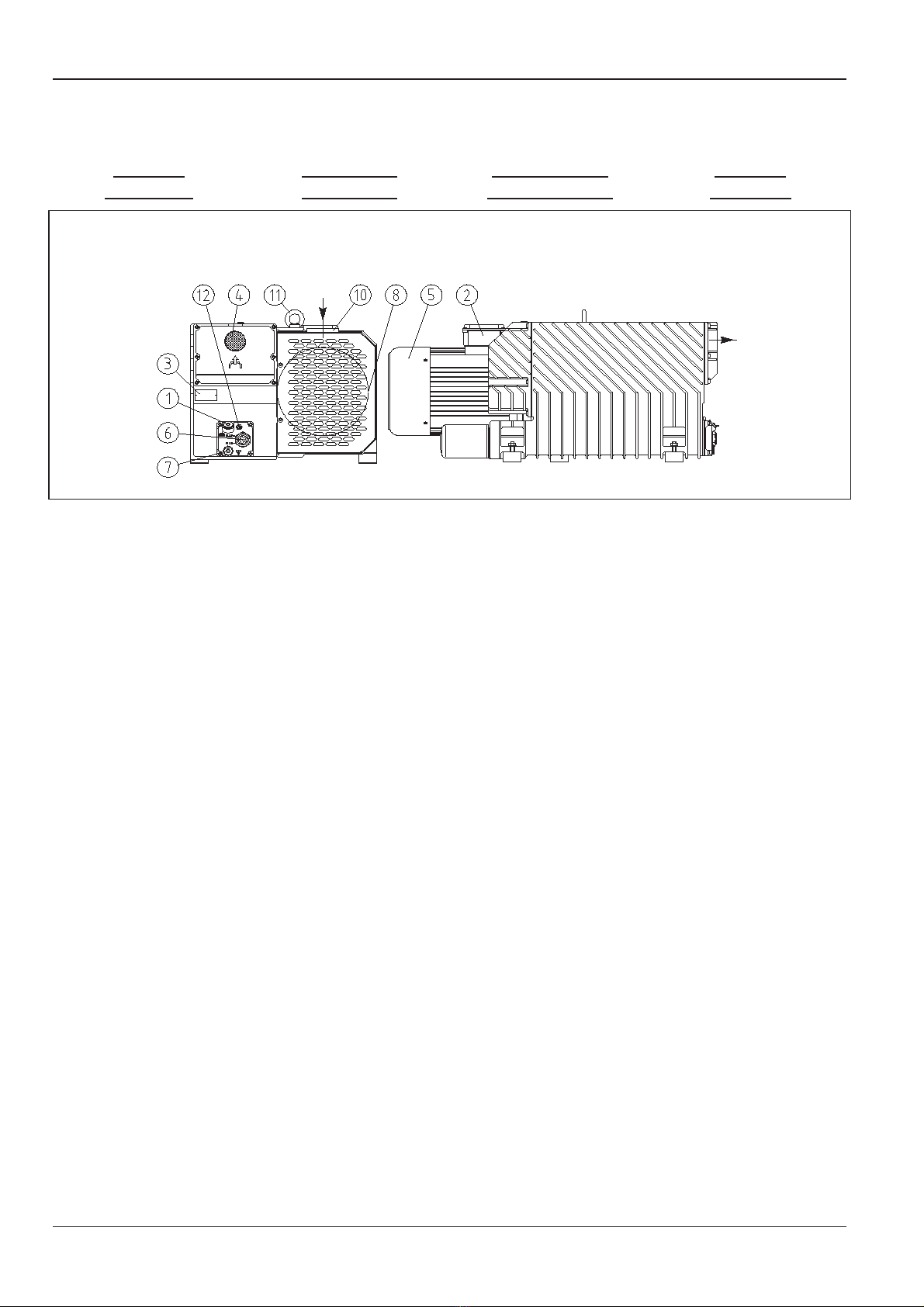

ɇɢɠɟɢɫɩɨɥɶɡɭɸɬɫɹɧɚɦɟɪɚɫɫɵɥɨɤɫɨɫɬɪɚɧɢɰɵ The numbers reported below are for cross-reference to the

drawing on page 3.

