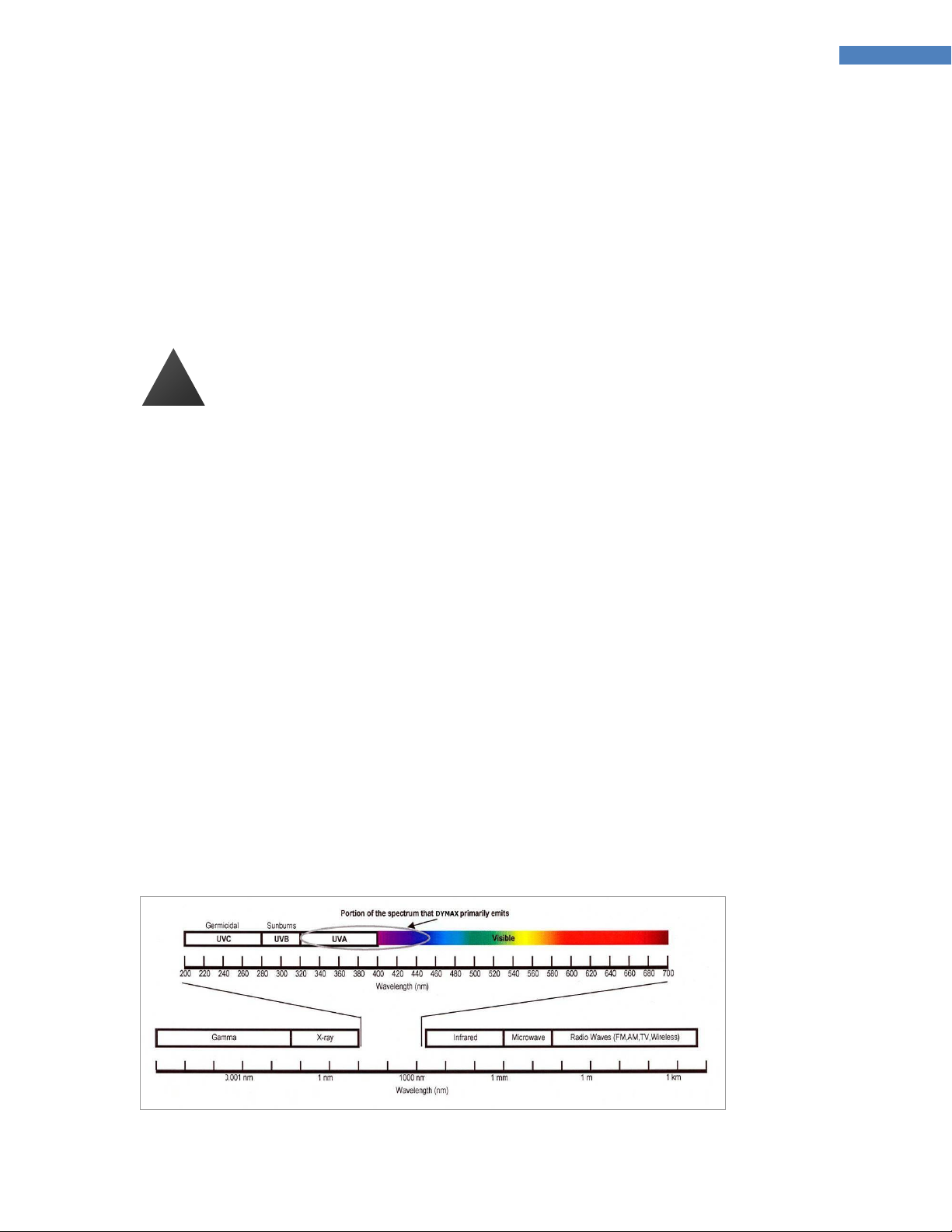

Standard Dymax UV light-curing systems have been designed primarily to emit UVA energy (Figure 1). The

energy emitted from the Dymax BlueWave® LED DX-1000 system is in the upper end of the UV portion of the

spectrum. UVA energy is generally considered the safest of the three UV ranges: UVA, UVB, and UVC.

Although OSHA does not currently regulate UV light exposure in the workplace, the American Conference of

Governmental Industrial Hygienists (ACGIH) does recommend Threshold Limit Values (TLVs) for ultraviolet

light.

The strictest interpretation of the TLV (over the UVA range) for workers’ eyes and skin allows continuous

exposure up to 1 mW/cm2(intensity). Unless you are placing bare hands into the curing area, it is unusual to

exceed these limits. To put 1 mW/cm2limit into perspective, a cloudless summer day will typically exceed

3 mW/cm2of UVA light, and also include the more dangerous UVB light (primarily responsible for sun tans,

sun burns, and skin cancer) as well.

Checking the Workstation

The human eye cannot detect "pure" UV light, only visible light. A radiometer should be used to measure stray

UV light to confirm the safety of a UV light-curing process. A workstation that exposes an operator to more

than 1 mW/cm2of UVA continuously should be redesigned.

Protecting Operators

Light-curing technology can be a regulatory compliant, "worker-friendly" manufacturing process when the

proper safety equipment and operator training is utilized. There are two ways to protect operators from UV

exposure: shield the operator and/or shield the source.

