Contents

Introduction................................................................................................................................................ 4

Where to Get Help .......................................................................................................................................................... 4

Safety.......................................................................................................................................................... 4

UV Light-Curing System Safety Considerations ............................................................................................................... 6

Product Overview........................................................................................................................................ 8

Description of the BlueWave 75...................................................................................................................................... 8

Assembly and Setup .................................................................................................................................... 9

Unpacking and Inspecting Your Shipment....................................................................................................................... 9

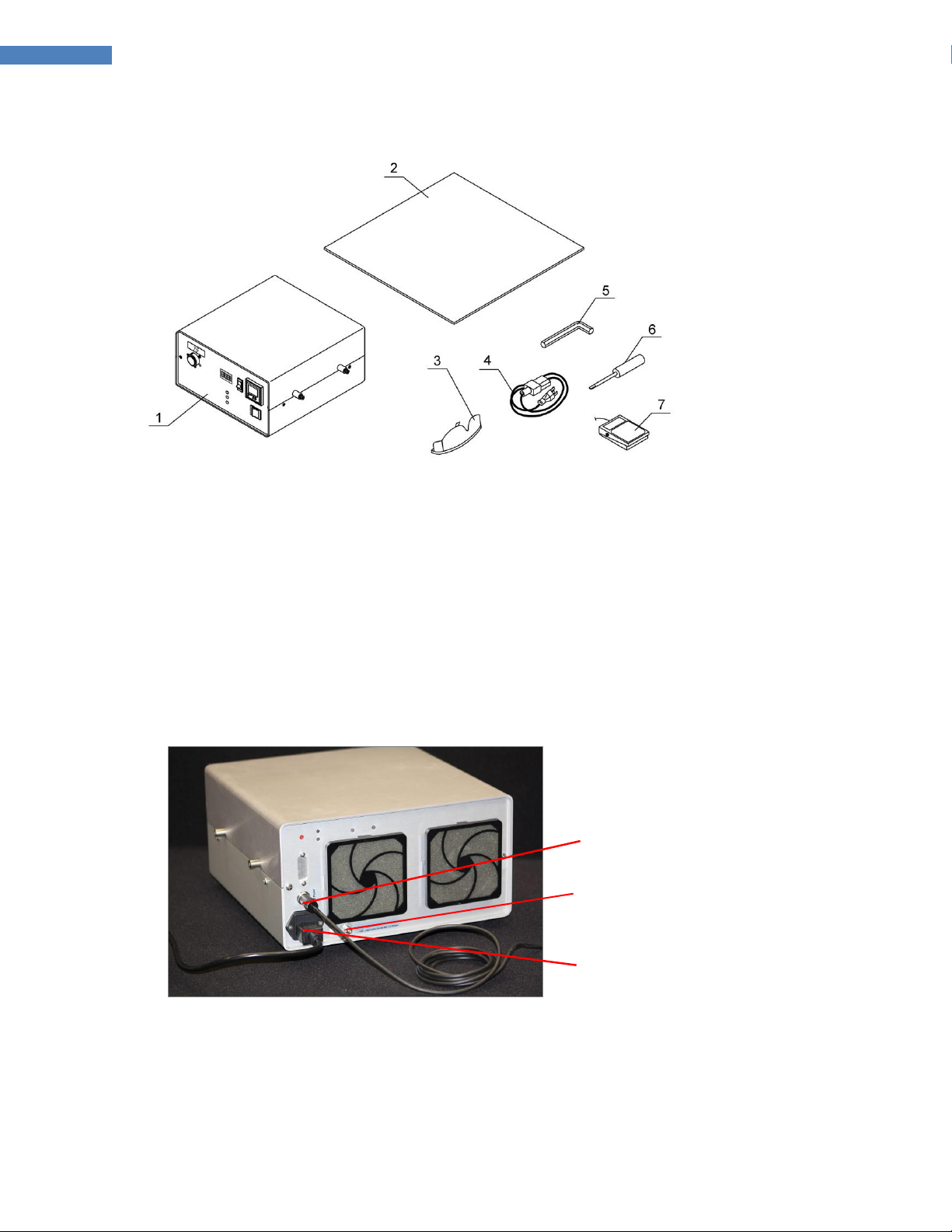

Parts Included with the BlueWave 75 ............................................................................................................................. 9

Installation and System Interconnect..........................................................................................................10

Settings and Adjustments...........................................................................................................................12

Intensity Adjustment..................................................................................................................................................... 12

Intensity Validation ....................................................................................................................................................... 12

Intensity Control............................................................................................................................................................ 12

Setting the Cycle Duration............................................................................................................................................. 13

Lamp Dual-Hour Meter.................................................................................................................................................. 14

System Operation.......................................................................................................................................15

Maintenance..............................................................................................................................................16

Lightguide Maintenance................................................................................................................................................ 16

Fuse Replacement ......................................................................................................................................................... 16

Fan Filter Maintenance.................................................................................................................................................. 16

Bulb Replacement ......................................................................................................................................................... 17

Troubleshooting.........................................................................................................................................19

Frequently Asked Questions.......................................................................................................................20

Spare Parts and Accessories........................................................................................................................22

Spare/Replacement Parts.............................................................................................................................................. 22

Options/Accessories...................................................................................................................................................... 23

Specifications.............................................................................................................................................24

Specifications................................................................................................................................................................. 24

Definition of Terms ....................................................................................................................................25

Warranty....................................................................................................................................................26

Replacement Bulb Warranty ......................................................................................................................................... 26

Index..........................................................................................................................................................27