xɈɬɤɪɨɣɬɟɩɪɨɛɤɭɦɚɫɥɨɡɚɥɢɜɧɨɝɨɨɬɜɟɪɫɬɢɹɩɨɡ.1); xUndo filler plug (no.1);

xɁɚɩɨɥɧɢɬɟ ɧɚɫɨɫ ɧɚɫɥɨɦ ɞɨ ɫɟɪɟɞɢɧɵ ɫɦɨɬɪɨɜɨɝɨ ɨɤɧɚ

ɩɨɡ.6);

xFill oil into the tank up to mid-range of Oil sight glass

(no.6);

xɁɚɤɪɨɣɬɟ ɦɚɫɥɨɧɚɥɢɜɧɨɟ ɨɬɜɟɪɫɬɢɟ ɢ ɩɪɨɬɪɢɬɟ ɧɚɫɨɫ

ɟɫɥɢɦɚɫɥɨɫɥɭɱɚɣɧɨɩɨɩɚɥɨɧɚɧɟɝɨ

xClose filler plug and wipe off any oil spills from the tank.

3.6 ɉɨɞɤɥɸɱɟɧɢɟɤɷɥɟɤɬɪɨɫɟɬɢ 3.6 Wiring.

ɉɨɞɤɥɸɱɟɧɢɟ ɞɨɥɠɧɨ ɨɫɭɳɟɫɬɜɥɬɶɫɹ

ɤɜɚɥɢɮɢɰɢɪɨɜɚɧɧɵɦ ɩɟɪɫɨɧɚɥɨɦ ɫ

ɫɨɨɬɜɟɫɬɜɭɸɳɢɦɢɞɨɩɭɫɤɚɦɢ

Wiring should be performed by properly skilled

personnel and in compliance with electrical

standards in force.

Fɉɪɨɜɟɪɶɬɟ ɫɨɨɬɜɟɬɫɬɜɢɟ ɫɟɬɢ ɞɚɧɧɵɦ ɧɚ

ɲɢɥɶɞɢɤɟ ɷɥɟɤɬɪɨɞɜɢɝɚɬɟɥɹ ɩɪɨɜɟɪɶɬɟ

ɩɪɚɜɢɥɶɧɨɫɬɶɧɚɩɪɚɜɥɟɧɢɢɜɪɚɳɟɧɢɹ FMake sure that supply voltage matches that on

motor rating plate (no.8).

Check that direction of rotation is correct.

ȼɫɟɝɞɚ ɧɭɠɧɨ ɩɪɟɞɭɫɦɚɬɪɢɜɚɬɶ ɫɢɫɬɟɦɭ ɷɥɟɤɬɪɢɱɟɫɤɨɣ

ɡɚɳɢɬɵɦɟɠɞɭɧɚɫɨɫɨɦɢɫɟɬɶɸ

An electric protection system should always be provided

between pump and mains.

Ɇɨɳɧɨɫɬɶɷɥɟɤɬɪɨɞɜɢɝɚɬɟɥɹɭɤɚɡɚɧɚɧɚɲɢɥɶɞɢɤɟ Electrical input values are reported on motor rating plate.

ɇɚɫɨɫ ɨɛɵɱɧɨ ɩɨɫɬɚɜɥɹɟɬɫɹ ɛɟɡ ɤɚɛɟɥɹ ɢ ɬɭɦɛɥɟɪɚ

ɜɤɥɸɱɟɧɢɹɞɥɹɩɨɞɛɨɪɚɷɬɢɯɚɤɫɫɟɫɭɚɪɨɜɢɡɭɱɢɬɟɞɚɧɧɵɟɧɚ

ɲɢɥɶɞɢɤɟɷɥɟɤɬɪɨɞɜɢɝɚɬɟɥɹɢɧɚɫɨɫɚ

The pump normally comes without power cable and switch; for

connection to mains see the diagram inside the terminal board or

on the motor rating plate.

3.7 ɉɪɢɫɨɟɞɢɧɟɧɢɹɧɚɜɯɨɞɟɢɜɵɯɨɞɟ 3.7 Intake and outlet connections.