Shield the Operator —UV-Blocking Eye Protection - UV-blocking eye protection is recommended when

operating UV light-curing systems. Both clear and tinted UV-blocking eye protection is available from Dymax.

UV-Blocking Skin Protection —Where the potential exists for UV exposure upon skin, opaque, UV-blocking

clothing, gloves, and full-face shields are recommended.

Shield the Source of UV

Any substrate that blocks UV light can be used as a shield to protect workers from stray UV light. The following

materials can be used to create simple shielding structures:

Rigid Plastic Film —Transparent or translucent/UV-blocking plastics (typically polycarbonate or acrylic) are

commonly used to create shielding where some level of transparency is also desired.

Flexible Film —Translucent UV-blocking, flexible urethane films can be used to quickly create workstation

shielding. This UV-blocking, flexible urethane film is available from Dymax, call for assistance. NOTE: The

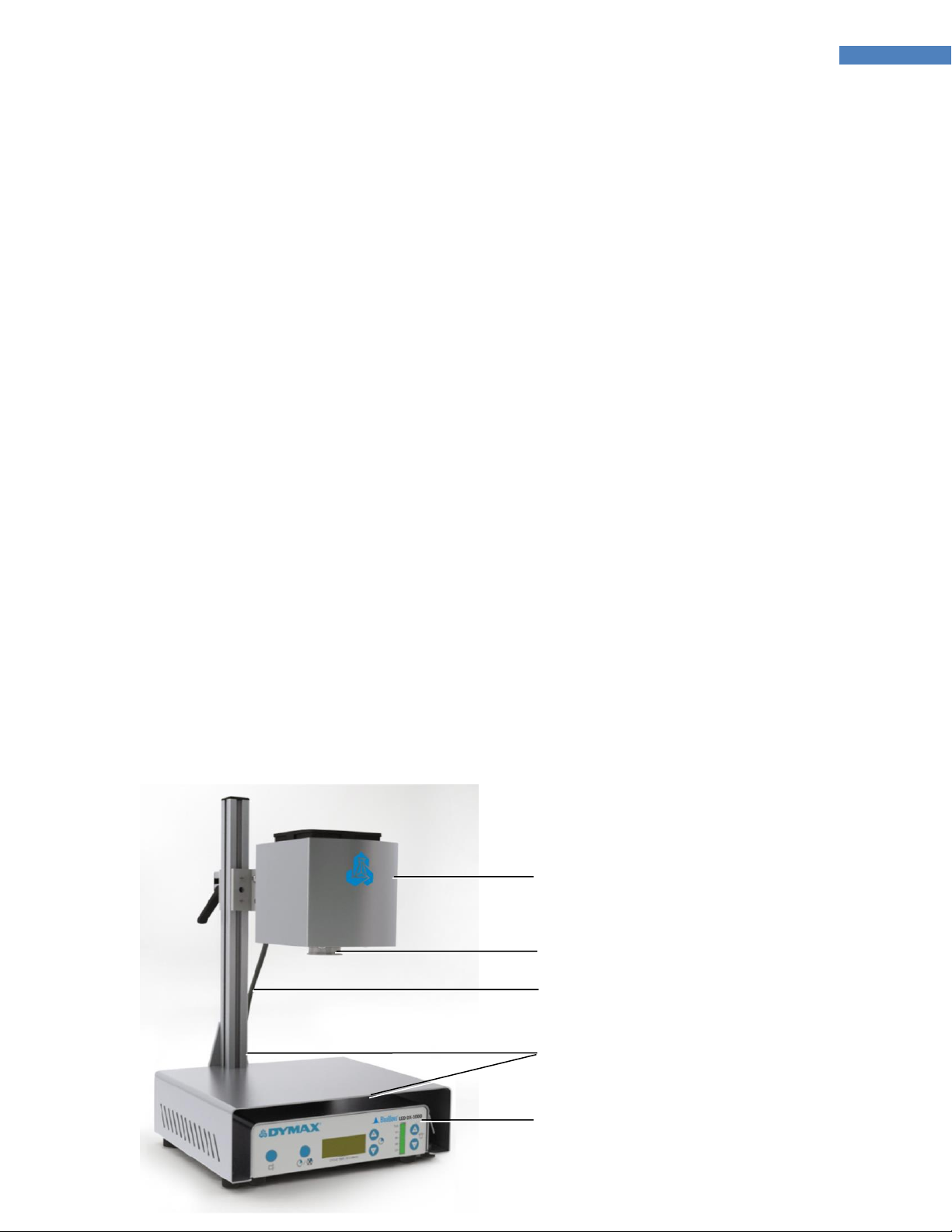

BlueWave® LED DX-1000 includes UV-blocking flexible film that is affixed with a magnetic strip that can be

used to attach it to the LED Head and trimmed to suit your application.

High-Temperature Surfaces

Surfaces exposed to high-intensity curing lights may rise in temperature. The intensity, distance, exposure

time, cooling fans, and composition of the surface can all affect the rise in surface temperature. In some cases,

exposed surfaces can reach temperatures capable of producing a burn or causing damage to a substrate. In

these cases, care must be taken to ensure either a more moderate surface temperature or appropriate

protection/training for operators. No infrared radiation is produced by these LED systems, so surface