Ʉɚɬɟɝɨɪɢɱɟɫɤɢ ɡɚɩɪɟɳɚɟɬɫɹ ɨɬɤɚɱɢɜɚɬɶ

ɤɢɫɥɨɪɨɞɢɥɢɤɢɫɥɨɪɨɞɧɵɟɫɦɟɫɢ It is strictly forbidden to intake gases like oxygen or

oxygen mixtures as this will lead to explosion hazard.

F

ɇɟɢɫɩɨɥɶɡɭɣɬɟɠɟɫɬɤɢɟɬɪɭɛɵɞɥɹ ɩɨɞɤɥɸɱɟɧɢɹ

ɧɚɫɨɫɚ ɞɚɜɥɟɧɢɟ ɧɚ ɜɵɯɨɞɟ ɧɟ ɞɨɥɠɧɨ

ɩɪɟɜɵɲɚɬɶ ɛɚɪɚ ɭɛɟɞɢɬɟɫɶ ɜ ɩɪɚɜɢɥɶɧɨɫɬɢ

ɩɨɞɤɥɸɱɟɧɢɹ

FDo not use stiff pipes to connect intake and outlet

(MAX overpressure at outlet: 0.3 bar).

Take care to connect pump to user system

correctly.

ɋɬɚɪɚɣɬɟɫɶɧɟɢɫɩɨɥɶɡɨɜɚɬɶɨɱɟɧɶɞɥɢɧɧɵɟɲɥɚɧɝɢɲɥɚɧɝɢ

ɦɚɥɨɝɨ ɞɢɚɦɟɬɪɚ ɲɥɚɧɝɢ ɫ ɛɨɥɶɲɢɦ ɤɨɥɢɱɟɫɬɜɨɦ ɢɡɝɢɛɨɜ

ɜɫɟɷɬɨɫɧɢɠɚɟɬɷɮɮɟɤɬɢɜɧɨɫɬɶɢɫɩɨɥɶɡɨɜɚɧɢɹɧɚɫɨɫɚ

Never use: friction hoses, too small diameters (never smaller

than intake diameter); avoid exceeding hose lenghts, tight bends

or bends spaced too closely.

F

ȼɫɟɝɞɚɢɫɩɨɥɶɡɭɣɬɟɧɚɫɨɫɬɨɥɶɤɨɫɮɢɥɶɬɪɨɦɩɟɪɟɞ

ɜɯɨɞɨɦ

F

Always install an intake filter, especially if the pump is

to work with flux that might contain foreign matters.

ɍɛɟɞɢɬɟɫɶ ɱɬɨ ɨɬɤɚɱɢɜɚɟɦɵɟ ɝɚɡɵ ɦɨɠɧɨ

ɜɵɛɪɚɫɵɜɚɬɶɜɚɬɦɨɫɮɟɪɭ

Make sure that discharged gases are let out of the

workplace.

Ƚɚɡɵ ɜɵɛɪɚɫɵɜɚɟɦɵɟ ɧɚɫɨɫɨɦ ɞɨɥɠɧɵ ɛɵɬɶ ɨɛɪɚɛɨɬɚɧɵ ɞɨ

ɬɚɤɨɣɫɬɟɩɟɧɢɱɬɨɛɵɧɟɩɪɢɧɟɫɬɢɜɪɟɞɨɤɪɭɠɚɸɳɟɣɫɪɟɞɟɢ

ɪɚɛɨɱɟɦɭɦɟɫɬɭ

The gases discharged by the pump should be handled in such a

way to prevent them from polluting the workplace and

surroundings.

ȿɫɥɢɢɦɟɟɬɫɹɨɩɚɫɧɨɫɬɶɨɛɪɚɡɨɜɚɧɢɹɤɨɧɞɟɧɫɚɬɚɜɨɬɜɨɞɹɳɟɟ

ɥɢɧɢɢ ɨɧɚ ɞɨɥɠɧɚ ɢɞɬɢ ɫ ɩɨɫɬɨɹɧɧɵɦ ɭɤɥɨɧɨɦ ɜɧɢɡ ɞɥɹ

ɩɪɟɞɨɬɜɪɚɳɟɧɢɹɫɬɟɤɚɧɢɹɤɨɧɞɟɧɫɚɬɚɜɧɚɫɨɫ

If condensable vapours are pumped, the discharge hose should be

routed downwards and have no bends to prevent the condensate

produced in the discharge line from building up or flowing back into

the pump.